Patents

Literature

147results about How to "Reduce the amount of entry" patented technology

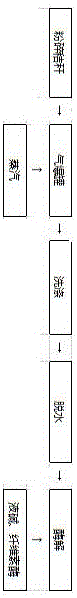

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

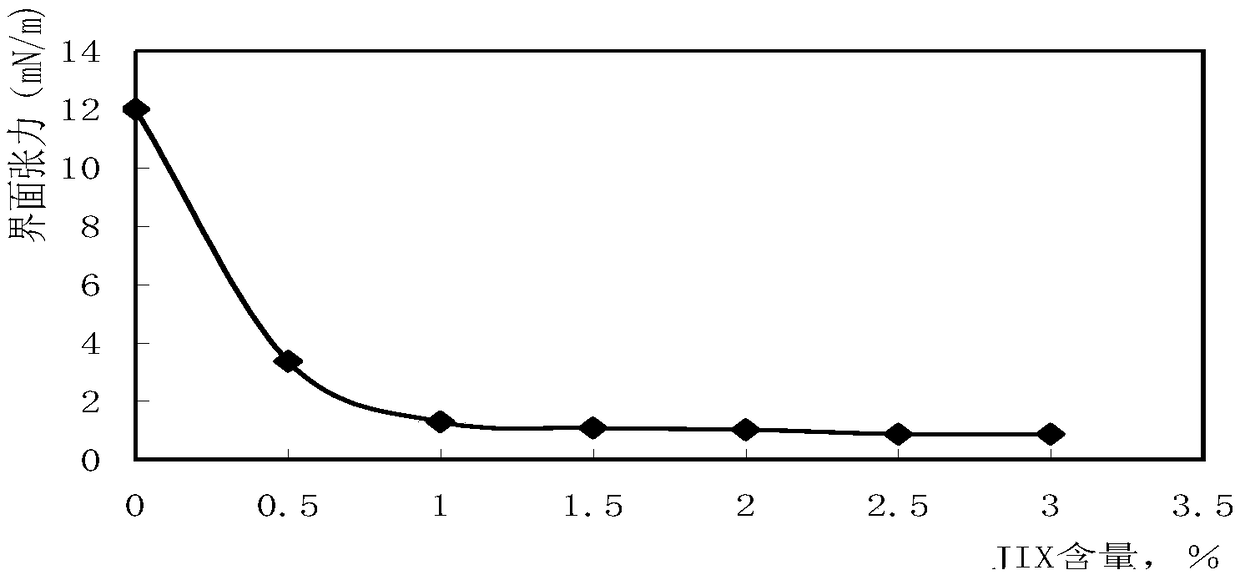

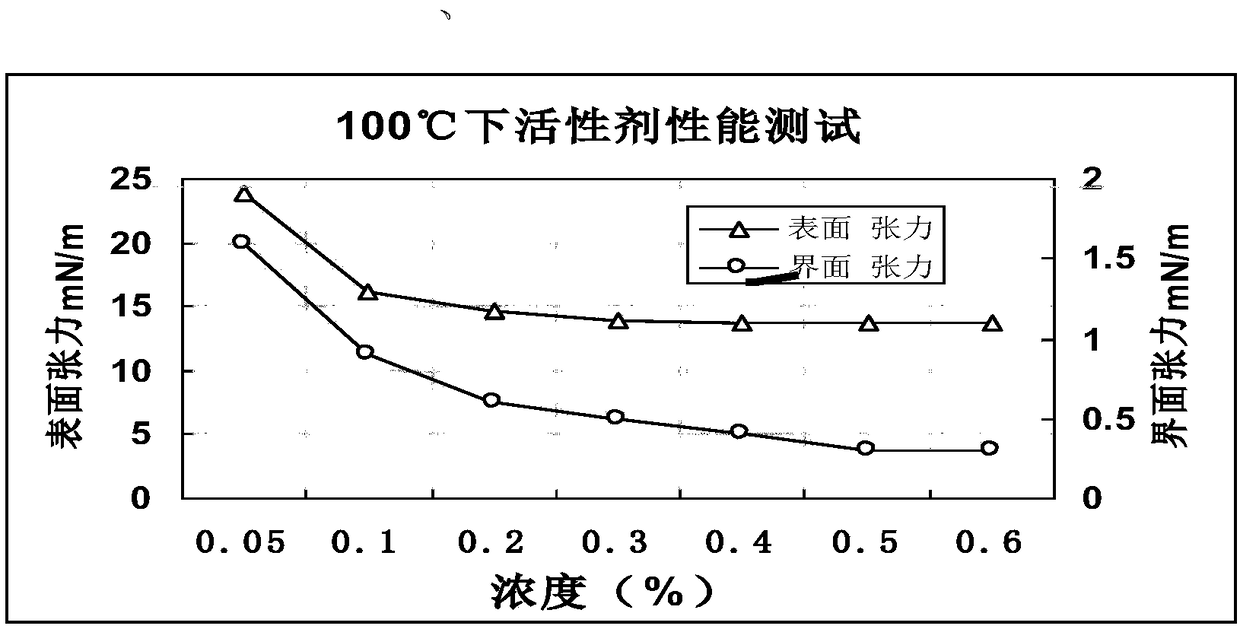

Ultra-low resistance acid-type microemulsion plugging removal and stimulation technology for low permeability oil well

ActiveCN101691839AGood dispersionStrong solubilizationFluid removalDrilling compositionSolubilityLiquid surfaces

The invention relates to a plugging removal and stimulation method for a low permeability oil well. The ultra-low resistance acid-type microemulsion is prepared by the following components: 10%-25% of acid, 5%-20% of oil, 5%-25% of alcohol, 0.5%-5% of surfactant, 0.5%-3% of inorganic salt, 0.3-1.5% of corrosion inhibitor and the balance water. The method comprises the following steps: injecting the prepared microemulsion in the oil bearing reservoir of the oil well, closing the oil well to react for 4-10h, cleaning the oil well, flowing the reaction exhaust liquor back, and completing the oilwell to perform normal production. The ultra-low resistance acid-type microemulsion used by the invention has thermodynamic stability, is a high dispersive acid-type microemulsion with good solubilization capacity, has ultra-low surface and interfacial tensions and good solubilization capacity and can increase the dispersive capacity of crude in water and the emulsification and peeling function to oil film; the microemulsion also has good dissolubility in water or oil and good fluidity due to high carrying capability and low seepage resistances so that the oil yield of the oil well is increased and the water content is reduced; the liquid surface tension in oil reservoir is reduced and the flow resistance of the crude is lowered so that the mining rate of the crude is increased and the plugging removal and stimulation of the oil well can be realized.

