Patents

Literature

42results about How to "Large diameter-to-thickness ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

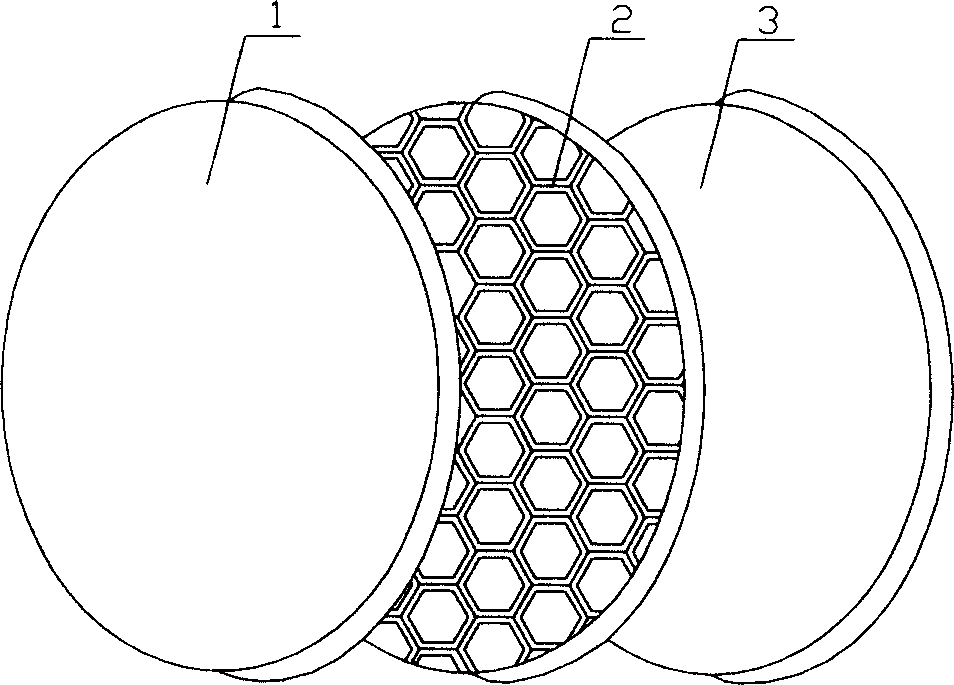

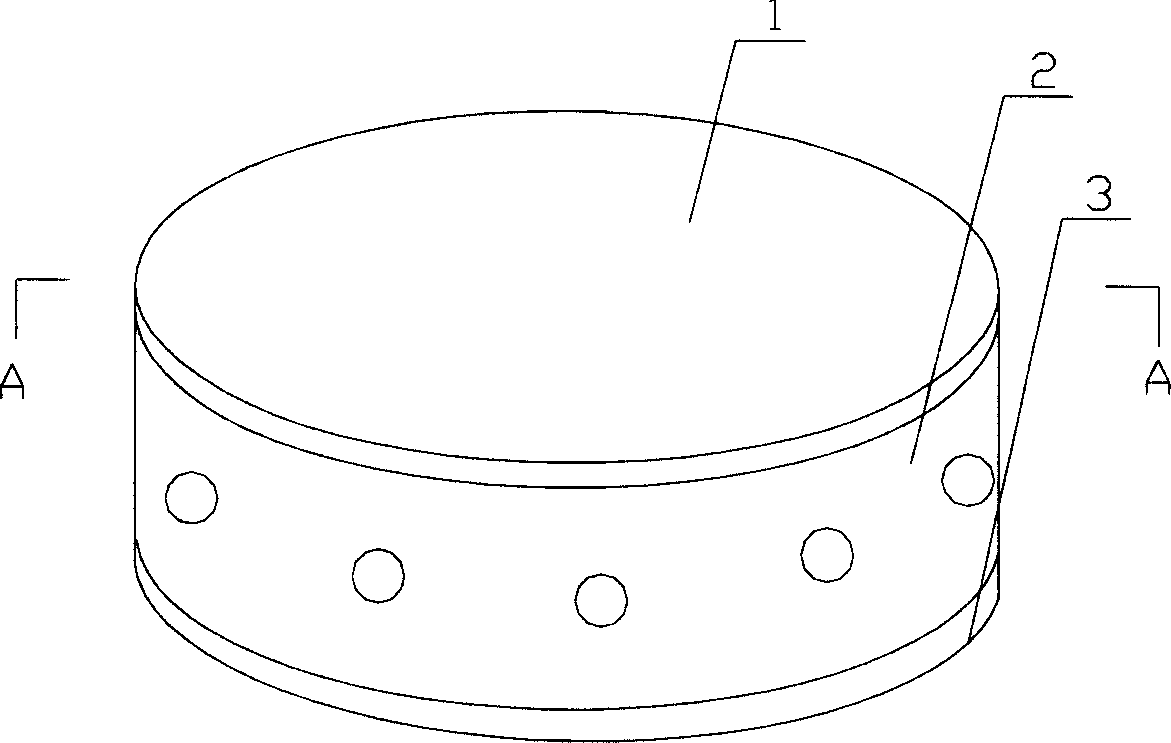

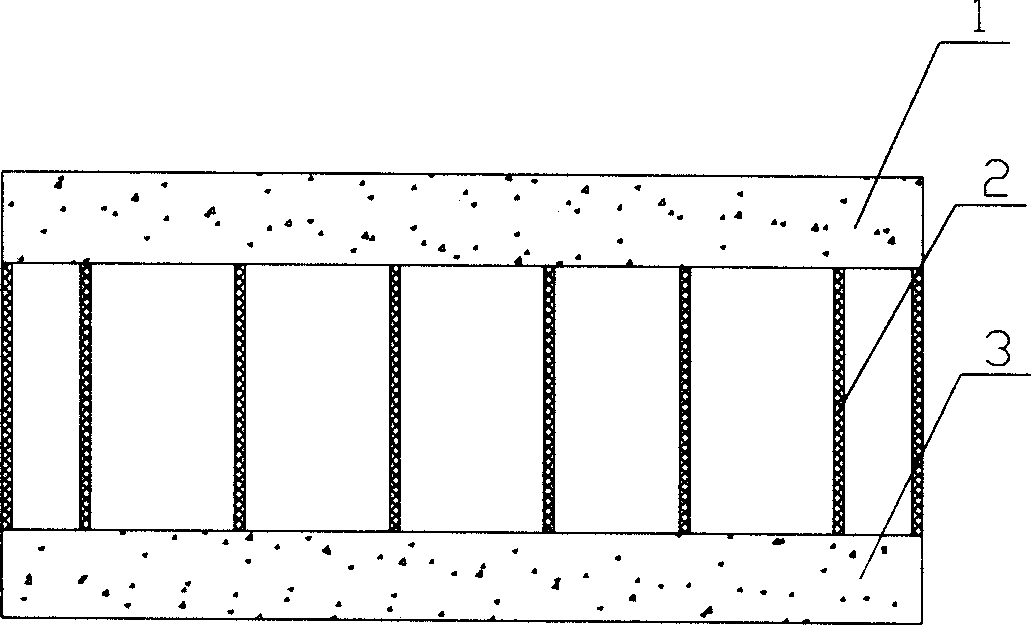

Reflection mirror with honeycomb sandwiched structure silicon carbide base composite material and its preparation method

The present invention relates to a silicon carbide base composite material reflector with honeycomb sandwich structure. It is characterized by that after the upper cover plate, sandwich layer with honeycomb structure and lower cover plate are bonded, then they are undergone the processes of siliconing and sintering treatment so as to obtain the invented reflector whole body with the characteristics of light weight, high rigidity and good workability, etc. Besides, said invention also provides its preparation method and concrete steps.

Owner:NAT UNIV OF DEFENSE TECH

Method for producing one-dimensional nanometer flake zinc powder by directly electrolyzing strong alkaline solution

InactiveCN102181886AImprove current efficiencyIncrease current densityNanotechnologyElectrolysisHigh energy

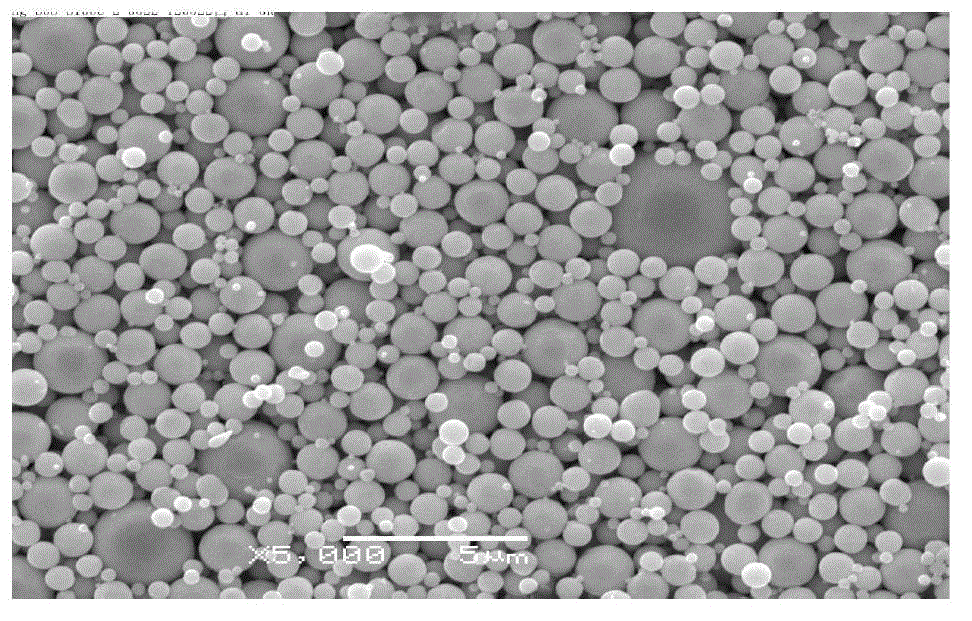

The invention provides a method for producing one-dimensional nanometer flake zinc powder by directly electrolyzing strong alkaline solution, relating to the production technology of flake zinc powder. The method is characterized by firstly preparing zinc-containing strong alkaline solution, wherein the solution contains 1-100g / L of Zn, 10-200g / L of OH<->, 5-70mg / L of additive A and 10-110mg / L ofadditive B; secondly taking a stainless steel plate as an anode and a magnesium plate as a cathode to electrolyze the solution for 1-180min under the following conditions: the distance between the two plates is 0.5-5cm; the current density is 100-2500A / m2; and the solution temperature is 10-100 DEG C, then stopping electrolysis, rapidly taking out the electrodeposit and washing the electrodepositwith water until the pH value of the water is lower than 8; and finally, rapidly vacuum-drying the washed electrodeposit, thus obtaining the one-dimensional nanometer flake zinc powder, wherein the electrolysis waste liquor is returned to be used for preparing the zinc-containing strong alkaline solution. The method has the following advantages and effects: the produced zinc powder has high activity, is flaky and is 10-100nm thick; the method is low in production cost and energy consumption, is simple to operate and is convenient for mass production; and the defects of high cost, high energy consumption, low capacity, difficulty in controlling quality and the like in the traditional production methods are thoroughly overcome.

