Nanoparticle reinforced metal-based composite material and preparation method thereof

A nanoparticle and composite material technology, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of long milling time, affecting the performance of composite materials, and low nanoparticle embedding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

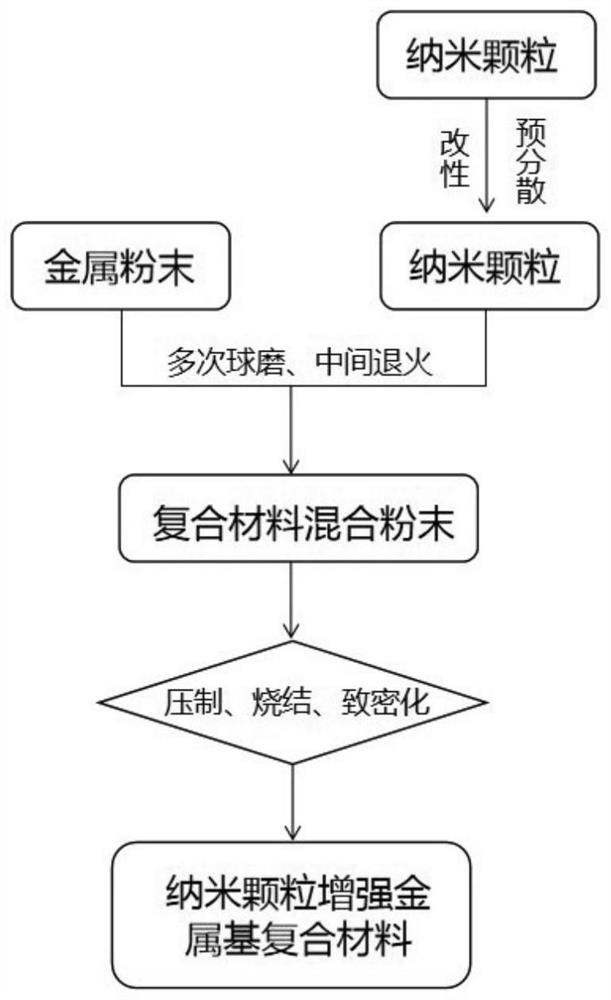

[0053] The preparation method of the nanoparticle-reinforced metal matrix composite provided by the invention comprises the following steps:

[0054] (1) Surface modification and pre-dispersion of nanoparticles:

[0055] The nanoparticles are subjected to surface modification treatment. After modification, the modified nanoparticles, metal powder and ball milling aid are mixed and then fully ultrasonicated in the ball milling medium to remove impurities on the surface of the nanoparticles and fully disperse the agglomerated nanoparticles;

[0056] (2) Initial stage of ball milling:

[0057] Add the mixture obtained in step (1) into the ball milling tank, then add ball milling media and ball milling aids, and perform low-speed ball milling, the ball mill speed is 10-250r / min, so that the materials in the ball milling tank are evenly mixed;

[0058] (3) Middle stage of ball milling:

[0059] Increase the rotational speed of the ball mill to 20-560r / min, and continue the ball m...

Embodiment 1

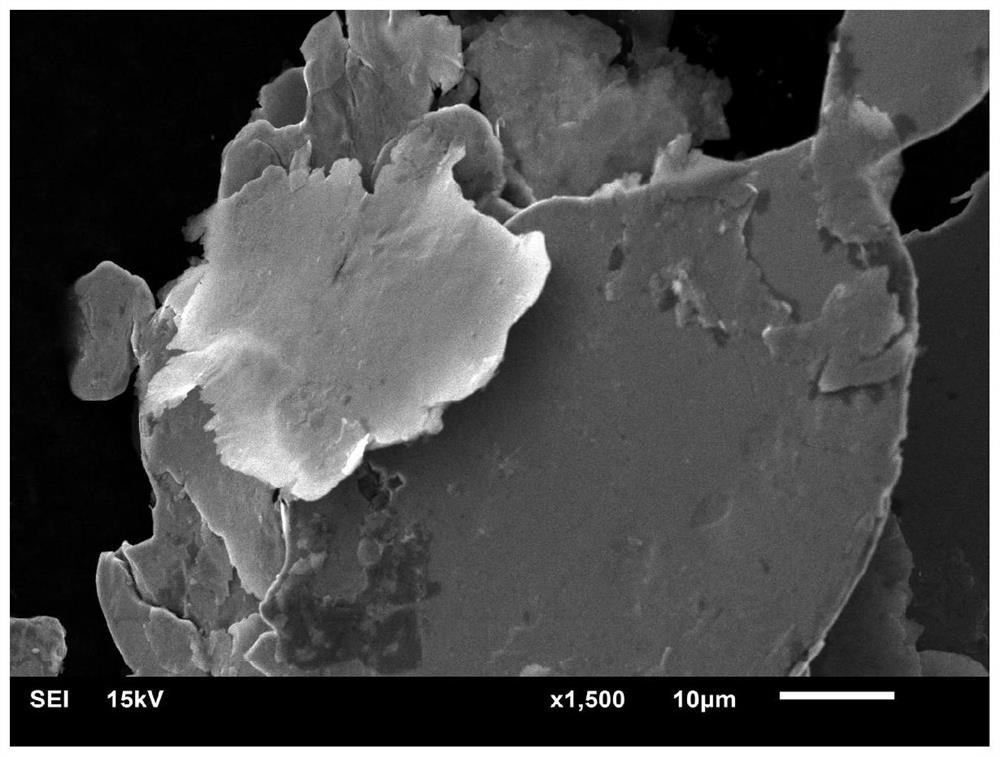

[0080] A kind of nano-SiC particle reinforced iron-based composite material, its preparation method comprises the steps:

