A method for preparing a self-oriented Z-type hexagonal ferrite substrate

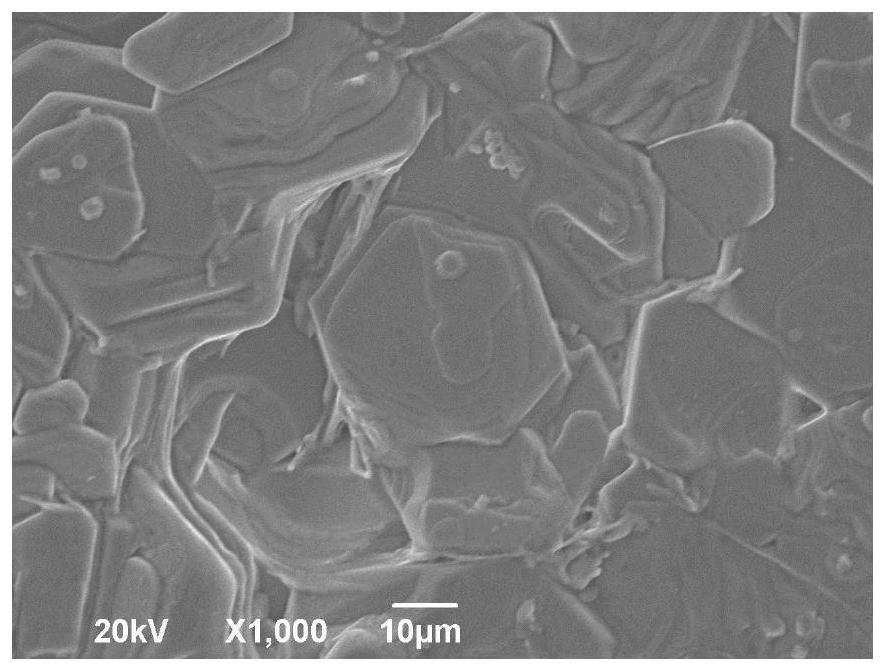

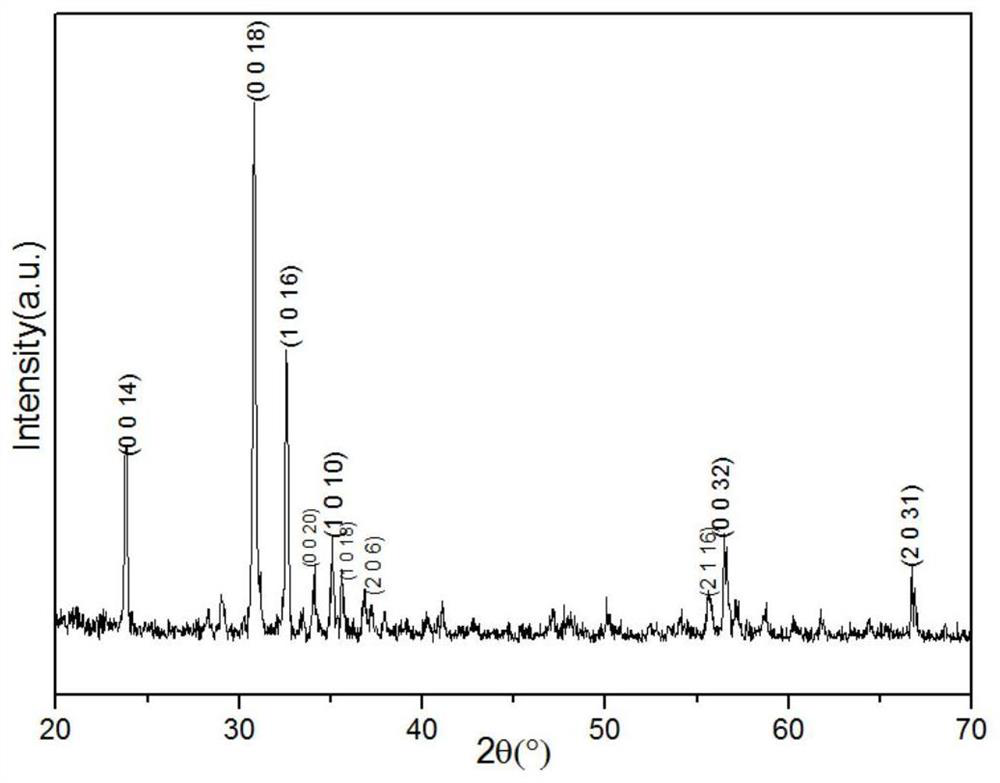

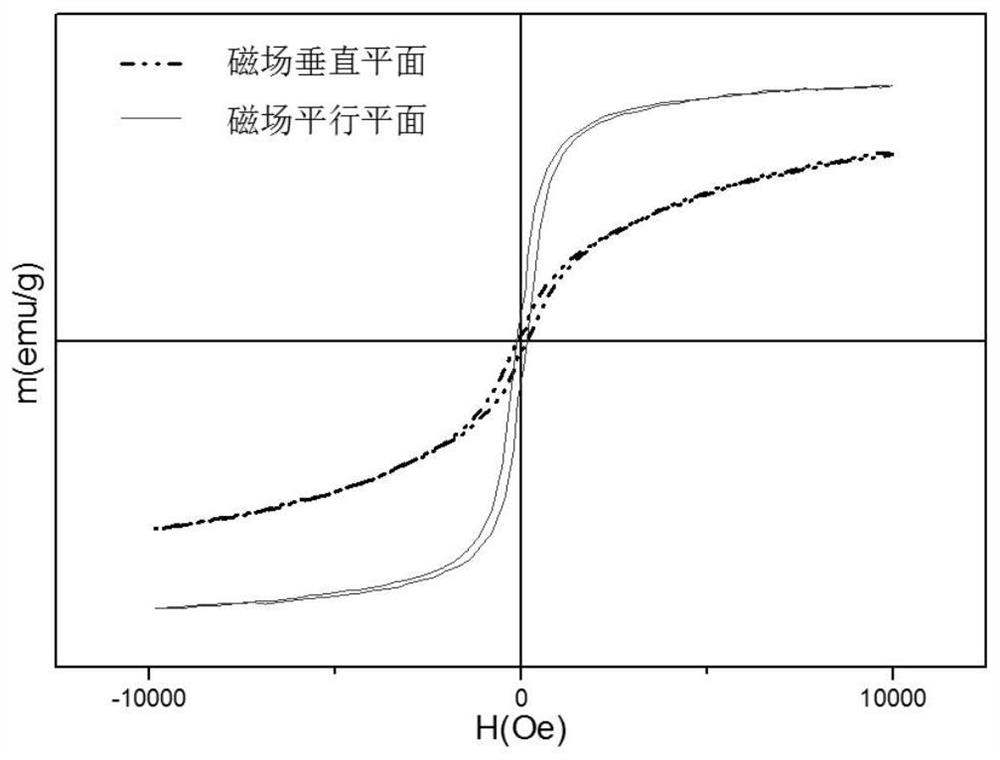

A hexagonal ferrite and orientation technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of complexity and inability to obtain the degree of orientation, and achieve improved orientation, excellent magnetic properties and magnetoelectric coupling Performance, the effect of uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing a self-oriented Z-type hexagonal ferrite substrate, including precursor preparation and molding sintering, the specific steps are as follows:

[0025] Step 1, preparation of precursor:

[0026] 1.1 Add ferric nitrate, strontium nitrate, and cobalt nitrate into deionized water, and mix evenly to obtain mixed liquid A; wherein, the concentration of ferric nitrate in mixed liquid A is 0.8-1.2mol / L, and the concentration of ferric nitrate, strontium nitrate, and cobalt nitrate The molar ratio is 24:(6~9):2;

[0027] 1.2 Prepare a strong alkali solution with a concentration of 6.5-13.5mol / L;

[0028] 1.3 Mix the mixed solution A obtained in step 1.1 with the strong alkali solution obtained in step 1.2 to obtain a mixed solution B, wherein the volume ratio of the mixed solution A to the strong alkali solution is 1:1;

[0029] 1.4 Transfer the mixed liquid B obtained in step 1.3 to the reaction kettle, seal it and fill it with nitrogen gas so that the ...

Embodiment 1

[0034] A method for preparing a self-oriented Z-type hexagonal ferrite substrate, including precursor preparation and molding sintering, the specific steps are as follows:

