Preparation method of a micron-sized large-diameter-thickness ratio particle shape sheet-like sendust powder with uniform particle size

A technology of sendust powder and large diameter-to-thickness ratio, which is applied in the field of ultrafine metal powder preparation, can solve the problems of small powder contact area and cannot meet the requirements of wave-absorbing materials, and achieve uniform particle size and high magnetic permeability , the effect of reducing the hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

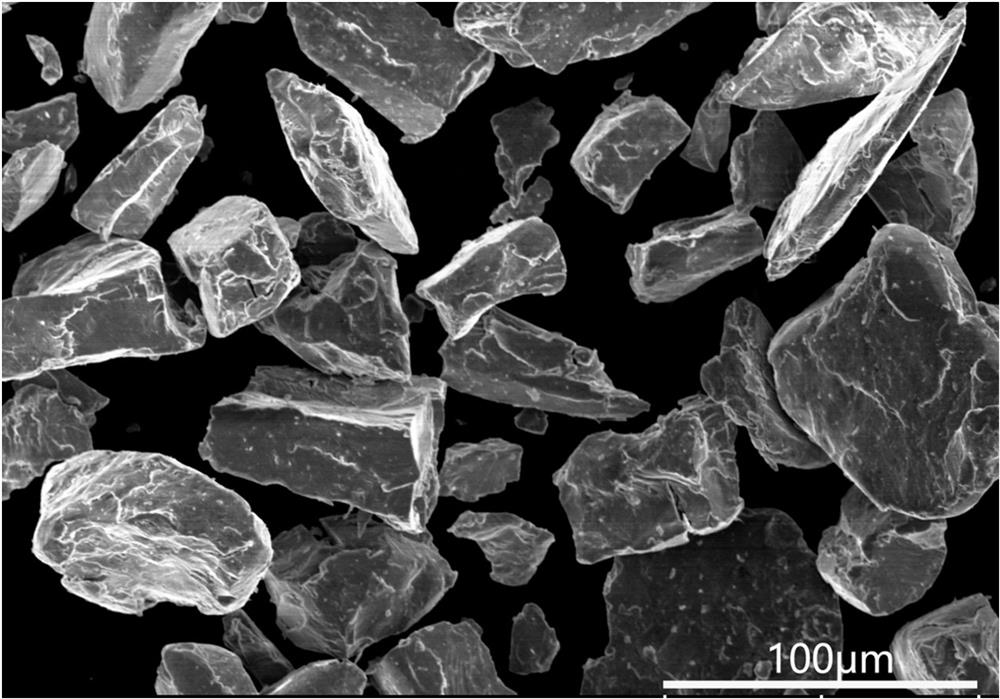

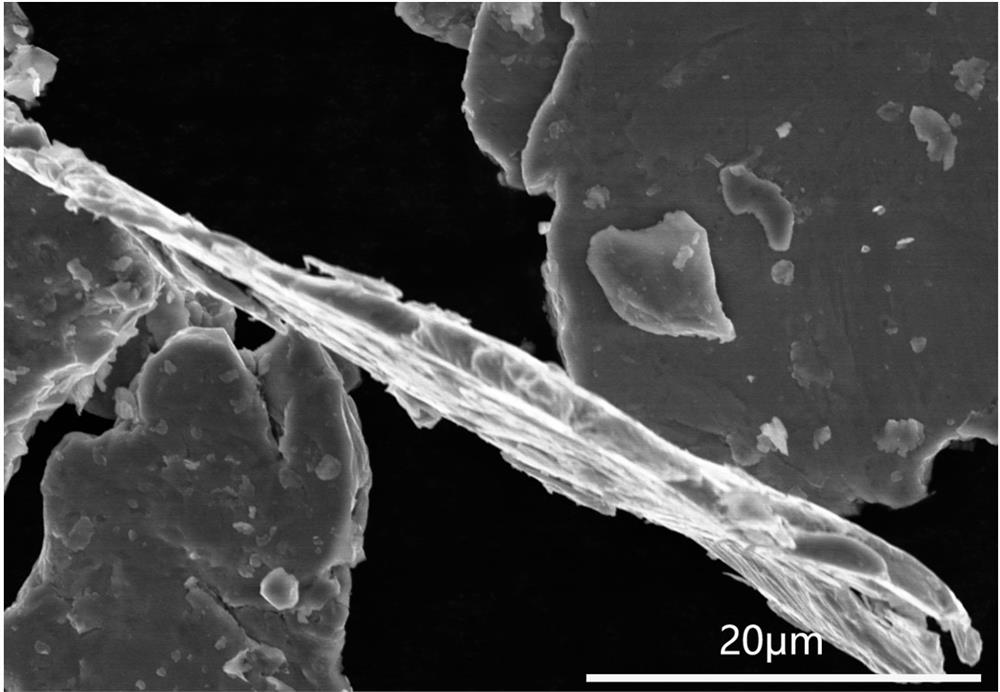

[0031] The specific steps for preparing sendust aluminum powder with uniform particle size, micron-scale large diameter-thickness ratio particle morphology and flaky shape are as follows:

[0032] (1) Wash 500g of crushed ferrosilicon aluminum alloy powder with a particle size of 50-80μm with acetone, dry it, and spread it evenly on the screen. The metal softener is glyceryl stearate. Spray evenly on the sendust powder, the atomization equipment is a small electric sprayer, the atomization spray time interval is 15min, and the number of atomization is 4 times; the amount of single atomization spray is 6% of the alloy powder amount.

[0033] (2) 30 minutes after the last spraying of the metal softener solution, put the sendust powder into the annealing furnace, and anneal under the protection of nitrogen, the annealing temperature is 400°C, and the holding time is 3h.

[0034] (3) Ultrasonic dispersion of the annealed sendust aluminum alloy powder with ethanol as the medium; ul...

Embodiment 2

[0040] The specific steps for preparing sendust aluminum powder with uniform particle size, micron-scale large diameter-thickness ratio particle morphology and flaky shape are as follows:

[0041] (1) Wash 500g of broken ferrosilicon aluminum alloy powder with a particle size of 50-80μm with acetone, dry it, spread it evenly on the screen, and mix glyceryl stearate and polydimethylsiloxane with a metal softener at a volume ratio of 2:1. It is made by mixing methyl silicone oil, and the metal softener is evenly sprayed on the sendust powder with atomization equipment. The atomization equipment is a small electric sprayer. The atomization spray time interval is 30 minutes, and the number of atomization is 3 times; The amount of atomized spraying is 10% of the amount of alloy powder.

[0042] (2) 30 minutes after the last spraying of the metal softener solution, put the sendust powder into the annealing furnace, and anneal under the protection of nitrogen, the annealing temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com