Owner:TONGJI UNIV

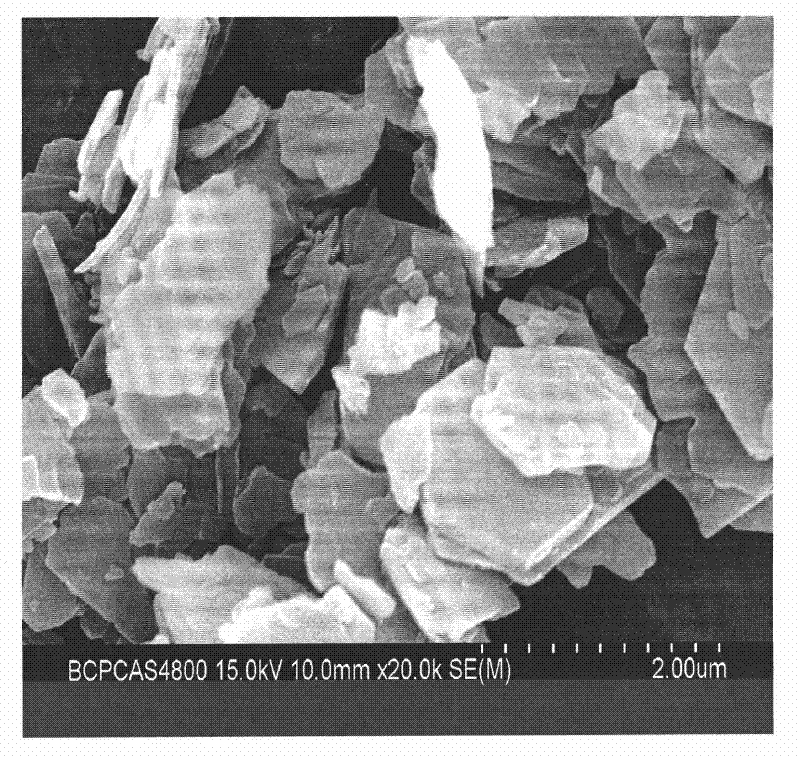

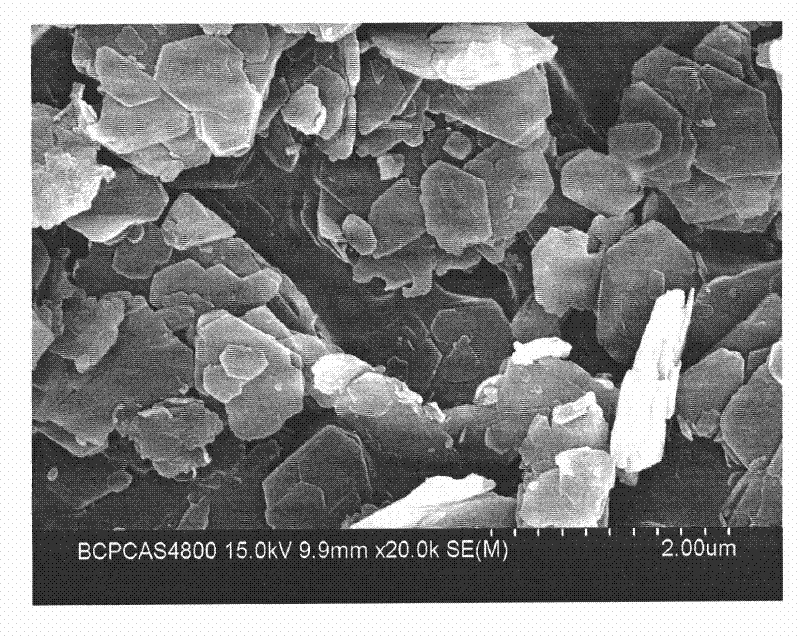

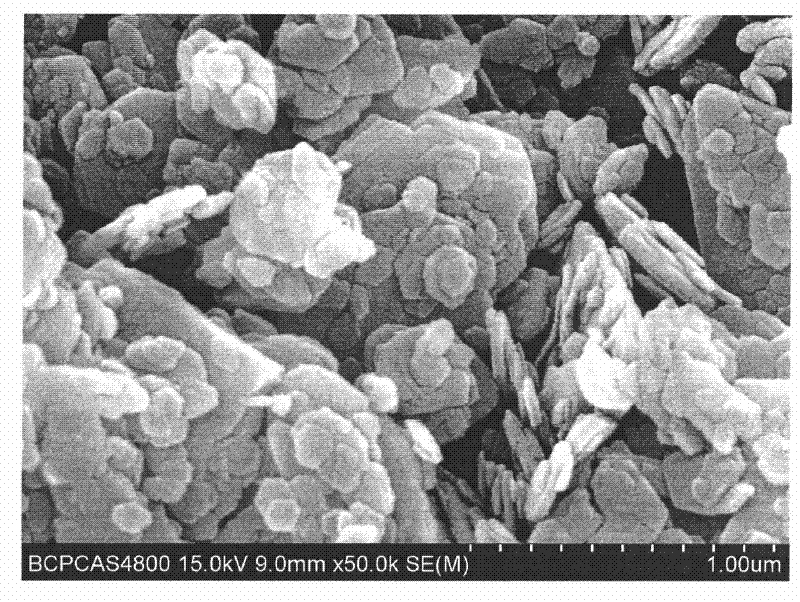

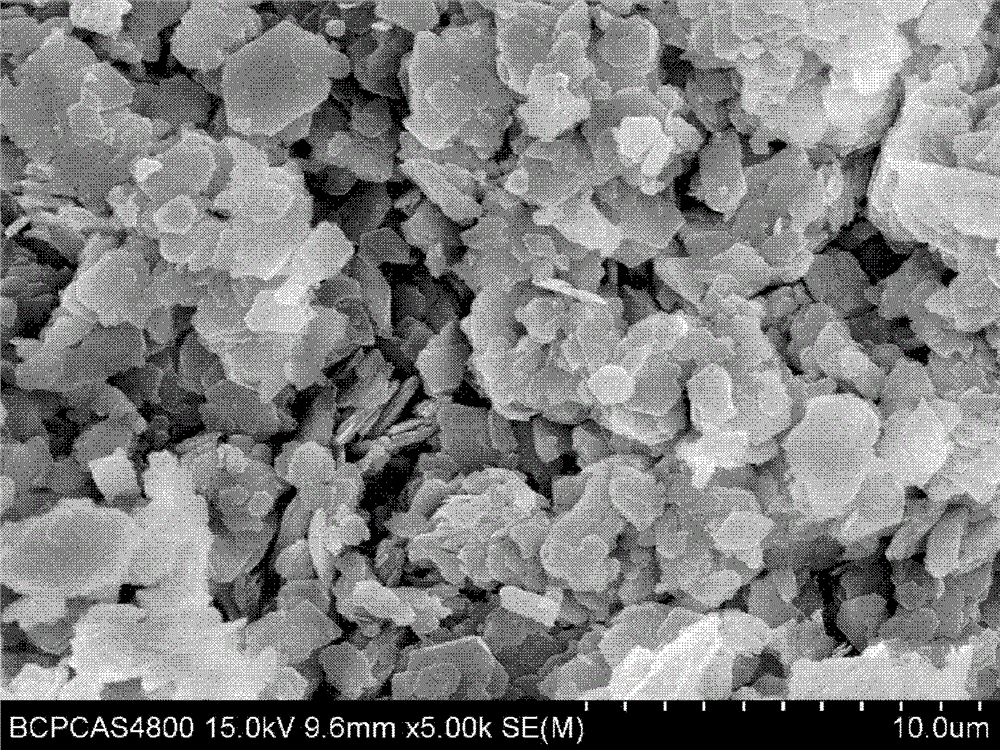

Coal-series hard kaolinite stripping method capable of keeping crystal form of kaolinite

The invention discloses a coal-series hard kaolinite stripping method. The method comprises the following steps of: crushing the coal-series hard kaolinite, mixing the crushed coal-series hard kaolinite with water and an intercalator to obtain intercalated compound pulp, striping the intercalated compound pulp by using medium spheres of three types grain sizes, and performing filtration washing and spray-drying to obtain the finished product. By the method, the hexagonal sheet-shaped crystal form of the kaolinite is kept relatively complete, and the content of hexagonal sheet-shaped kaolinite crystals is 30 to 60 percent.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

