Automatic membrane change device of automatic filling binding machine

An automatic filling and automatic film changing technology, which is applied in the direction of packaging material feeding device, packaging, transportation packaging, etc., can solve the problems of abnormal film conveying, affecting production efficiency, unqualified packaging, etc., and achieves simple loading and unloading, easy debugging, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

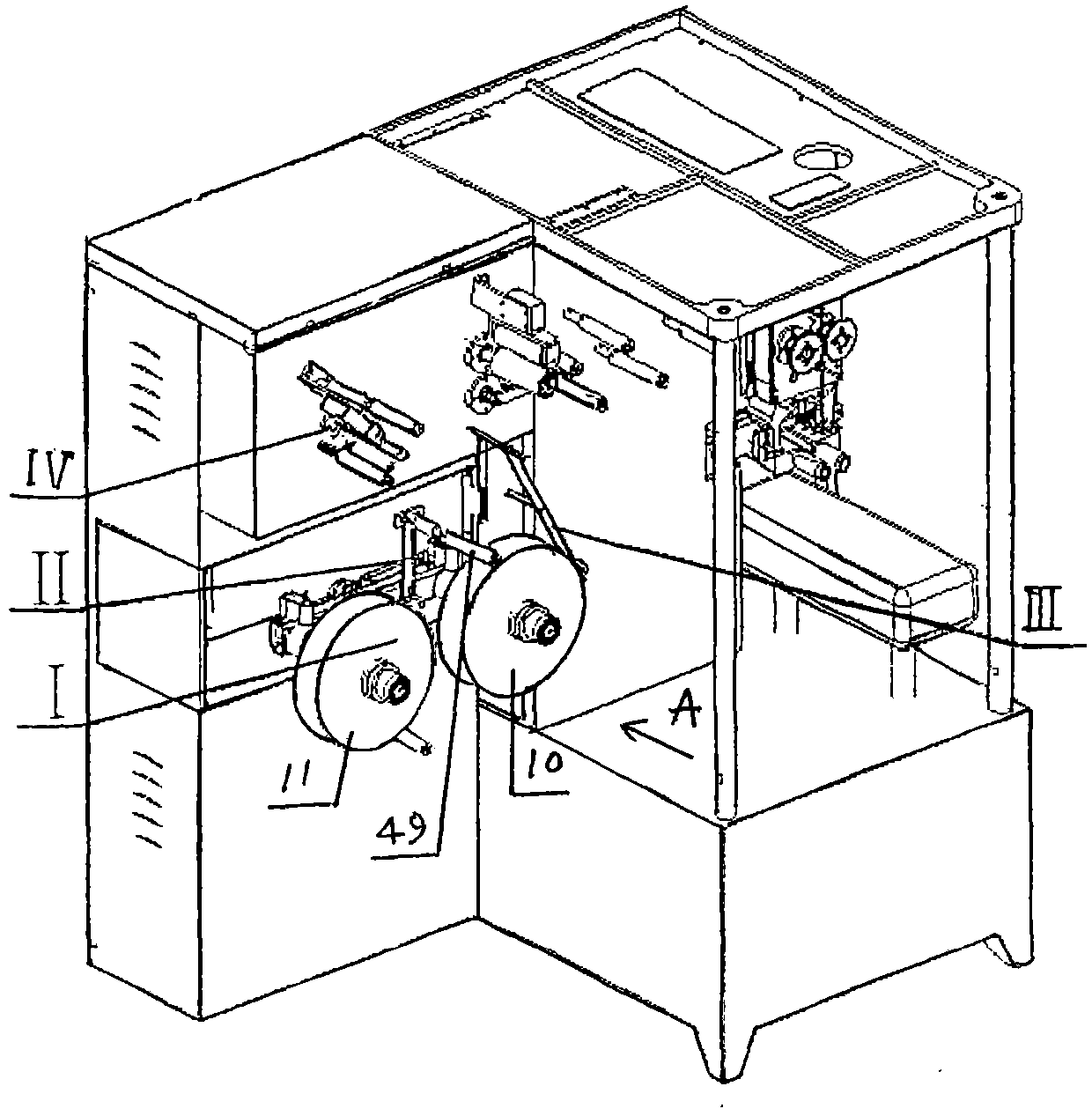

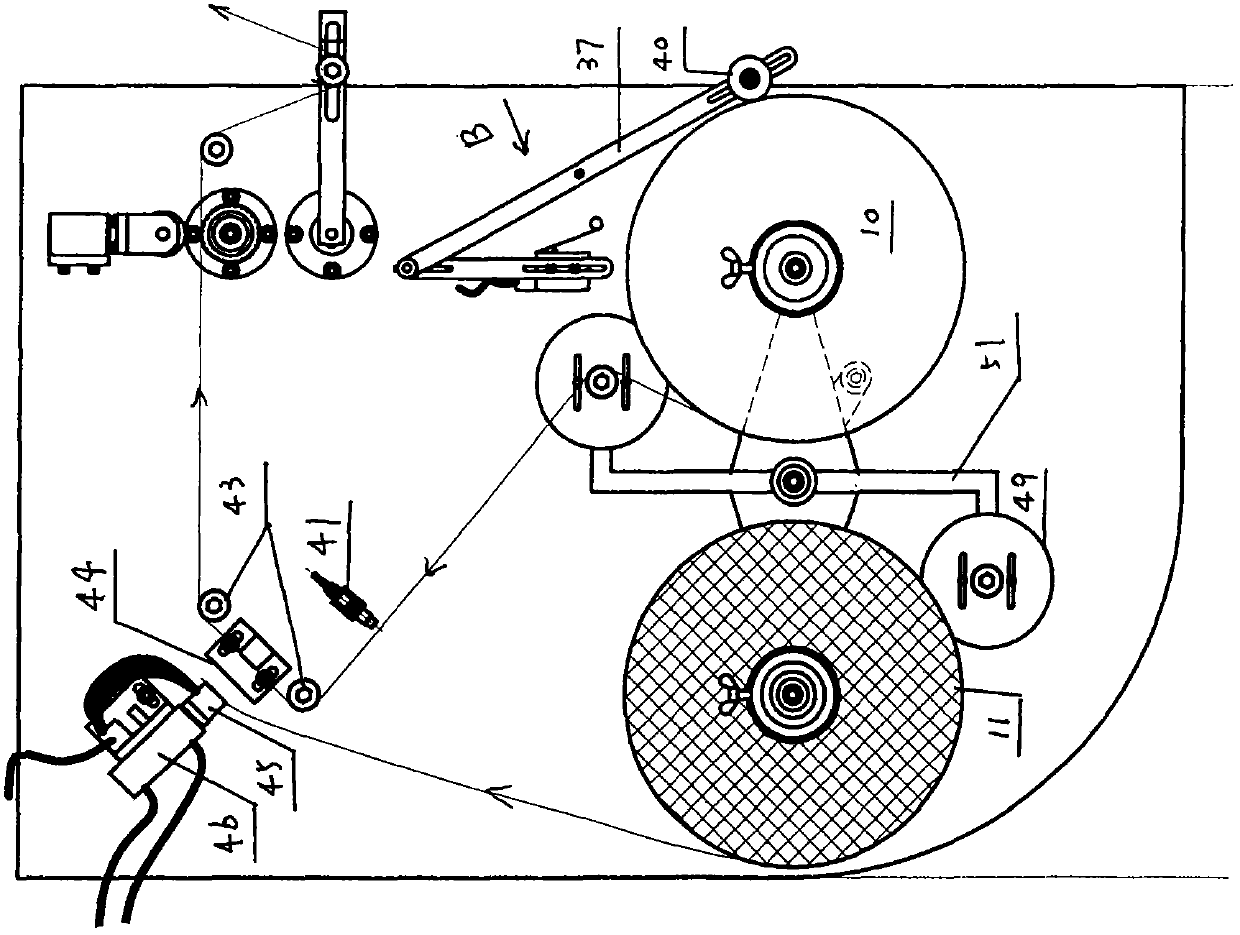

[0023] Further detailed explanation in conjunction with accompanying drawing, figure 2 The arrow in shows the direction of membrane transmission;