Owner:陕西中孚石油信息技术有限公司 +1

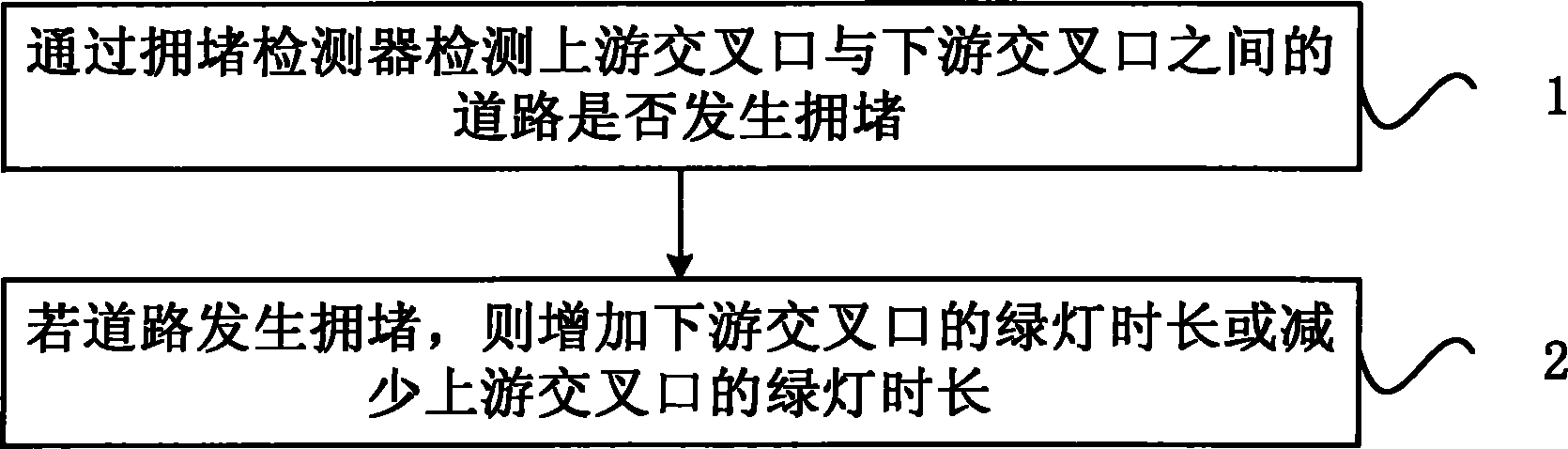

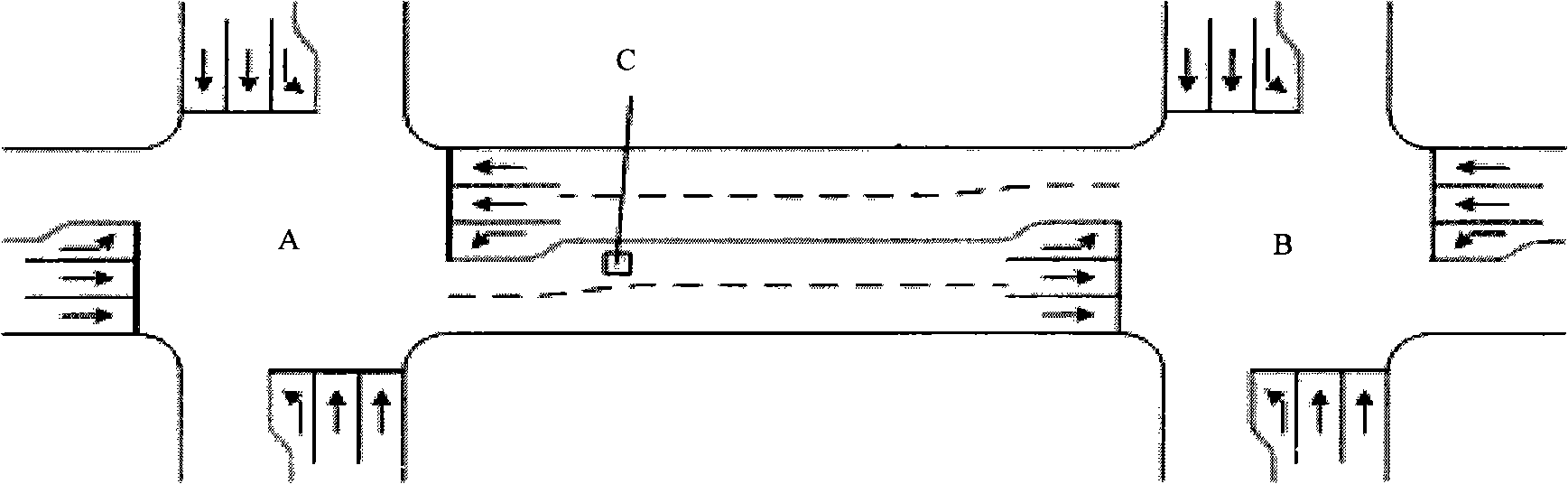

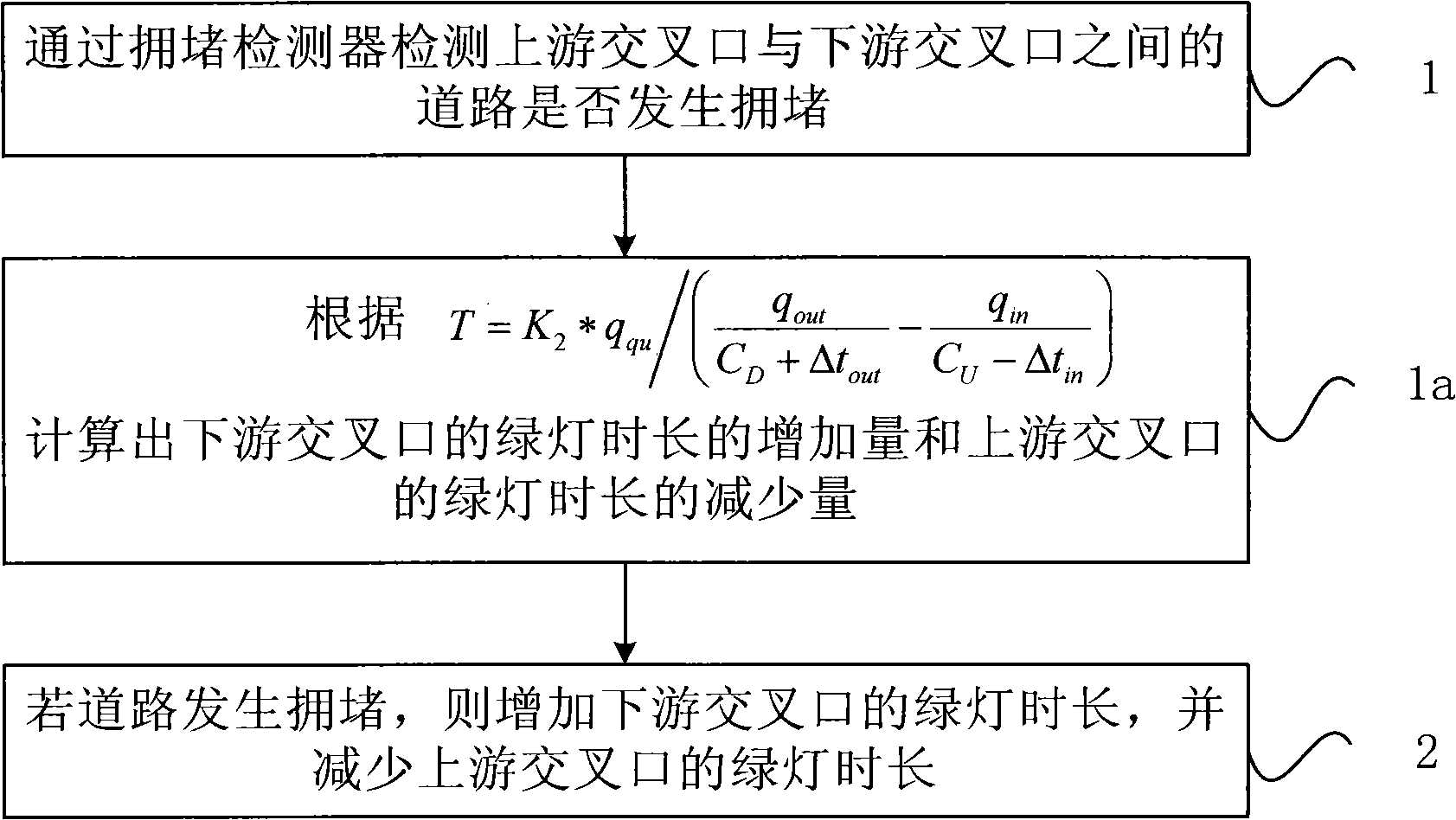

Method and device for controlling traffic signals of intersections

ActiveCN102005124AFast and smoothReduce the amount of entryControlling traffic signalsTraffic capacityEngineering

The invention provides a method and device for controlling traffic signals of intersections. The method for controlling traffic signals of intersections comprises the following steps: (1) detecting whether the road between an upstream intersection and a downstream intersection is congested or not by a congestion detector, wherein the congestion detector is arranged between the upstream intersection and the downstream intersection; and (2) if the road is congested, prolonging the time of the green light of the downstream intersection or shortening the time of the green