Online leakage detection method and device for non-oxidation furnace radiant tube containing shielding hydrogen gas

A technology without oxidation furnace and radiant tube, which is applied in the direction of detecting the appearance of fluid at the leak point and using liquid/vacuum degree for liquid tightness measurement. , to achieve the effect of improving accuracy and reliability, shortening test cycle and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

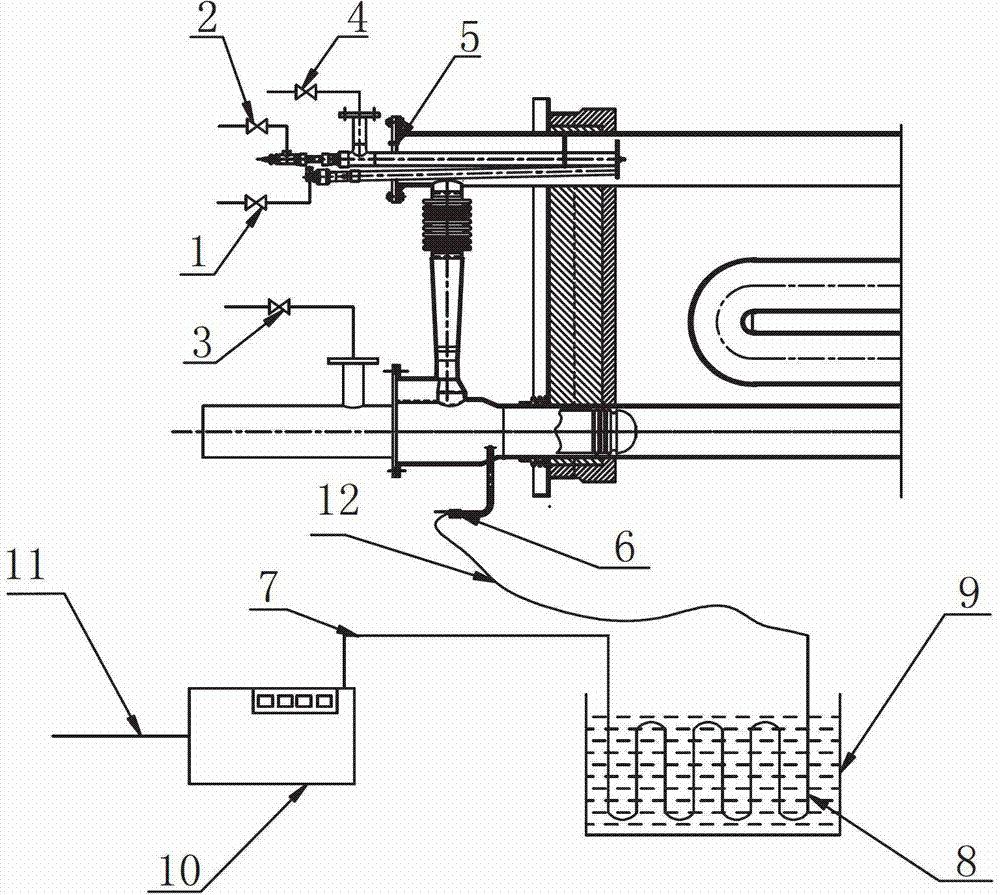

[0026] Such as figure 1 A nitrogen-hydrogen (or all-hydrogen) protective gas non-oxidation furnace radiant tube online leak detection device includes a hydrogen analyzer 10, and the hydrogen analyzer 10 is connected to the burner row of the non-oxidation furnace radiant tube through the gas sampling tube 7 The smoke pipe sampling interface 6, the outlet of the hydrogen analyzer 10 is connected to the exhaust pipe 11, the other end of the gas sampling pipe 7 is connected to the output end of the sample gas cooler 8, and the input end of the sample gas cooler 8 passes through the sample gas cooling pipe 12 Connect the burner smoke exhaust pipe sampling joint 6 on the radiant tube of the non-oxidizing furnace. The sample gas cooler 8 adopts a steel pipe with a diameter of 4mm to fold 20 serpentine and circuitous structural tubes whose height is less than the net depth of the bucket. The two ends of the sample gas cooler 8 are reserved for about 350 mm long straight sections, and ...

