Continuous cleaning device for vacuum pump and method thereof

A technology for cleaning devices and vacuum pumps, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids. It can solve problems such as time-consuming and labor-intensive shutdown cleaning, decreased vacuum degree of vacuum pumps, and damage to continuous production. Guarantee The effect of product quality, vacuum degree is not reduced, and the form is novel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

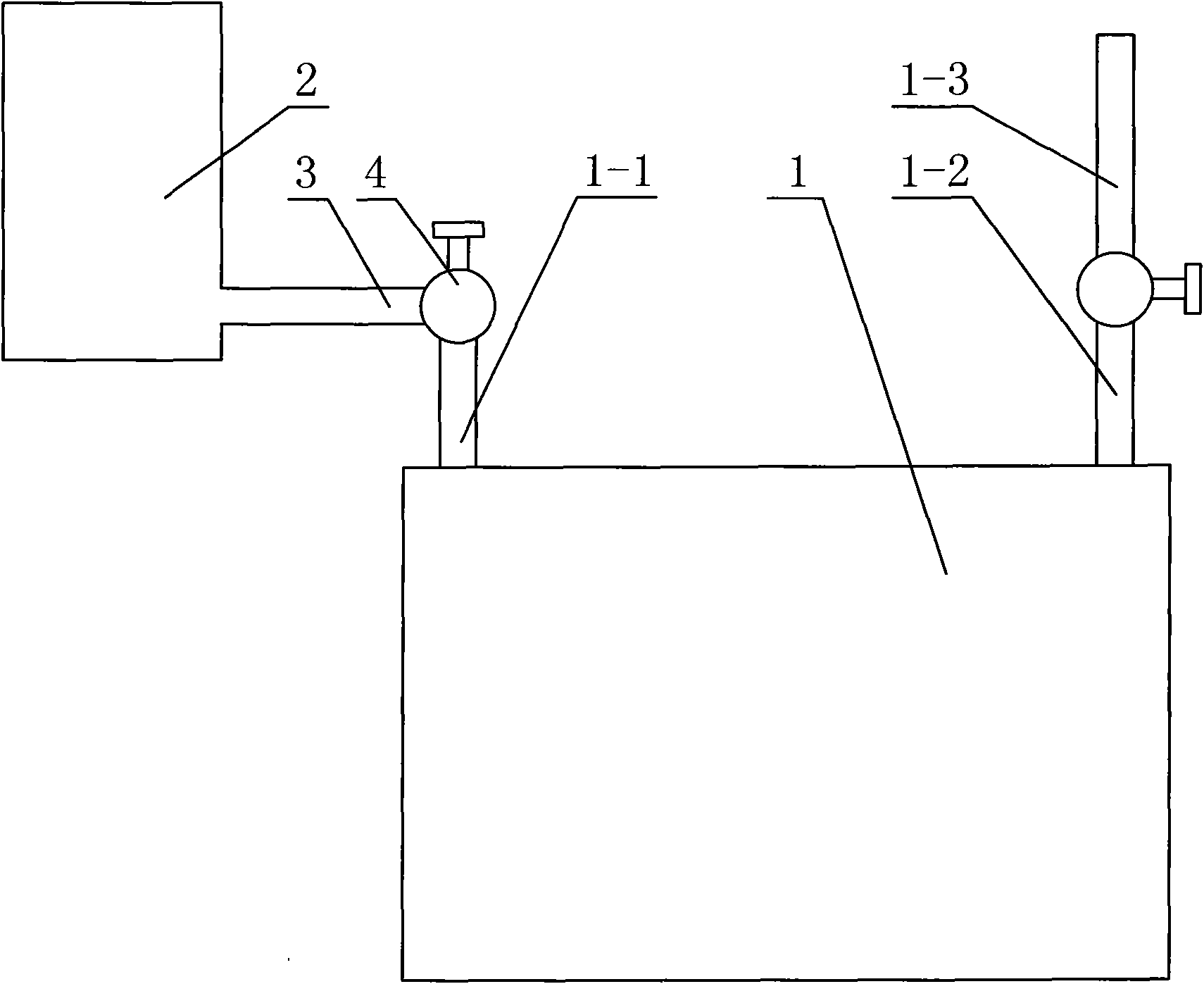

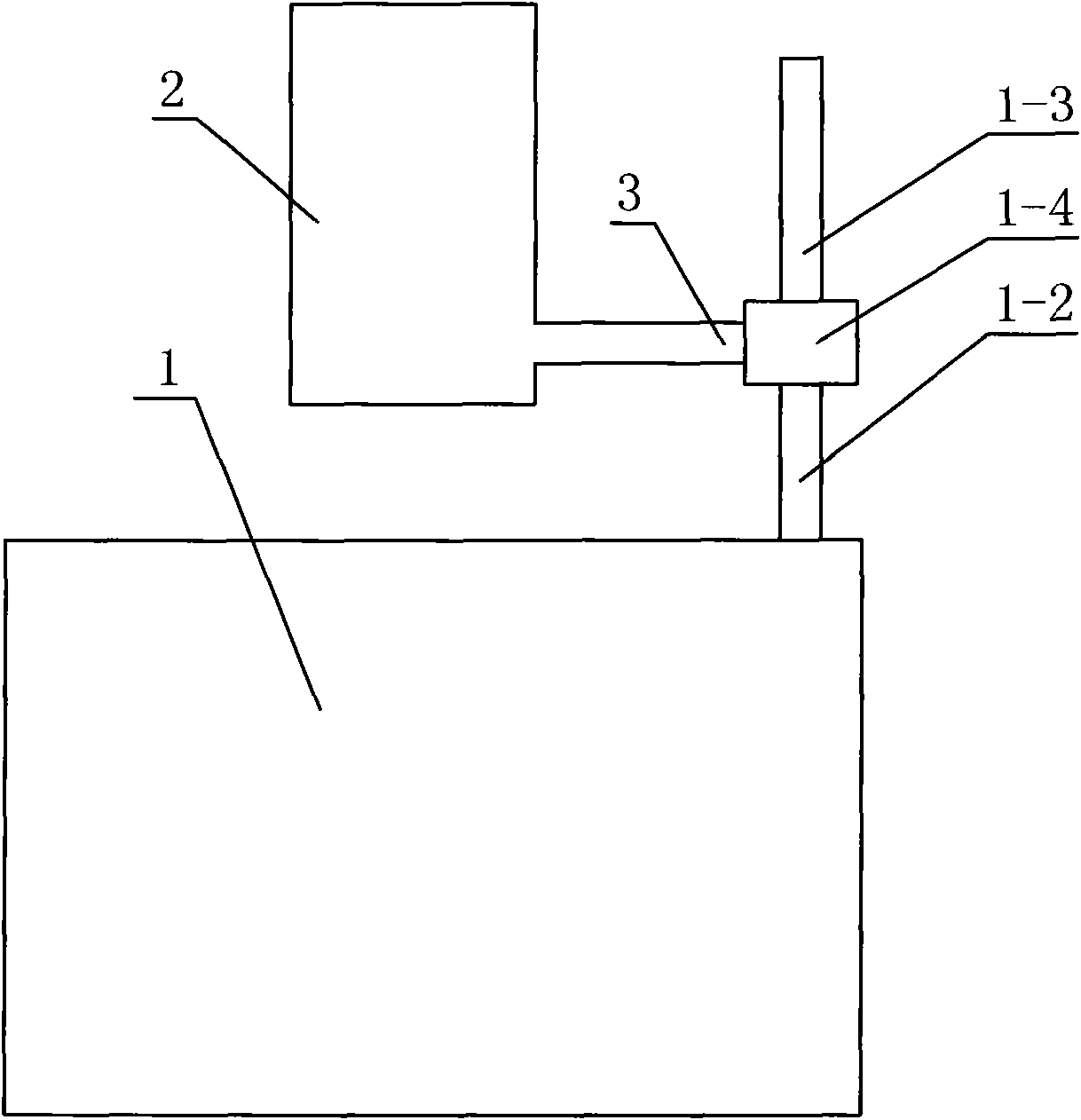

