Dissociation method of coal-series hard kaolinite rock lamella

A hard, coal-based technology, applied in chemical instruments and methods, inorganic chemistry, inorganic pigment treatment, etc., can solve problems such as complex process, difficult to keep crystal shape intact, and difficult to obtain lamellar products, so as to achieve simple equipment operation, Low production cost and good dissociation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

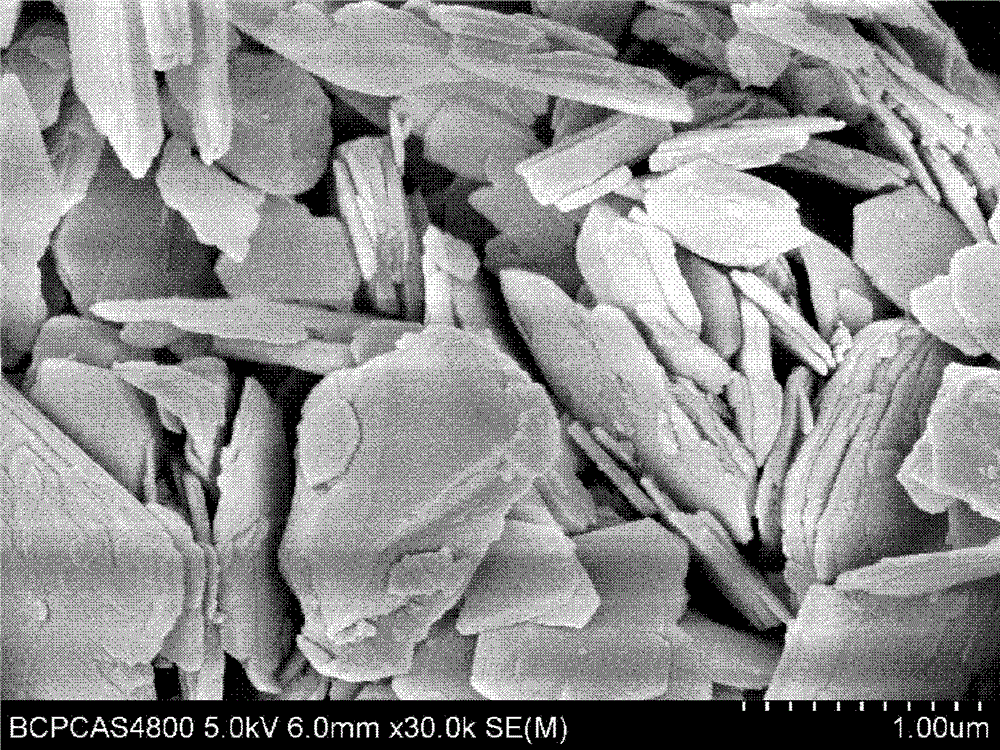

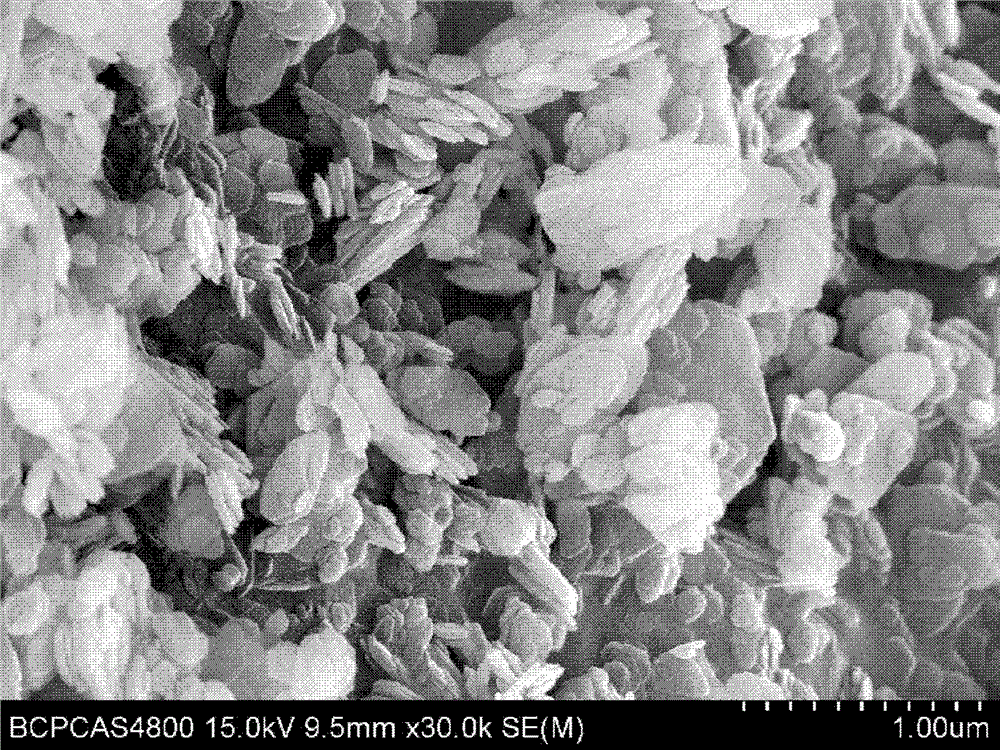

[0053] Select coarse-grained kaolinite and crush it, prepare the intercalation composite slurry according to the mass ratio of kaolin: water: potassium acetate = 1:10:0.4. After stirring and standing, the prepared intercalation composite The slurry is centrifuged to obtain the intercalation composite binder and intercalation agent solution, and the intercalation composite binder is put into a calcining furnace at a heating rate of 10°C / min to 350°C, and the temperature is kept constant for 1.5 hours. Wash with water, filter, and finally make 45% mud, and then spray-dry to get finished product. The obtained product D97=2.0μm, the thickness of the wafer ≤150nm, the hexagonal flaky kaolinite crystal in the finished product accounts for 30%, the whiteness is 85%, and the average diameter-thickness ratio is 15:1.

Embodiment 2