light of the upstream intersection. When the road is congested, by prolonging the time of the green light of the downstream intersection, vehicles on the congested road can pass through the downstream intersection and run away from the congested road because of longer green light time, so that the congested road can be unblocked quickly; or by shortening the time of the green light of the upstream intersection, the number of the vehicles running on the congested road is reduced, so that the congested road can also be unblocked quickly, thereby realizing the purpose of reducing the occurrence of the phenomenon that the traffic capacity of the road network in a large range is lowered because a single intersection is congested.

Owner:QINGDAO HISENSE TRANS TECH

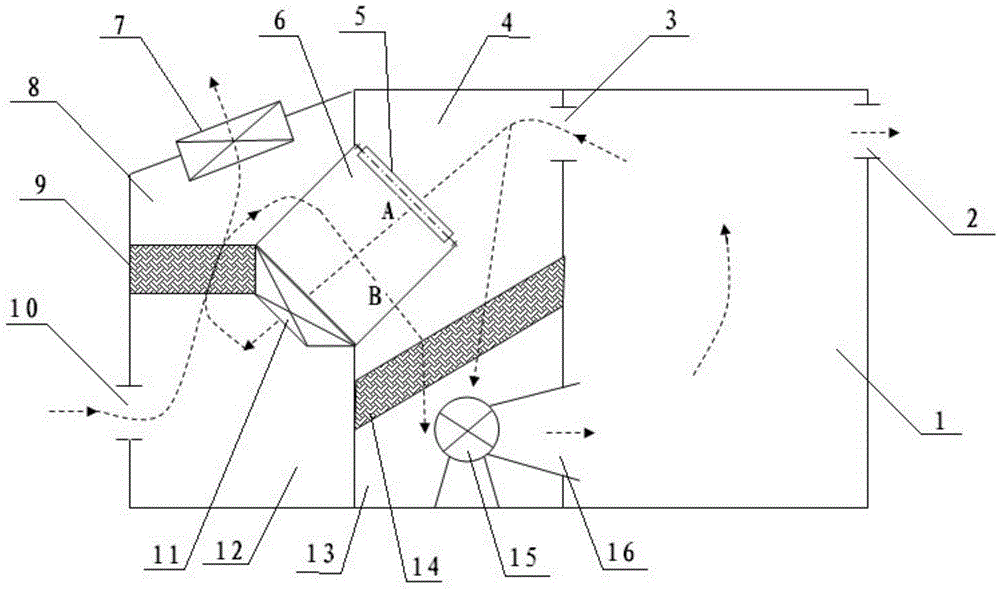

Air source heat pump drying house with air inlet of evaporator as fresh air inlet of drying house

