Conveying and temporary storage workstation device with guiding function

A workstation and guidance technology, applied in the direction of conveyor objects, transportation and packaging, etc., to achieve the effects of improving efficiency, preventing manual negligence, and reducing injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

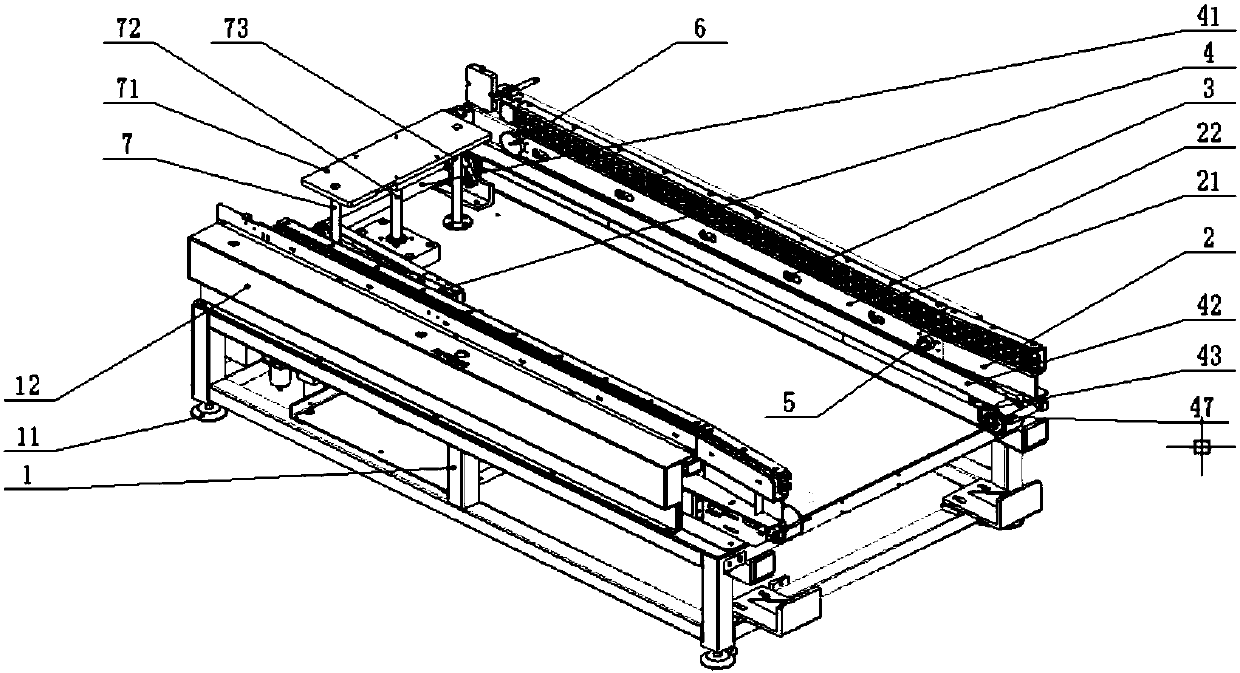

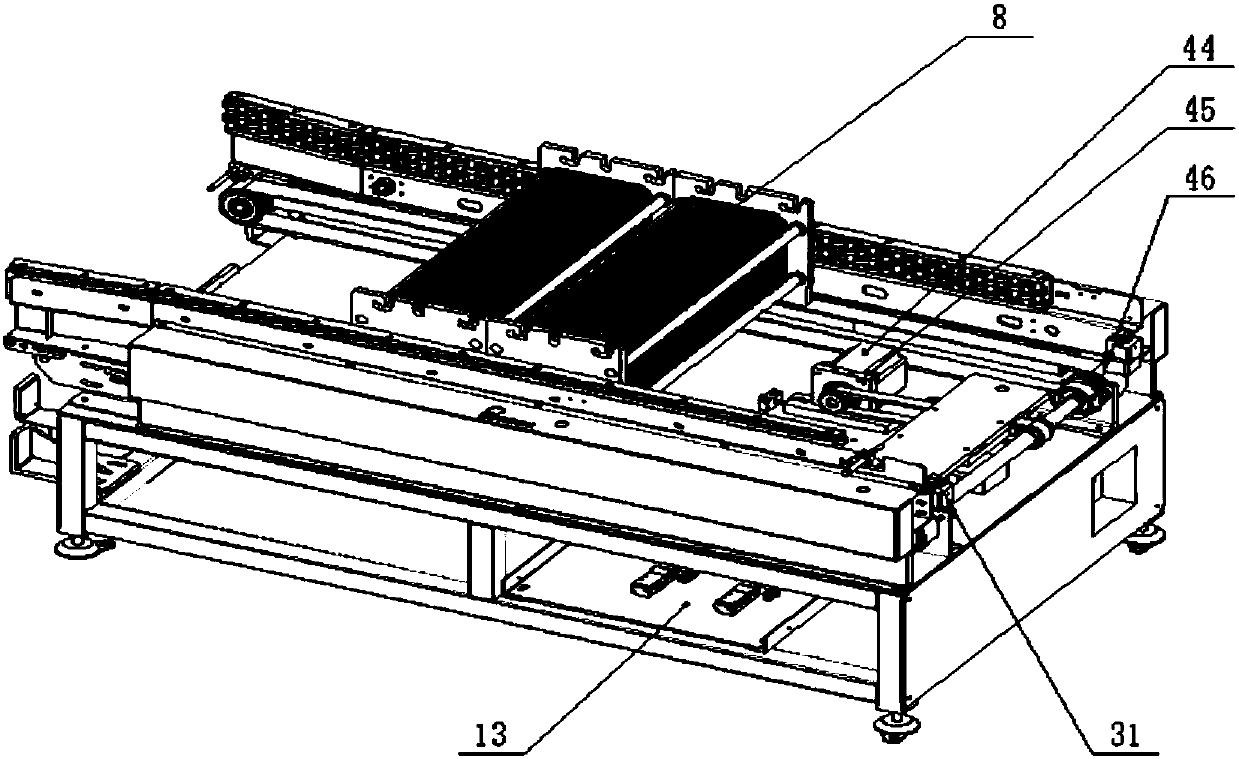

[0019] Such as figure 1 , figure 2 The structure shown is a transport buffer workstation device with a guide, including a frame 1, wherein there are sealing plates 12 on both sides of the frame 1, and there are photoelectric sensors in the detection mechanism 3 inside the sealing plates 12 on both sides; Electrical components are installed on the board 13, and the guiding and fixed bottom plate 22 of the double-sided guiding mechanism 2 is fixed on both sides of the table panel of the frame 1; The sensor is fixed on one side of the guiding and fixed base plate, and the in-position sensor 31 is installed at the end of the guiding mechanism 2. The motor conveying structure 4 uses the rotation of the motor 44 to drive the synchronous wheel 43 to rotate; the blocking mechanism 5 stretches on the detection mechanism 3 through the cylinder shaft To block the flower basket, the positioning structure 6 locates the flower basket through the expansion and contraction of the cylinder s...

Embodiment 2

[0021] A transport buffer workstation device with guidance, including a frame 1, wherein there are sealing plates 12 on both sides of the frame 1, and photoelectric sensors in the detection mechanism 3 are arranged in the sealing plates 12 on both sides; On the electrical parts, the guiding and fixing bottom plate 22 of the double-sided guiding mechanism 2 is fixed on both sides of the table panel of the frame 1; On one side of the guide fixed base plate, the in-position sensor 31 is installed at the end of the guide mechanism 2, and the motor conveying structure 4 uses the rotation of the motor 44 to drive the synchronous wheel 43 to rotate; the blocking mechanism 5 blocks the flower basket by stretching the cylinder shaft on the detection mechanism 3 The positioning structure 6 locates the flower basket at one end of the detection mechanism 3 through the expansion and contraction of the cylinder shaft; the lifting mechanism 7 is located at one end of the frame 1, and pushes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com