Deformation polishing disc based on piezoelectric ceramic drivers

A piezoelectric ceramic and drive technology, applied in the field of aspheric mirror polishing equipment, can solve the problems of poor stability of the polishing disc and small diameter-thickness ratio of the polishing disc, and achieve the effects of compact structure, low cost and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

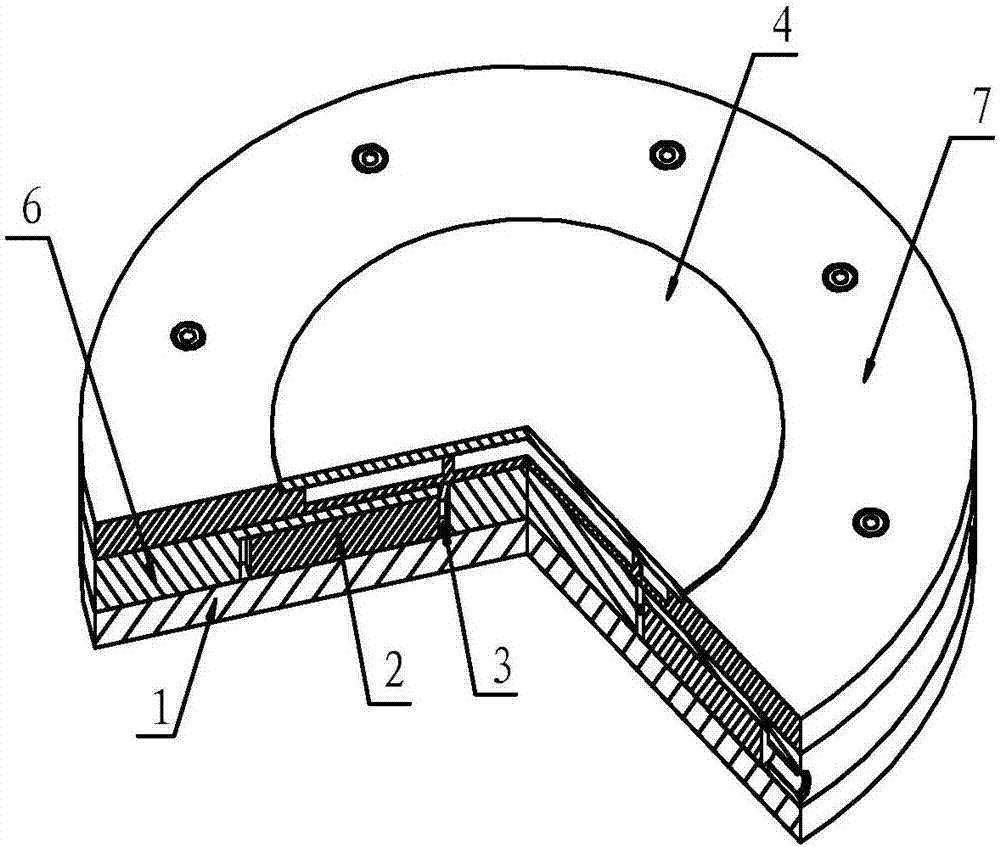

[0030] like figure 1 As shown, a deformed polishing disc based on piezoelectric ceramic drivers includes a base 1, a piezoelectric ceramic driver 2, an elastic sheet 3 and a base plate 4, that is to say, the elastic sheet 3 and the piezoelectric ceramic driver 2 One-to-one arrangement, the piezoelectric ceramic driver 2 is located on the upper surface of the base 1, the substrate 4 is located above the piezoelectric ceramic driver 2, the lower surface of the base 1 is provided with a conductive slip ring 5, and the piezoelectric ceramic The driver 2 is connected to a voltage source through a conductive slip ring 5, and the base plate 4 is an aluminum spherical thin plate.

[0031] The elastic piece 3 is installed on the upper surface of the base 1 along its radial direction, and in order to increase the diameter-thickness ratio of the polishing disc, the piezoelectric ceramic driver 2 is installed on the upper surface of the base 1 along its axial direction, and one end thereo...