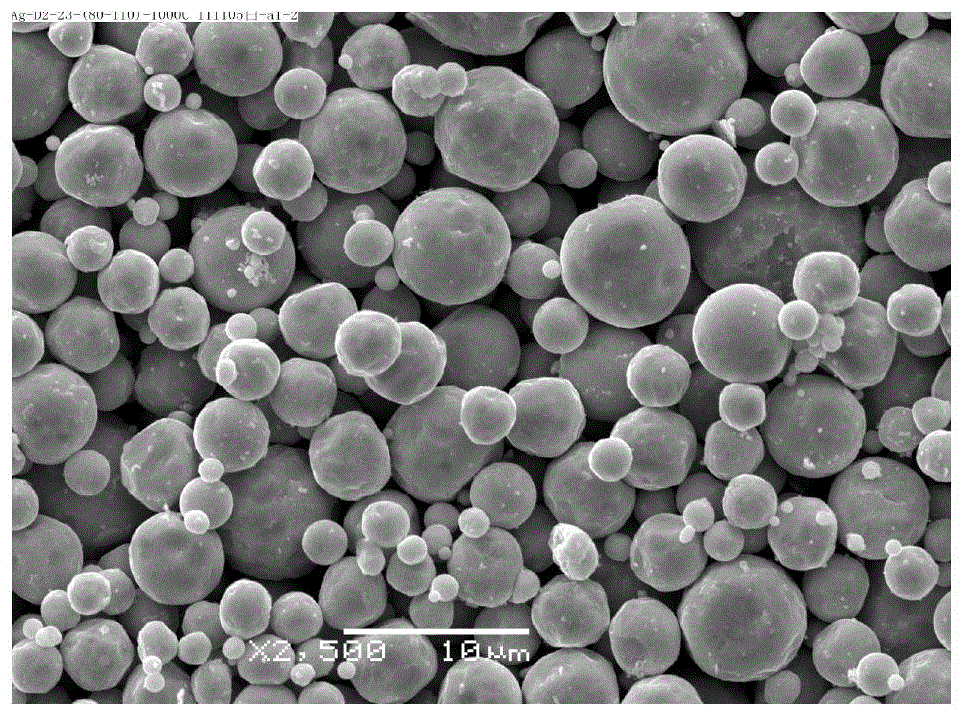

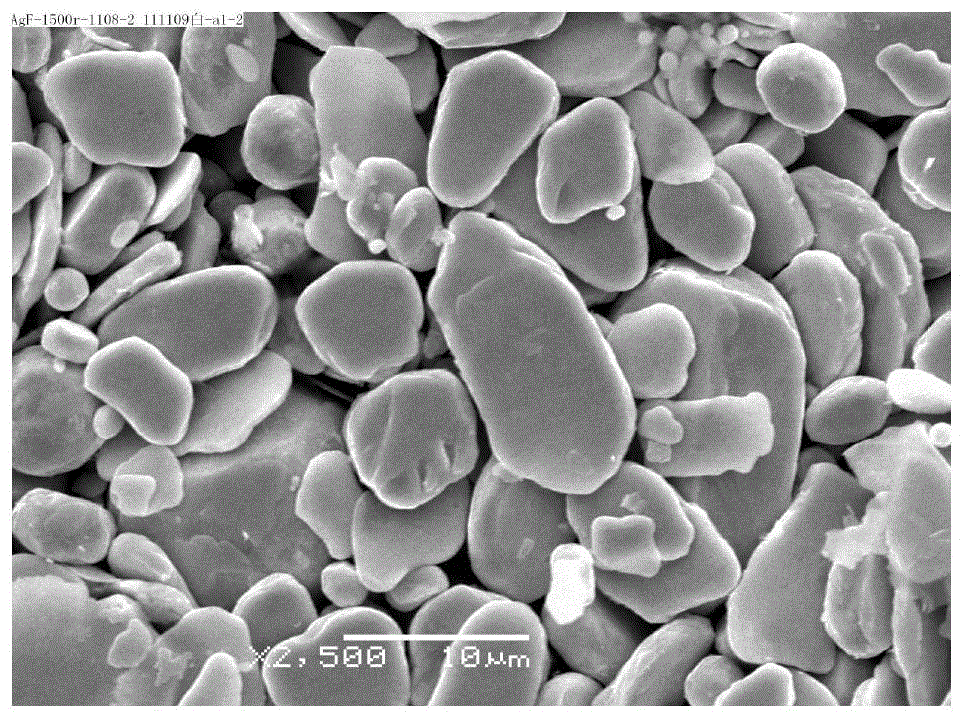

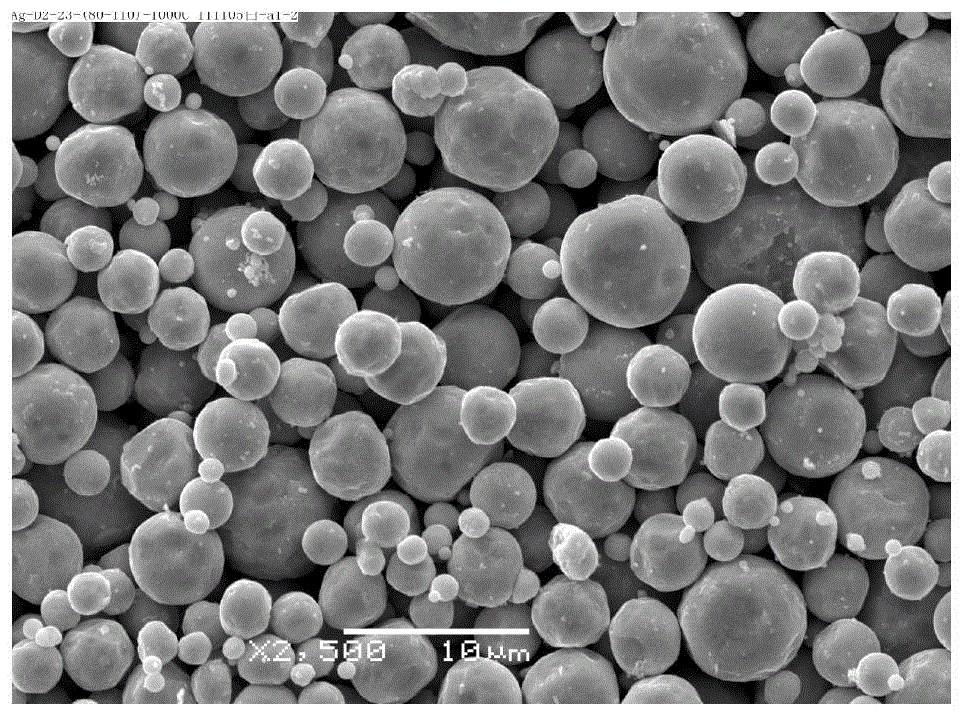

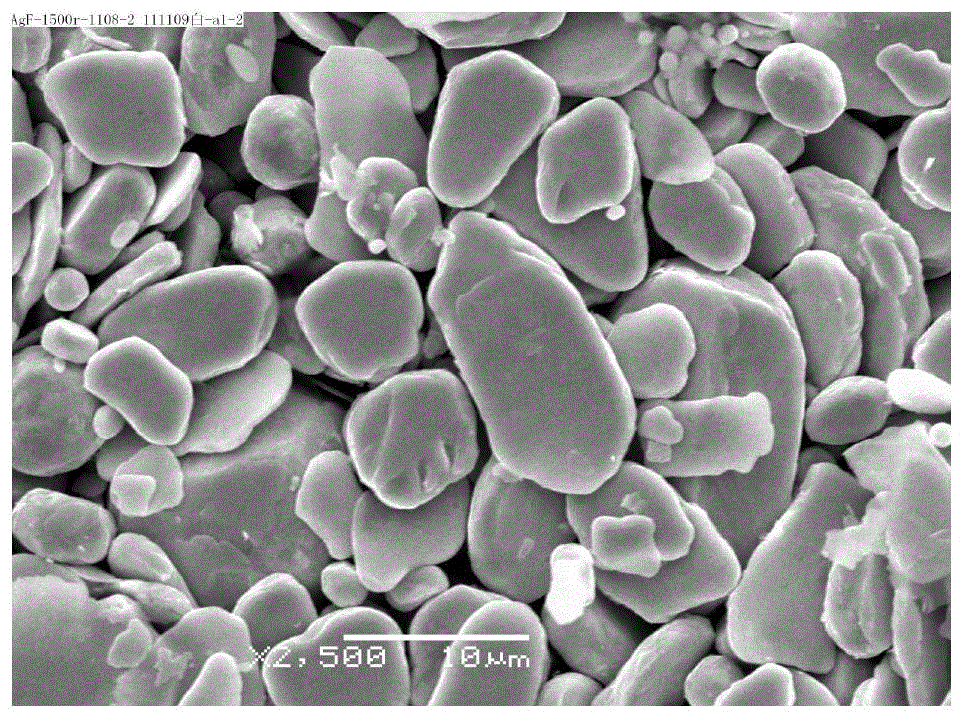

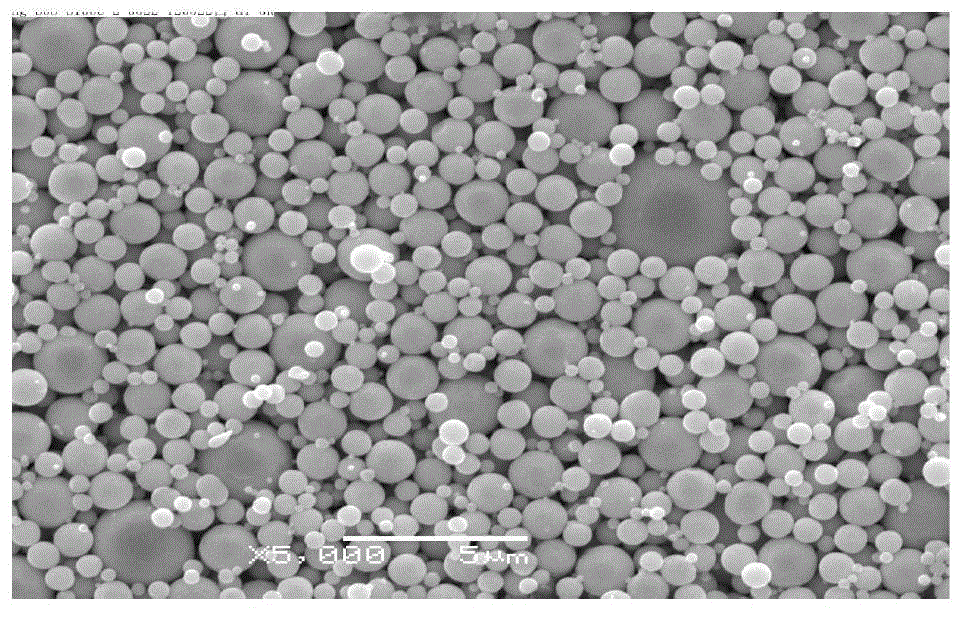

Method for preparing flake silver powder

The invention discloses a method for preparing flake silver powder. The method comprises the following steps of: taking silver powder prepared by a physical vapor deposition method as a raw material, adding the silver powder into an organic solvent, and carrying out mechanical dispersion processing so as to obtain dispersed slurry; feeding the dispersed slurry to a grinder, connecting a material outlet into a finished product kettle after carrying out cyclic grinding for 1-3 hours, and thus obtaining required flake silver powder slurry; and drying the flake silver powder slurry through spray drying, thereby obtaining the flake silver powder. The method disclosed by the invention has the advantages of simple process flow, good dispersion performance, stable performance index, high yield, short processing time, and easiness in industrialized production.

Owner:JIANGSU BOQIAN NEW MATERIALS

Graphene antibacterial electrostatic spraying timber priming paint for reducing sheet material VOCs release and production method thereof

ActiveCN106916513ARelease blockImprove dispersion uniformityAntifouling/underwater paintsPaints with biocidesSlurryAnti bacteria

The invention discloses a graphene antibacterial electrostatic spraying timber priming paint for reducing sheet material VOCs release and a production method thereof. The priming paint comprises an aqueous resin adhesive, a wetting dispersant, an antifreezing agent, a thickening agent, an antifoaming agent, an anti-VOCs functional filling material, an antibacterial electrostatic slurry, a pH conditioning agent, a bactericide, a dry membrane antiseptic and water. The anti-VOCs functional filling material comprises active carbon, nano negative ion powder, a coupling agent and water. The antibacterial electrostatic slurry is obtained by dispersing graphene and nano silver. The priming paint uses the characteristics of high graphene conductivity, large specific surface area and large radius-thickness ratio, small addition amount of graphene enables mutual stacking after film forming of the priming paint, a compact membrane structure is formed, sheet material VOCs release is obstructed, and the electrostatic spraying requirement of the paint can be simultaneously reached, and the absorption effect of the active carbon and the decomposition of a low molecular organic matter by the negative ion powder are used, and the functions for enriching and decomposing VOCs can be achieved.

Owner:上海烯古能源科技有限公司

Method for preparing superfine flaky zinc-containing alloy powder by wet ball milling as well as product and application of superfine flaky zinc-containing alloy powder

ActiveCN110508825AGood dispersionIncrease the frequency of collisionsTransportation and packagingMetal-working apparatusFiltrationSlurry

The invention discloses a method for preparing superfine flaky zinc-containing alloy and an application of the superfine flaky zinc-containing alloy. Spherical atomized zinc-containing alloy powder, aball milling solvent, a grinding aid, a ball milling medium and a dispersant are added to ball milling tank in proportion, and the materials are subjected to wet ball milling under heating and temperature control conditions; and obtained ball-milled slurry is subjected to filtration, ultrasonic cleaning, rinsing and drying in sequence, and flaky zinc-containing alloy powder is obtained, wherein the flake diameter range of the powder is 8-20 micron, the radius-to-thickness ratio is (30-50):1, and the apparent density is 0.85 g / cm<3>-0.95 g / cm<3>. The prepared superfine flaky zinc-containing alloy powder has high flaky degree, high radius-to-thickness ratio, high covering power, smooth surface, low oxidation degree and good particle size distribution, and can be applicable to the productionfields of waterborne Dacromet coatings, inorganic waterborne zinc-rich aluminum paint and waterborne heavy anti-corrosion coatings with different specification requirements after treatment and classified screening.

Owner:湖南昊宏新材料科技有限公司

Thermistor composite material with high sensitivity and high-temperature resistance, and preparation method thereof

InactiveCN107286538AReduced reunion mobilityImprove stabilityElectrical resistance and conductanceCross-link

The invention discloses a thermistor composite material with high sensitivity and high-temperature resistance. The thermistor composite material comprises the following raw materials by weight: 5 to 7 parts of graphene, 45 to 55 parts of a polymer material, 3 to 7 parts of a rare earth mixture, 15 to 25 parts of a conductive auxiliary material, 3 to 5 parts of a coupling agent, 6 to 8 parts of a metal oxide filling material, 20 to 30 parts of acrylic resin, 3 to 5 parts of a cross-linking aid and 2 to 4 parts of a performance improving aid. The thermistor composite material provided by the invention is low in initial resistance, fast in response speed and excellent in correlation between temperature and resistance, maintains good stability and reliability in severe environments like high temperature and has substantially prolonged service life; Meanwhile, a preparation method for the thermistor composite material uses easily available raw materials, is low in cost and simple in process, and has high practical value and good application prospects.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

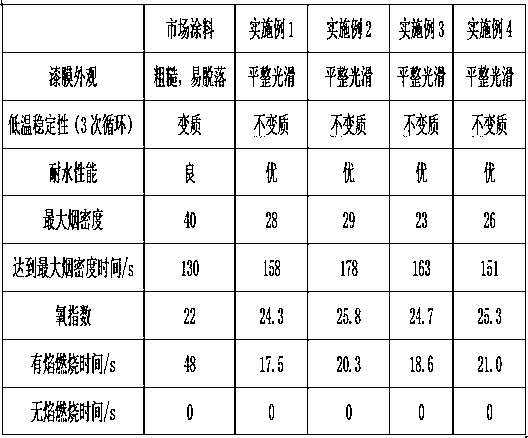

Special paint for granary wall body and preparation method thereof

InactiveCN108977044AHighlight substantive featuresSignificant progressFireproof paintsPolyurea/polyurethane coatingsSlagUltraviolet

The invention discloses special paint for a granary wall body and a preparation method thereof. The paint is prepared by taking polyurethane, hollow glass microsphere, blast furnace slag, titanium white powder, bamboo charcoal, vermiculite powder, perfluorohexyl ethanol, acetyl tributyl citrate, polyethylene wax, organic silicon, a de-foaming agent, a thickening agent, a flame retardant and a dispersant as raw materials; the paint has very high low temperature resisting performance, high moisture-proof performance and very high waterproof performance; the mechanical strength and adhesion forceof a paint film are enhanced and cracks are prevented; the paint is used for preventing ultraviolet rays and water from penetrating through the paint film and the service life of the paint film is prolonged; the paint has the advantages of heat insulation and heat preservation, and high moisture-proof performance, insect-proof performance and fireproof performance.

Owner:GUANGXI JISHUN ENERGY TECH

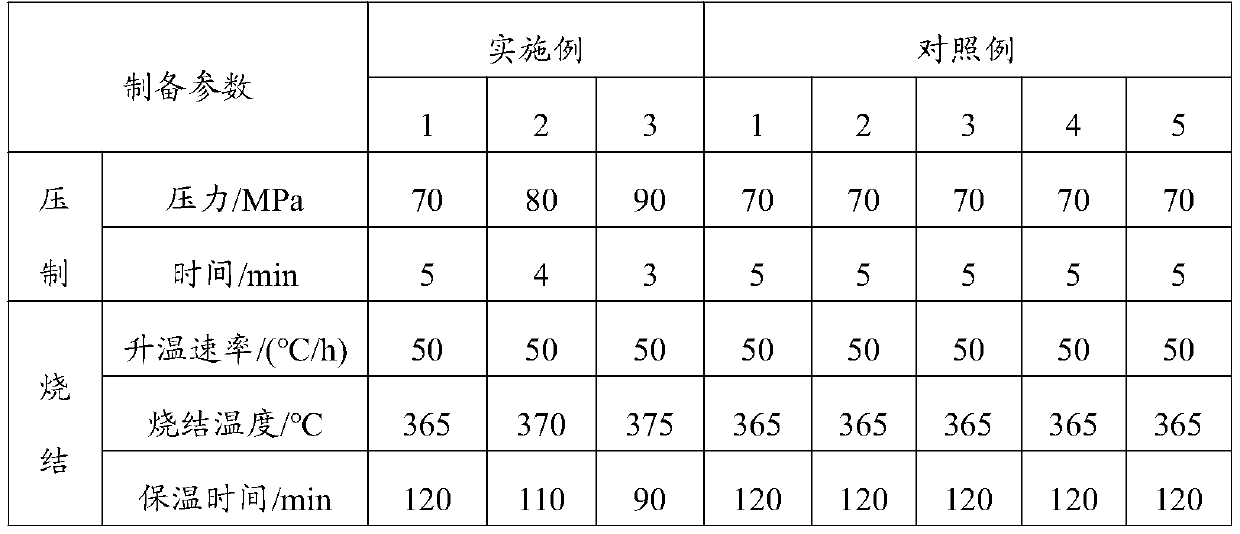

Polytetrafluoroethylene friction material with high elastic modulus and preparation method and application thereof

The invention relates to the technical field of composite materials, in particular to a polytetrafluoroethylene friction material with a high elastic modulus and a preparation method and application thereof. The provided polytetrafluoroethylene friction material with the high elastic modulus is prepared from, by mass, 55-70 parts of polytetrafluoroethylene, 15-35 parts of mica, 5-15 parts of glassfibers, 5-15 parts of nano alumina and 1-5 parts of graphite. The polytetrafluoroethylene friction material prepared from the raw materials in proportion has the advantages of great wear resistance,stable friction coefficient and the like on the basis of the high elastic modulus, and can meet the requirements of ultrasonic motors for friction materials.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of waterborne rainbow aluminum paste

InactiveCN108250847ALarge diameter-to-thickness ratioGood rainbow effectInksPigment treatment with macromolecular organic compoundsChemical industryMicro structure

The invention relates to the technical field of chemical industry, in particular to a preparation method of waterborne rainbow aluminum paste. The preparation method comprises the following steps: step one, coating a PET thin film with certain thickness with a layer of waterborne release coating of which the thickness of a dry film is not smaller than 1mu m; step two, plating a film coating with alayer of aluminum with the purity of 99.99 percent by using a PVD method, thus forming an aluminum-plated film, wherein the film thickness is seen in the description; step three, carrying out surfacecarving on the aluminum-plated film by laser engraving or molding, endowing the surface of a flat aluminum-plating layer with a micro-structure to obtain an aluminum layer which can generate interference and diffraction to light. According to the preparation method of the waterborne rainbow aluminum paste, disclosed by the invention, a waterborne aluminum pigment with rainbow effects selects a high-purity aluminum wire as a raw material; the high-purity aluminum wire is subjected to vapor deposition on the PET thin film by adopting a vacuum evaporation method; the high-purity aluminum wire isendowed with great diameter-thickness ratio and excellent rainbow effects by mould pressing, and is subjected to waterborne surface treatment at later stage to obtain a product. The waterborne rainbow aluminum paste is subjected to surface waterborne treatment based on oily rainbow aluminum paste; meanwhile, the rainbow effects of the waterborne rainbow aluminum paste are not affected.

