Method for simultaneously determining contents of oxygen, nitrogen, and hydrogen in titanium alloy

A titanium alloy and hydrogen content technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of simultaneous detection of oxygen, nitrogen and hydrogen, cumbersome method operation, low analysis efficiency, etc., and achieve great practical and popularization value , Accurate test results, accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

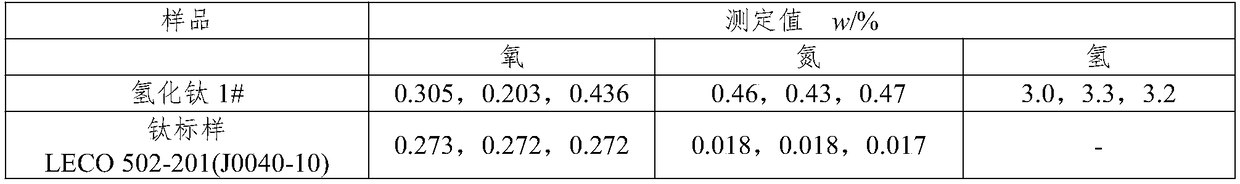

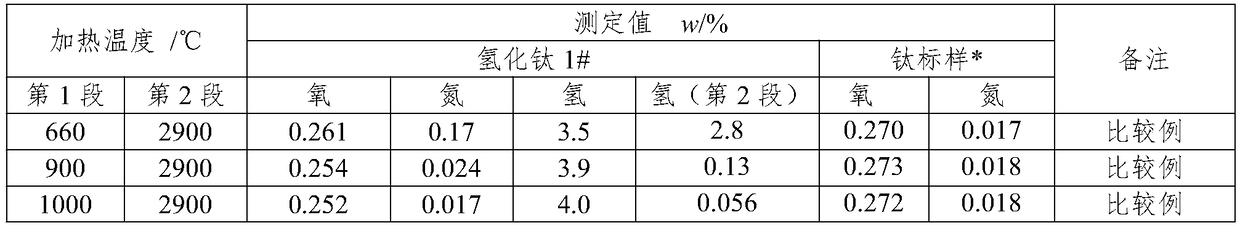

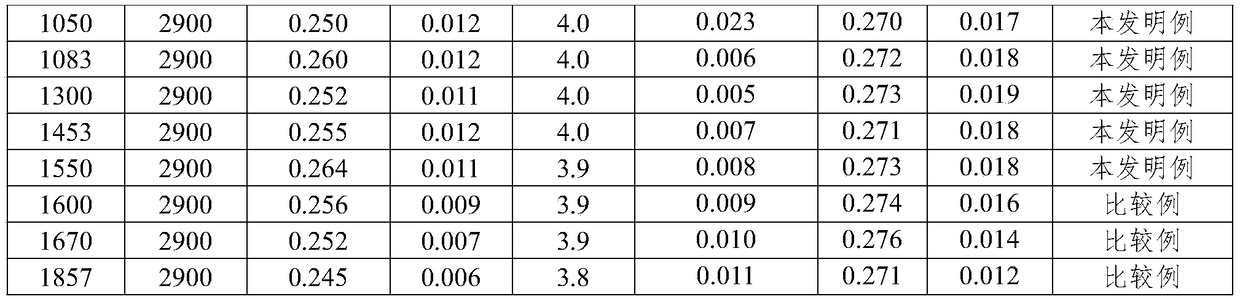

[0063] Embodiment 1 adopts the inventive method to measure the content of oxygen, nitrogen, hydrogen in titanium hydride simultaneously

[0064] Quantitatively weigh the titanium hydride sample and place it in a metal nickel capsule, then add metal nickel particles, and cut the nickel particles into particles of 1 mm to 2 mm with a fine nickel wire with a diameter of 1 mm. The mass ratio of nickel flux (nickel capsule + nickel particles) to the sample was controlled at 14:1, and the mass ratio of metallic nickel particles to the sample was controlled at 8:1. Put the above-mentioned metal nickel capsule containing the sample into the oxygen, nitrogen and hydrogen analyzer for measurement. The method of the present invention adopts a two-stage heating method to simultaneously measure the oxygen, nitrogen, and hydrogen contents in the sample, the heating temperature of the first stage is 1400°C, and the heating temperature of the second stage is 2900°C. The metal nickel capsule ...

Embodiment 2

[0070] Embodiment 2 adopts the inventive method to measure the content of oxygen, nitrogen, hydrogen in titanium hydride simultaneously

[0071] In order to verify the accuracy of oxygen measurement by the method of the present invention, a standard addition recovery test of oxygen was specially carried out. Quantitatively weigh the titanium hydride 2# sample in the nickel capsule, quantitatively add the oxygen standard sample in titanium, operate and measure in the same way as in Example 1, and the results are shown in the following table:

[0072] Table 10

[0073]

[0074] It can be seen from Table 10 that the recovery rate of oxygen addition is in the range of 95% to 106%, indicating that the method of the present invention has good oxygen determination accuracy.

Embodiment 3

[0075] Embodiment 3 adopts the inventive method to measure the content of nitrogen in high-hydrogen titanium powder or high-hydrogen titanium alloy powder

[0076]Quantitatively weigh high-hydrogen titanium powder or high-hydrogen titanium alloy powder samples (the mass fraction of hydrogen is 0.17% to 1.21%) and place them in a metal nickel capsule, then add metal nickel particles, and cut the nickel particles into 1mm diameter with 1mm fine nickel wire Particles of ~2mm. The mass ratio of nickel flux (nickel capsule + nickel particles) to the sample was controlled at 18:1, and the mass ratio of metallic nickel particles to the sample was controlled at 8:1. Put the above-mentioned metal nickel capsule containing the sample into the oxygen, nitrogen and hydrogen analyzer for measurement. The method of the present invention adopts a two-stage heating method to simultaneously measure the oxygen, nitrogen, and hydrogen contents in the sample, the heating temperature of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com