InactiveCN104359290AReduce the amount of entryIncrease temperatureHeat pumpsDrying gas arrangementsCold airBusiness efficiency

The invention discloses an air source heat pump drying house with the air inlet of an evaporator as the fresh air inlet of a drying house. The air source heat pump drying house comprises an air source heat pump, the drying house and an air-to-air total heat exchanger, and the housing of the air source heat pump is divided into a first chamber and a second chamber. When an automatic air door is closed, under the function of a condenser fan, relatively closed circulating air is generated to heat the drying house; when the temperature of material in the drying house is increased to certain temperature and humidity is increased, the automatic air door is opened, so that the air inlet of the evaporator serves as the fresh air inlet of the drying house. With the overall system structure configuration and the utilization of cold air after the heat exchange of the evaporator as a basis and the opening and closing of the automatic air door as a switching condition, the material drying method in which dehumidification and moisture removal are carried out at the same time is innovated, thus realizing the organic combination of a variety of operating modes; the overall functional trend of the system can be automatically, flexibly and conveniently changed to meet the different and even contradictory requirements of all material drying stages; the great increases of both energy efficiency ratio and material drying speed can be taken into consideration; equipment investment is saved.

Owner:湖南省浏阳市择明热工器材有限公司

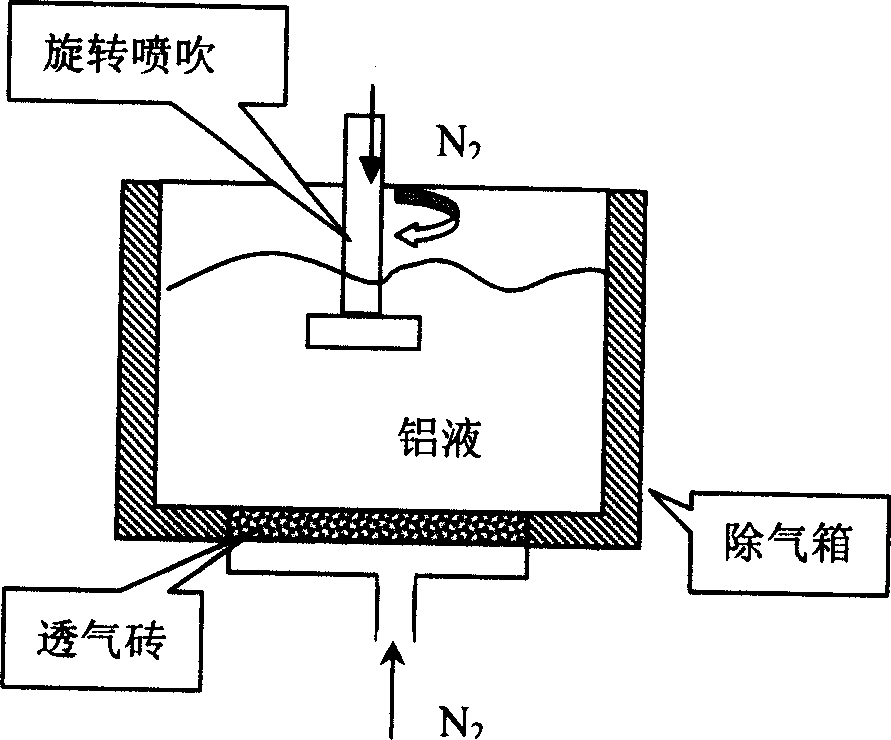

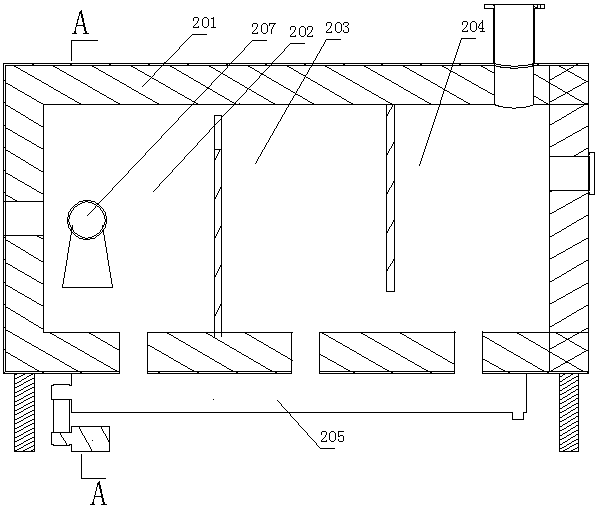

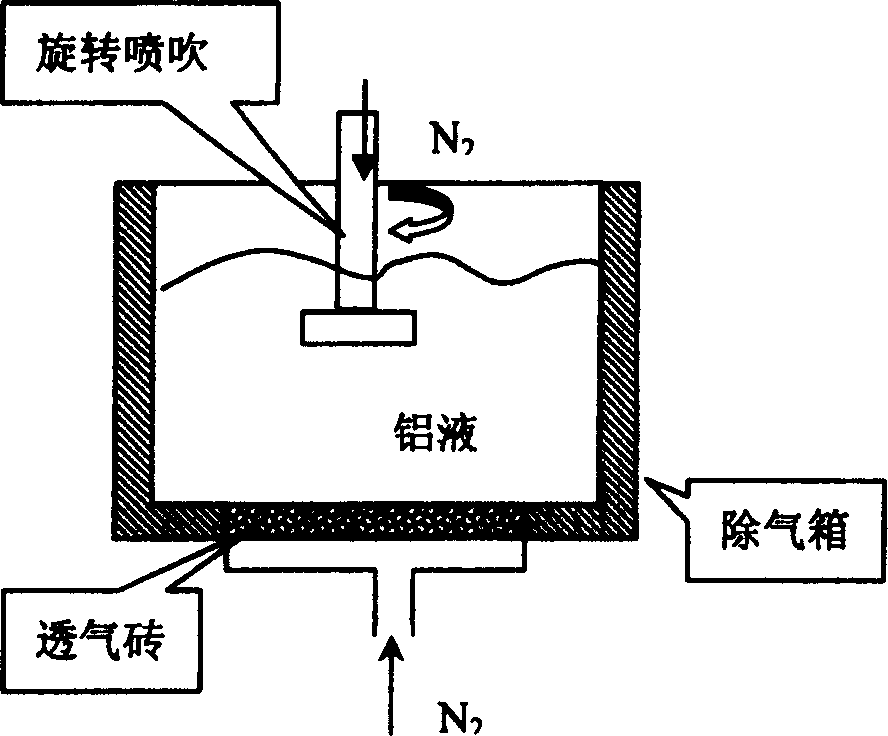

Method of purifying aluminium alloy melt

A process for cleaning the molten Al-alloy by removing hydrogen features that the inertial gas is sprayed onto top surface of molten Al-alloy contained in a degassing case via rotating nozzle while onto the bottom of the molten Al-alloy via the air-permeable bricks on the bottom of the degassing case.

Owner:江西金达通新材料科技有限公司

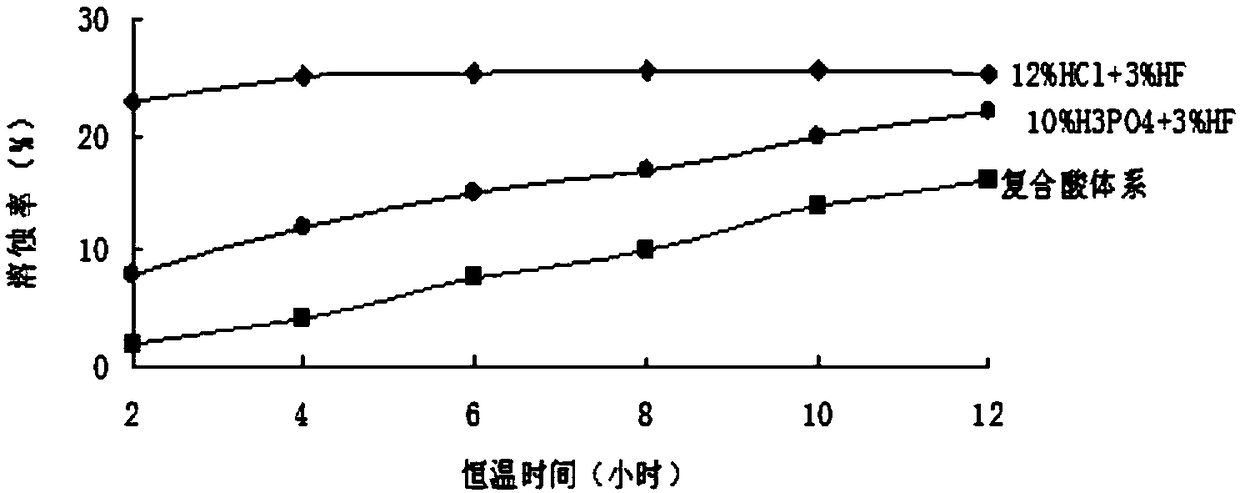

Compound acid blockage removing fluid for oil-water wells of ultralow-permeability oil fields

InactiveCN108822819ASlow reaction speedStrong penetrating abilityDrilling compositionEnvironmental chemistryCorrosion

The invention discloses a compound acid blockage removing fluid. The blockage removing fluid is prepared from raw materials in parts by weight as follows: 4-6 parts of a foam flushing fluid, 20-30 parts of a prepad fluid, 70-100 parts of main acid and 10-20 parts of postpad fluid. The acid fluid has higher capacity of removing organic sediment pollution and high acid residue and emulsifying resistance. The acid fluid has low corrosion speed and good swelling inhibition and does not change the original water wetting characteristic of the stratum.

