A spray freeze sublimation dryer

A spray freezing, sublimation drying technology, applied in sublimation, spray evaporation, chemical instruments and methods, etc., can solve problems that have not yet been discovered, and achieve the effects of protection stability, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

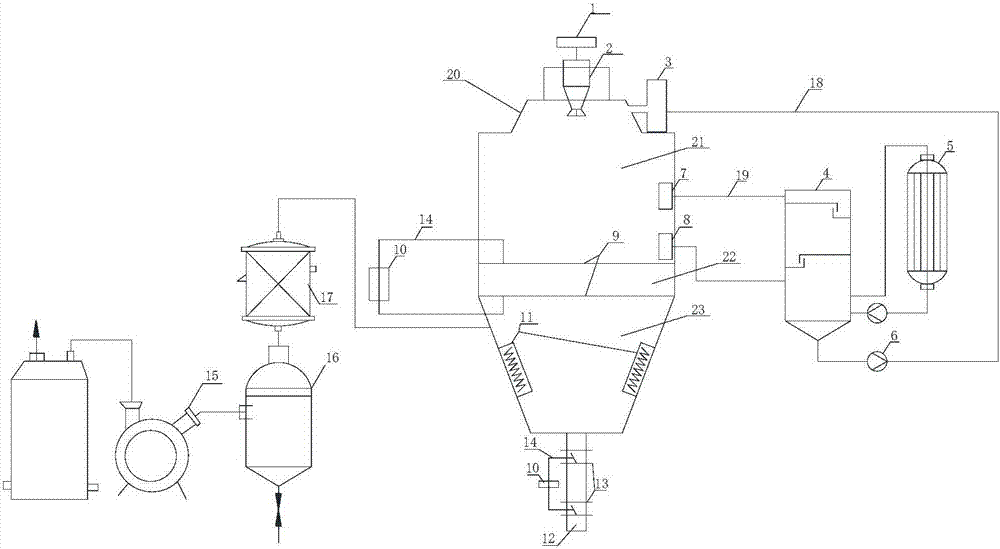

[0021] This embodiment provides a centrifugal spray freeze-sublimation dryer, the schematic diagram of which is shown in figure 1 shown.

[0022] exist figure 1 Among them, 1 is the feeding device; 2 is the centrifugal spray device; 3 is the liquid inert heat transfer medium injector; 4 is the inert heat transfer medium liquefaction tower; 5 is the condenser; 6 is the pipeline pump; 7 is the gaseous inert heat transfer Medium absorption device; 8 is a liquid inert heat transfer medium recovery device; 9 is a grid partition; 10 is an electric control device; 11 is a heating device; 12 is a discharge port; 13 is a valve; 14 is an electric wire; 15 is vacuuming device; 16 is a gas-liquid separator; 17 is a condenser; 18 is a liquid inert heat transfer medium pipeline; 19 is an inert heat transfer medium pipeline. 20 is a drying tower, 21 is a spray freezing bin, 22 is a buffer bin, and 23 is a vacuum drying bin.

[0023] A centrifugal spray freeze-sublimation dryer, comprising...

Embodiment 2

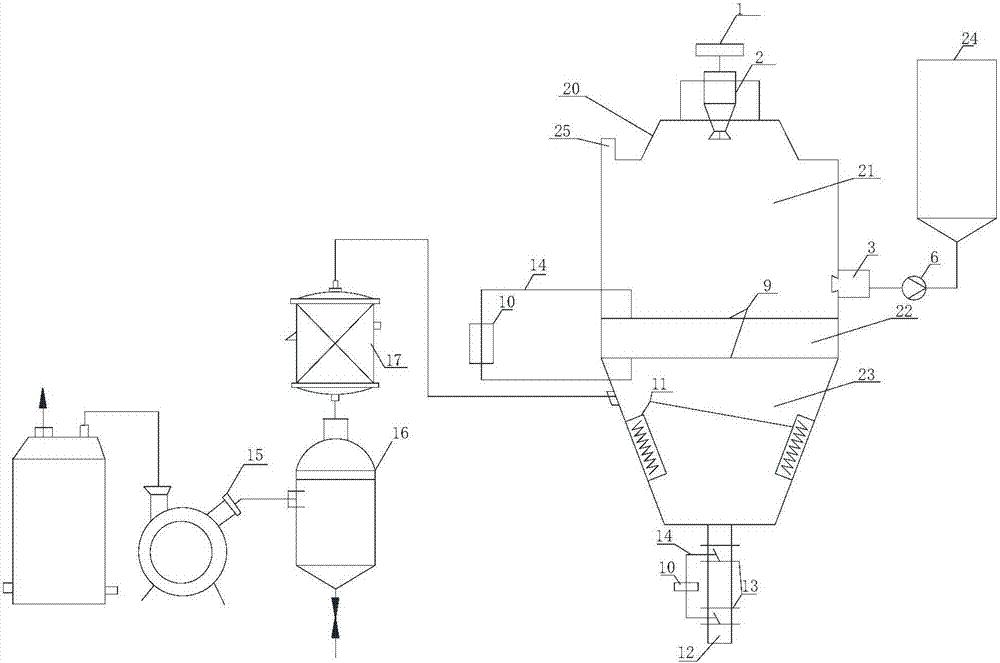

[0034] This embodiment provides the second spray freeze sublimation dryer, its structural schematic diagram is as follows figure 2 shown.

[0035] exist figure 2 Among them, 1 is a feeding device; 2 is a spray device; 3 is a liquid inert heat transfer medium injector; 24 is a liquid nitrogen bottle, 25 is a nitrogen outlet, 6 is a pipeline pump; 7 is a nitrogen absorption device; 8 is a liquid Nitrogen recovery device; 9 is a grid partition; 10 is an electric control device; 11 is a microwave generator; 12 is a discharge port; 13 is a valve; 14 is an electric wire; 15 is a vacuum device; 16 is a gas-liquid separator; 17 is a condenser; 20 is a drying tower, 21 is a spray freezing bin, 22 is a buffer bin, and 23 is a vacuum drying bin.

[0036] A spray freeze-sublimation dryer, comprising a drying tower 20, the upper end of the drying tower 20 is provided with a feeding device 1, the lower part of the feeding device 1 is connected with a spraying device 2 through a pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com