Polytetrafluoroethylene friction material with high elastic modulus and preparation method and application thereof

A technology of polytetrafluoroethylene and friction materials, applied in the field of composite materials, can solve problems such as not being able to meet high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

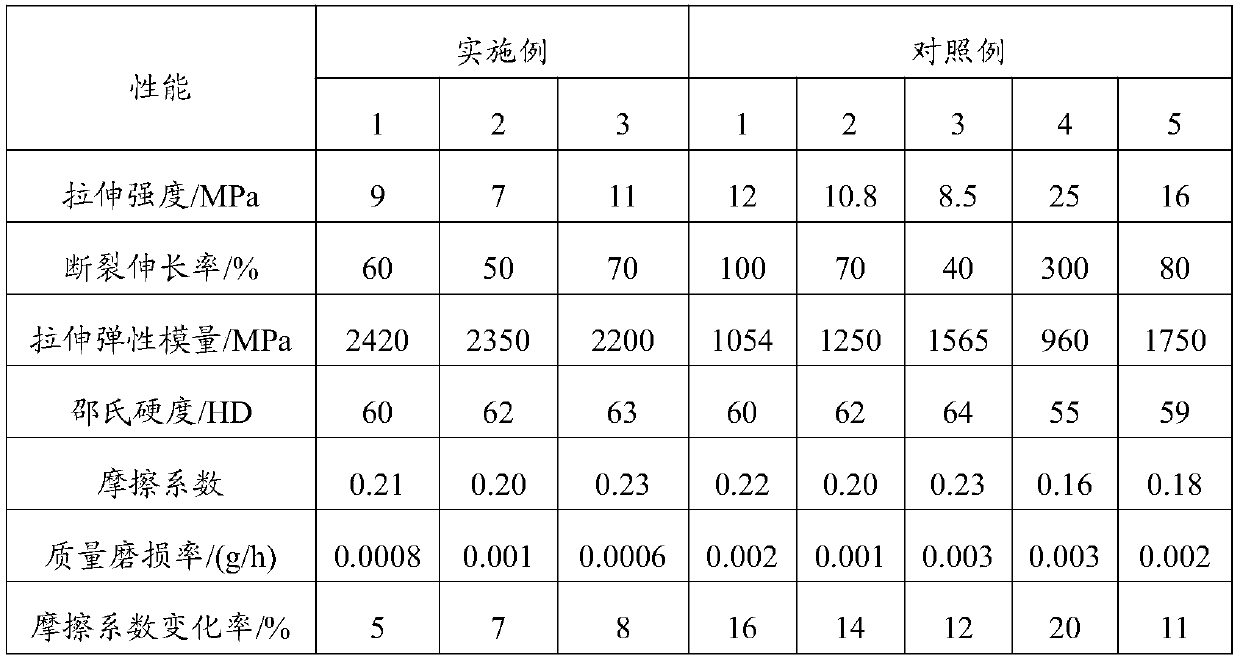

Examples

preparation example Construction

[0036] The present invention provides a preparation method of the polytetrafluoroethylene friction material described in the above technical solution, comprising the following steps:

[0037] The polytetrafluoroethylene, mica, glass fiber, nano-alumina and graphite are mixed and pressed and sintered in sequence to obtain the polytetrafluoroethylene friction material.

[0038] The invention mixes polytetrafluoroethylene, mica, glass fiber, nano-alumina and graphite to obtain a mixture. In the present invention, there is no special limitation on the order and mixing method of each preparation raw material, as long as each component can be mixed evenly.

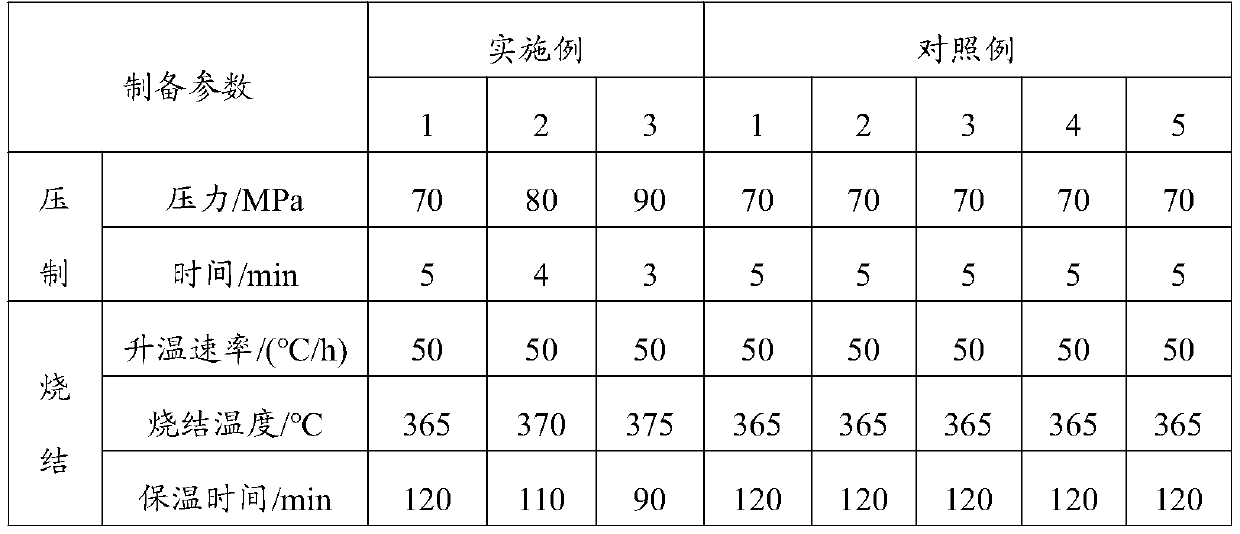

[0039] After the mixed material is obtained, the present invention compresses the mixed material to obtain a pressed material. In the present invention, the pressing pressure is preferably 70-100 MPa, more preferably 80-90 MPa; the time is preferably 3-5 minutes, more preferably 3-4 minutes. In the present invention, the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com