Special paint for granary wall body and preparation method thereof

A technology for walls and granaries, which is applied in the field of special coatings for granary walls and its preparation. It can solve the problems of poor artificial aging resistance, poor thermal insulation, and no fire protection performance, and achieve the best corrosion resistance, bright colors, and tinting strength. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

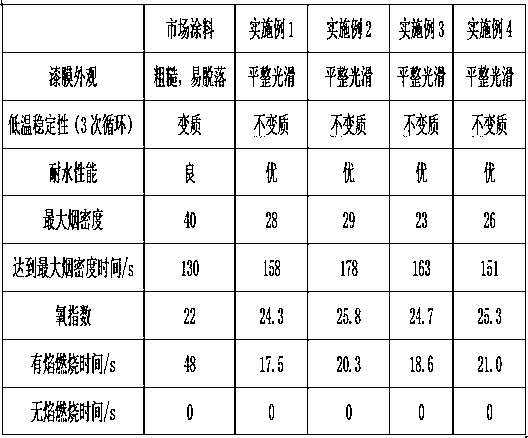

Examples

Embodiment 1

[0064] Special paint for granary walls, including the following raw materials in parts by weight: 100 parts of polyurethane; 50 parts of hollow glass microspheres; 20 parts of blast furnace slag; 20 parts of titanium dioxide; 15 parts of bamboo carbon; 15 parts of vermiculite powder; 3 parts; 3 parts of acetyl tributyl citrate; 5 parts of polyethylene wax; 1 part of silicone; 3 parts of defoamer; 3 parts of thickener; 3 parts of flame retardant; 3 parts of dispersant.

[0065] The average particle size of the hollow glass microspheres is 500nm; the blast furnace slag is obtained by drying and grinding the granulated blast furnace slag, and the mesh number is 150 mesh; the bamboo carbon has a mesh number of 150 mesh; Described vermiculite powder, mesh number is 150 orders; The particle diameter of described polyethylene wax is 0.3 μ m; Described organosilicon, is silicone oil; Described defoamer, is polyoxyethylene polyoxypropylene pentaerythritol ether; The agent is methyl cel...

Embodiment 2

[0073] Special paint for granary walls, including the following raw materials in parts by weight: 110 parts of polyurethane; 60 parts of hollow glass microspheres; 30 parts of blast furnace slag; 30 parts of titanium dioxide; 20 parts of bamboo carbon; 17 parts of vermiculite powder; 4 parts; acetyl tributyl citrate 4 parts; polyethylene wax 6 parts; silicone 2 parts; defoamer 4 parts; thickener 4 parts; flame retardant 4 parts; dispersant 4 parts.

[0074] The average particle size of the hollow glass microspheres is 700nm; the blast furnace slag is obtained by drying and grinding the granulated blast furnace slag, and the mesh number is 200 mesh; the bamboo charcoal has a mesh number of 200 mesh; Described vermiculite powder, mesh number is 200 orders; The particle diameter of described polyethylene wax is 1 μ m; Described organosilicon, is silicone oil; Described defoamer, is polyoxyethylene polyoxypropanolamine ether; The agent is hydroxypropyl methylcellulose; the dispers...

Embodiment 3

[0082] Special paint for granary walls, including the following raw materials in parts by weight: 120 parts of polyurethane; 65 parts of hollow glass microspheres; 40 parts of blast furnace slag; 40 parts of titanium dioxide; 25 parts of bamboo carbon; 17 parts of vermiculite powder; 5 parts of acetyl tributyl citrate; 7 parts of polyethylene wax; 3 parts of silicone; 4 parts of defoamer; 4 parts of thickener; 4 parts of flame retardant; 4 parts of dispersant.

[0083] The average particle size of the hollow glass microspheres is 800nm; the blast furnace slag is obtained by drying and grinding the granulated blast furnace slag, and the mesh number is 250 mesh; the bamboo charcoal has a mesh number of 250 mesh; The vermiculite powder has a mesh number of 250 mesh; the particle diameter of the polyethylene wax is 1.5 μm; the organosilicon is silicone oil; the defoamer is polyoxypropylene glyceryl ether; the thickener is Sodium carboxymethyl cellulose; the dispersant is BYK161. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com