Method for preparing lignin-based carbon fiber hydrogen storage material by electrostatic spinning process

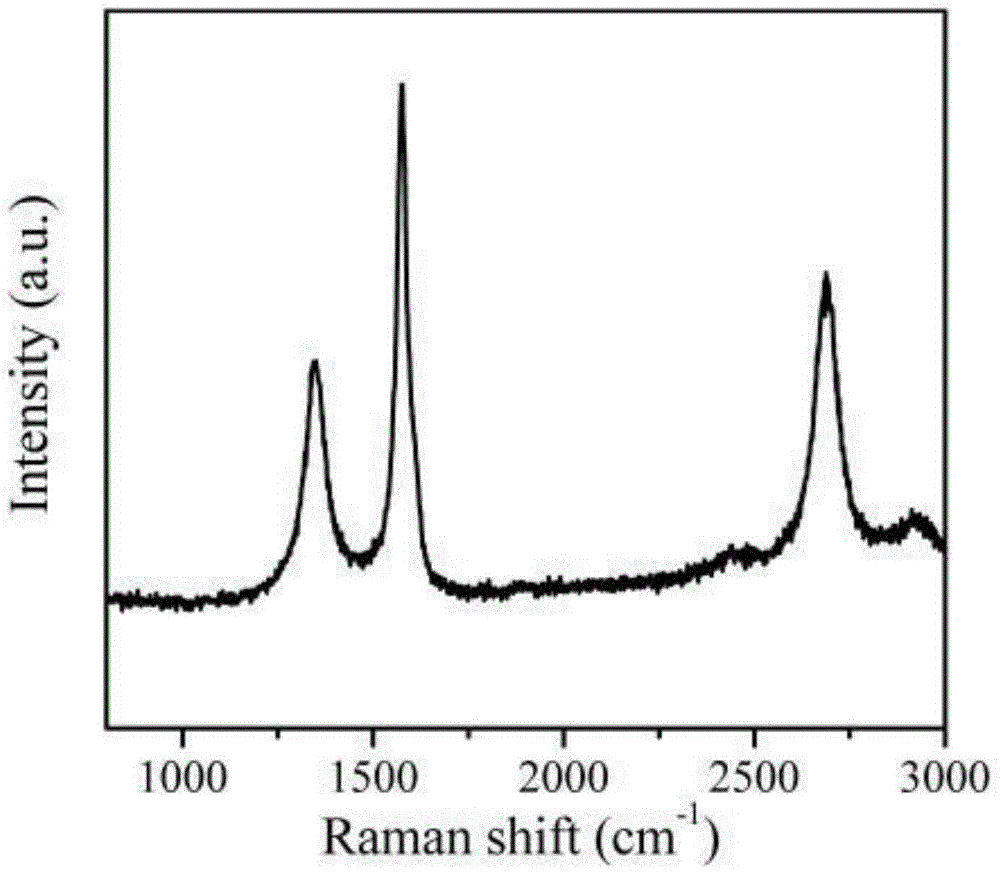

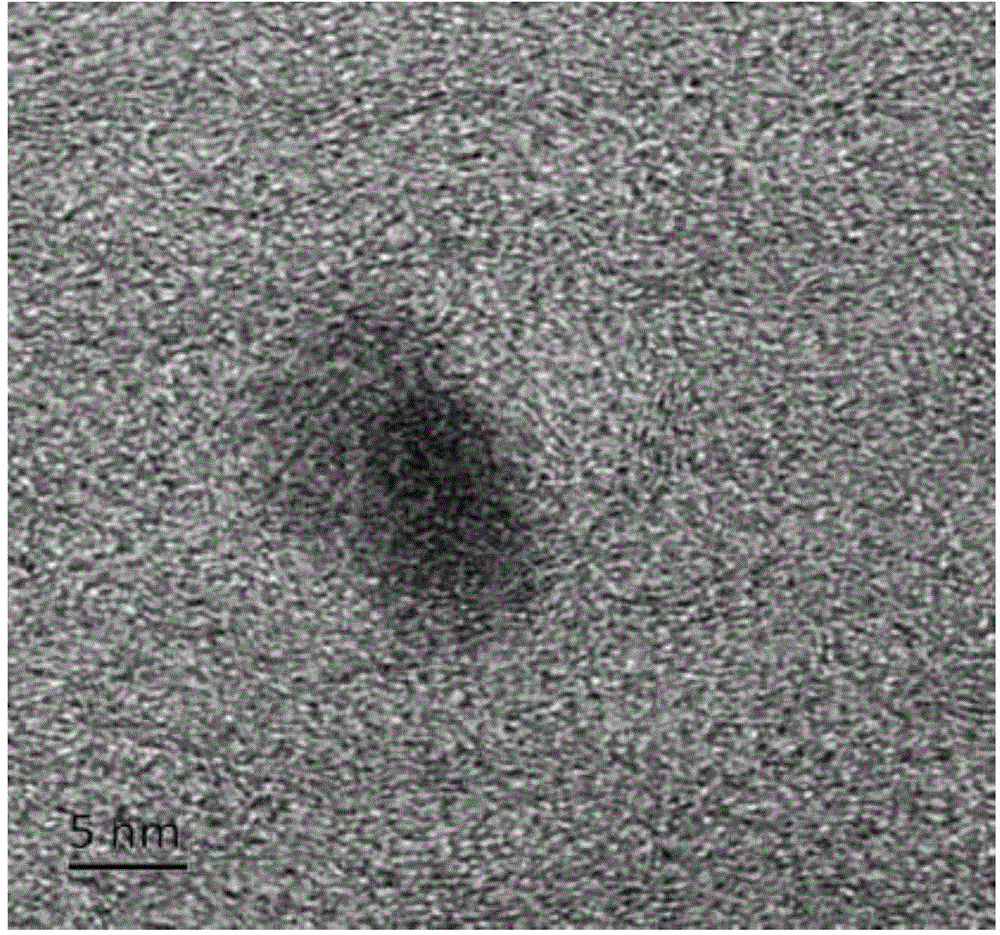

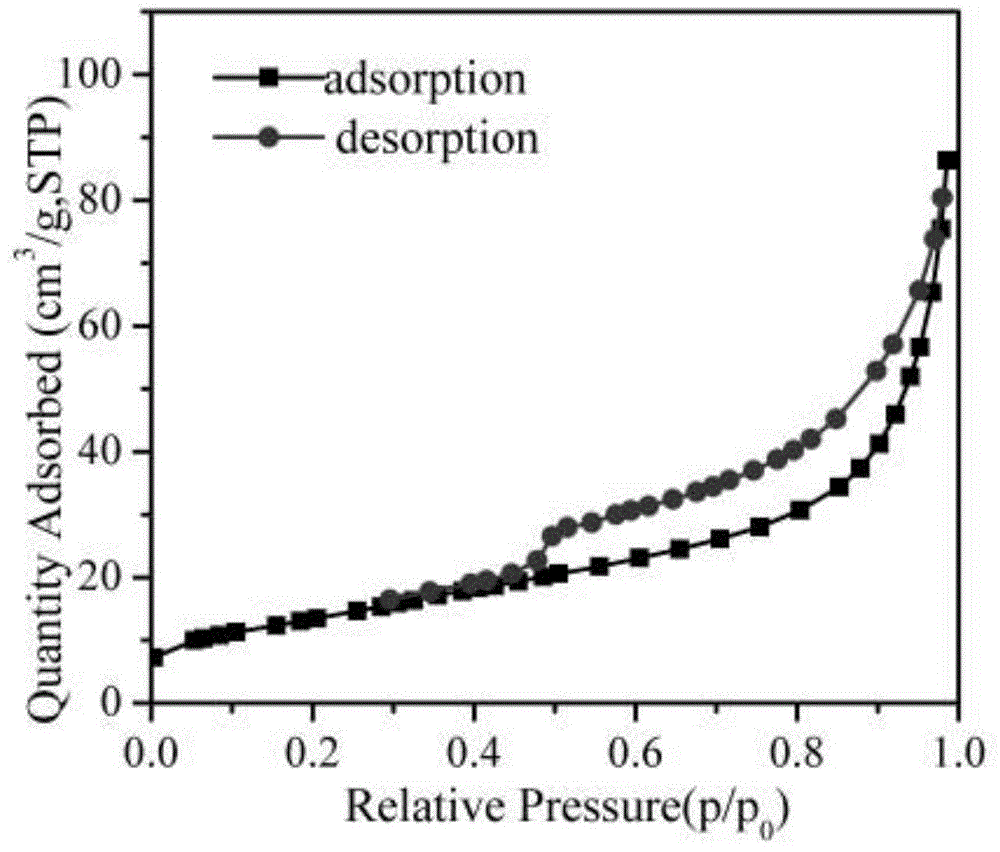

An electrospinning, lignin-based technology, applied in fiber processing, fiber chemical characteristics, filament/thread forming, etc., can solve the problems of limited reserves, high price, environmental pollution, etc., and achieve easy operation, low price, The effect of high degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of spinning solution: Take 1 g of LN, 1 g of PAN, 0.4 g of nickel acetate, 0.1 g of boric acid and 17 ml of DMF, and stir on a magnetic stirrer at 25 °C until completely dissolved to form a uniform spinning solution .

[0028] 2. Preparation of composite fibers by electrospinning: Under the conditions of voltage 18 kv, receiving distance 15 cm, spinning solution flow rate 0.8 ml / h, and electrospinning temperature 45 ℃, LN / PAN composite micro-nano fibers were obtained by electrospinning and dried in a vacuum oven at 70 °C for 8 h.

[0029] 3. Pre-oxidation: The dried LN / PAN composite micro-nanofibers were pre-oxidized at 280 °C for 1 h in an air atmosphere in a muffle furnace.

