Method for preparing flake silver powder

The technology of flake silver powder and metallic silver powder is applied in the field of preparation of flake silver powder. Excellent properties and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

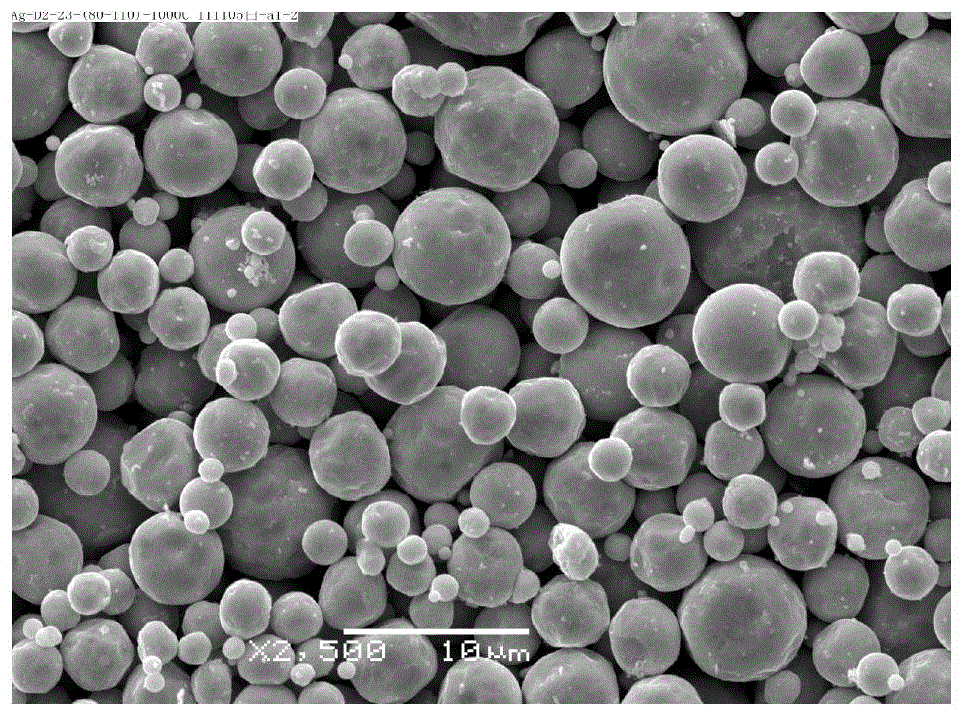

[0034] 1) Weigh 5kg of spherical silver powder with a silver content > 99.99% and a particle size of about 2 μm and good dispersion prepared by physical vapor deposition, pour it into 25L of absolute ethanol, add it to a stirring tank and ultrasonically stir for 15 minutes to make a silver powder slurry ;

[0035] 2) Weigh 2 kg of Φ0.5mm diameter zirconia grinding beads and add them to the grinding chamber of the sand mill, and add the silver powder slurry in step (1) into the grinding chamber through the pneumatic pump, the flow rate is 2L / min, and the outlet of the sand mill Or it can also be called the mixing tank connected to the discharge port of the sanding chamber in step (1), so that the sanded material enters the mixing tank, and after the material is stirred, it returns to the grinding chamber for circular grinding, and at the same time starts the sand mill at a speed of 800r / min ; At the same time, cold water is used to cool the grinding chamber, and the temperature...