Embodiment 2

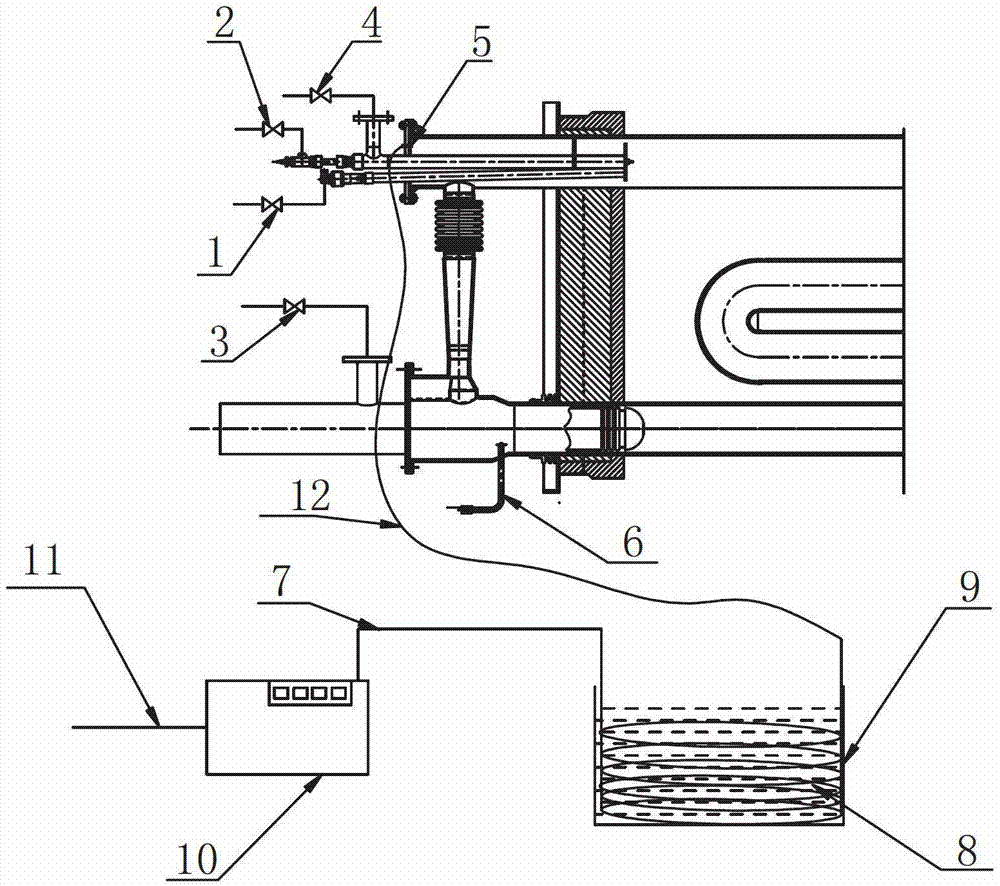

[0032] Such as figure 2 Another nitrogen-hydrogen (or all-hydrogen) protective gas non-oxidation furnace radiant tube online leak detection device includes a hydrogen analyzer 10, and the hydrogen analyzer 10 is connected to the pressure measurement of the non-oxidation furnace radiant tube through the gas sampling tube 7 The nozzle 5 and the outlet of the hydrogen analyzer 10 are connected to an exhaust pipe 11, the other end of the gas sampling pipe 7 is connected to the output end of the sample gas cooler 8, and the input end of the sample gas cooler 8 is connected to the The pressure measuring nozzle 5 on the radiant tube of the oxidation furnace will be cooled by immersing the cooler 8 in the cooling tank 9, wherein the cooling tank 9 is a water basin filled with cold water with a water temperature of 8°C, and the sample gas cooler 8 adopts a diameter of 15 continuous circles with a diameter less than the inner diameter of the cooling tank 9 are made for a steel pipe of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com