Owner:HEFEI SUNRISE PIGMENTS

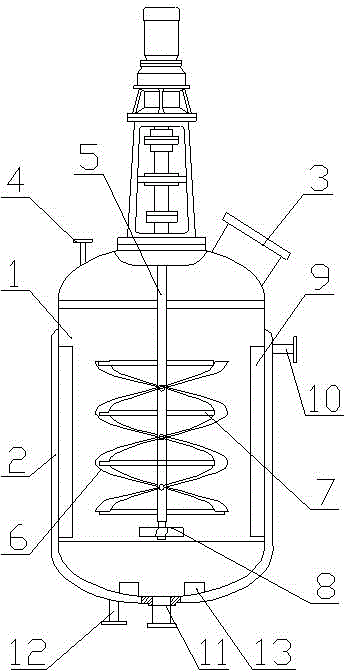

Graphite chemical substance intercalation reaction vessel and technological method thereof

InactiveCN105521752AFree to useWon't happenChemical/physical/physico-chemical stationary reactorsIntercalation reactionSulfur

The invention relates to a graphite chemical substance intercalation reaction vessel and a technological method thereof. The reaction vessel comprises a reaction vessel body (1), a mixer shaft (5) is arranged on the central part of the reaction vessel body (1) along the vertical direction, two spiral stirring vanes (6) are arranged on the mixer shaft (5), the two spiral stirring vanes (6) symmetrically wind around the mixer shaft (5) in a spiral mode, spiral directions of the two spiral stirring vanes (6) are opposite, a support (7) is arranged between the two spiral stirring vanes (6), multi-strip elastic racks (9) are uniformly arranged on an inner wall of the reaction vessel body (1), and a supersonic generator (13) is arranged at the bottom of the reaction vessel body (1). The invention provides the graphite chemical substance intercalation reaction vessel and the technological method thereof, pollution by harmful gas such as SOx and NOx or heavy metal ions cannot be generated during a production process, sulfur residue does not exist in the product, oxidation resistance is good, defect of graphene is not generated easily, and final product quality can be effectively guaranteed.

Owner:江苏碳谷二维世界科技有限公司

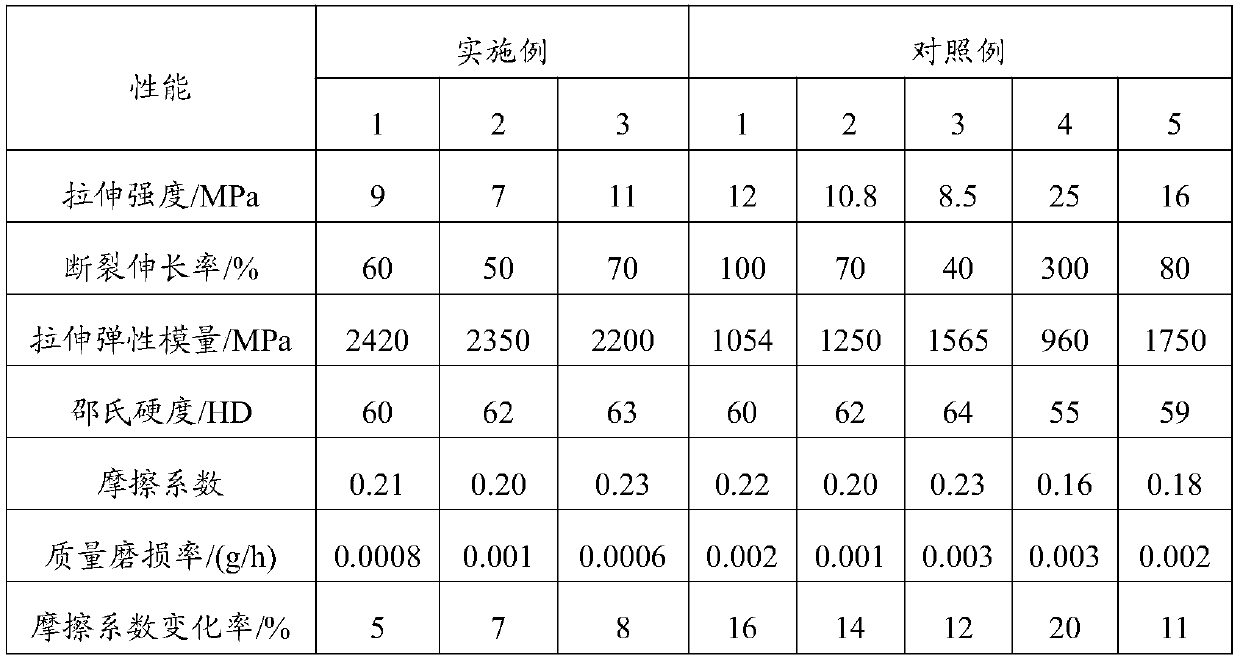

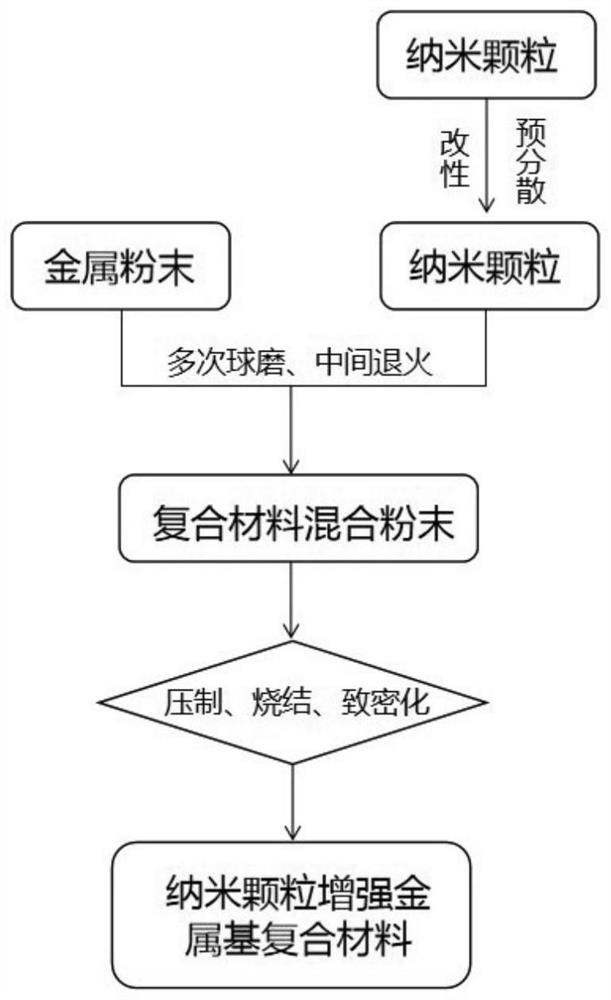

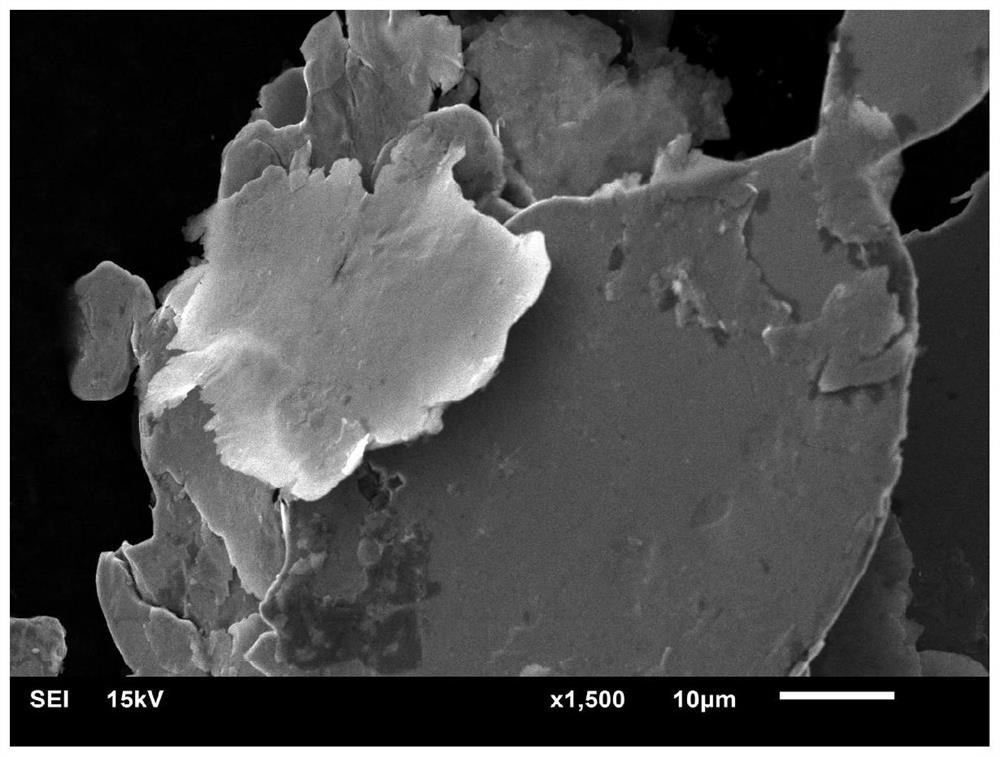

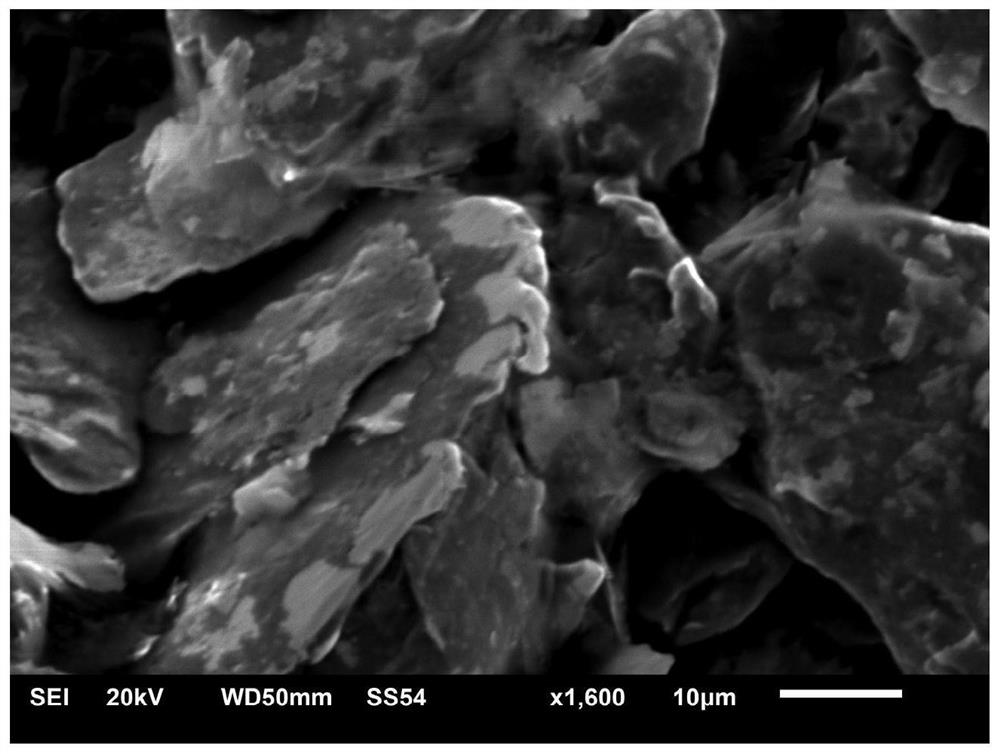

Nanoparticle reinforced metal-based composite material and preparation method thereof

ActiveCN112846198AWell mixedFacilitate de-intercalationTransportation and packagingMetal-working apparatusMechanical crushingNanoparticle

The invention belongs to the technical field of composite materials, and discloses a nanoparticle reinforced metal-based composite material and a preparation method thereof. The method comprises the steps that firstly, surface modification and pre-dispersion are carried out on nanoparticles, so that the nanoparticles are in a relatively dispersed state before ball milling; low-speed ball milling in the initial stage of ball milling is carried out, and materials are fully mixed evenly; in the middle stage of ball milling, metal powder flaking and nanoparticle embedding mechanisms are combined, the work hardening phenomenon of flaky metal powder is reduced and eliminated through stress relief annealing, and the problems that nanoparticles are disembedded on the surface of the flaky metal powder and the load is small are solved; and finally, the rotating speed is reduced, the flaky powder with the large radius-thickness ratio is mechanically crushed through grinding balls, and then fine-scale-shaped nanoparticle reinforced metal-based composite powder is obtained through pressing, sintering and densification treatment. Through the steps of surface modification, pre-dispersion treatment, stress relief annealing added in the ball milling process and the like, the problem of work hardening of the metal powder is effectively solved, nanoparticles are dispersed more uniformly, and the loading capacity is higher.

