High-toughness polyurethane adhesive

A polyurethane adhesive, high toughness technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, polymer adhesive additives, etc., can solve the problem that the bonding strength cannot meet its requirements, and achieve the bonding strength and heat resistance. Good properties, good water resistance, and the effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

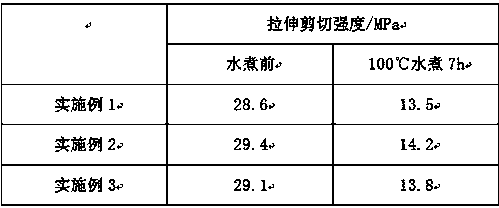

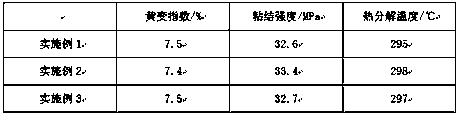

Embodiment 1

[0019] A high-toughness polyurethane adhesive made from the following raw materials in parts by weight:

[0020] Mica powder modified bentonite compound 15, casein 5, epoxy resin 10, polyurethane prepolymer 60, water-based silicone defoamer 2, plasticizer 0.8, catalyst 0.5;

[0021] Wherein the -NCO content of the polyurethane prepolymer is 2%;

[0022] Mix polyurethane prepolymer with casein and epoxy resin, stir and mix at 30°C and 200rpm for 30 minutes, then add water-based silicone defoamer, continue stirring for 10 minutes, heat to 52°C, add mica powder modified bentonite to compound Material and plasticizer, stirred for 4 minutes, heated to 80°C, added catalyst, stirred and reacted at 100rpm for 3 hours, cooled and discharged.

[0023] Further, the preparation method of the mica powder modified bentonite composite comprises the following steps:

[0024] (1) Ball mill 8 parts of mica powder at 10°C, add 8 parts of dilute nitric acid solution with a mass fraction of 5%, ...

Embodiment 2

[0031] A high-toughness polyurethane adhesive made from the following raw materials in parts by weight:

[0032] Mica powder modified bentonite compound 18, casein 7, epoxy resin 12, polyurethane prepolymer 80, water-based silicone defoamer 3, plasticizer 0.9, catalyst 0.55;

[0033] Wherein the -NCO content of the polyurethane prepolymer is 4%;

[0034] Mix polyurethane prepolymer with casein and epoxy resin, stir and mix at 35°C and 210rpm for 35 minutes, then add water-based silicone defoamer, continue stirring for 12 minutes, heat to 53°C, add mica powder modified bentonite to compound Material and plasticizer, stirred for 5 minutes, heated to 83°C, added catalyst, stirred and reacted at 120rpm for 4 hours, cooled and discharged.

[0035] Further, the preparation method of the mica powder modified bentonite composite comprises the following steps:

[0036] (1) Ball mill 9 parts of mica powder at 11°C, add 10 parts of dilute nitric acid solution with a mass fraction of 7%...

Embodiment 3

[0042] A high-toughness polyurethane adhesive made from the following raw materials in parts by weight:

[0043] Mica powder modified bentonite compound 20, casein 8, epoxy resin 15, polyurethane prepolymer 100, water-based silicone defoamer 3, plasticizer 1, catalyst 0.6;

[0044] Wherein the -NCO content of the polyurethane prepolymer is 5%;

[0045] Mix polyurethane prepolymer with casein and epoxy resin, stir and mix at 40°C and 220rpm for 40 minutes, then add water-based silicone defoamer, continue stirring for 15 minutes, heat to 55°C, add mica powder modified bentonite to compound Material and plasticizer, stirred for 6 minutes, heated to 85°C, added catalyst, stirred and reacted at 150rpm for 5 hours, cooled and discharged.

[0046] Further, the preparation method of the mica powder modified bentonite composite comprises the following steps:

[0047] (1) Ball mill 10 parts of mica powder at 12°C, add 15 parts of dilute nitric acid solution with a mass fraction of 10%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com