Embodiment 2

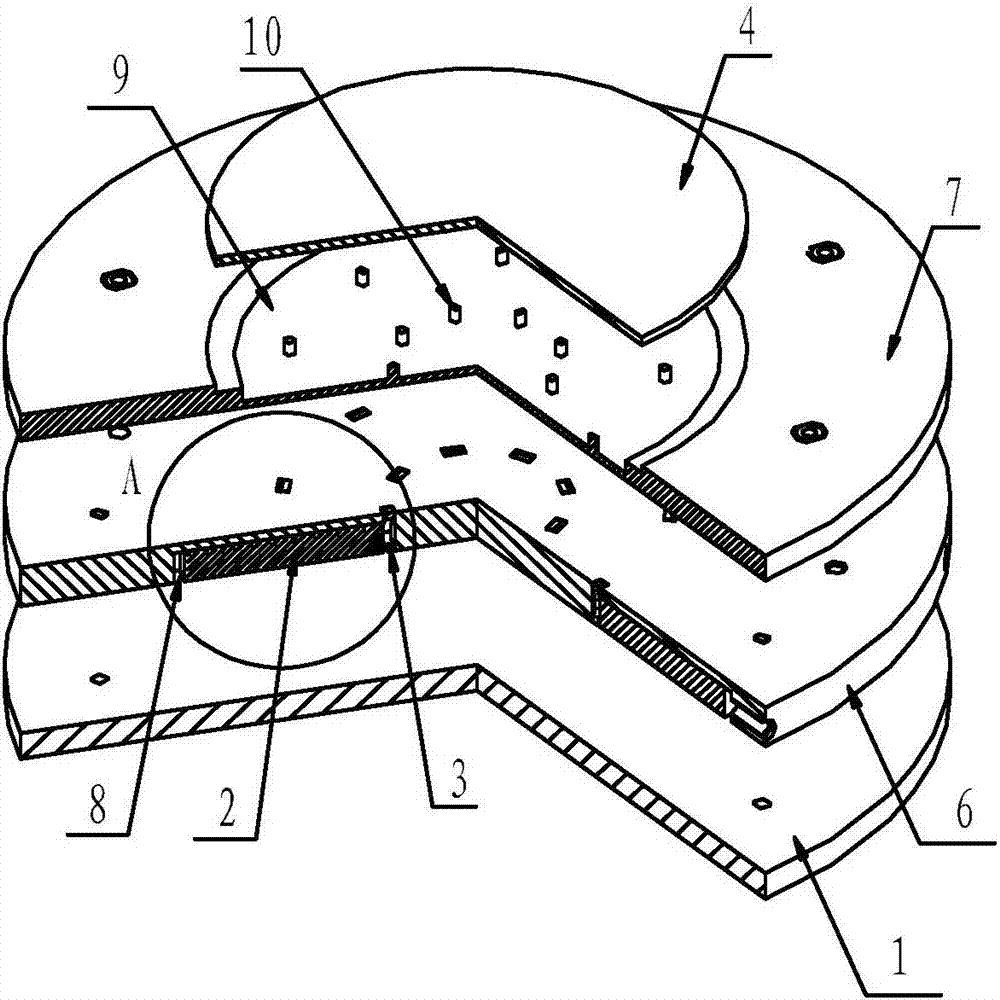

[0037] like Figure 2-4 As shown, the same parts of this embodiment and Embodiment 1 will not be repeated, and the difference is:

[0038]A fixed disc 6 is provided between the base 1 and the base plate 4 for installing the piezoelectric ceramic driver 2 and the elastic sheet 3. A long groove 8 is provided in the fixed disc 6, and the piezoelectric ceramic driver 2, elastic The pieces 3 are all located in the elongated groove 8 , and the clamping member is located at the edge of the fixed disk 6 and abuts against the end of the piezoelectric ceramic driver 2 .

[0039] Above the piezoelectric ceramic driver 2 is provided a support plate 7 of aluminum structure or steel structure, a groove 9 is provided in the support plate 7, the base plate 4 is located in the groove 9, and the upper surface of the base plate 4 Higher than the upper surface of the support plate 7, it is convenient for the base plate 4 to polish the aspheric mirror. The corresponding elastic sheet 3 is provide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com