Owner:CISDI ENG CO LTD +1

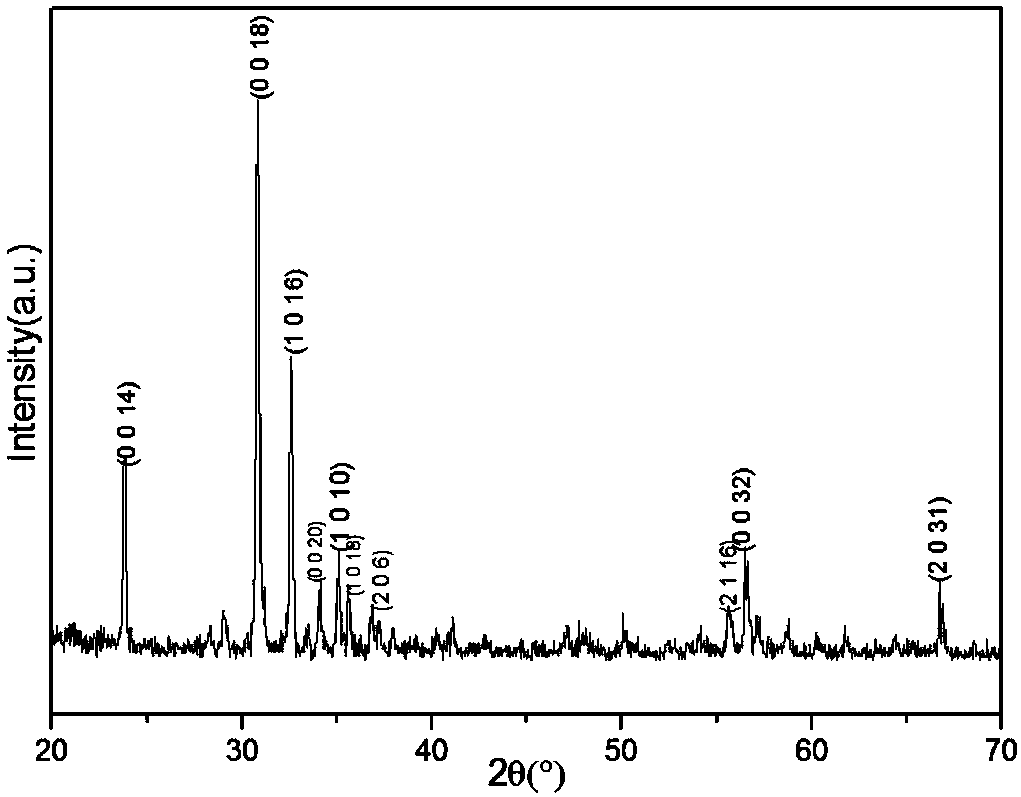

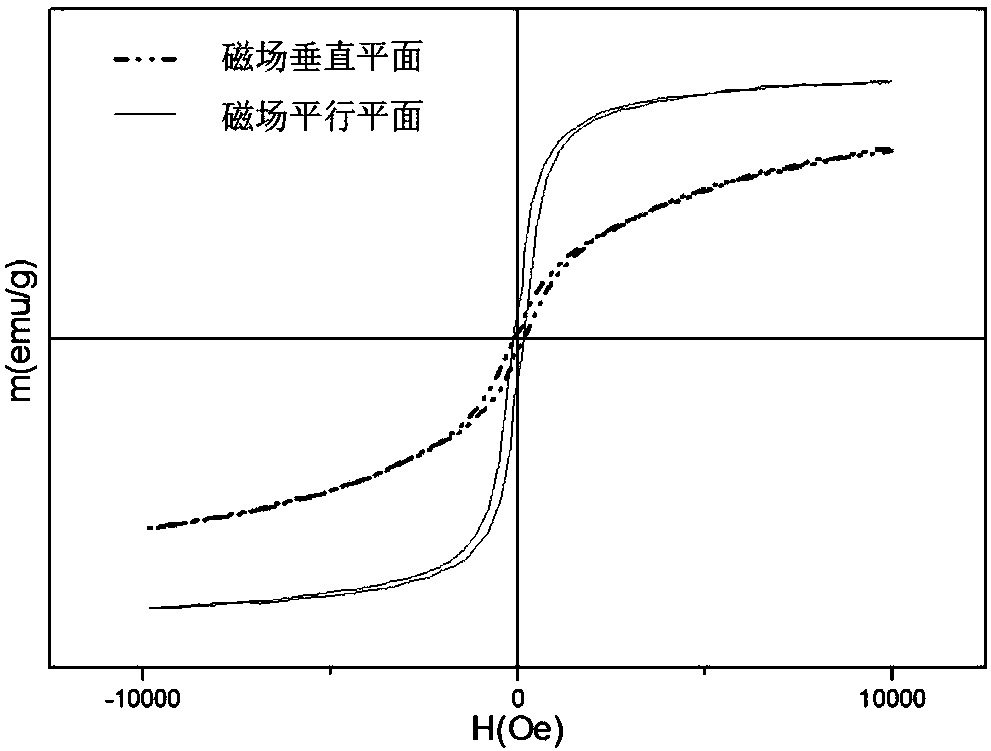

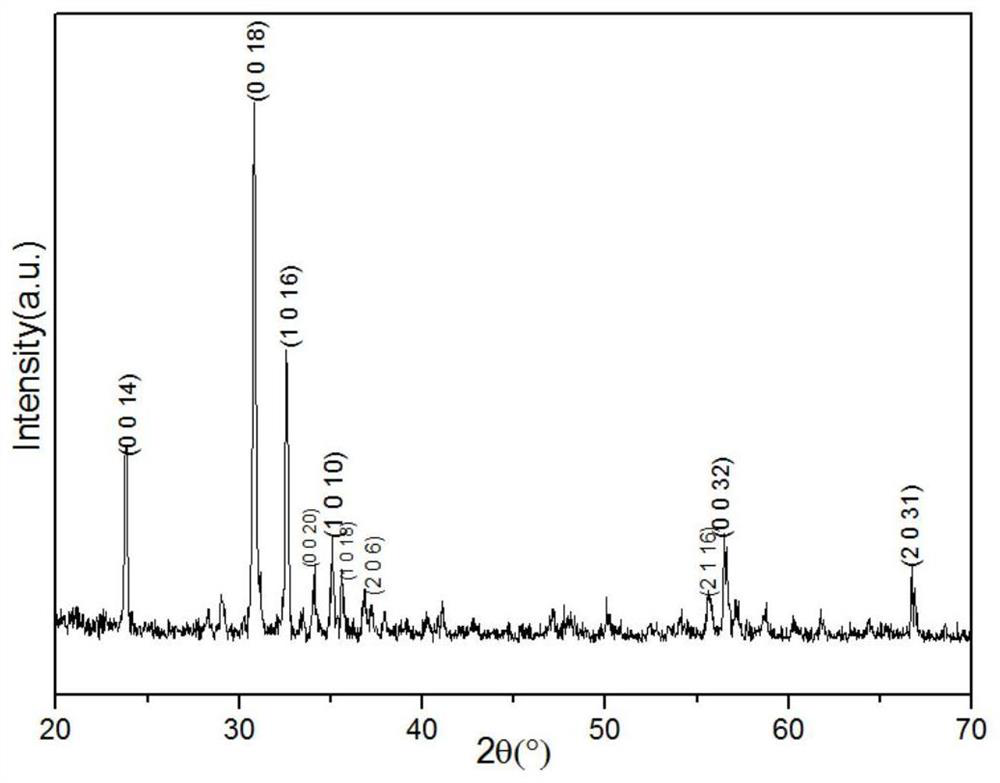

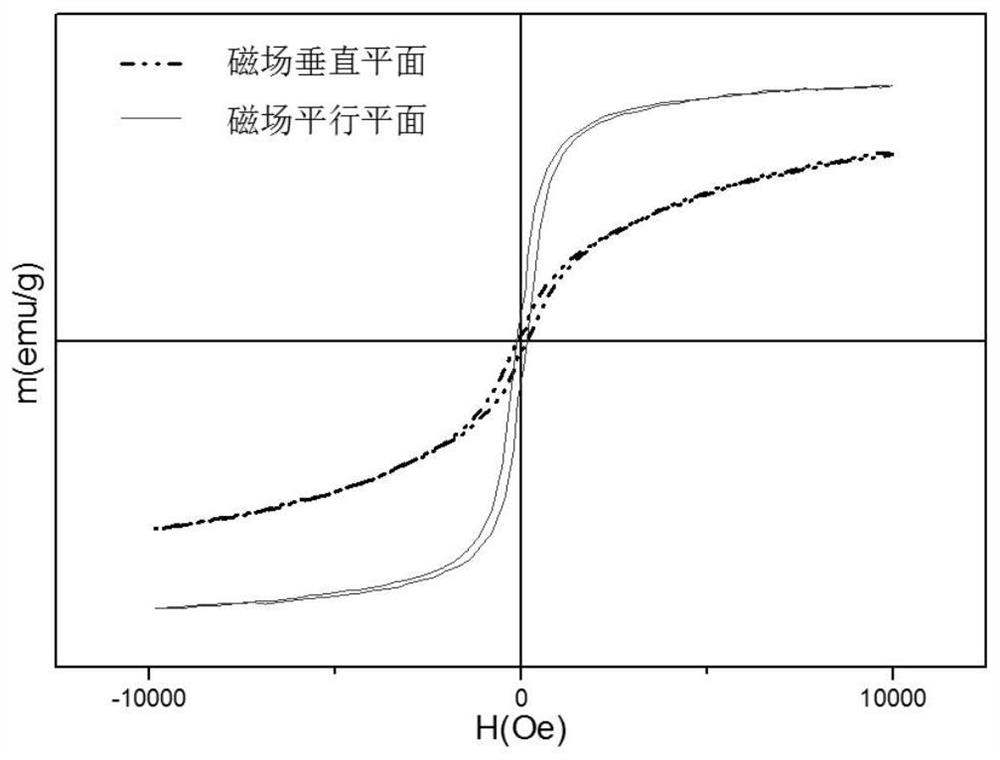

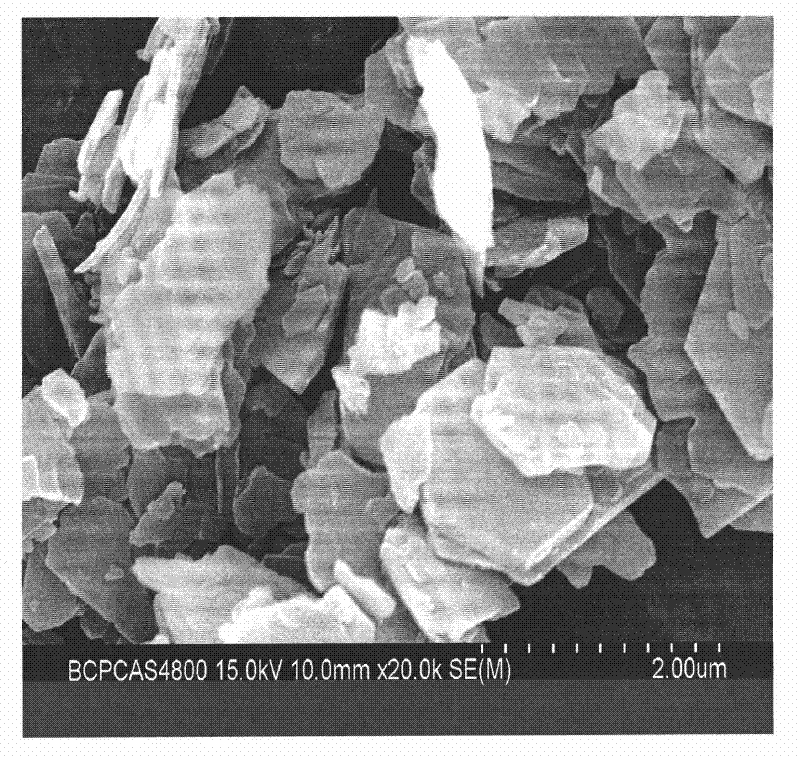

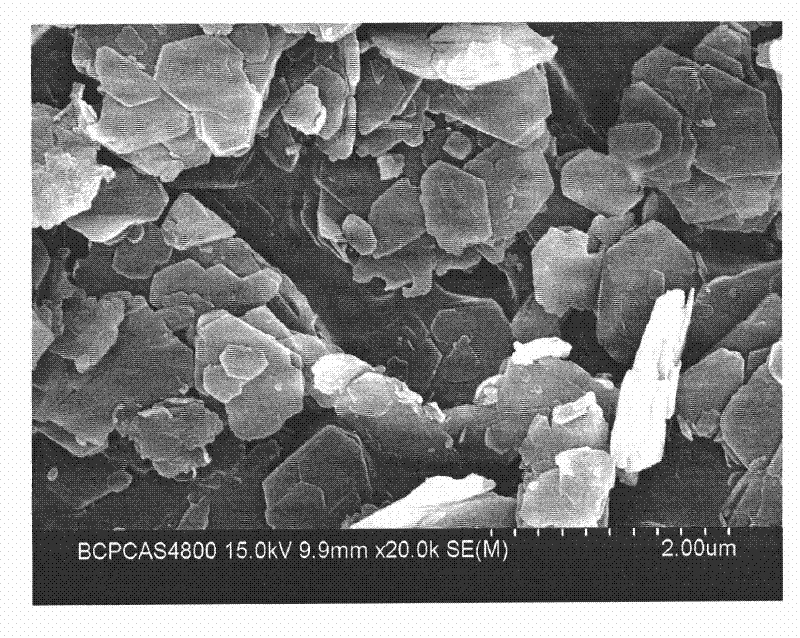

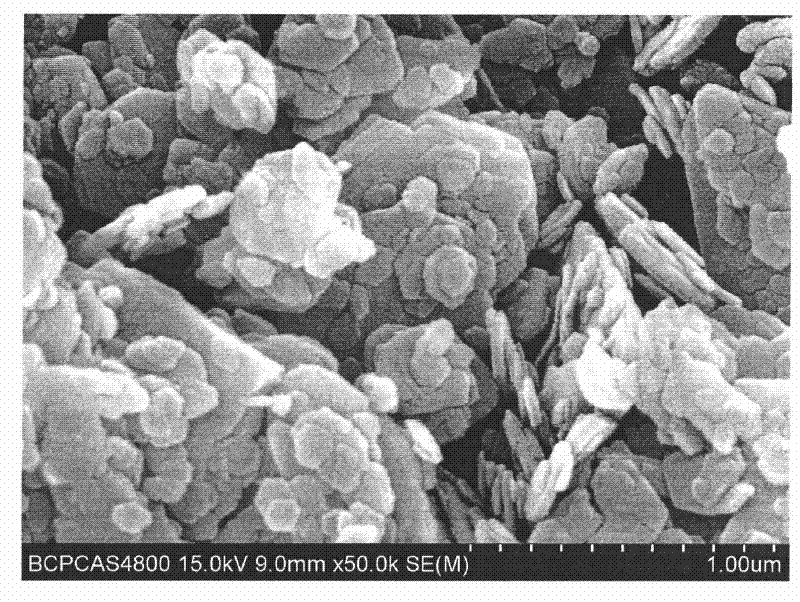

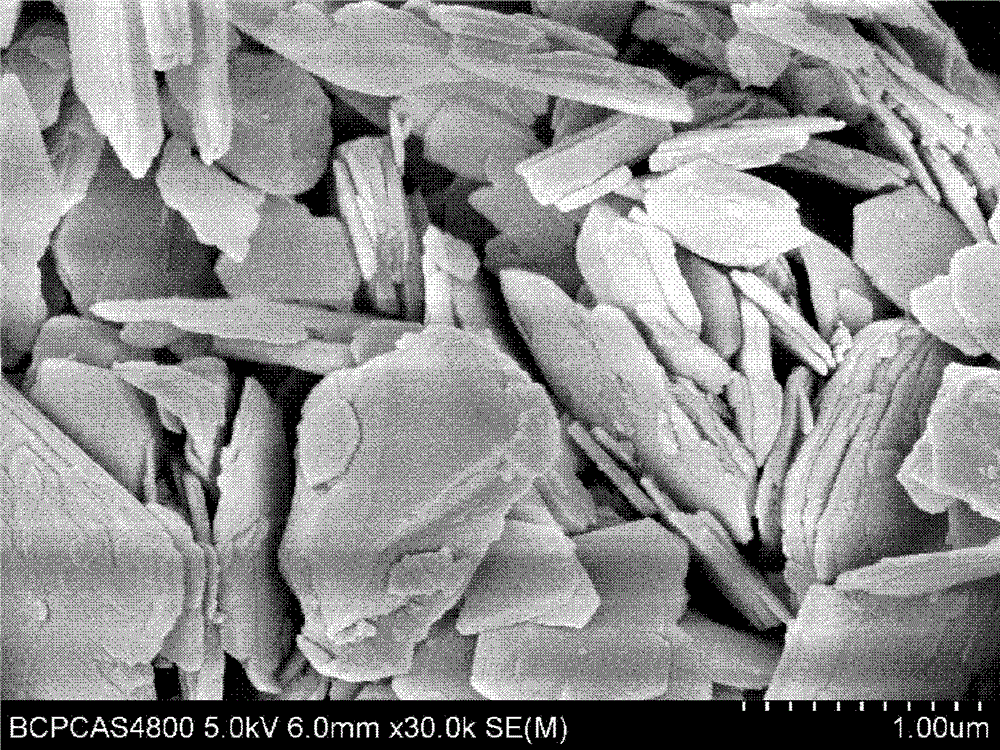

Preparation method of self-orientation Z-type hexaferrite substrate

ActiveCN108329022ASelf-orientedGood orientationInductances/transformers/magnets manufactureMagnetizationUltimate tensile strength

The invention relates to a preparation method of a self-orientation Z-type hexaferrite substrate and belongs to the technical field of magnetic materials. The method includes: using a hydrothermal method to acquire precursor powder using M phase as the main crystal phase, wherein the M-phase precursor is large in diameter-thickness ratio, even in particle size distribution, free of agglomeration and the like, is a quite ideal texturing growth template and does not need an extra grain template. The Z-type hexaferrite substrate obtained by the method has a self-orientation feature, the orientation of the Z-type hexaferrite substrate does not need a complex casting process and an additional magnetic field, the specific saturation magnetization of the obtained Z-type hexaferrite substrate canreach 51.3emu / g after self-orientation, and the orientation degree of the Z-type hexaferrite substrate in the (001) direction is increased to 66.2%.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for preparing three-dimensional graphene microstructure filler modified polymer composite

InactiveCN109401192AEvenly dispersedAvoid overlappingPolymer scienceThree dimensional microstructure

The invention belongs to the technical field of composite preparation, and particularly relates to a method for preparing a three-dimensional graphene microstructure filler modified polymer composite.The method comprises the following steps that graphene foam and a polymer liquid medium are added to a vessel and subjected to mechanical stirring, and the graphene foam is crushed to obtain a mixedsuspension; and the mixed suspension is subjected to exhausting, precipitation, cooling or a method of directly initiating polymerization to obtain the three-dimensional graphene microstructure fillermodified polymer composite. The graphene filler has a special three-dimensional microstructure which has a large radius-thickness ratio and a presence form of an sheet-like irregular hollow tube different from the sheet shape of usual graphene; and meanwhile, the shape and processing method of the polymer composite are not limited by the size and form of the adopted graphene foam, and the polymercomposite has molding diversity and industrial feasibility.

Owner:JINAN UNIVERSITY

High-toughness polyurethane adhesive

InactiveCN110903804AHigh strengthImprove water resistanceNon-macromolecular adhesive additivesProtein adhesivesPolyurethane adhesiveSodium Bentonite

