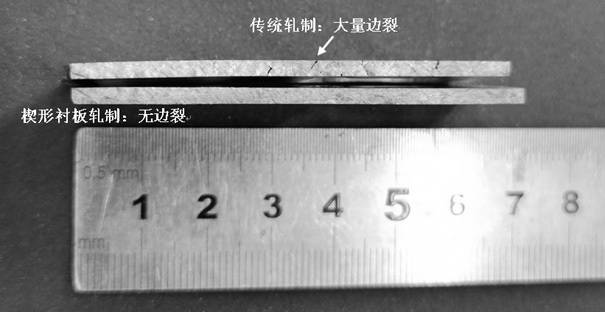

Wedge-shaped lining plate for hard and brittle high-modulus magnesium alloy and edge crack control rolling method and application of wedge-shaped lining plate

A magnesium alloy plate and magnesium alloy technology, applied in metal rolling, temperature control, chemical instruments and methods, etc., can solve problems such as hard and brittle high-modulus magnesium alloys that are difficult to roll and deform, and achieve increased elongation, improved efficiency, good ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

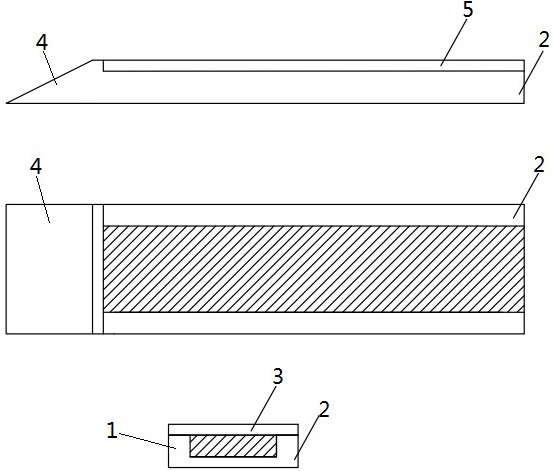

[0041] Such as figure 1As shown, the wedge-shaped liner body 1 containing a 1050 aluminum alloy is prefabricated containing the rectangular groove 5 and one end of the aluminum alloy material of the wedge end portion 4, and the wedge end portion 4 is disposed on the groove plate 2, and the height of the wedge end 4 3 mm higher than the rectangular groove 5, the wedge end 4 is 45 °, the width of the wedge liner is 50 mm, and the depth of the rectangular groove 5 is 5 mm, and the rectangular groove 5 side is side by side. Side of the wedge liner The width is 5 mm; the MG-9Al-1Zn alloy magnesium alloy plate consistent with the rectangular groove 5 width and height is in addition to the front and rear end, and the aluminum alloy wedge is embedded after coating with a polyimide film having a thickness of 0.1 mm. In the rectangular groove 5 of the plate, cover the cover 3; together the above-described aluminum alloy line together with the magnesium alloy plate at 300 ° C for 5 min; comb...

Embodiment 2

[0043] The wedge-shaped liner body 1 containing the aluminum alloy material containing the rectangular groove 5 and one end of the wedge end portion 4 is prefabricated with 3003 aluminum alloy, and the wedge end portion 4 is disposed on the groove plate 2, and the height of the wedge end 4 is longer than the rectangle. The groove 5 is 5 mm higher, the wedge end angle is 15 °, the width-shaped liner is 300 mm, the depth of the rectangular groove 5 is 30 mm, and the rectangular groove 5 side edge distance width liner side edge width is 10mm. The MG-9Al-1Zn alloy magnesium alloy plate consistent with the rectangular groove 5 width and the height is except that the front and rear ends are covered with a polyimide film having a thickness of 0.5 mm. In the groove 5, the cover plate 3 is covered; the above-described aluminum alloy line is held together with the magnesium alloy plate at 450 ° C for 20 min; the heat-insulating aluminum alloy line is synchronously rolled together with the m...

Embodiment 3

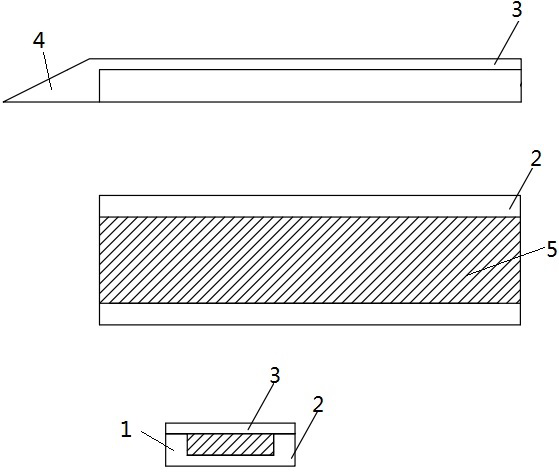

[0045] Such as figure 2 As shown, a 5052 aluminum alloy is selected, and the wedge-shaped liner body 1 containing the rectangular groove 5 and one end is the aluminum alloy material of the wedge end portion 4 is prefabricated, and the wedge end portion 4 is disposed on the cover plate 3, and the height of the wedge end 4 4 mm higher than the rectangular groove 5, the wedge end 4 angle is 30 °, the width of the wedge liner is 200 mm, the depth of the rectangular groove 5 is 20 mm, and the rectangular groove 5 side is from the side of the wedge-shaped liner. The width is 8 mm; the Mg-9Al-1Zn alloy magnesium alloy plate consistent with the rectangular groove 5 width and height is in addition to the front and rear ends, and the aluminum alloy wedge is embedded after coating with a polyimide film having a thickness of 0.3 mm. In the rectangular groove 5 of the plate, cover the cover 3; together the above-described aluminum alloy line with the magnesium alloy plate at 350 ° C for 15 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com