Perovskite light-emitting layer and manfuacturing method thereof, light-emitting device and display device

A perovskite and light-emitting layer technology, applied in the field of liquid crystal display, can solve the problems of low efficiency of tin-based perovskite light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0037] figure 1 It is a schematic diagram of the structure of the perovskite light-emitting layer according to the first embodiment of the present invention. Such as figure 1 As shown, a perovskite light-emitting layer includes a perovskite light-emitting film layer 10 and an encapsulation film layer 20 that wraps the perovskite light-emitting film layer 10, and the encapsulation film layer includes compound A. The formula is X 2+ SO 3 2- R, where X 2+ It is a divalent metal ion, and R is a benzene ring structure containing a hydroxyl functional group. Among them, R contains at least one benzene ring structure, for example, R can contain one benzene ring structure, two benzene ring structures connected together (naphthalene structure) or three benzene ring structures connected together (anthracene structure) . That is, the benzene ring structure R containing a hydroxyl functional group includes one or more of a benzene structure containing at least one hydroxyl functional grou...

no. 2 example

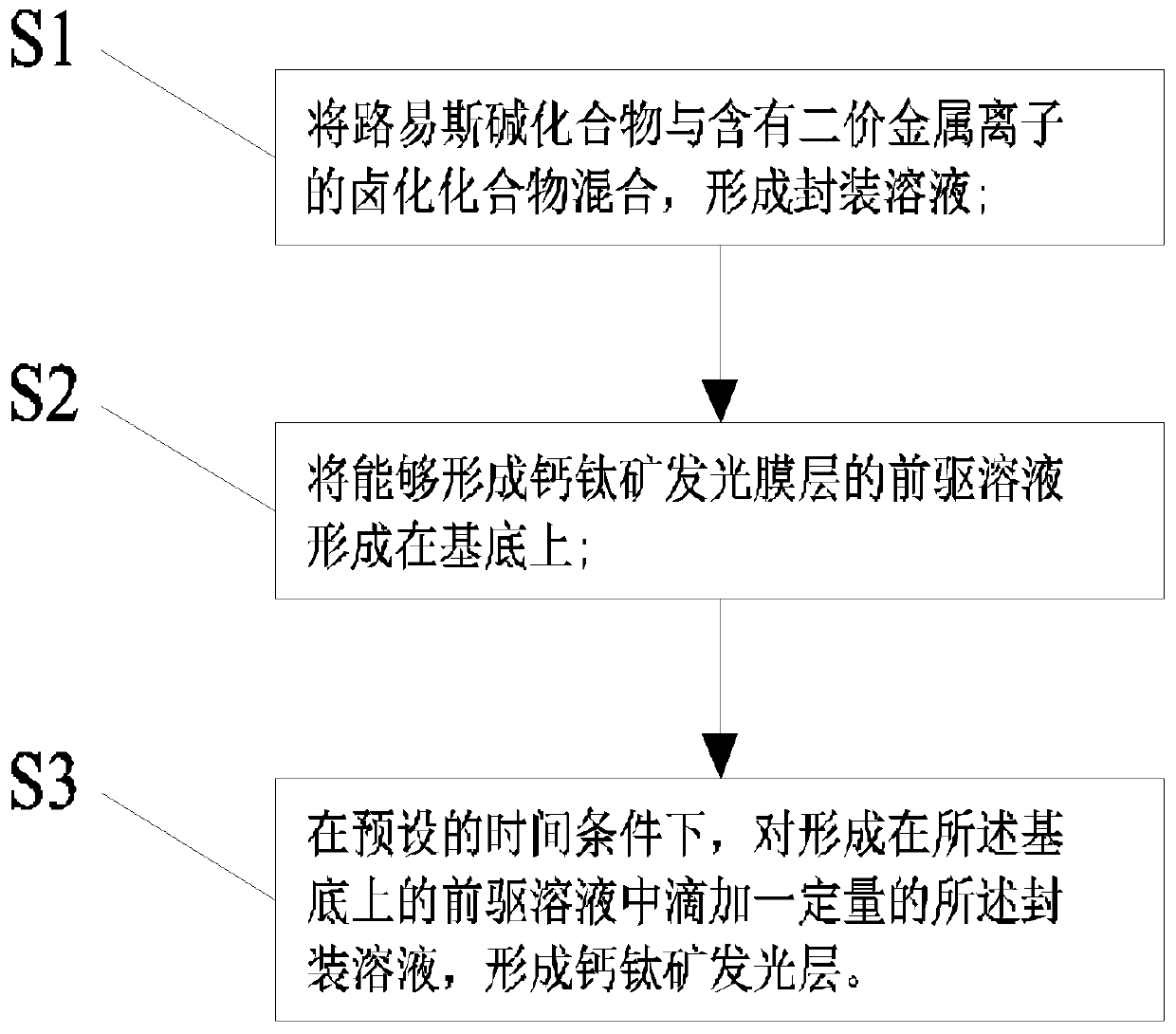

[0046] Based on the technical concept of the embodiment of the present invention, the embodiment of the present invention also provides a method for preparing the perovskite luminescent layer. figure 2 It is a flow chart of the preparation method of the perovskite luminescent layer in the second embodiment of the present invention. Such as figure 2 As shown, the preparation method of the perovskite luminescent layer includes:

