Multichannel piezoelectric deformable mirror driving power source based on charge driving

A technology for driving a power supply and a deformable mirror, applied in the optical field, can solve the problems affecting the control accuracy of the deformable mirror, the deformation hysteresis effect of the piezoelectric deformable mirror, etc., and achieve the effects of easy control, low cost, and reduction of the hysteresis effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

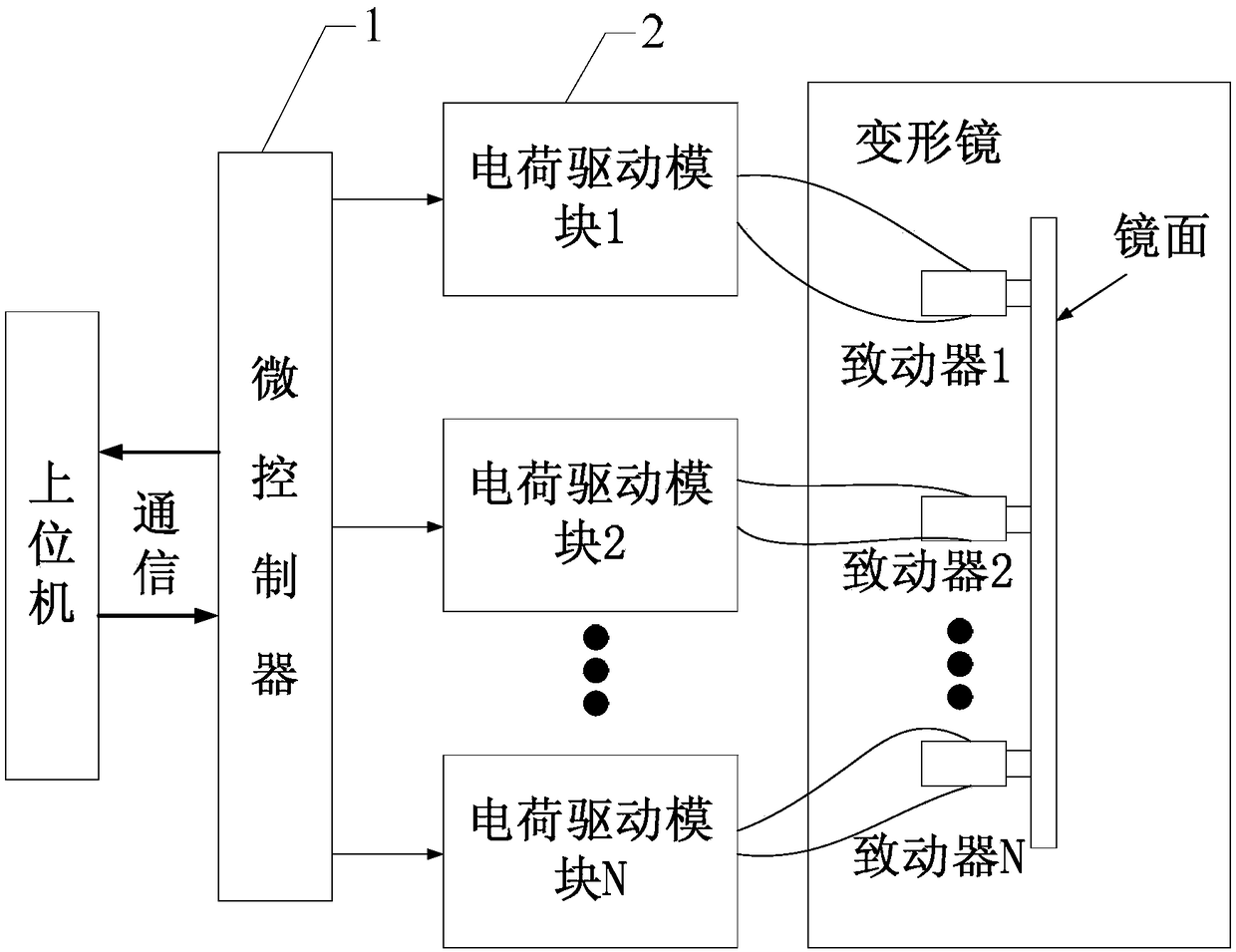

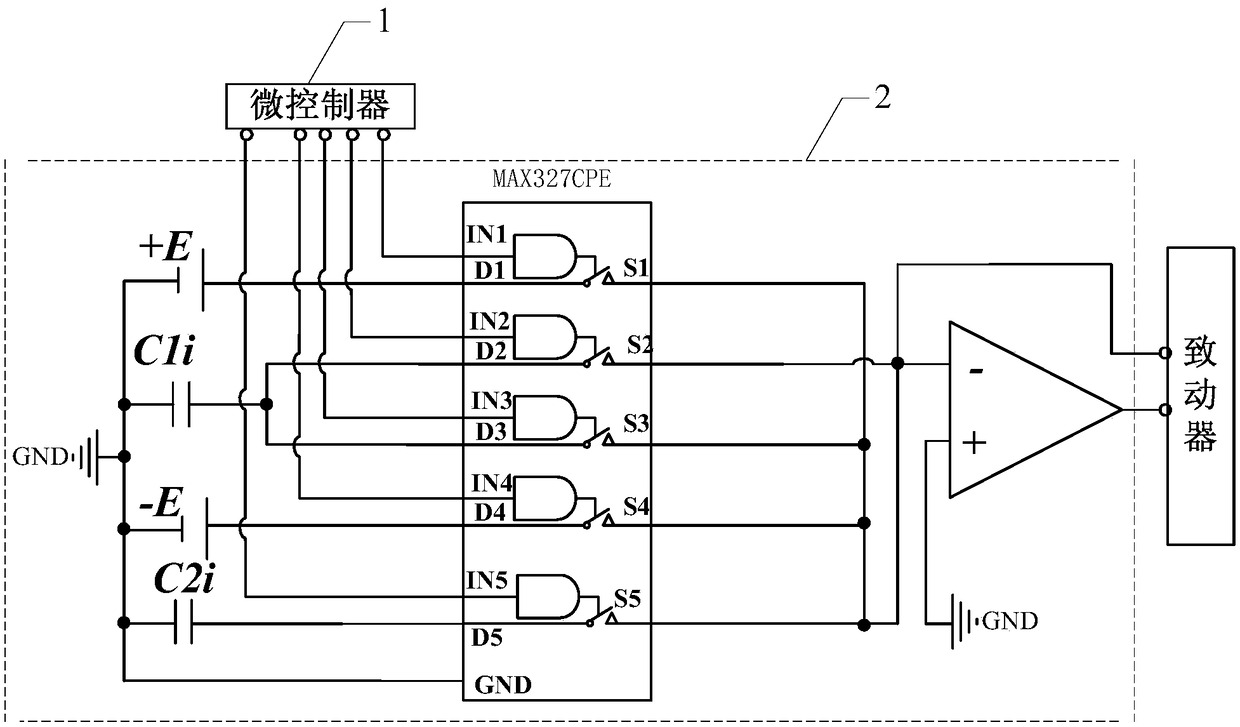

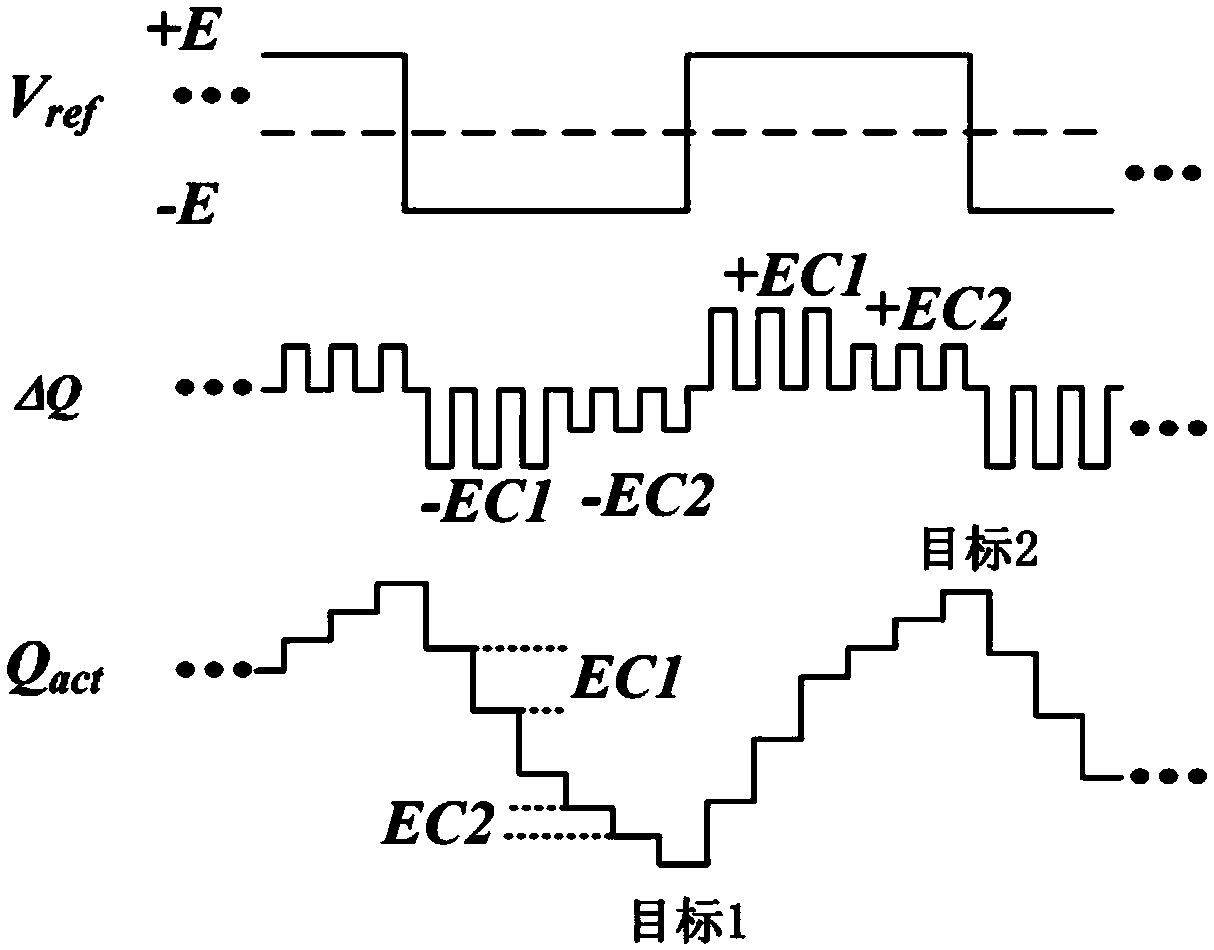

[0019] Specific implementation mode one: refer to figure 1 This embodiment is described in detail. In the charge-driven multi-channel piezoelectric deformable mirror drive power supply described in this embodiment, the deformable mirror is composed of a mirror surface and a plurality of actuators, and the plurality of actuators are arranged below the mirror surface. It is used to receive a voltage signal and convert the voltage signal into strain, so as to form a driving force applied to the mirror surface, thereby changing the surface shape of the mirror surface. It is characterized in that it includes a microcontroller 1 and a plurality of charge drive modules 2,

[0020] The microcontroller 1 is used to control the corresponding charge drive module 2 to complete two actions according to the received instructions: the switching action for charging the capacitor and the switching action for discharging the capacitor,

[0021] Each charge driving module 2 is used to receive th...

specific Embodiment approach 2

[0024] Specific embodiment two: this embodiment is a further description of the multi-channel piezoelectric deformable mirror drive power based on charge drive described in specific embodiment one. In this embodiment, the capacitor in each charge drive module 2 is one or There are multiple capacitors, and the capacitance values of multiple capacitors differ by 5 to 10 times.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment further describes the charge-driven multi-channel piezoelectric deformable mirror driving power described in Embodiment 1. In this embodiment, multiple charge-driven modules 2 have the same or different structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com