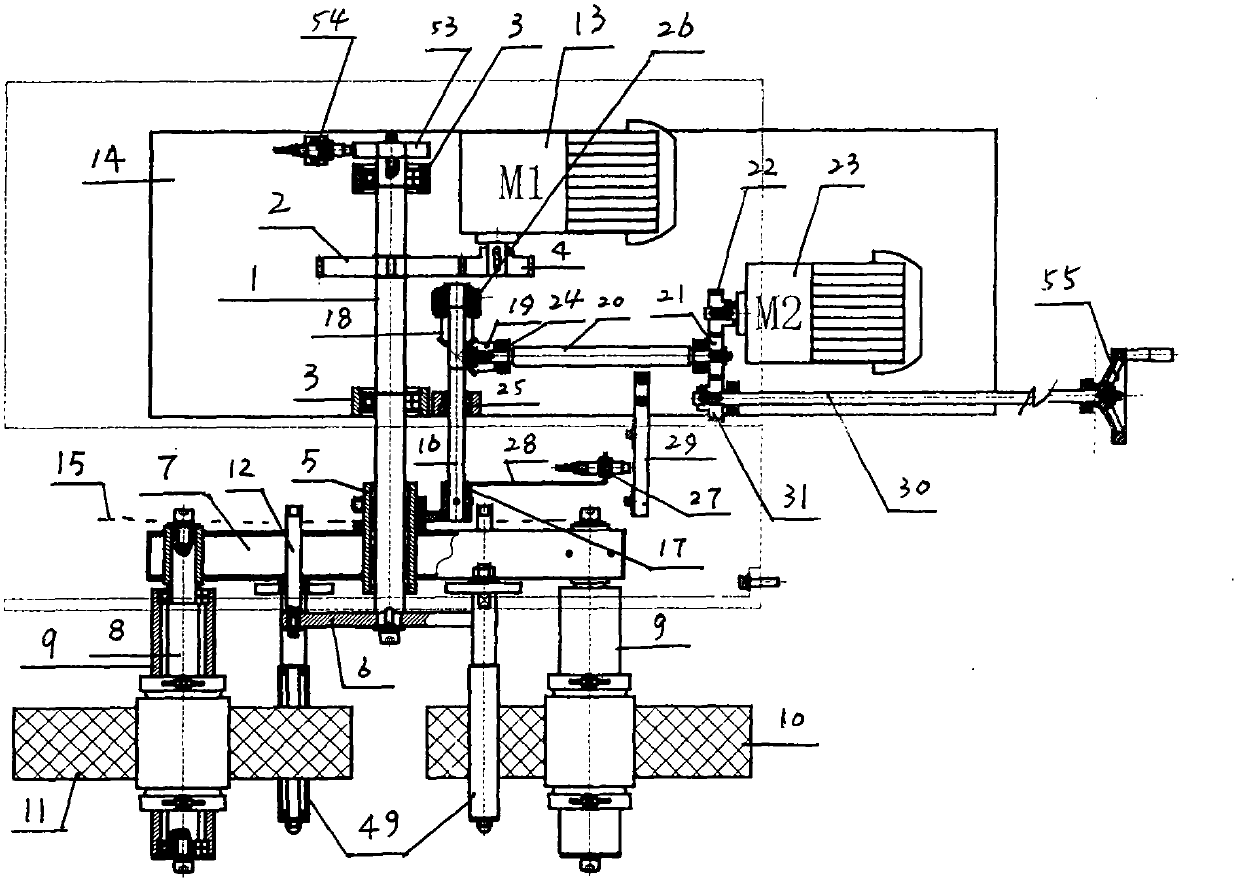

[0024] Such as Figure 1~6 Shown, the structure of the film changing roll device 1 is that the changing roll shaft 1 bearing type of the power input gear 2 is installed on two main bearing blocks 3 fixedly mounted on the flat frame plate 14, and one end of the changing roll shaft 1 faces After crossing the functional hole on the vertical plate 15 and installing the shaft sleeve 5, the detachable fixed shift fork 6 is fixed on the shaft end, and the connecting plate 7 is fixed on the shaft sleeve 5, and the two ends of the connecting plate 7 are symmetrical. The mandrel 8 with a large drum 9 is fixedly installed in each formula. The film roll 10 and the spare film roll 11 are respectively detachably mounted on the large drum 9. The connecting plate 7 is also detachably fixed with In the film guide mechanism that is synchronously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com