The invention discloses a high-toughness polyurethane adhesive. The adhesive has the advantages of high strength, good water resistance, good toughness and good yellowing aging resistance, bonding strength and heat resistance after being cured. According to the invention, mica powder is subjected to ball milling treatment by utilizing diluted nitric acid, so a lamellar structure of the mica powderis preliminarily separated; the mica powder is modified by utilizing a silane coupling agent and alginic acid, so the dispersion characteristic of the mica powder is reinforced, and the polarity of the mica powder is improved; sodium ions are contained among sodium bentonite layers, and the sodium bentonite is subjected to an ion exchange reaction by utilizing hexadecyl trimethyl ammonium bromide, so cations of the hexadecyl trimethyl ammonium bromide enter bentonite layers to enlarge the interlayer spacing of the bentonite, and the dispersity and toughness of the bentonite are improved; andthe bentonite is subjected to ion exchange again by utilizing benzyltributylammonium bromide, so the steric hindrance of the bentonite is larger, and the discreteness of the bentonite is higher.

Owner:界首市鸿鑫塑业有限公司

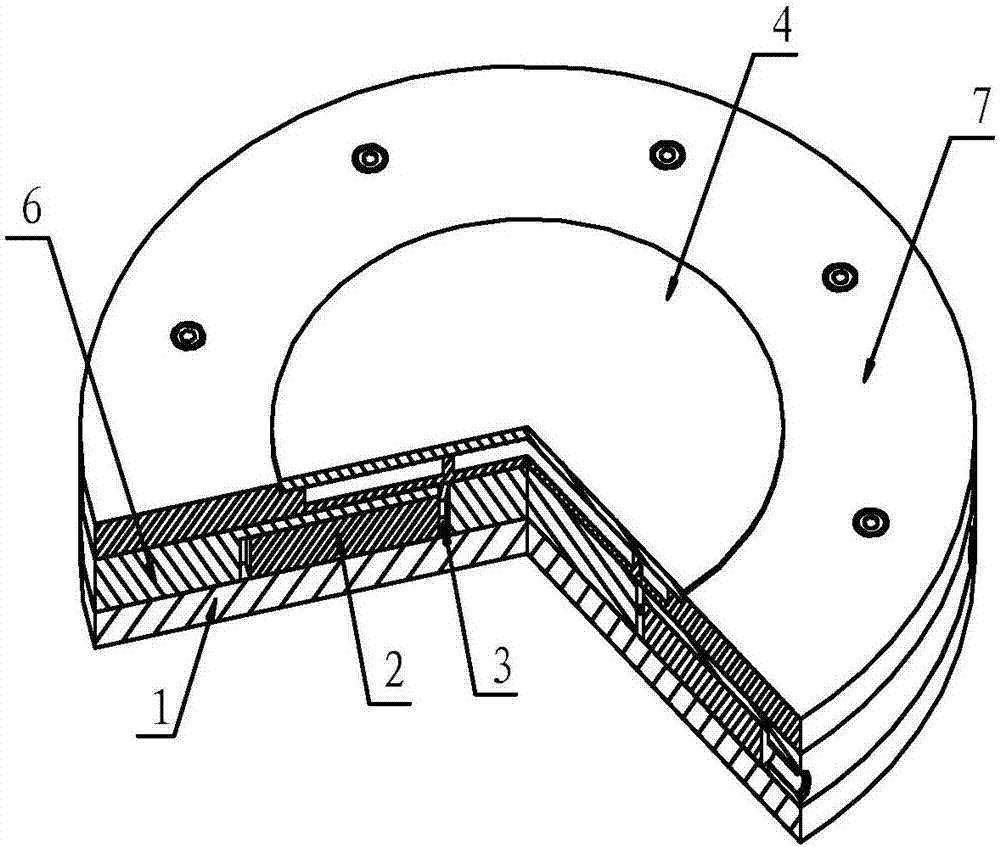

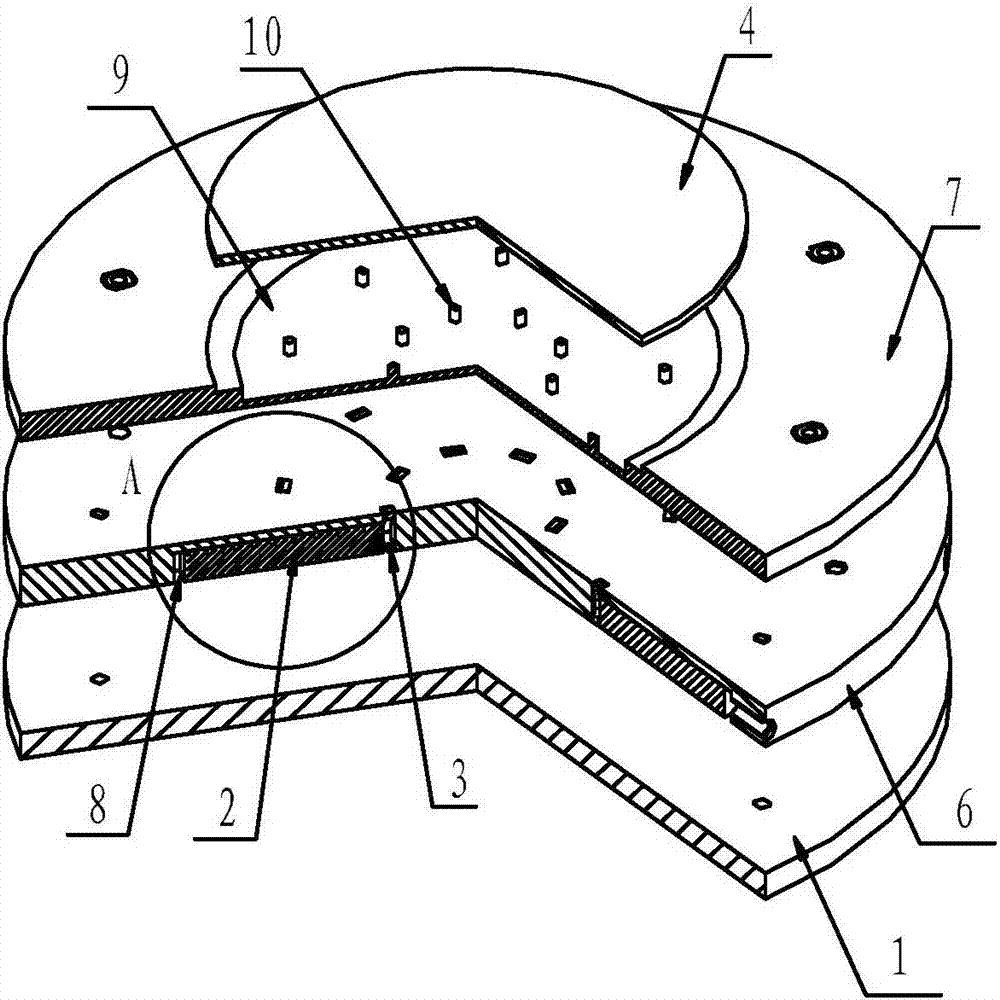

Deformation polishing disc based on piezoelectric ceramic drivers

PendingCN107052947AChange face shapeLarge diameter-to-thickness ratioOptical surface grinding machinesSurface shapeExtrusion

The invention relates to a deformation polishing disc based on piezoelectric ceramic drivers and belongs to the technical field of aspherical mirror polishing equipment. The deformation polishing disc comprises a base, the multiple piezoelectric ceramic drivers located on the base, and base discs located above the piezoelectric ceramic drivers and further comprises a plurality of elastic pieces. The elastic pieces are installed on the upper surface of the base in the radial direction of the elastic pieces and are arranged in one-to-one correspondence with the piezoelectric ceramic drivers. The piezoelectric ceramic drivers are installed on the upper surface of the base in the axial direction of the piezoelectric ceramic drivers, and one ends of the piezoelectric ceramic drivers point to the center of the base. The elastic pieces abut against the ends, pointing to the center of the base, of the piezoelectric ceramic drivers. After the piezoelectric ceramic drivers apply extrusion force to the elastic pieces, the elastic pieces generate expansion and contraction quantity in the axial direction of the elastic pieces so as to change the surface shapes of the base discs. According to the deformation polishing disc, the radius-thickness ratio of the polishing disc is increased, the structure is compact, the stability of the polishing disc during rotation and the congruency of the polishing disc and a workpiece are improved significantly, cost is low, and the service life of the piezoelectric ceramic drivers can be prolonged.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