[0055] Select fine-grained kaolinite and crush it, prepare the intercalation composite slurry according to the mass ratio of kaolin: water: potassium acetate = 1:1:0.3. After stirring and standing, the prepared intercalation composite The slurry is centrifuged to obtain the intercalation composite binder and intercalant solution, and the intercalation composite binder is put into a calcining furnace at a heating rate of 5° C. / min to 250° C. at a constant temperature for 2.5 hours. It is washed with water, filtered, and finally made into a 40% slurry, and then spray-dried to obtain a finished product. The obtained finished product D97=2.0μm, the wafer thickness ≤150nm, the hexagonal flake kaolinite crystals in the finished product account for 35%, the whiteness is 85%, and the average diameter-thickness ratio is 15:1.

Embodiment 3

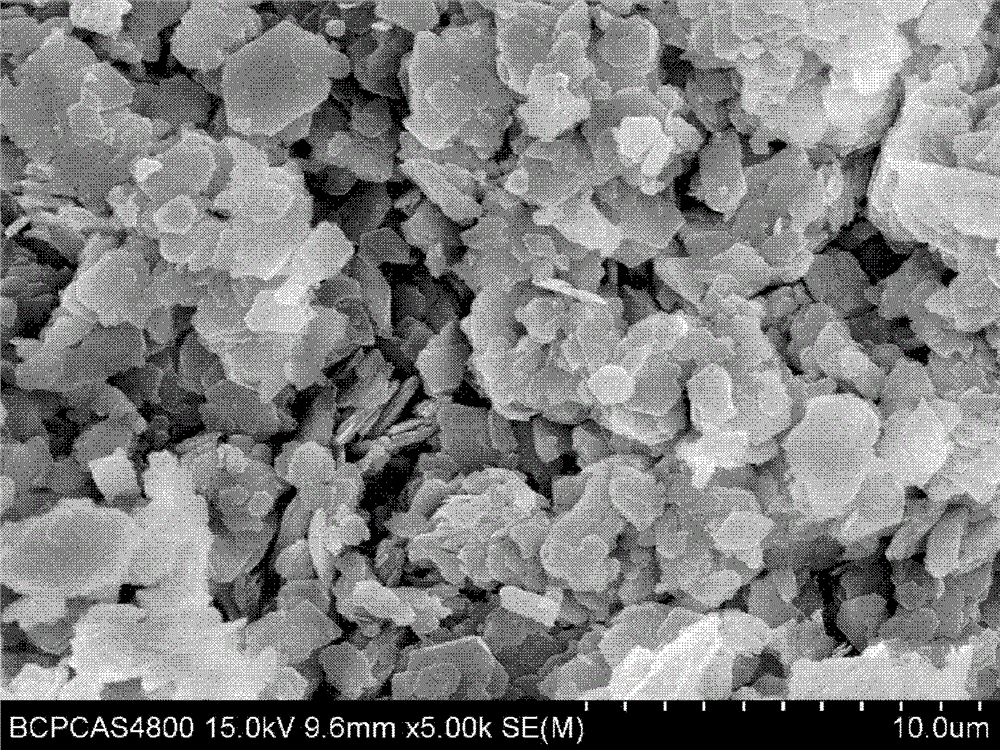

[0057] Select coarse crystalline kaolinite and crush it into 325 mesh. The intercalation composite slurry was prepared according to the mass ratio of kaolin: water: potassium acetate = 1:2:0.15, stirred for 30 minutes and then allowed to stand for 12 hours. The prepared intercalation composite slurry is centrifuged to obtain the intercalation composite binder and intercalant solution, and the intercalation composite binder is put into a calciner at a temperature rising rate of 10°C / min to 300°C , Constant temperature for 2.5 hours. And use 3 times the water for washing, and finally make 45% mud, and then spray-dry the product. The obtained product D97=2.0μm, the wafer thickness ≤150nm, the hexagonal flaky kaolinite crystals in the finished product account for 30%, the whiteness is 87%, and the average diameter-to-thickness ratio is 16:1. See attached figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com