Manufacturing method of semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., to achieve the effects of improving electrical properties, increasing driving current, and increasing carrier mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It can be seen from the background art that there are still problems to be solved in the formation process of semiconductor devices in the prior art.

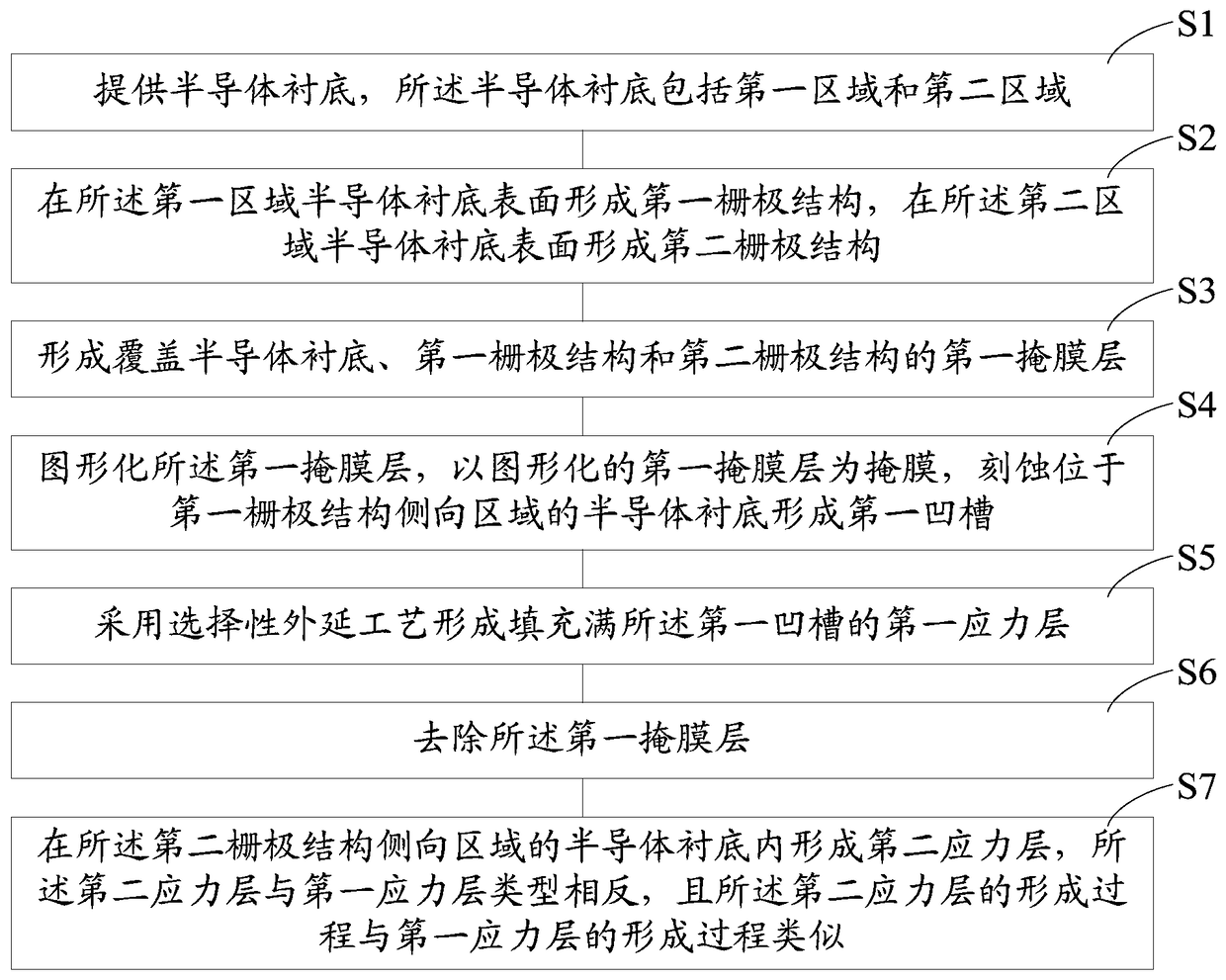

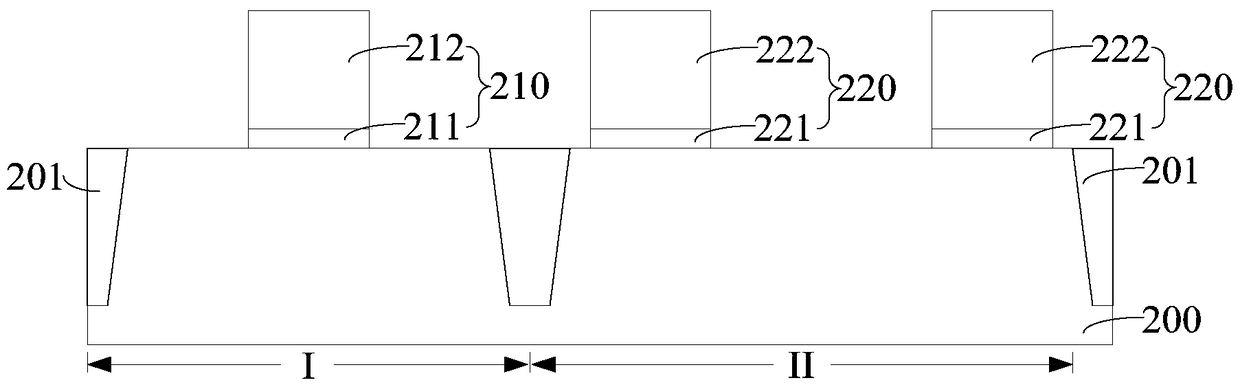

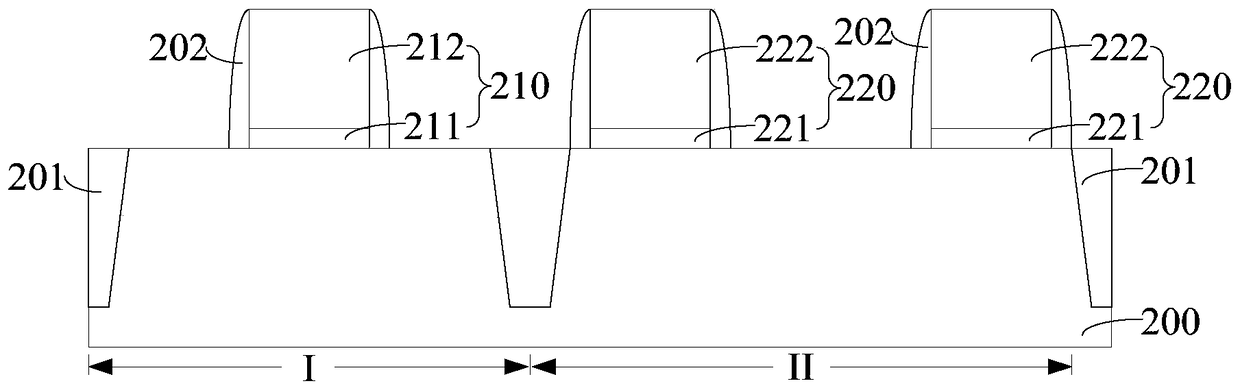

[0031] According to the research on the formation process of semiconductor devices, it is found that the formation process of semiconductor devices includes the following steps, please refer to figure 1 : Step S1, providing a semiconductor substrate, the semiconductor substrate includes a first region and a second region; Step S2, forming a first gate structure on the surface of the semiconductor substrate in the first region, and forming a semiconductor substrate in the second region A second gate structure is formed on the surface of the substrate, and there are offset spacers on both sides of the first gate structure and the second gate structure; step S3, forming a covering semiconductor substrate, the first gate structure and the second gate structure The first mask layer of the pole structure; step S4, patterning t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com