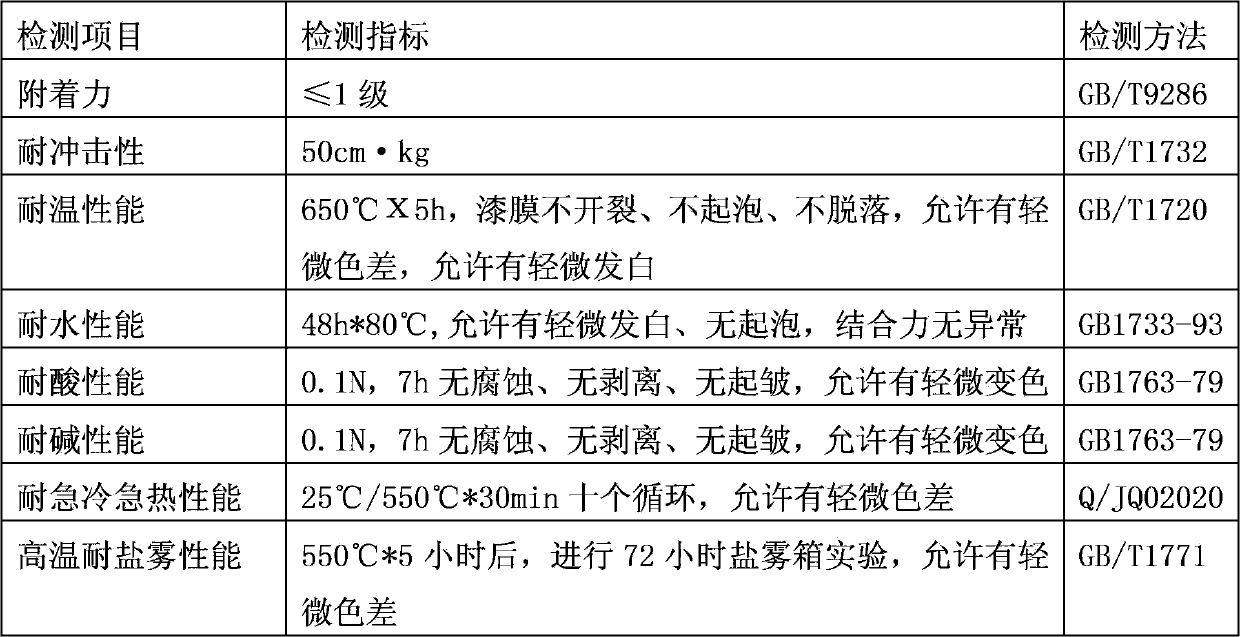

High-temperature-resistant anticorrosive paint and preparation method thereof

InactiveCN102719191BImprove bindingGood color retentionAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyester

The invention discloses high-temperature-resistant anticorrosive paint and a preparation method thereof. The paint comprises finishing paint and a primer which are matched, wherein calculated by mass percentage, the raw-material formula of the finishing paint comprises the following components: 20-30 percent of polyester modified organic silicon resin, 20-40 percent of filler, 30-50 percent of thinner and 0.5-1 percent of auxiliary agent; the filler is the mixture of glass powder, talcum powder, mica powder and carbon black; the raw-material formula of the primer comprises the following components: 10-20 percent of organic-silicon modified epoxy resin, 10-20 percent of phenolic resin, 20-40 percent of primer filler, 30-50 percent of thinner and 0.5-1 percent of auxiliary agent; and the primer filler is the mixture of iron red, mica powder, talcum powder and glass powder. The fillers adopted by the invention have the performances of acid resistance, alkali resistance, heat resistance, fire resistance, insulation and the like, and the obtained paint has the advantages of good weather resistance, high-temperature resistance, small color difference, good anticorrosive performance, good bonding force and low preparation cost.

Owner:SOUTH CHINA UNIV OF TECH

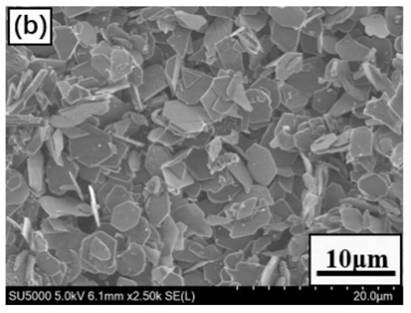

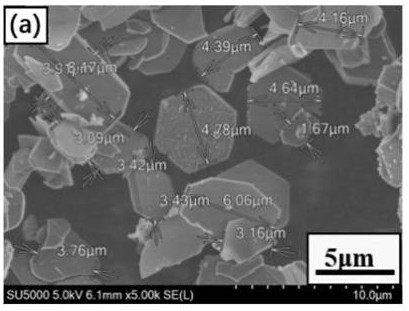

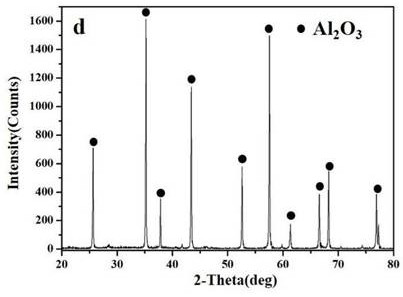

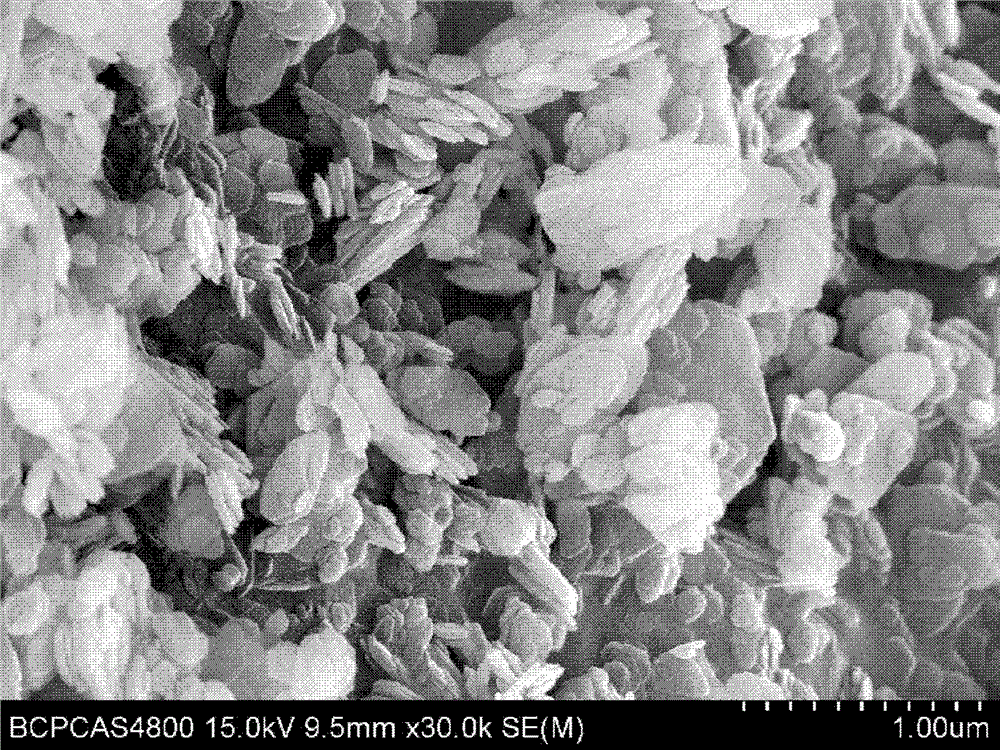

Flaky alpha alumina and preparation method thereof

PendingCN114715925ALarge diameter-to-thickness ratioGood effectMaterial nanotechnologyChemical industryAluminum fluorideCrucible

The invention provides a preparation method of flaky alpha aluminum oxide, which comprises the following steps: (1) weighing molten salt and an aluminum source, putting the molten salt and the aluminum source into a container, adding deionized water for dissolving, ultrasonically dispersing uniformly, and drying to obtain a mixture; (2) putting the mixture dried in the step (1) into a mortar, adding aluminum fluoride, and uniformly grinding; and (3) putting the powder in the step (2) into a crucible, putting the crucible into a heating furnace, heating to 750-900 DEG C, keeping the temperature for 0.5-5 hours, taking out a solid matter, grinding, and carrying out ultrasonic washing to obtain the flaky alpha aluminum oxide. The preparation method of the flaky alpha alumina is low in preparation temperature and short in reaction time, and the production cost is greatly reduced. The invention also provides the flaky alpha aluminum oxide prepared by the preparation method of the flaky alpha aluminum oxide, the average radial size of the flaky alpha aluminum oxide is 4-5 microns, the thickness is 150-250 nm, and the radius-thickness ratio is 16-25.

Owner:BAISE UNIV

Preparation method of two-dimensional alumina powder

InactiveCN109319813ALarge diameter-to-thickness ratioFlat surfaceAluminium oxides/hydroxidesCalcinationNanotechnology

The invention discloses a preparation method of two-dimensional alumina powder. The preparation method includes the steps of mixing aluminum salt, ammonia water and concentrated nitric acid accordingto a certain ratio, and allowing the three to react at a certain temperature to obtain transparent aluminum sol; uniformly applying the aluminum sol onto a surface-modified base by an applicator, andpeeling off a cured film after baking to obtain flaky powder; subjecting the flaky powder to high-temperature calcination to obtain the two-dimensional alumina powder. The two-dimensional alumina powder obtained by the method has the advantages of flat surface, smoothness, compactness, uniform thickness, large diameter-to-thickness ratio and the like.

Owner:SUN YAT SEN UNIV

A method for preparing a self-oriented Z-type hexagonal ferrite substrate

ActiveCN108329022BSelf-orientedGood orientationInductances/transformers/magnets manufactureCondensed matter physicsParticle-size distribution

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A method for exfoliating coal-measure hard kaolinite that keeps kaolinite crystal form

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Preparing method of inflame-retarding type big-diameter plate-shaped calcium carbonate

ActiveCN107055585AIncrease surface areaWith flame retardant effectCalcium/strontium/barium carbonatesMicrometerHydrotalcite

The invention provides a preparing method of inflame-retarding type big-diameter plate-shaped calcium carbonate. On the basis of a traditional preparing method of plate-shaped calcium carbonate, the draw ratio of fibroid light calcium carbonate is adjusted, graphene is added, in a grinding process, graphene is regarded as a base plane, the diameter of obtained plate-shaped calcium carbonate is obviously increased, the radius-thickness ratio is also increased accordingly, and meanwhile the advantages of the traditional method that the particles are uniform, the particle diameters are narrow in distribution are maintained, and the inflame-retarding type big-diameter plate-shaped calcium carbonate is large in superficial area and high in covering power; magnesium-aluminum hydrotalcite of which the particle diameter is 50-200 micrometers is added to conduct joint grinding, on one hand, the lamellar surface of the magnesium-aluminum hydrotalcite is tiled with graphene, and the radius-thickness ratio of calcium carbonate is further increased; on the other hand, in the grinding process, the magnesium-aluminum hydrotalcite forms nanoscale small particles, the nanoscale small particles are dispersed to the surface of plate-shaped calcium carbonate, and prepared plate-shaped calcium carbonate has a certain inflaming retarding effect.

Owner:浙江振鑫新材料科技有限公司

A method for preparing ultrafine flaky zinc-containing alloy powder by wet ball milling and its product and application

ActiveCN110508825BGood dispersionIncrease the frequency of collisionsTransportation and packagingMetal-working apparatusZinc alloysSlurry

The invention discloses a preparation method and application of an ultra-fine scaly zinc-containing alloy. The spherical atomized zinc-containing alloy powder and ball milling solvent, grinding aid, ball milling medium and dispersing agent are put into a ball milling tank in proportion, Heating and temperature-controlled wet ball milling. Then, the obtained ball-milled slurry is successively subjected to filtration, ultrasonic cleaning, rinsing, drying and other processes to obtain the scaly zinc-containing alloy powder. , the bulk density is 0.85g / cm 3 ‑0.95g / cm 3 . The ultrafine scaly zinc-containing alloy powder prepared by the invention has high flake degree, large diameter-to-thickness ratio, strong covering power, smooth surface, low oxidation degree and good particle size distribution. Production of water-based dacromet coatings, inorganic water-based zinc-rich aluminum paints and water-based heavy-duty anti-corrosion coatings with different specifications.

