Method for preparing three-dimensional graphene microstructure filler modified polymer composite

A technology for composite materials and polymers, which is applied in the field of preparing polymer composite materials modified by three-dimensional graphene microstructure fillers, which can solve the problems of limited shape and size, difficulty in preparing size molding structures, etc., and achieve less structural defects and prevent flakes The effect of overlapping layers and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of method for preparing graphene / thermosetting polymer composite material, realizes by following scheme:

[0037] (1) Weigh 0.05 g of graphene foam prepared by chemical vapor deposition method, and 10 g of epoxy resin (diglycidylether of bisphenol A, DGEBA). Place them in a 50ml beaker and heat to 70°C. Stir with a polytetrafluoroethylene stir bar for 5 minutes at a rate of 10 rpm. Add 0.4 g of curing agent (2-ethyl-4-methylimidazole), and then stir slowly for 0.3 minutes.

[0038] (2) Put the mixture obtained in step (1) into a mold, heat at 80 degrees Celsius for 4 hours, and at 170 degrees Celsius for 1 hour, and cool to room temperature with the furnace to obtain a graphene / thermosetting polymer composite material.

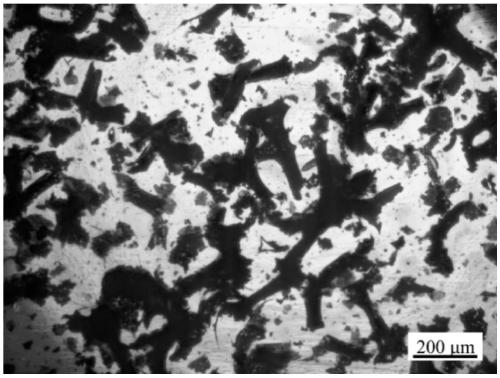

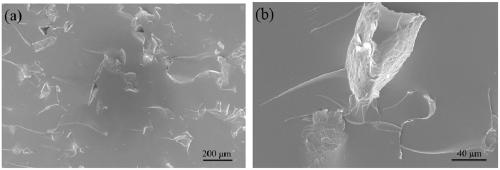

[0039] Through analysis: the graphene filler is uniformly dispersed in the composite material, with a size of 50-200 μm, such as figure 1 Shown is the OM photograph of the graphene / thermosetting polymer composite material that present embodime...

Embodiment 2

[0044] A kind of method for preparing graphene / thermosetting polymer composite material, realizes by following scheme:

[0045] (1) Graphene foam 0.05g prepared by vapor deposition method, epoxy resin (DGEBA) 5g and 15g acetone are placed in a 50ml beaker, with a speed of 60 revs / min, stirred for 10 minutes with a polytetrafluoroethylene stirrer, After removing acetone, 0.4 g of a curing agent (2-ethyl-4-methylimidazole) was added, followed by gentle stirring for 0.3 minutes.

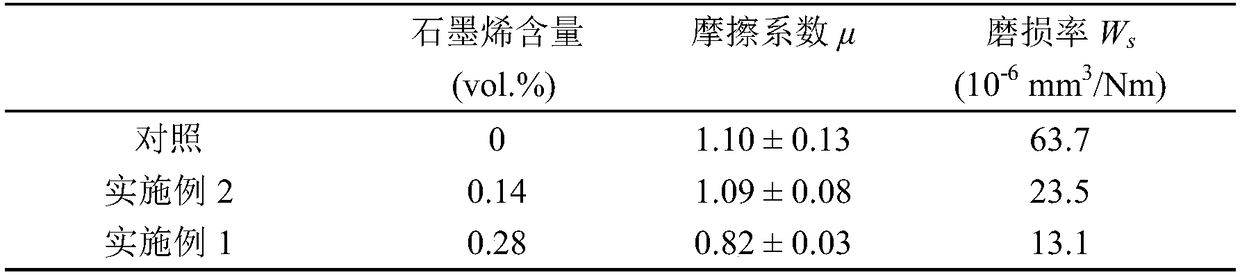

[0046] (2) Put the mixture obtained in step (1) into a mold, heat at 80 degrees Celsius for 4 hours, and at 170 degrees Celsius for 1 hour, and cool to room temperature with the furnace to obtain a graphene / thermosetting polymer composite material. The abrasion resistance test of composite materials is shown in Table 1.

Embodiment 3

[0048] A kind of method for preparing graphene / thermoplastic polymer composite material, realizes by following scheme:

[0049] Add 1 g of polyurethane to 8 ml of N,N-dimethylformamide, then add 5 mg of graphene foam, and stir for 10 minutes at a rate of 20 rpm. The N,N-dimethylformamide was removed by evaporation to obtain a graphene / thermoplastic polymer composite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com