[0030] 4. Calcination: Heat the pre-oxidized fiber to 400 °C at a rate of 3 °C / min under an argon atmosphere of 200 ml / min, and then pass H 2 / N 2 After the temperature reached 700 °C, the mixed gas was turned off, and the temperature was continued to rise to 1600 °C with argon ...

Embodiment 2

[0033] 1. Preparation of spinning solution: Weigh 1 g of alkali lignin, 1 g of PAN, 0.4 g of nickel acetate, 0.1 g of boric acid and 17 ml of DMF, stir on a magnetic stirrer at 25 °C until completely dissolved to form a uniform spinning solution.

[0034] 2. Preparation of composite fibers by electrospinning: under the conditions of voltage 22 kv, receiving distance 15 cm, spinning solution flow rate 0.5 ml / h, and electrospinning temperature 45 ℃, alkali lignin / PAN composite micro-nano was obtained by electrospinning Fibers were dried in a vacuum oven at 70 °C for 8 h.

[0035] 3. Pre-oxidation: The dried alkali lignin / PAN composite micro-nanofibers were pre-oxidized in a muffle furnace at 280 °C for 1 h in an air atmosphere.

[0036] 4. Calcination: Heat the pre-oxidized fiber to 400 °C at a rate of 3 °C / min under an argon atmosphere of 200 ml / min, and then pass H 2 / N 2 After the temperature reached 700 °C, the mixed gas was turned off, and the temperature was raised to 1...

Embodiment 3

[0039] 1. Prepare spinning solution: weigh 1 g of LN, 1 g of polyvinylpyrrolidone (PVP), 0.4 g of nickel acetate, 0.1 g of boric acid and 17 ml of DMF, stir on a magnetic stirrer at 25 °C until completely dissolved A homogeneous spinning solution is formed.

[0040] 2. Preparation of composite fibers by electrospinning: Under the conditions of voltage 18 kv, receiving distance 15 cm, spinning solution flow rate 0.8 ml / h, and electrospinning temperature 45 °C, LN / PVP composite micro-nano fibers were obtained by electrospinning, and placed Dry in a vacuum oven at 70 °C for 8 h.

[0041] 3. Pre-oxidation: The dried LN / PVP composite micro-nanofibers were pre-oxidized at 280 °C for 1 h in an air atmosphere in a muffle furnace.

[0042] 4. Calcination: Heat the pre-oxidized fiber to 400 °C at a rate of 3 °C / min under an argon atmosphere of 200 ml / min, and then pass H 2 / N 2 After the temperature reached 700 °C, the mixed gas was turned off, and the temperature was raised to 1600 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com