Owner:湖南昊宏新材料科技有限公司

Dissociation method of coal-series hard kaolinite rock lamella

InactiveCN103289447BLarge diameter-to-thickness ratioFacilitate dissociationSilicon compoundsPigment physical treatmentKaoliniteSlurry

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

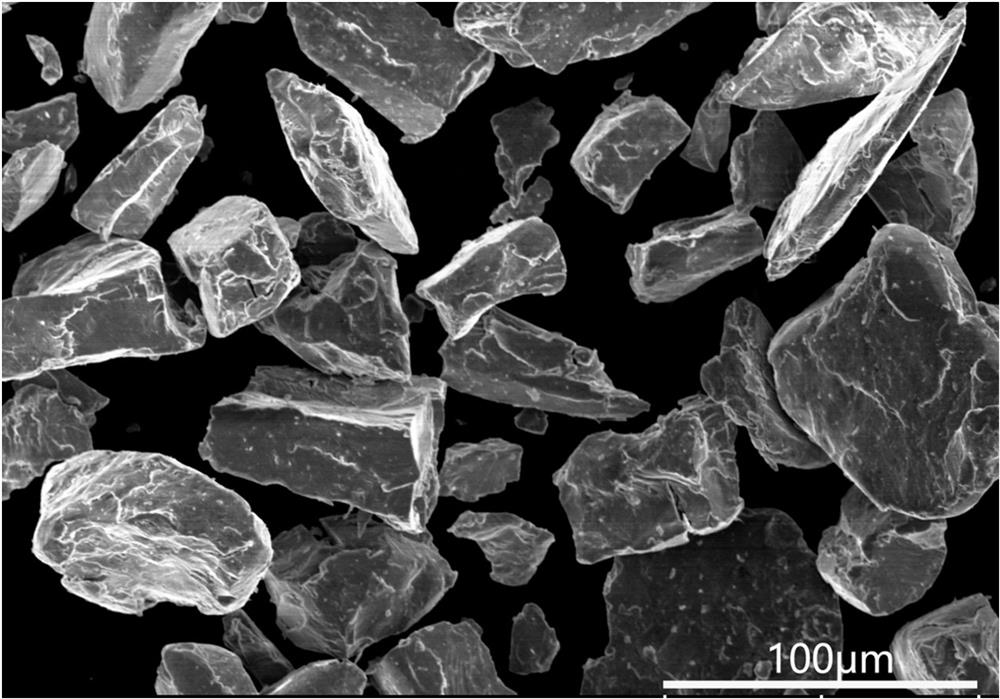

Preparation method of a micron-sized large-diameter-thickness ratio particle shape sheet-like sendust powder with uniform particle size

ActiveCN112207283BImprove hardness and brittlenessReduce hardness and brittlenessFerrosiliconAluminium powder

The invention discloses a method for preparing sendust aluminum powder with a uniform particle size and a micron-scale large diameter-thickness ratio particle shape, which belongs to the technical field of ultrafine metal powder preparation. The flaky sendust powder prepared by this method has a high flaking rate, a thickness between 1-2 μm, uniform particle size, a diameter-thickness ratio of about 30-38:1, and good soft magnetic properties. By softening the surface of the sendust powder before ball milling, the method can greatly increase the flaking rate of the sendust powder under the premise of ensuring its magnetic properties. Flake sendust powder with large diameter-thickness ratio can further reduce the internal air gap of the magnetic ring made of flake powder. It still has high permeability and low loss at high frequency.

Owner:HEFEI UNIV OF TECH

Flake zinc and zinc-aluminium alloy powder wet method producing process

InactiveCN1186153CImprove surface oxidation resistanceLarge diameter-to-thickness ratioGranularitySolvent

Owner:肖骁

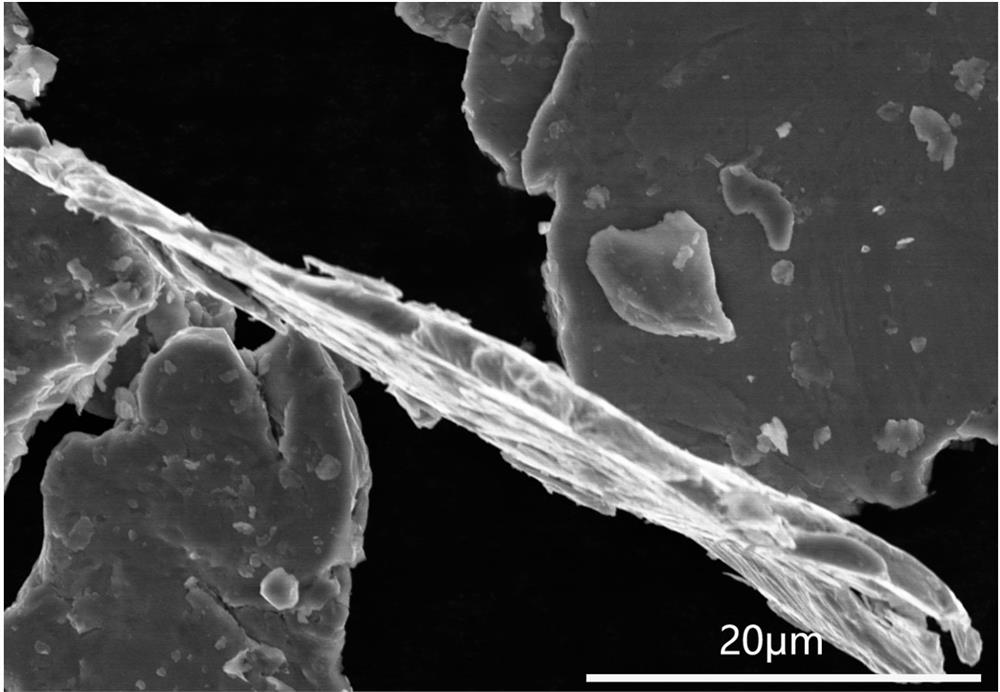

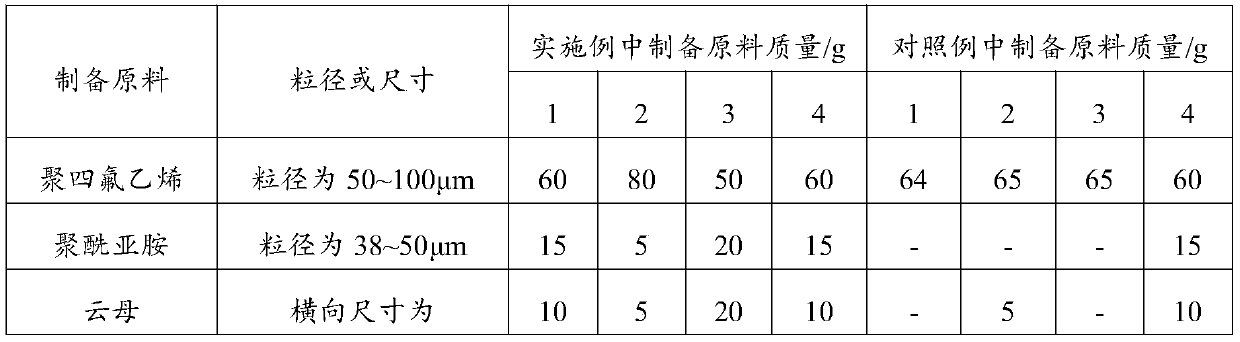

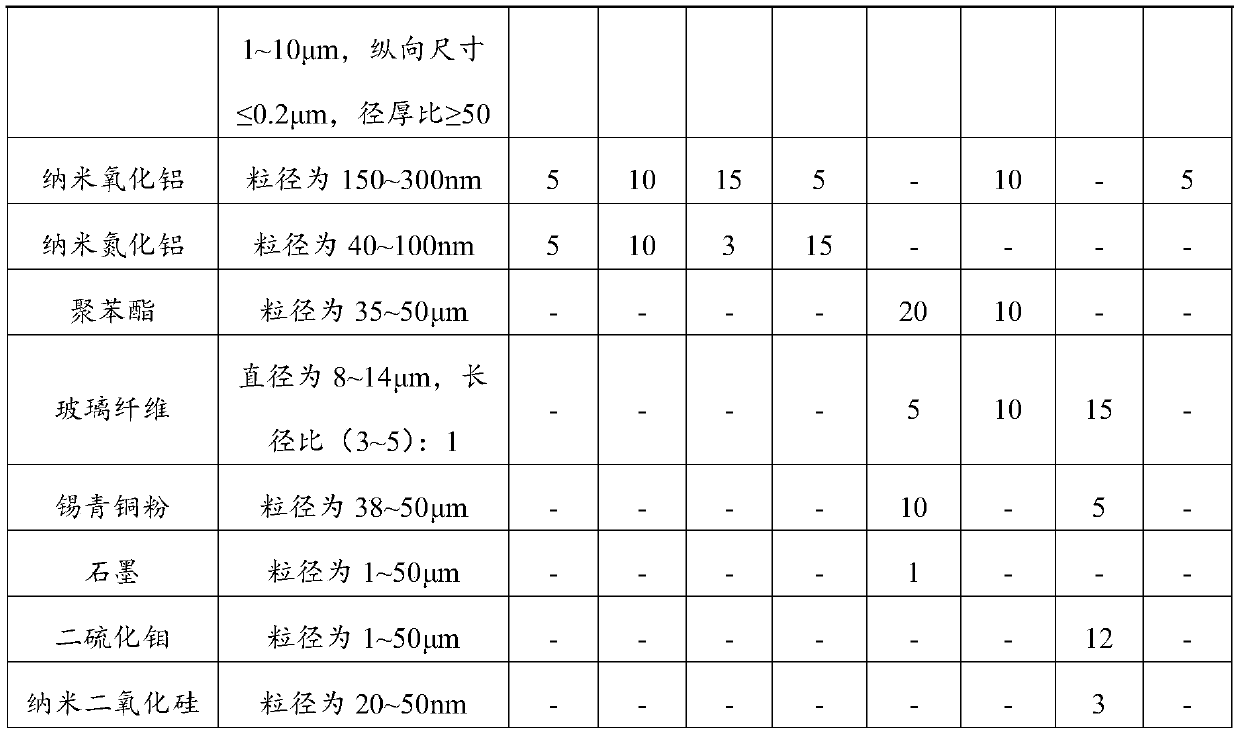

A high thermal conductivity insulating polytetrafluoroethylene friction material and its preparation method and application

ActiveCN109912910BCorrosion resistanceStable coefficient of frictionPlastic/resin/waxes insulatorsHeat-exchange elementsElectric machineryPolytetrafluoroethylene

The invention relates to the technical field of composite materials and in particular relates to a high heat conduction insulating polytetrafluoroethylene friction material as well as a preparation method and application thereof. The high heat conduction insulating polytetrafluoroethylene friction material provided by the invention comprises the following preparation raw materials in parts by mass: 50-80 parts of polytetrafluoroethylene, 5-20 parts of polyimide, 5-20 parts of mica, 5-15 parts of nanometer aluminum oxide and 1-10 parts of nano aluminum nitride. The polytetrafluoroethylene friction material prepared from the raw materials in a ratio has the characteristics of being stable in wearing resistance, stable in friction coefficient, and the like on the basis of high heat conductionand high insulation properties, and requirements of ultrasonic motors on friction materials can be met.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of preparation method of flame-retardant large-diameter flake calcium carbonate

ActiveCN107055585BIncrease surface areaWith flame retardant effectCalcium/strontium/barium carbonatesMicrometerHydrotalcite

The invention provides a preparing method of inflame-retarding type big-diameter plate-shaped calcium carbonate. On the basis of a traditional preparing method of plate-shaped calcium carbonate, the draw ratio of fibroid light calcium carbonate is adjusted, graphene is added, in a grinding process, graphene is regarded as a base plane, the diameter of obtained plate-shaped calcium carbonate is obviously increased, the radius-thickness ratio is also increased accordingly, and meanwhile the advantages of the traditional method that the particles are uniform, the particle diameters are narrow in distribution are maintained, and the inflame-retarding type big-diameter plate-shaped calcium carbonate is large in superficial area and high in covering power; magnesium-aluminum hydrotalcite of which the particle diameter is 50-200 micrometers is added to conduct joint grinding, on one hand, the lamellar surface of the magnesium-aluminum hydrotalcite is tiled with graphene, and the radius-thickness ratio of calcium carbonate is further increased; on the other hand, in the grinding process, the magnesium-aluminum hydrotalcite forms nanoscale small particles, the nanoscale small particles are dispersed to the surface of plate-shaped calcium carbonate, and prepared plate-shaped calcium carbonate has a certain inflaming retarding effect.

Owner:浙江振鑫新材料科技有限公司

Method for preparing flake silver powder

The invention discloses a method for preparing flake silver powder. The method comprises the following steps of: taking silver powder prepared by a physical vapor deposition method as a raw material, adding the silver powder into an organic solvent, and carrying out mechanical dispersion processing so as to obtain dispersed slurry; feeding the dispersed slurry to a grinder, connecting a material outlet into a finished product kettle after carrying out cyclic grinding for 1-3 hours, and thus obtaining required flake silver powder slurry; and drying the flake silver powder slurry through spray drying, thereby obtaining the flake silver powder. The method disclosed by the invention has the advantages of simple process flow, good dispersion performance, stable performance index, high yield, short processing time, and easiness in industrialized production.

Owner:JIANGSU BOQIAN NEW MATERIALS

A kind of water-based nano flake copper-zinc alloy slurry and preparation method thereof

The invention discloses a water-based nano-sheet copper-zinc alloy paste, which comprises the following raw materials by mass percentage: 10 to 20 percent of flake copper-zinc alloy particles, 1 to 3 percent of orientated alignment agent, 2 to 4 percent of surface treatment agent, 3 to 10% of thickener, 15 to 25% of cosolvent, 0 to 2% of dispersant, and 50 to 60% of deionized water. The dispersant is one of BYK-2091, BYK-184, BYK-185, BYK-187, BYK-190, BYK-191, BYK-192, BYK-193, BYK-194N, BYK-198, BYK-199, BYK-2010, BYK-2012 and BYK-2015 or a composition thereof. The invention also discloses a preparation method of the water-based nano flake copper-zinc alloy paste. The water-based nano flake copper-zinc alloy paste obtained by the invention has the advantages of regular shape of copper-zinc alloy particles, large diameter-thickness ratio, good dispersibility and good storage stability.

Owner:HEFEI SUNRISE PIGMENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com