Owner:兰州凯宏中原石油科技有限公司

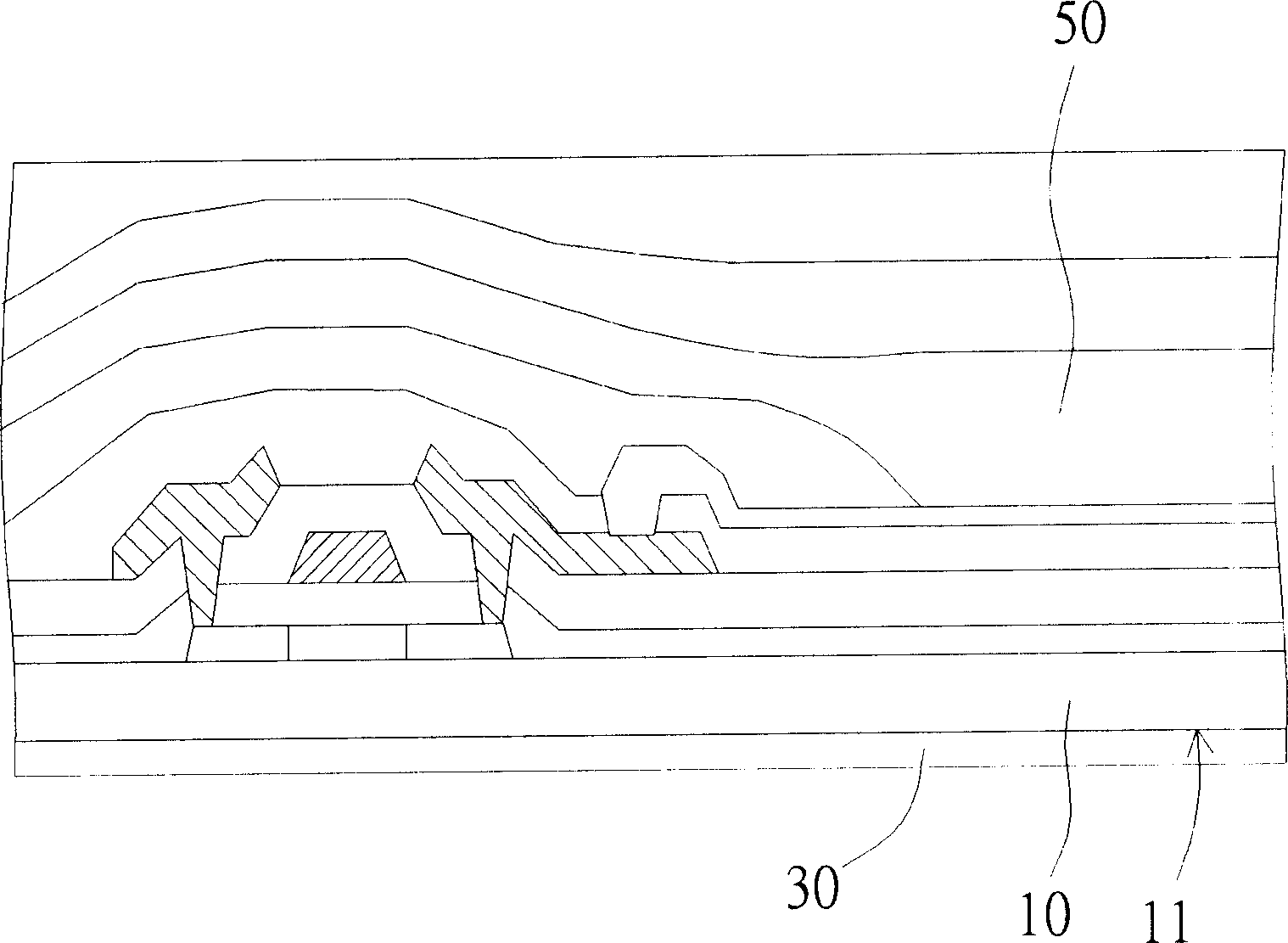

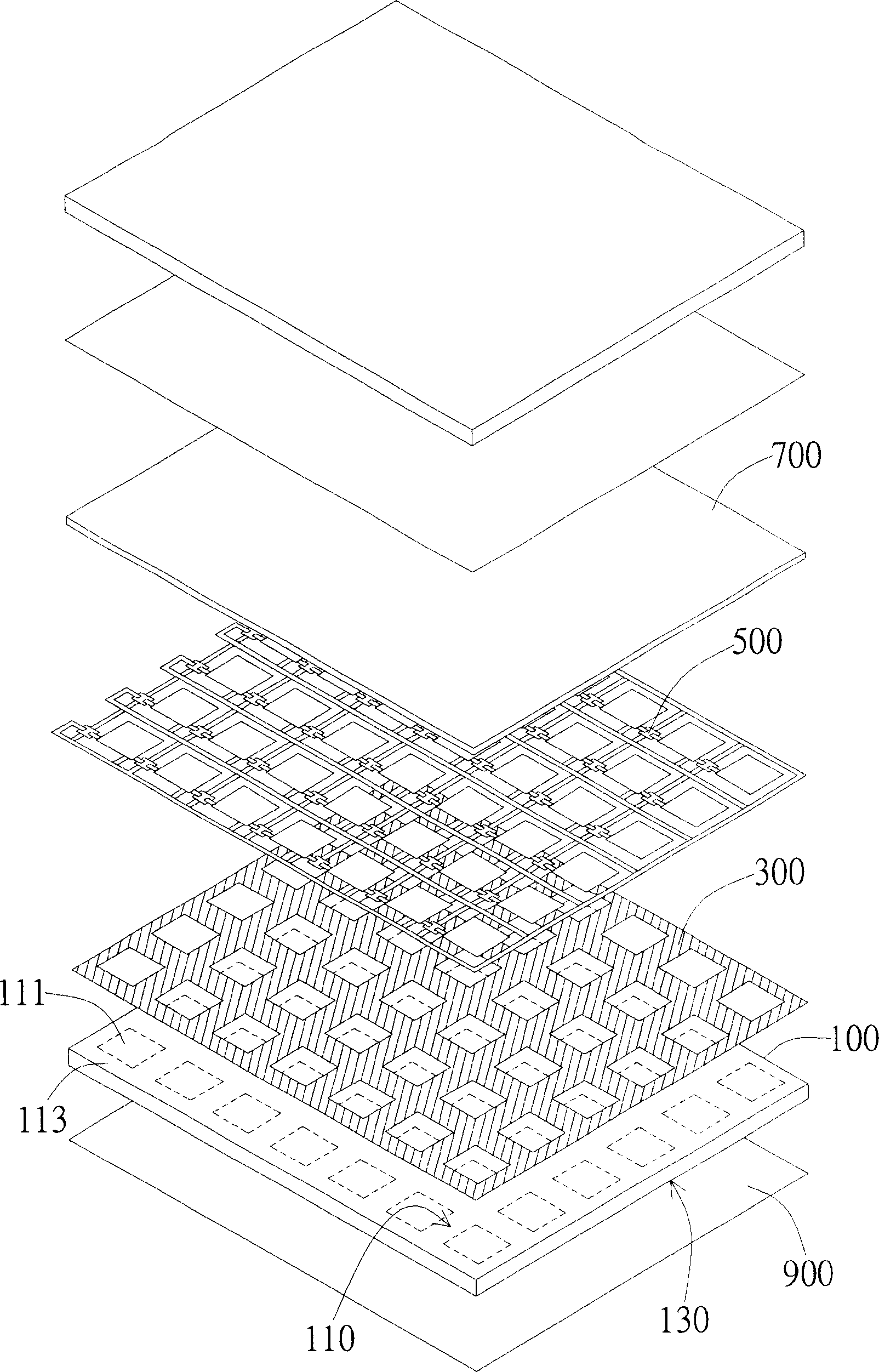

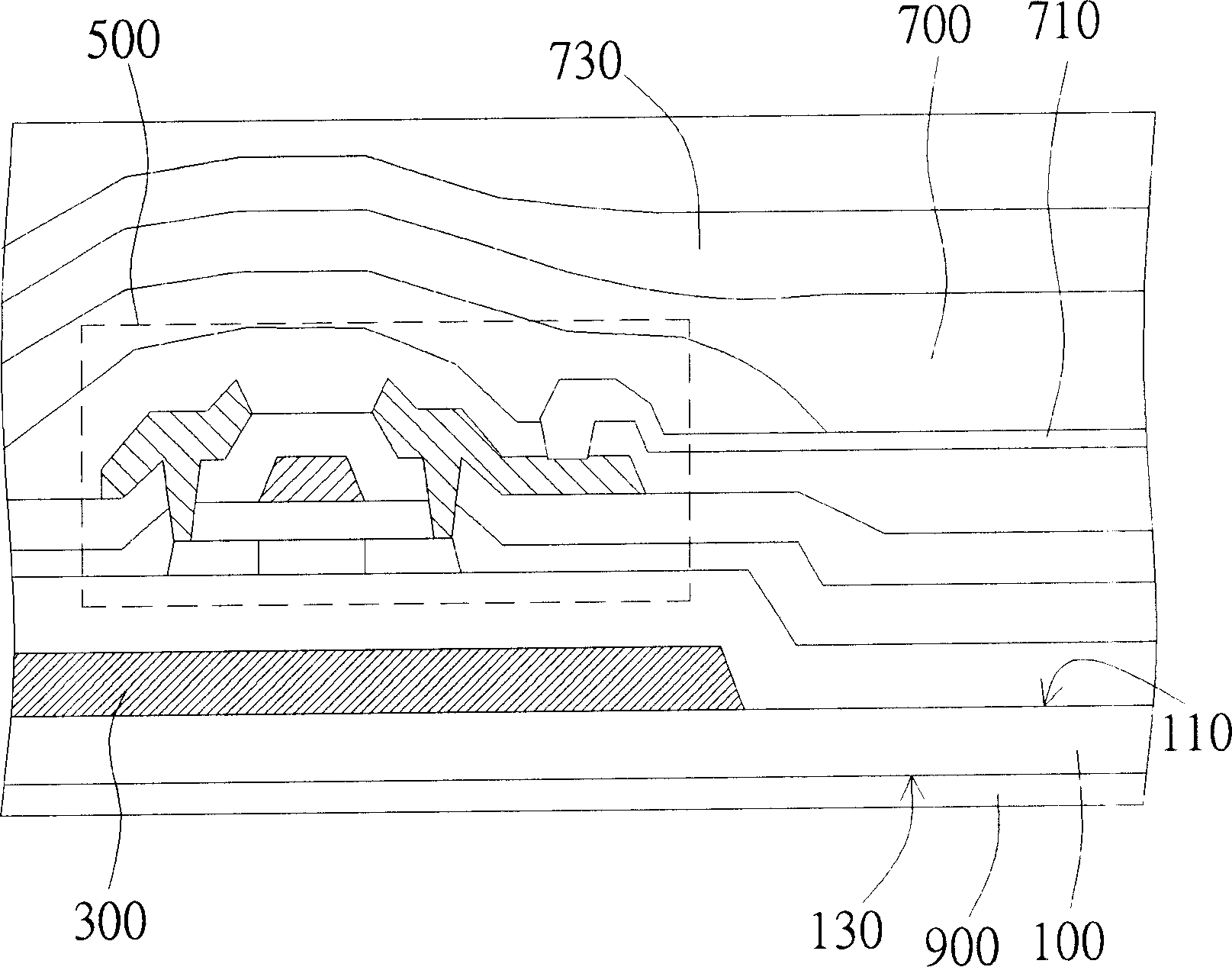

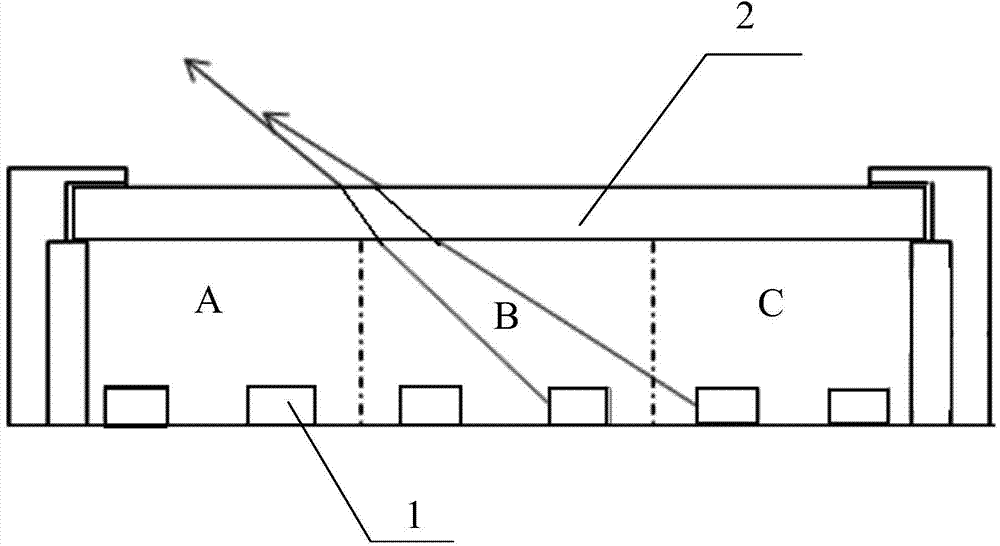

