Method for significant reduction of bracket support of gob-side roadway of fully-mechanized mining face

A fully mechanized mining face and working face technology, applied in the direction of pillars/brackets, mining equipment, earthwork drilling and mining, etc., can solve the problems of difficult recovery construction, heavy workload, and high support body strength, so as to reduce the amount of roadway maintenance, Solve the effect of large deformation and ensure personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

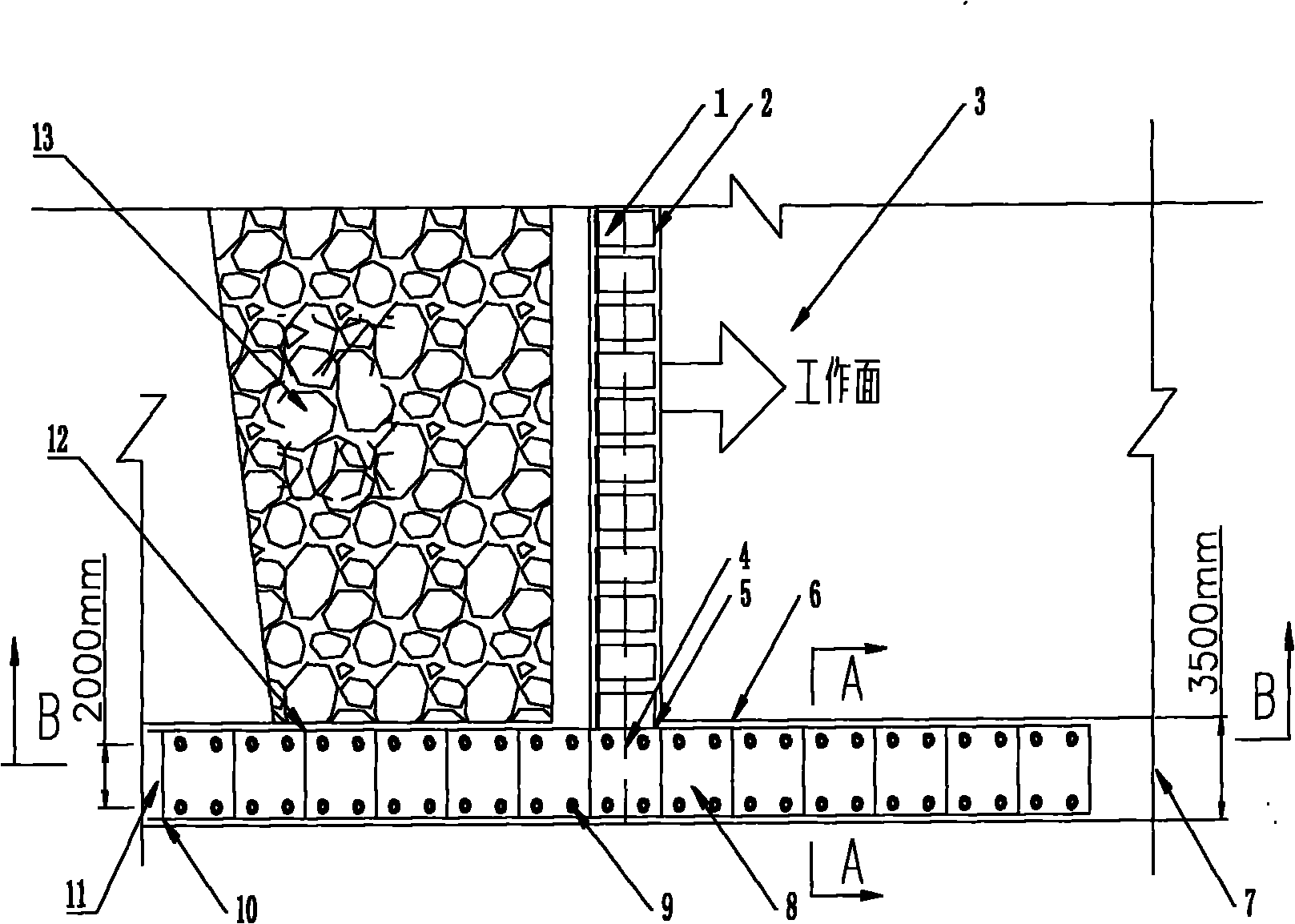

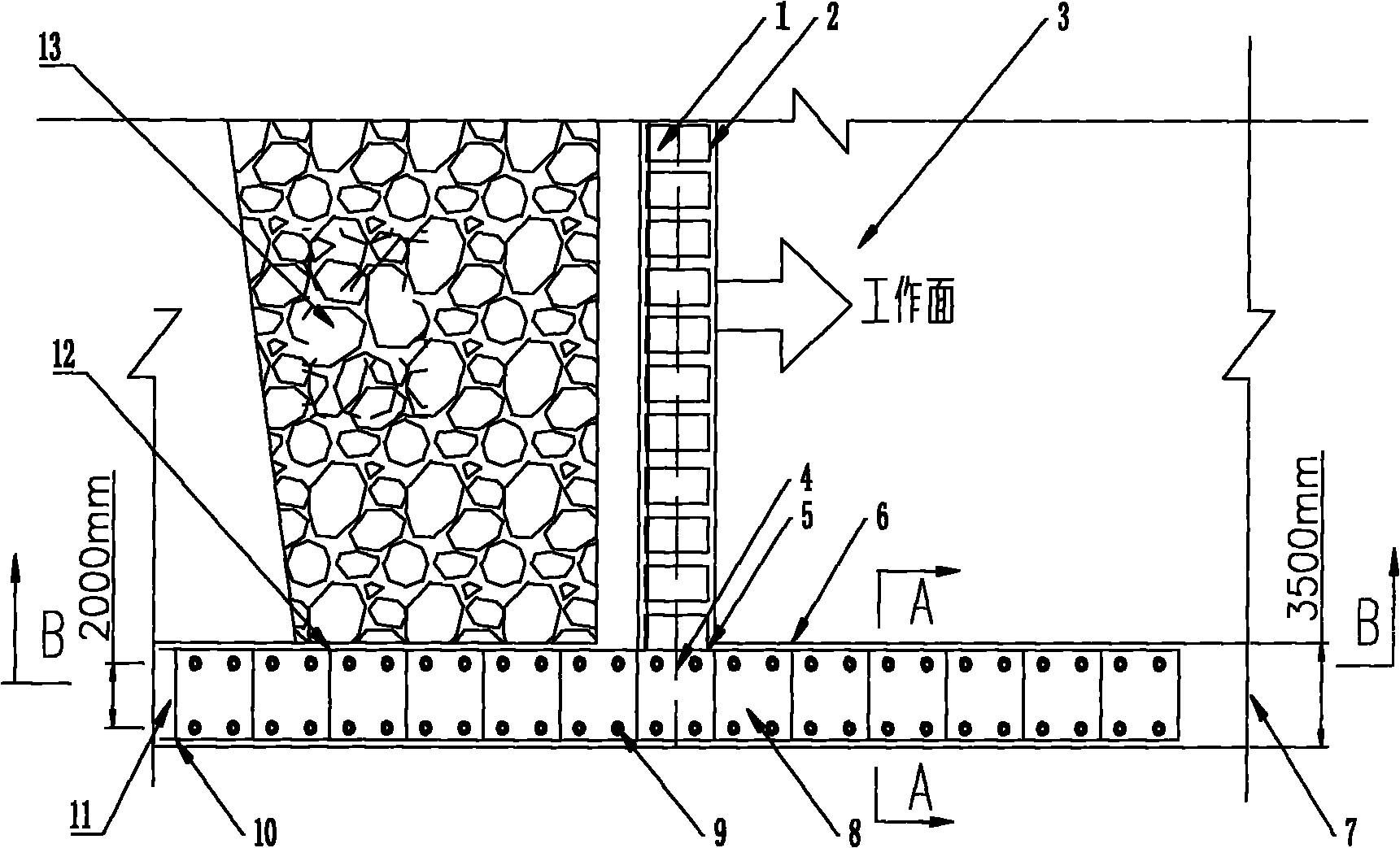

[0029] The coal mining roadway support project directly adopts the technology of support and inclined arrangement to support the roadway.

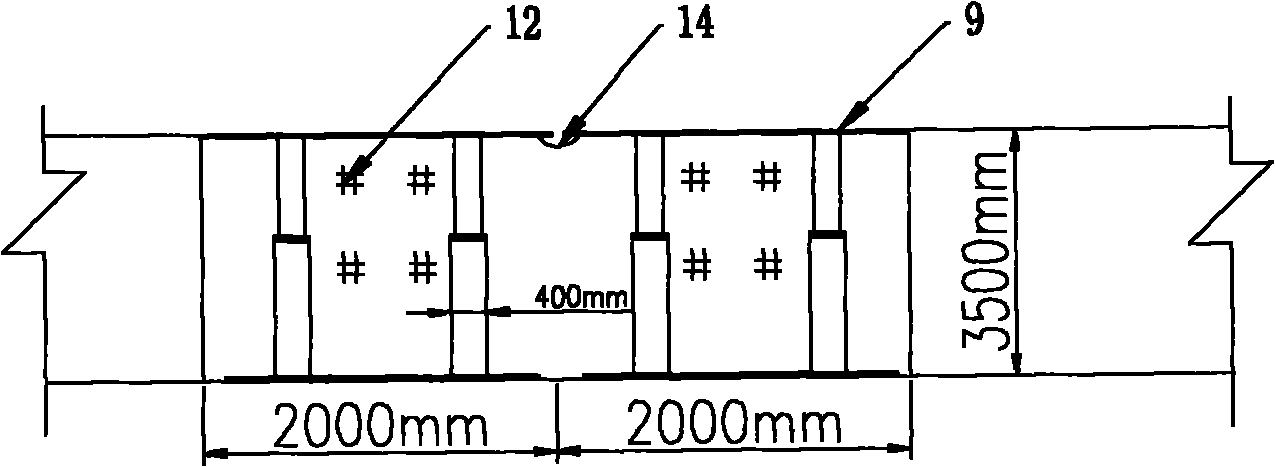

[0030] The so-called support is a specially designed hydraulic large-shrinkage supporting support. Each group is composed of four columns, an integral skylight top beam and an unsealed base; the support length × width = 3.5m × 1.5m, height 1.7m~3.2m The shrinkage is more than 1.6m, and the working resistance is about 3500kN.

[0031] Such as figure 1 Shown: First, the preparatory work before fully mechanized mining is carried out. On the working face 3, install all the equipment, including the working face support 1 and the conveyor, etc. into the cutout; 2. Use the installation center line 4 of the first set of supports 8 behind the working face 3 as the center line of the working face support 1; install the conveyor below the working face support 1, and the equipment is installed and ready for production.

[0032] The support roadway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com