Persulfate compound activator and its preparation method and application

A composite activator, persulfate technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. The problems such as low rate and severe operating conditions can improve the activation effect, strong activation performance and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

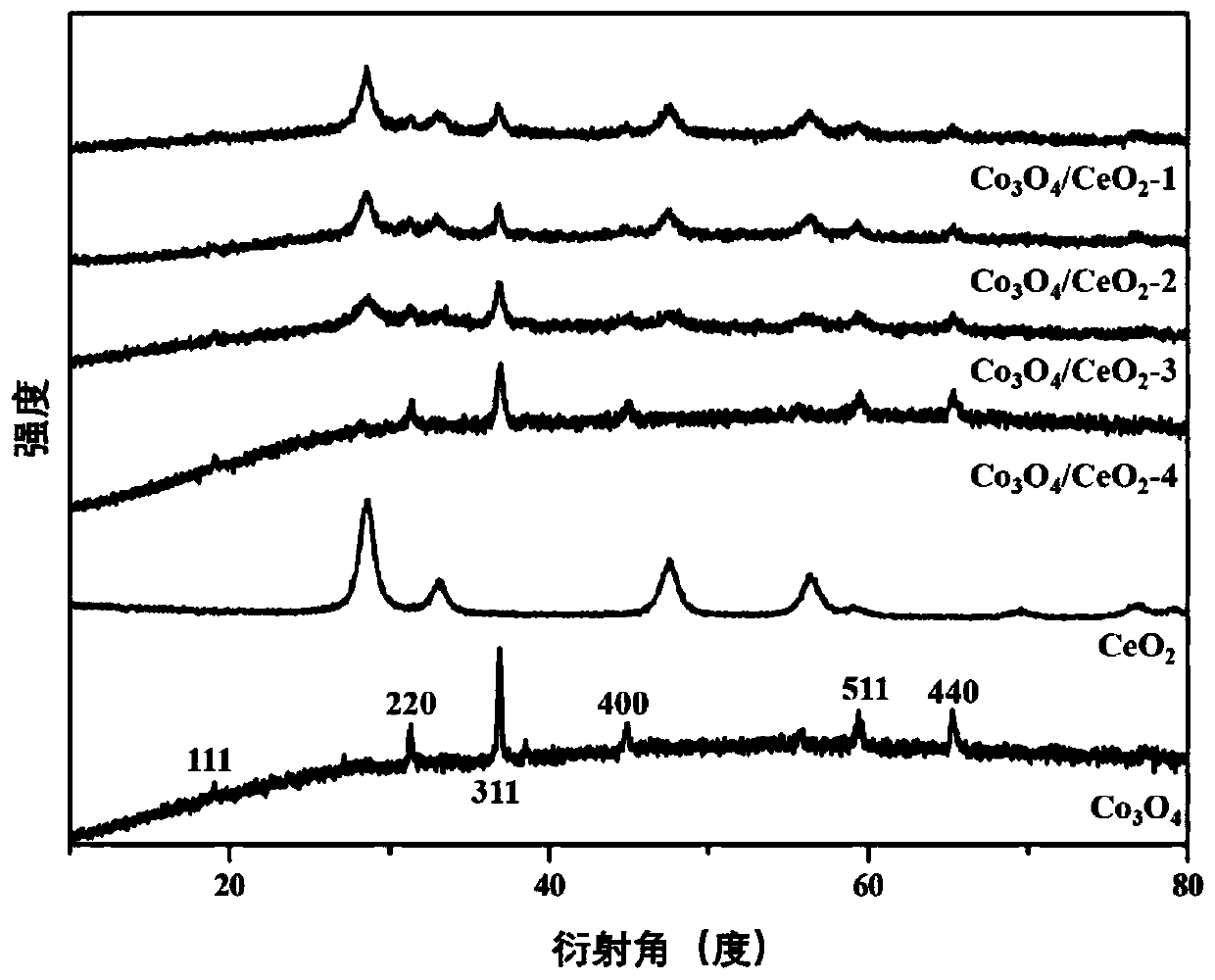

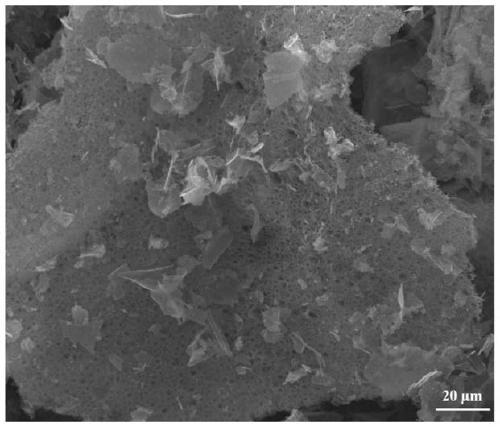

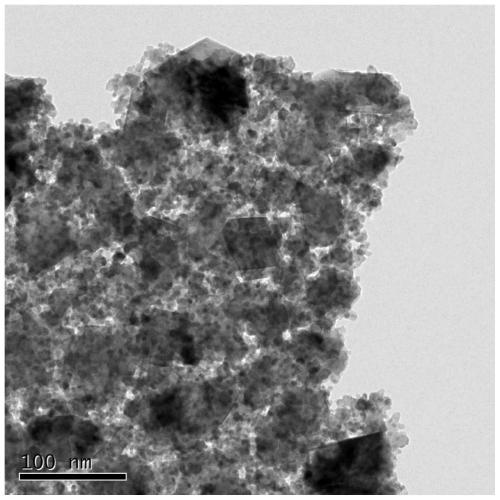

[0032] A persulfate composite activator of the present invention includes flake-shaped Co 3 O 4 And lumpy CeO 2 , The flaky Co 3 O 4 CeO covered in block 2 Surface, where Co 3 O 4 Co and CeO in 2 The molar ratio of Ce in it is 2.6:1.4.

[0033] The method for preparing the persulfate composite activator of this embodiment includes the following steps:

[0034] (1) Weigh 2.7g of cobalt nitrate, 2.2g of cerium nitrate and 4.9g of polyvinyl alcohol to grind in an agate mortar, wherein the molar ratio of cobalt to cerium is 2.6:1.4, and the masses of polyvinyl alcohol, cerium nitrate and cobalt nitrate are combined The ratio is 1:1.

[0035] (2) Put the mixture obtained after uniform grinding in step (1) into a crucible, pour 15ml of deionized water, and after mixing, put it into a muffle furnace for calcination, and control the heating rate of the muffle furnace to 10℃ / min, kept at 500°C for 30 min, and the calcined product is cooled and ground to obtain the cobalt tetroxide-ceria per...

Embodiment 2

[0037] A persulfate composite activator of the present invention, its composition and structure are basically the same as those in the examples, and the only difference is that Co 3 O 4 Co and CeO in 2 The molar ratio of Ce in it is 2.8:1.2.

[0038] The preparation method of the persulfate composite activator of this embodiment described above is basically the same as that of embodiment 1, except that: in step (1), the molar ratio of cobalt in cobalt nitrate to cerium in cerium nitrate is 2.8: 1.2, named Co 3 O 4 / CeO 2 -2.

Embodiment 3

[0040] A persulfate composite activator of the present invention, its composition and structure are basically the same as those in the examples, and the only difference is that Co 3 O 4 Co and CeO in 2 The molar ratio of Ce in it is 3.0:1.0.

[0041] The preparation method of the persulfate composite activator of this embodiment described above is basically the same as that of Example 1, except that: in step (1), the molar ratio of cobalt in cobalt nitrate to cerium in cerium nitrate is 3.0: 1.0, named Co 3 O 4 / CeO 2 -3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com