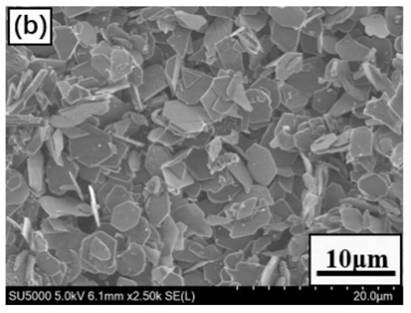

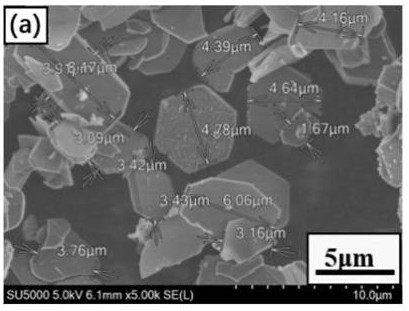

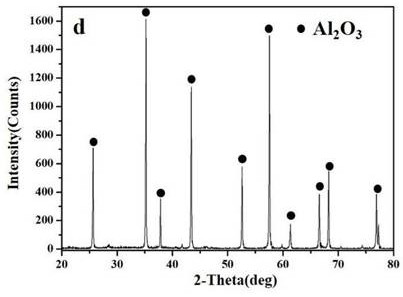

Flaky alpha alumina and preparation method thereof

An alpha alumina and flake technology, applied in the field of flake alpha alumina and its preparation, can solve the problems of high sintering temperature, long holding time, increased cost, etc., and achieve low calcination temperature, short holding time and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] A preparation method of flaky alpha alumina, comprising the following steps:

[0040] (1) Weigh 4.5g of sodium chloride and potassium chloride and 2g of aluminum hydroxide, put them into a beaker, add 100mL of deionized water, and ultrasonically disperse them evenly. Cool to obtain mixture A;

[0041] (2) weigh 0.1 g of aluminum fluoride and put it into an alumina mortar together with mixture A described in step (1), and grind evenly to prepare mixture B;

[0042] (3) The mixture B described in the step (2) was transferred to an alumina crucible, then put into a box-type resistance furnace and calcined at a temperature of 750 ° C for 180 min, the heating rate was 9 ° C / min, and the sample was cooled to room temperature, Take out the alumina crucible, and transfer the sample in the alumina crucible to a beaker;

[0043] Add 300-400 mL of water to the beaker, put it into an ultrasonic cleaner, disperse and dissolve by ultrasonic, and after it is completely dissolved, le...

Embodiment 2

[0047] A preparation method of flaky alpha alumina, comprising the following steps:

[0048] (1) Weigh 4.5g each of sodium chloride and potassium chloride, and 2g aluminum hydroxide, put them into a beaker, add 100mL of deionized water, and disperse evenly by ultrasonic, then put the beaker into a blast drying oven and dry at 120°C for 3h, Cool to obtain mixture A;

[0049] (2) weigh 0.1 g of aluminum fluoride and put it into an alumina mortar together with mixture A described in step (1), and grind evenly to prepare mixture B;

[0050] (3) The mixture B described in the step (2) was transferred to an alumina crucible, then put into a box-type resistance furnace for calcination at a temperature of 800 ° C for 60 min, the heating rate was 9 ° C / min, and the sample was cooled to room temperature, Take out the alumina crucible, and transfer the sample in the alumina crucible to a beaker;

[0051] Add 300-400 mL of water to the beaker, put it into an ultrasonic cleaner, disperse...

Embodiment 3

[0055] A preparation method of flaky alpha alumina, comprising the following steps:

[0056] (1) Weigh 4.5g each of sodium chloride and potassium chloride, and 2g aluminum hydroxide, put them into a beaker, add 100mL of deionized water, and disperse evenly by ultrasonic, then put the beaker into a blast drying oven and dry at 120°C for 3h, Cool to obtain mixture A;

[0057] (2) weigh 0.1 g of aluminum fluoride and put it into an alumina mortar together with mixture A described in step (1), and grind evenly to prepare mixture B;

[0058] (3) The mixture B described in the step (2) was transferred to an alumina crucible, then put into a box-type resistance furnace and calcined at a temperature of 900 ° C for 30 min, the heating rate was 9 ° C / min, and the sample was cooled to room temperature, Take out the crucible and transfer the sample in the crucible to the beaker;

[0059] Add 300-400 mL of water to the beaker, put it into an ultrasonic cleaner, disperse and dissolve by u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com