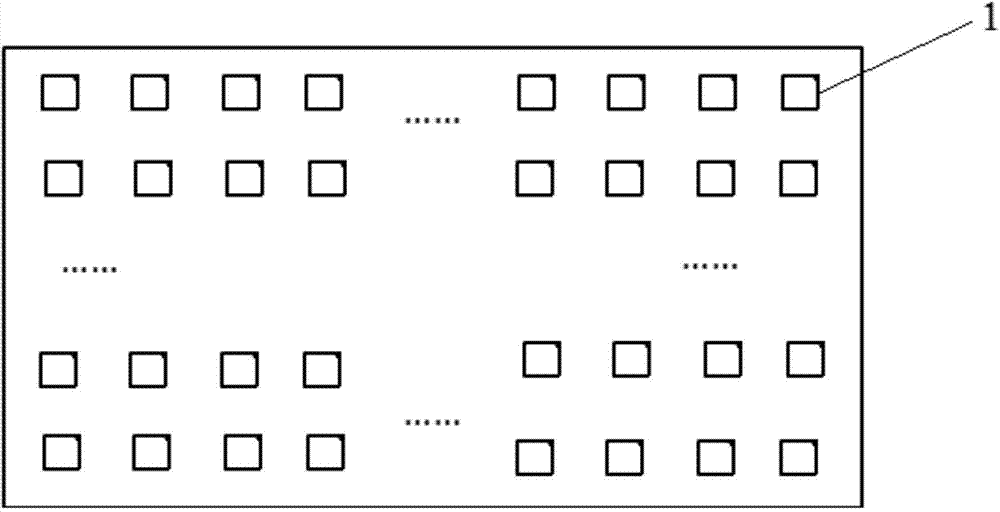

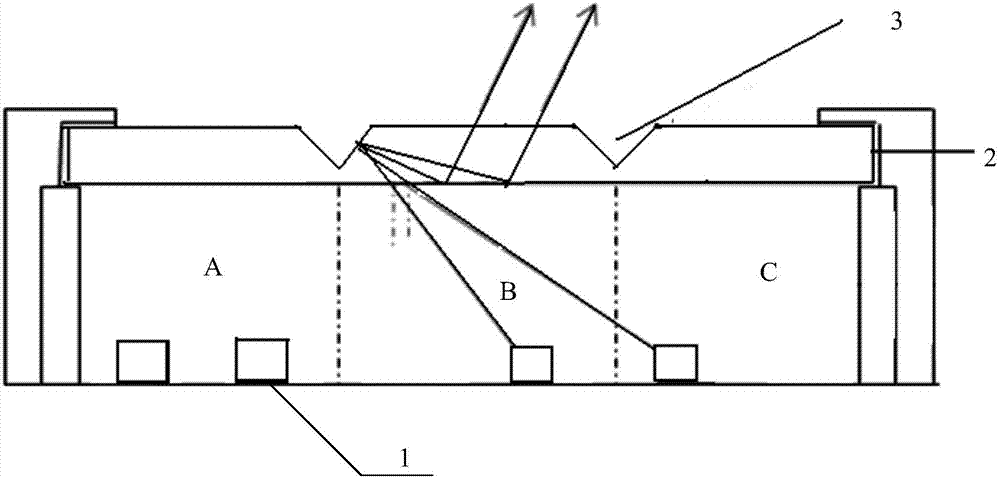

Display in low reflectivity built from self-luminescence elements

InactiveCN1917230AReduce the amount of