Method for obtaining hydrogen content of galvanized plate substrate

An acquisition method and technology of galvanized sheet, which is applied in the field of galvanized sheet, high-strength steel and pickling sheet, can solve the problem that the hydrogen content of the galvanized sheet steel matrix cannot be accurately obtained, and achieve saving of processing and cost, simple and convenient, Avoid the effect of being corroded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

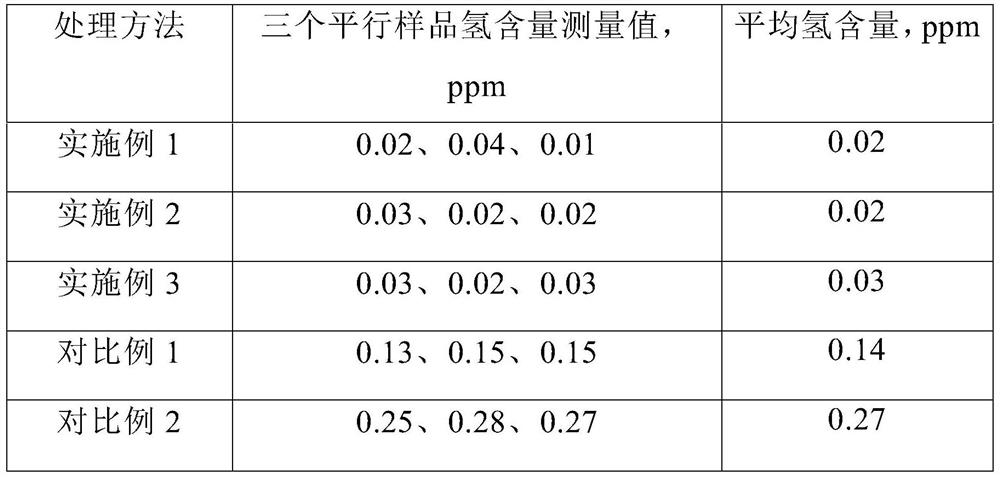

Embodiment 1

[0036] 1. Use a shearing machine to cut a 100mm×20mm sheet sample from the DP1180GI strip steel, and then use an industrial degreasing agent with a mass fraction of 2% at a temperature of 70°C (Pacca brand degreasing agent, model FCS-364S) to degrease the surface. Oil;

[0037] 2. After degreasing, rinse the sample with a large amount of water, then place it in an acetone solution and vibrate it ultrasonically for 10 minutes, then dry the surface and store it in a low-temperature liquid nitrogen tank for 24 hours;

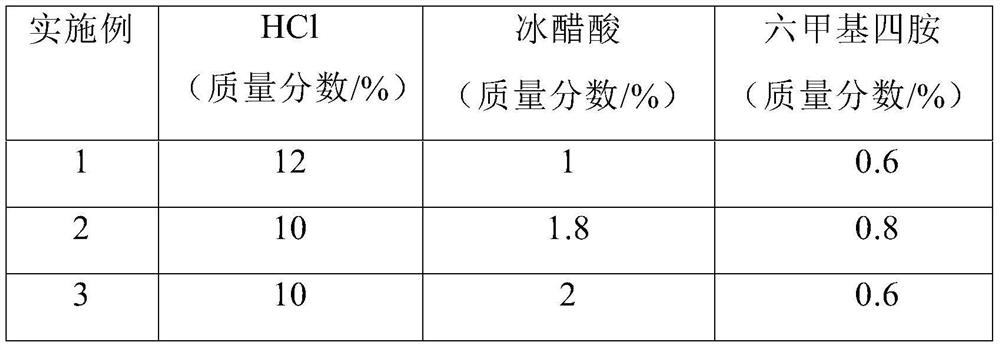

[0038] 3. Use deionized water to configure pickling solution 1. The specific formula is shown in Table 1, and the prepared solution is placed in condensed water at 5°C for 5 hours;

[0039]4. After taking out the galvanized sheet from the liquid nitrogen, quickly place it in the pickling solution and soak for 80s until the zinc layer disappears completely to obtain the matrix; when the galvanized sheet is soaked, the temperature of the pickling solution is 18°C. I...

Embodiment 2

[0044] 1. Use a shearing machine to cut a 100mm×20mm sheet sample from the DP1180GI strip steel, and then use an industrial degreasing agent with a mass fraction of 3% at a temperature of 70°C to degrease the surface;

[0045] 2. After degreasing, rinse the sample with a large amount of water, then place it in an acetone solution and vibrate it ultrasonically for 10 minutes, then dry the surface and store it in a low-temperature liquid nitrogen tank for 24 hours;

[0046] 3. Use deionized water to configure pickling solution 2. The specific formula is shown in Table 1, and the prepared solution is placed in condensed water at 5°C for 5 hours;

[0047] 4. Take the galvanized sheet out of the liquid nitrogen and quickly place it in the pickling solution to soak for 60s until the zinc layer disappears completely to obtain the matrix; when the galvanized sheet is soaked, the temperature of the pickling solution is 25°C. Immediately after soaking, take out the substrate after dezin...

Embodiment 3

[0052] 1. Use a shearing machine to cut a 100mm×20mm sheet sample from the DP1180GI strip steel, and then use an industrial degreasing agent with a mass fraction of 5% at a temperature of 70°C to degrease the surface;

[0053] 2. After degreasing, rinse the sample with a large amount of water, then place it in an acetone solution and vibrate it ultrasonically for 10 minutes, then dry the surface and store it in a low-temperature liquid nitrogen tank for 24 hours;

[0054] 3. Use deionized water to configure pickling solution 3. The specific formula is shown in Table 1, and the prepared solution is placed in condensed water at 5°C for 5 hours;

[0055] 4. After taking out the galvanized sheet from liquid nitrogen, quickly place it in the pickling solution and soak for 90s until the zinc layer completely disappears to obtain the matrix; when the galvanized sheet is soaked, the temperature of the pickling solution is 40°C. Immediately after soaking, take out the dezincified subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com