Preparation method of graphite material for oxygen-nitrogen-hydrogen analysis instrument

A technology for analysis instruments and graphite materials, which is applied in the field of preparation of graphite materials for oxygen, nitrogen and hydrogen analysis instruments, can solve problems such as difficult to meet, and achieve the effects of preventing product adhesion, preventing product cracking, and reducing resistance between materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

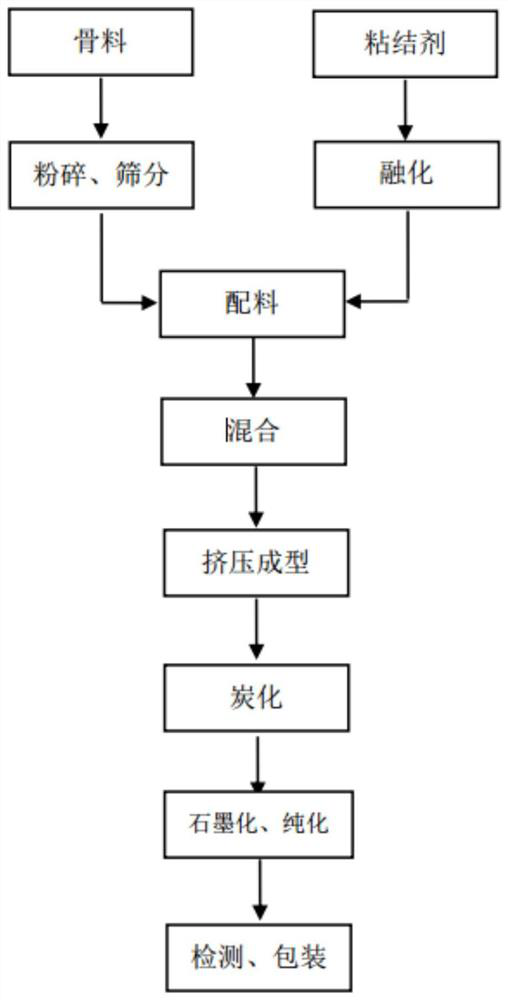

[0024] In this embodiment, the main performance indicators of aggregate microcrystalline graphite and binder coal tar pitch are as follows: microcrystalline graphite: ash content 0.32%; nitrogen content 0.013%; degree of graphitization 93.3%; coal tar pitch: softening point 85°C; Toluene insoluble matter 22.4%; quinoline insoluble matter 7.1%; specific process see figure 1 , the production process of the present embodiment is carried out according to the following steps:

[0025] Step 1: Crush the dried microcrystalline graphite until it passes through a 0.15m sieve, of which the components larger than 0.075mm account for 31%, and use it as aggregate for later use; heat the coal tar pitch to 160°C to fully melt;

[0026] Step 2: weigh according to the percentage by weight of microcrystalline graphite 76%, coal tar pitch 24%;

[0027] Step 3: Put the weighed microcrystalline graphite into the mixing equipment under normal pressure, then add fully melted coal tar pitch, mix at ...

Embodiment 2

[0061] In this embodiment, the main performance indicators of aggregate microcrystalline graphite and binder coal tar pitch are as follows: microcrystalline graphite: ash content 0.32%; nitrogen content 0.013%; degree of graphitization 93.3%; warm coal tar pitch: softening point 85°C ; Toluene insoluble matter 22.4%; Quinoline insoluble matter 7.1%; Specific process see figure 1 , the production process of the present embodiment is carried out according to the following steps:

[0062] Step 1: Crush the dried microcrystalline graphite until it passes through a 0.15m sieve, of which the components larger than 0.075mm account for 39%, and use it as aggregate for later use; heat the coal tar pitch to 165°C to fully melt;

[0063] Step 2: weigh according to the percentage by weight of microcrystalline graphite 78%, coal tar pitch 22%;

[0064] Step 3: Put the weighed microcrystalline graphite into the mixing equipment under normal pressure, then add fully melted coal tar pitch, m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com