Self-repairing material for oil and gas well cementation and preparation method

A self-repairing material and well cementing technology, applied in the field of oil drilling, can solve the problems of cement sheath losing its sealing ability, reducing the production life of oil wells, and poor mechanical properties of cement stone, so as to reduce the elastic modulus, increase deformation ability, and high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

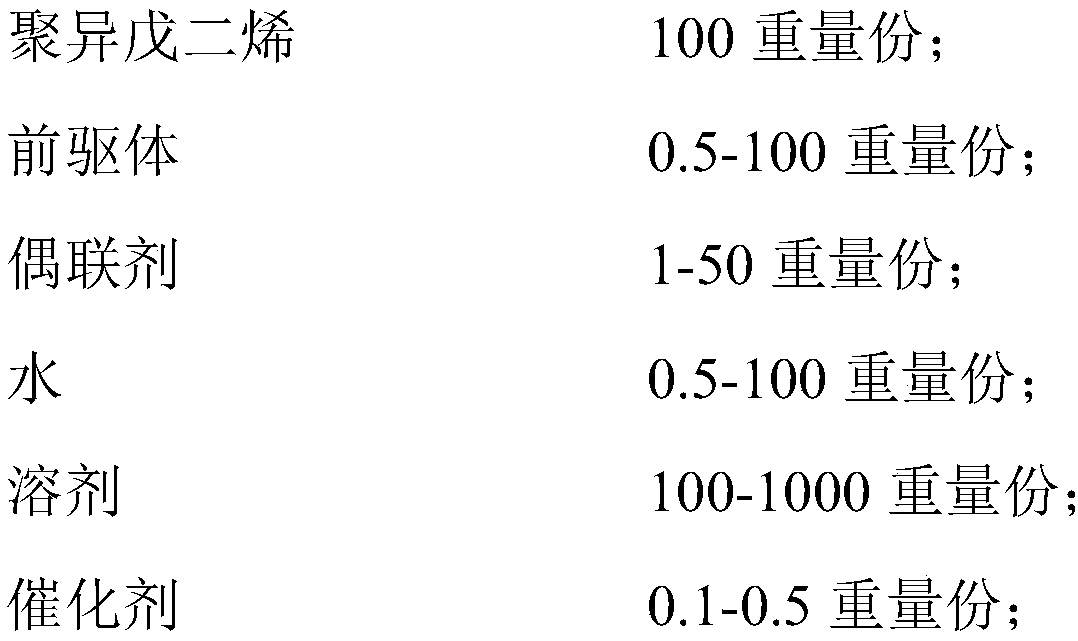

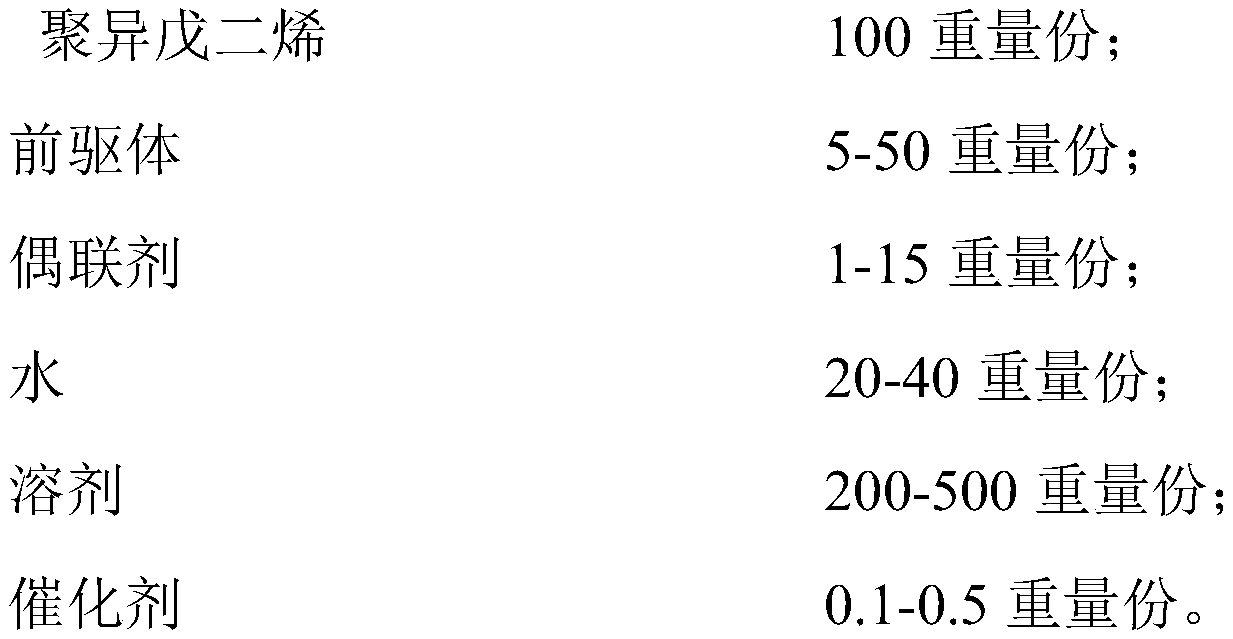

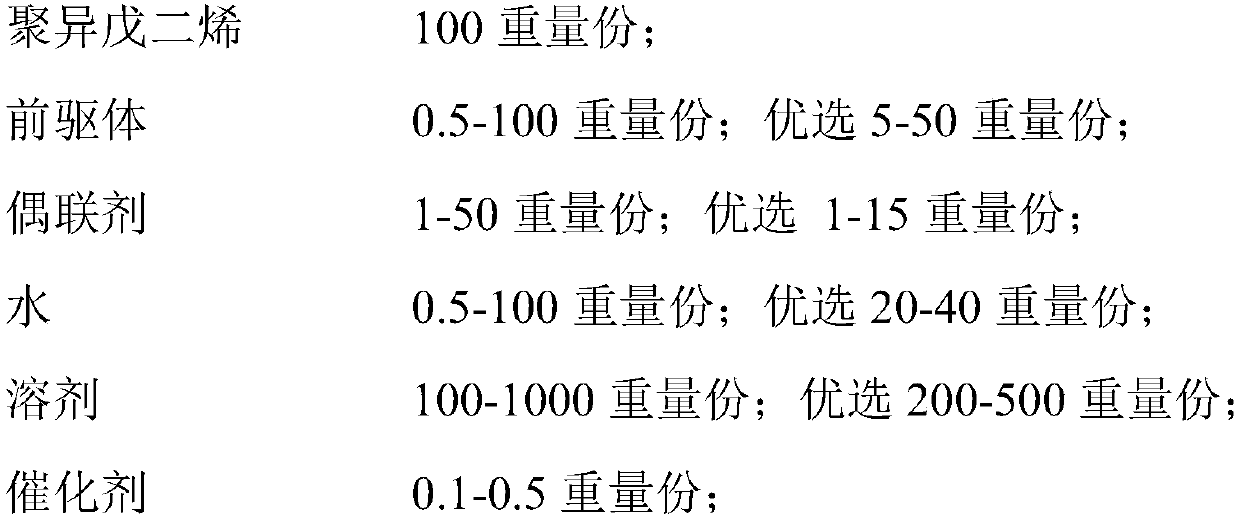

Method used

Image

Examples

Embodiment 1

[0055] Add 100 parts by weight of polyisoprene particles (average particle diameter 1.5 mm) to 1000 parts by weight of ethanol, add 10 parts by weight of water, 5 parts by weight of hydroxyl-terminated polysiloxane, and 0.5 parts by weight of hydrochloric acid, and at 30 ° C Stir for 60 minutes, then continuously inject 90 parts by weight of water and 40 parts by weight of ethyl orthosilicate within 120 minutes, and stir at constant temperature for 5 hours to carry out hydrolysis and condensation reaction. After the reaction was completed, the product was suction-filtered, and dried at a constant temperature at 50° C. to a constant weight.

Embodiment 2

[0057]Add 100 parts by weight of polyisoprene particles (average particle diameter 1.5 mm) to 450 parts by weight of tetrahydrofuran, add 1 part by weight of water, 50 parts by weight of trimethoxysilane, and 0.1 part by weight of ethylenediamine, and at 60 ° C Stir for 30 minutes, then continuously inject 1 weight part of sodium silicate within 60 minutes, and stir at constant temperature for 4 hours to carry out hydrolysis and condensation reaction. After the reaction was completed, the product was suction-filtered, and dried at a constant temperature at 50° C. to a constant weight.

Embodiment 3

[0059] Add 100 parts by weight of polyisoprene particles (average particle diameter 1.5 mm) to 200 parts by weight of ethanol, add 10 parts by weight of water, 25 parts by weight of hydroxyl-terminated polysiloxane, and 0.3 parts by weight of ethyl acetate, and heat at 60°C Stir for 30 minutes under the same conditions, then continuously inject 40 parts by weight of water and 90 parts by weight of trichlorosiloxane within 60 minutes, and stir at constant temperature for 4 hours to carry out the hydrolysis and condensation reaction. After the reaction was completed, the product was suction-filtered, and dried at a constant temperature at 50° C. to a constant weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com