[0047] S1. Mixing the Lewis base compound and the halogenated compound containing divalent metal ions to form an encapsulating solution;

[0048] S2, forming a precursor solution capable of forming a perovskite luminescent film layer on the substrate;

[0049] S3. Under a preset time condition, drop a certain amount of the packaging solution into the precursor solution formed on the substrate to form a perovskite light-emitting layer.

[0050] Among them, the halogenated compound can be one or more of fluorinated compounds, chlorinated compounds, brominated c...

no. 3 example

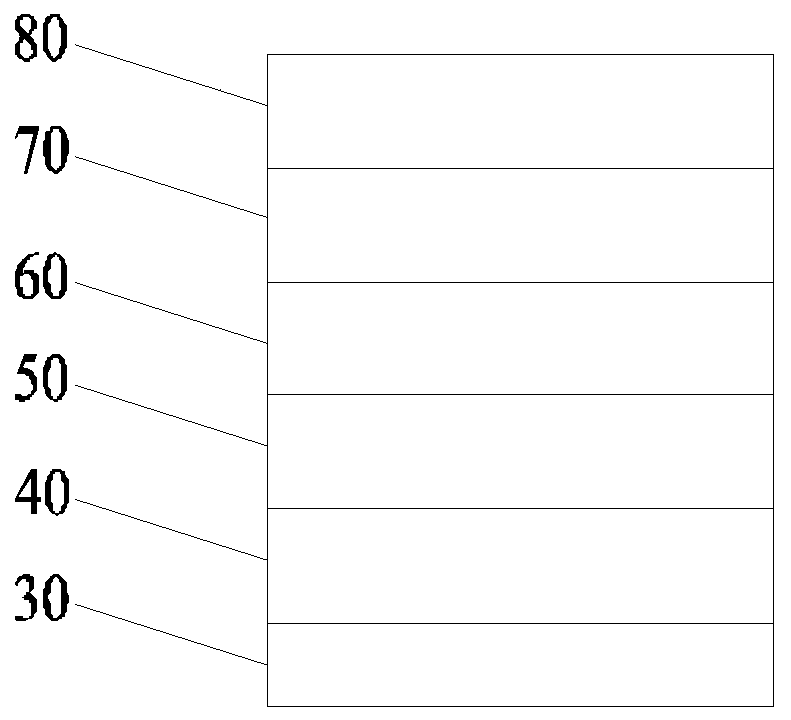

[0069] Figure 4 It is a schematic diagram of the structure of the light emitting diode in the third embodiment of the present invention. Figure 4 Shows the inverted structure of a tin-based perovskite light-emitting diode, such as Figure 4 As shown, the tin-based perovskite light-emitting diode includes a substrate 30, an electron transport layer 70, a perovskite light-emitting layer 60, a hole transport layer 50, a hole injection layer 40, and a cathode 80 which are sequentially stacked from bottom to top.

[0070] The manufacturing method of the above tin-based perovskite light-emitting diode includes:

[0071] (1) Pre-treat the substrate. The pretreatment of the substrate includes: ultrasonically cleaning the substrate with isopropanol and water, and then irradiating the substrate with ultraviolet for 5-10 minutes. Among them, the substrate is a conductive ITO glass substrate.

[0072] (2) Form an electron transport layer. The forming of the electron transport layer includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com