Embodiment 2

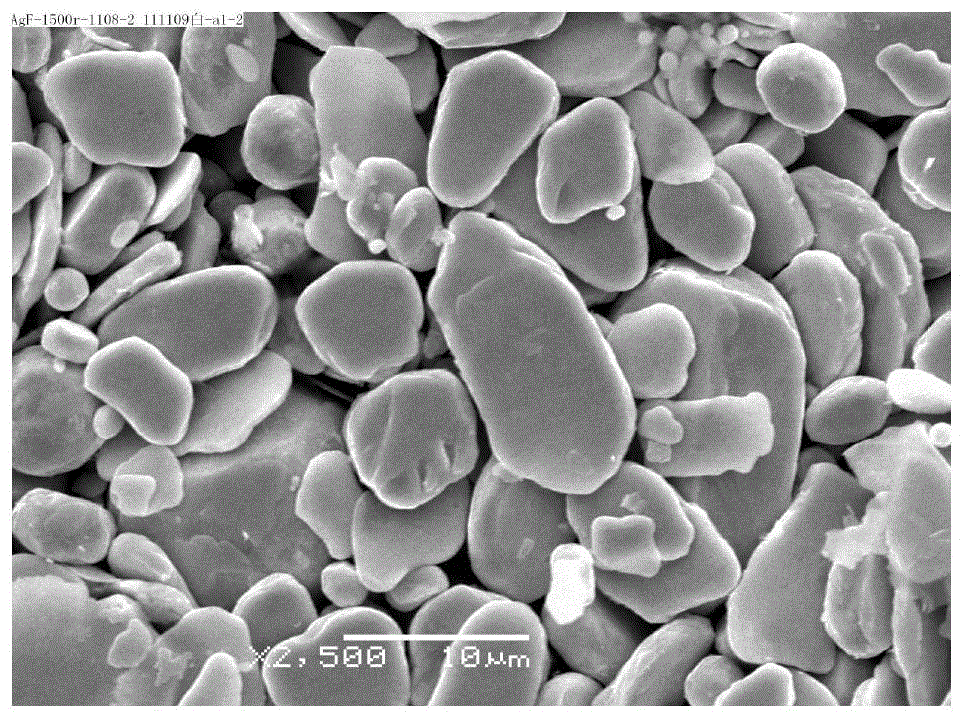

[0039] 1) Weigh 2 kg of spherical silver powder with a silver content >99.99% and a particle size of about 0.8 μm and good dispersion prepared by physical vapor deposition, add it to a mixing tank, pour 10 L of absolute ethanol, add 300 g of stearic acid, and ultrasonically Stir for 20 minutes to make a silver powder slurry.

[0040] 2) Weigh 2 kg of Φ0.3mm diameter zirconia grinding beads and add them to the grinding chamber of the sand mill, add the silver powder slurry into the grinding chamber through the pneumatic pump, and connect the outlet of the grinding chamber to the mixing tank in step (1), with a flow rate of 1L / min, start the sand mill at the same time, the rotating speed is 800r / min, circularly grind for 1h, connect the finished product kettle to obtain the silver powder slurry of sheet.

[0041] 3) After the flaky silver powder slurry is precipitated, it is washed with absolute ethanol to make a flaky silver slurry.

[0042] 4) Take out the flake silver slurr...

Embodiment 3

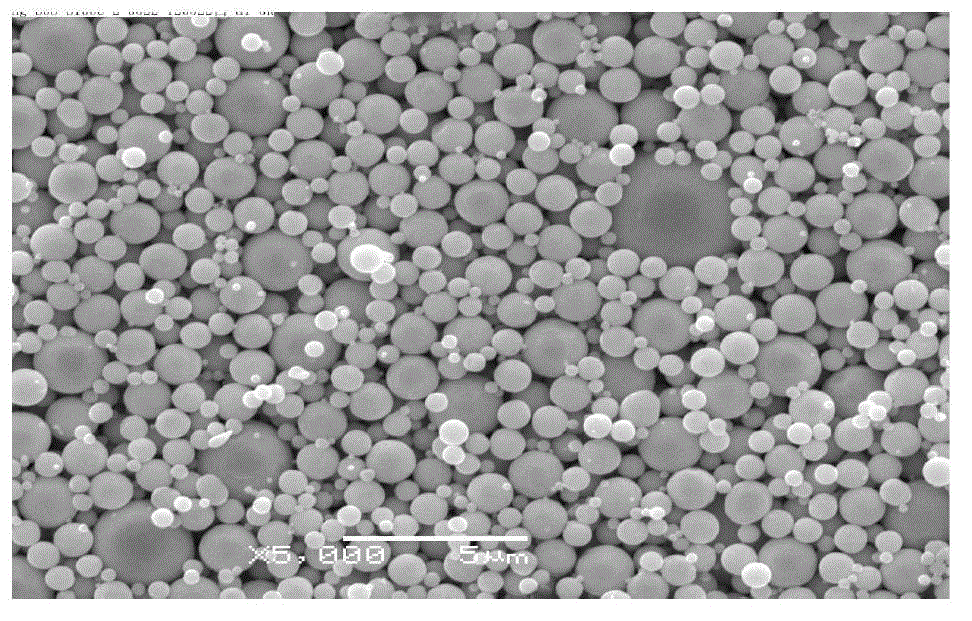

[0045] 1) Weigh 10kg of spherical silver powder with a silver content > 99.99% and a particle size of about 0.5μm and good dispersion prepared by physical vapor deposition, add it to a small mixing tank, pour it into 50L of absolute ethanol, and add 1000g of stearin acid, and stirred for 30 minutes to make a silver powder slurry.

[0046]2) Weigh 2 kg of Φ0.3mm diameter zirconia grinding beads and add them to the grinding chamber of the sand mill with a flow rate of 1L / min. Put the silver powder slurry into the grinding chamber through the pneumatic pump, and stir in step (1) at the outlet of the grinding chamber tank, start the sand mill at the same time, the rotating speed is 800r / min, circularly grind for 1h, and receive the silver powder slurry in the finished product kettle.

[0047] 3) After the flaky silver powder slurry is precipitated, it is washed with absolute ethanol to prepare ethanol flaky silver powder slurry with a solid content of 25%.

[0048] 4) Take out th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com