[0035] Step 1, preparation of precursor:

[0036] 1.1 Weigh 61.526g ferric nitrate (Fe(NO 3 ) 3 9H 2 O), 7.98g strontium nitrate (Sr(NO 3 ) 2 ), 3.6746g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) add 150mL deionized water, stir and mix evenly to obtain mixed solution A;

[0037] 1.2 Weigh 55g NaOH and add it into 150mL deionized water, stir and dissolve to obtain a strong alkali solution;

[0038] 1.3 Mix the mixed solution A obtained in step 1.1 with the strong alkali solution obtained in step 1.2 to obtain mixed solution B;

[0039]1.4 Transfer the mixed liquid B obtained in step 1.3 to the reaction kettle, seal it and fill it with nitrogen, so that the initial pressure in the reaction kettle is 1.5MPa, run the reaction kettle, and hydrothermally heat it at a stirring rate of 100r / min and a temperatur...

Embodiment 2

[0044] Compared with embodiment 1, this embodiment differs in that: in step 2, the sintering temperature is 1200° C., and the sintering time is 6 h; other steps are the same as in embodiment 1.

[0045] Table 1 is the performance and evaluation result of the ferrite substrate material that embodiment 1 and embodiment 2 obtain; As can be seen from table 1, the Z-type hexagonal ferrite substrate material that the present invention obtains has higher degree of orientation, adopts the present invention The method can realize the preparation of a self-aligned substrate material.

[0046] The performance of the substrate material that the embodiment of table 1 obtains

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Orientation degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com