Graphite chemical substance intercalation reaction vessel and technological method thereof

A technology of chemical substances and intercalation reactions, applied in the field of material science, can solve problems such as reducing production costs, achieve the effects of ensuring electrical conductivity, avoiding the use of strong acids and strong oxidants, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

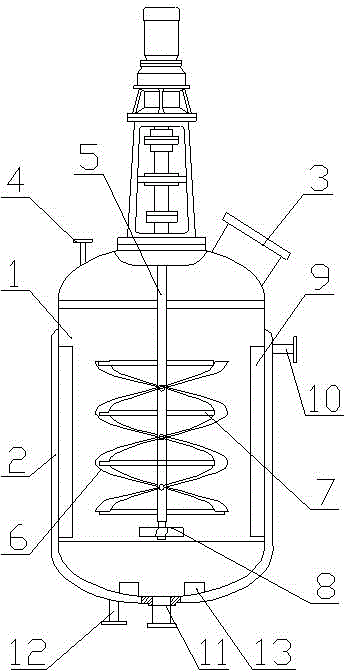

Image

Examples

Embodiment 1

[0042] Inject 50kg of graphite flakes and 350kg of deionized water into the reactor, and at the same time add 7.5kg of sodium dodecylbenzenesulfonate into the reactor, start the stirring shaft to mix the materials evenly; after stirring evenly, add sodium carbonate into the reactor and hydrochloric acid, keep the temperature in the reactor at 60°C, keep the pressure at 2atm, keep the rotation speed of the stirring shaft at 1000rpm / min, use an ultrasonic rod with a frequency of 50w to sonicate, and the reaction time is 3h. Discharged into the storage tank, let stand for 24h to get the first product.

Embodiment 2

[0044] Inject 30kg of graphite flakes and 250kg of benzimidazole into the reactor, add 5kg of ethylene glycol to the reactor at the same time, start the stirring shaft to mix the materials evenly; Keep the temperature at 70°C, keep the pressure at 2atm, keep the rotation speed of the stirring shaft at 1500rpm / min, use an ultrasonic rod with a frequency of 60w to sonicate, and the reaction time is 3h. Set for 24h to get the first product.

Embodiment 3

[0046] Inject 20kg of graphite flakes and 300kg of N-methylpyrrolidone into the reactor, add 5kg of polyvinyl alcohol into the reactor at the same time, start the stirring shaft to mix the materials evenly; after stirring evenly, add 2,4-dinitro For imidazole, keep the temperature in the reactor at 60°C, keep the pressure at 2atm, keep the rotation speed of the stirring shaft at 1200rpm / min, use an ultrasonic rod with a frequency of 50w to sonicate, and the reaction time is 3h. After the reaction is stopped, the upper suspension is discharged through the outlet. In the storage tank, let it stand for 24 hours to obtain the first product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com