Graphitized stephanoporate material with carbon element and method of producing the same

A technology of graphitization and porous carbon, applied in the field of preparation of graphitized porous carbon materials, which can solve the problems of pore structure damage, many synthesis steps, and low degree of graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

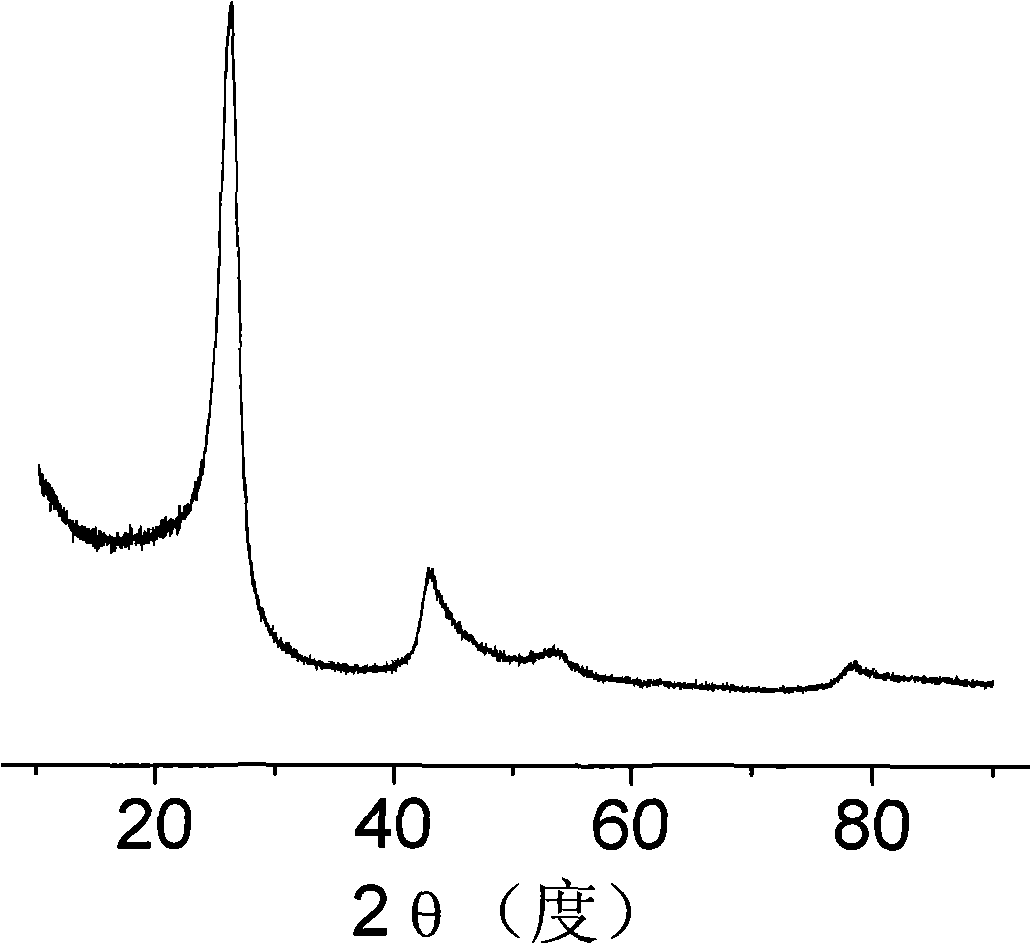

[0016] 2.3 grams of resorcinol are dissolved in 45 grams of water and cobalt oxide colloid solution containing 0.04 mole of cobalt element (the hydrated cobalt oxide colloidal sol particles are obtained by the reaction of acetic acid and cobalt hydroxide), adding 5 grams of concentration is 37% formaldehyde, After stirring evenly, react at 50°C for 0.5 hours, filter the solid product, dry at 100°C, carbonize at 900°C in nitrogen for 2 hours, soak the product in 20% hydrochloric acid for 24 hours, filter, and dry to obtain graphitized porous carbon. The comparison area is about 250m 2 / g, magnetic. The X-ray diffraction pattern of the material is as figure 1 shown.