[0081] (1) Surface modification and pre-dispersion of nanoparticles:

[0082] Select spherical nano-SiC particle powder with a particle size of 100nm, dry the nano-powder at 80°C for 1-2h, and then bake at 500°C for 2h to obtain modified nano-SiC. Weigh the modified nano-SiC and ultrafine iron powder with a mass ratio of 1:5, add 0.5wt% stearic acid, mix and sonicate in absolute ethanol for 0.5h.

[0083] (2) Initial stage of ball milling:

[0084] Put the mixture prepared in step (1) into the ball milling tank, add appropriate amount of absolute ethanol and stearic acid, and carry out ball milling, the ball-to-material ratio is 10:1, the ball mill speed is 80rpm, ball milling for 2 hours, and the material in the ball milling tank Mix well.

[0085] (3) Middle stage of ball milling:

[0086] Subsequently, the rotating speed of the ball mill was increas...

Embodiment 2

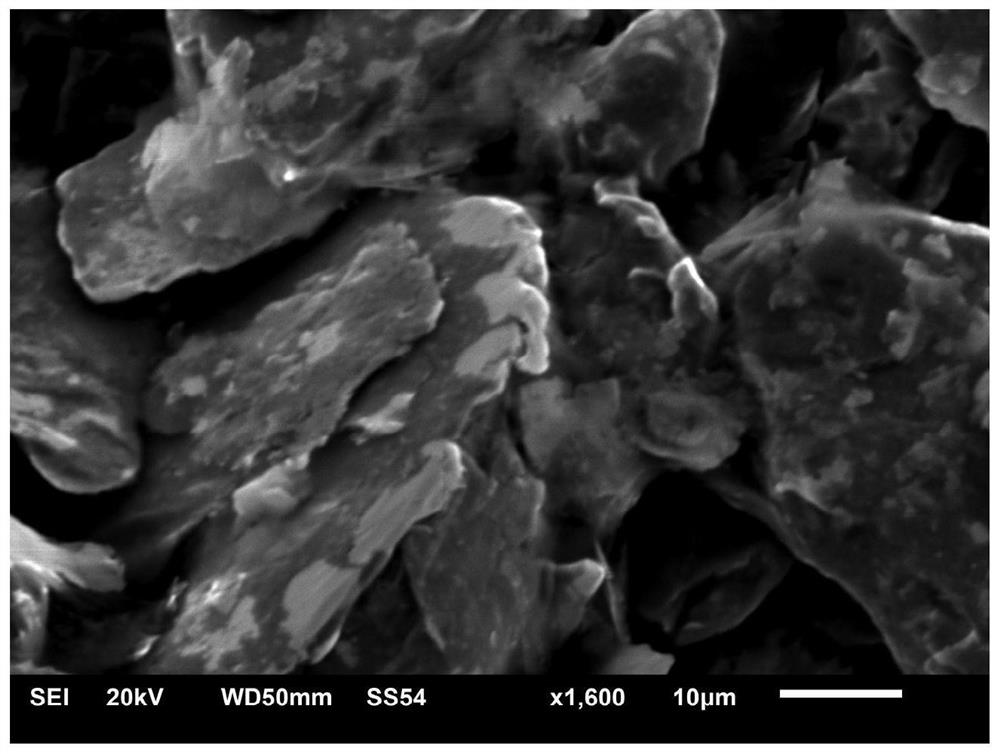

[0093] A nano-Al 2 o 3 Particle-reinforced nickel-based composite material, its preparation method comprises the steps:

[0094] (1) Surface modification and pre-dispersion of nanoparticles:

[0095] Select spherical nano-Al with a particle size of 30nm 2 o 3 Granular powder, dry the nano-powder at 100°C for 1h, and then bake it at 800°C for 0.5h to obtain the modified nano-Al 2 o 3 . Weigh the modified nano-Al with a mass ratio of 1:99 2 o 3 and ultra-fine nickel powder, and then add 0.5wt% stearic acid, mix and ultrasonicate in absolute ethanol for 1h.

[0096] (2) Initial stage of ball milling:

[0097] Put the mixture prepared in step (1) into the ball milling tank, add appropriate amount of absolute ethanol and Tween 80, and carry out ball milling. The materials are sufficient.

[0098] (3) Middle stage of ball milling:

[0099] Subsequently, the rotational speed of the ball mill was increased to 560r / min, and after ball milling for 12 hours, the material was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com