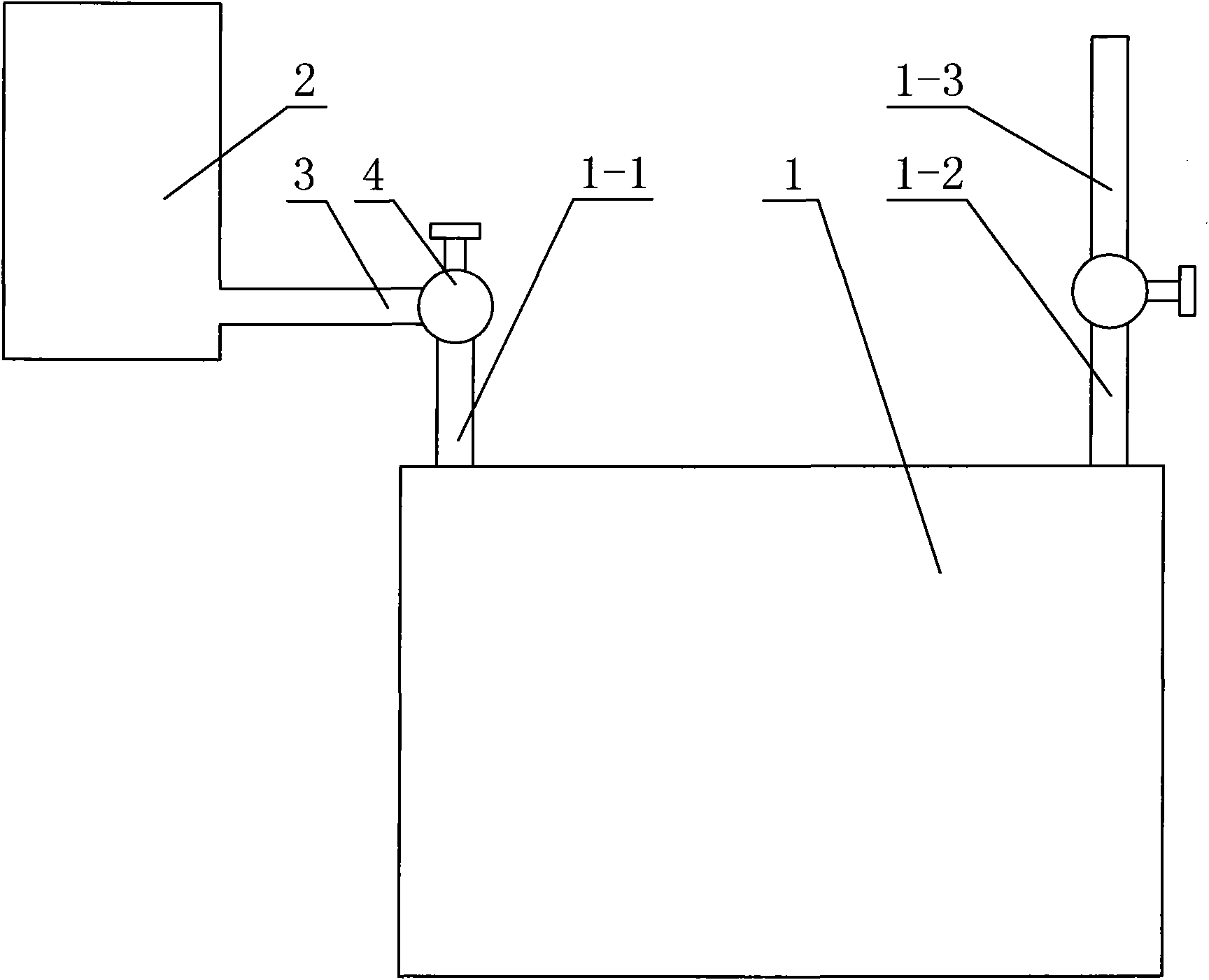

[0017] Embodiment 1: as figure 1 The shown first embodiment of the vacuum pump continuous cleaning device of the present invention includes a cleaning liquid supply system, and the cleaning liquid supply system has a cleaning liquid storage tank 2 with a built-in cleaning liquid, a cleaning liquid delivery pipeline 3 and a cleaning solution delivery pipeline The on-off valve 4 provided on 3, the cleaning liquid delivery pipeline 3 is connected to the cleaning liquid inlet 1-1 provided on the pump body of the vacuum pump 1 and communicated with the inner cavity of the pump body.

[0018] According to the physical characteristics of the viscous jelly being melted and reduced in viscosity when heated, the cleaning liquid is hot water, and the temperature of the hot water is 50-100°C.

[0019] According to the chemical characteristics of the viscous jelly that can react with alkaline solvents, the cleaning solution contains alkaline cleaners.

[0020] A method for uninterrupted c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com