Embodiment 2

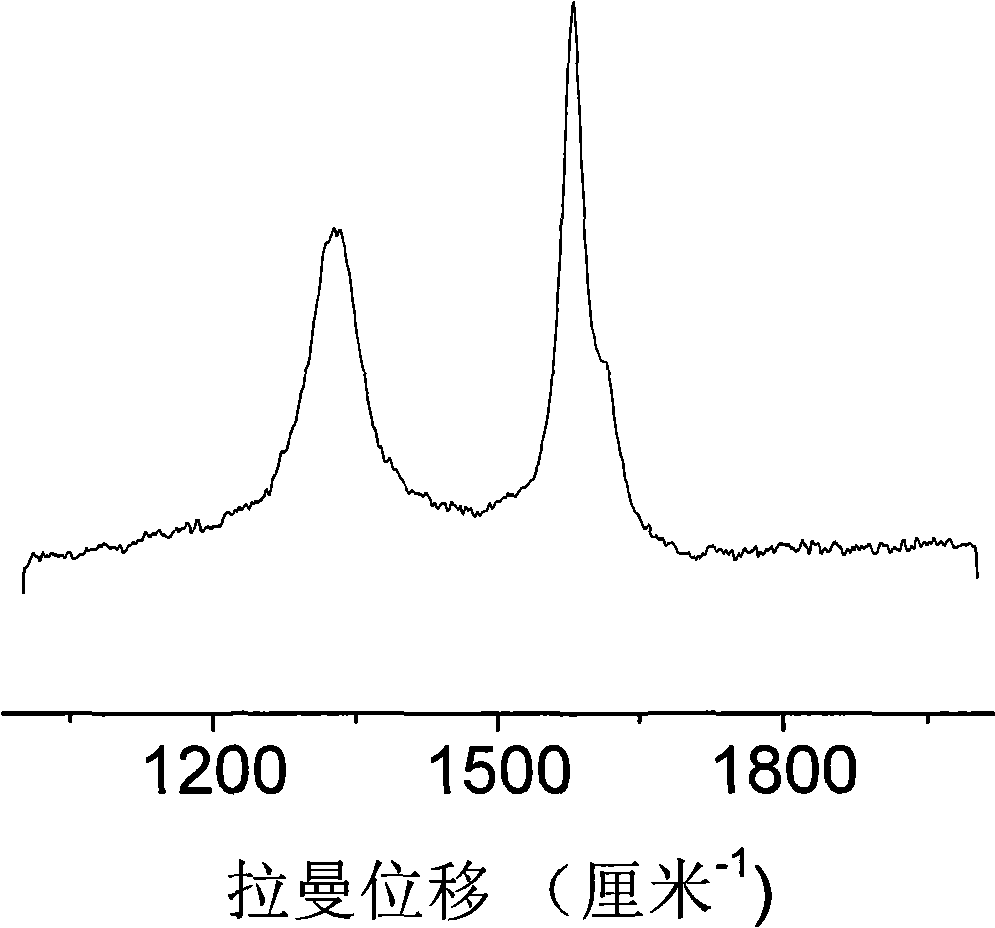

[0018] Dissolve 2 grams of phenol in 35 grams of water containing 0.04 moles of iron and iron oxide colloidal solution (the hydrated iron oxide sol particles are obtained by the reaction of acetic acid and ferric hydroxide), add 5 grams of formaldehyde with a concentration of 37%, and stir well , react at 80°C for 4 hours, filter the solid product, dry at 100°C, carbonize at 800°C in nitrogen for 2 hours, soak the product in 10% hydrochloric acid for 2 hours, filter, and dry to obtain graphitized porous carbon with a comparative area of about 470m 2 / g, with magnetic properties, the Raman spectrum of the material is shown as figure 2 shown.

Embodiment 3

[0020] 2.4 grams of phloroglucinol are dissolved in 35 grams of water and iron oxide colloid solution containing 0.02 mole of iron (the hydrated iron oxide sol particles are obtained by adding sodium hydroxide to partially hydrolyze ferric nitrate), adding 4.2 grams of 37% Formaldehyde, stir well, react at 50°C for 1 hour, filter the solid product, dry at 100°C, carbonize at 900°C in nitrogen for 2 hours, soak the product in 10% hydrochloric acid for 2 hours, filter, and dry to obtain graphitized porous Carbon, comparative area about 330m 2 / g, magnetic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com