entryIncrease contrastSolid-state devicesSemiconductor devicesDisplay deviceDark color

Owner:AU OPTRONICS CORP

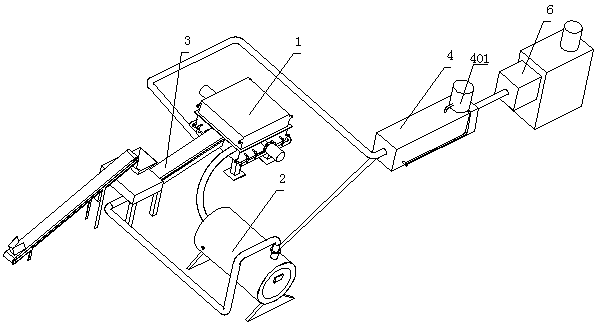

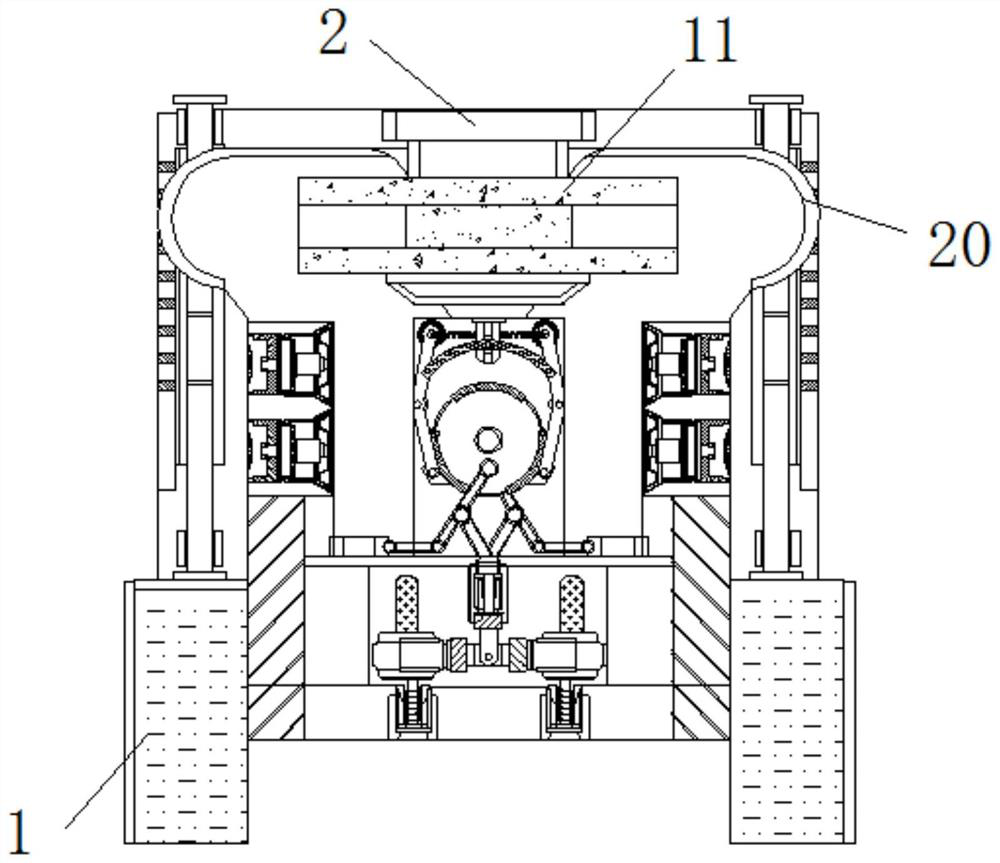

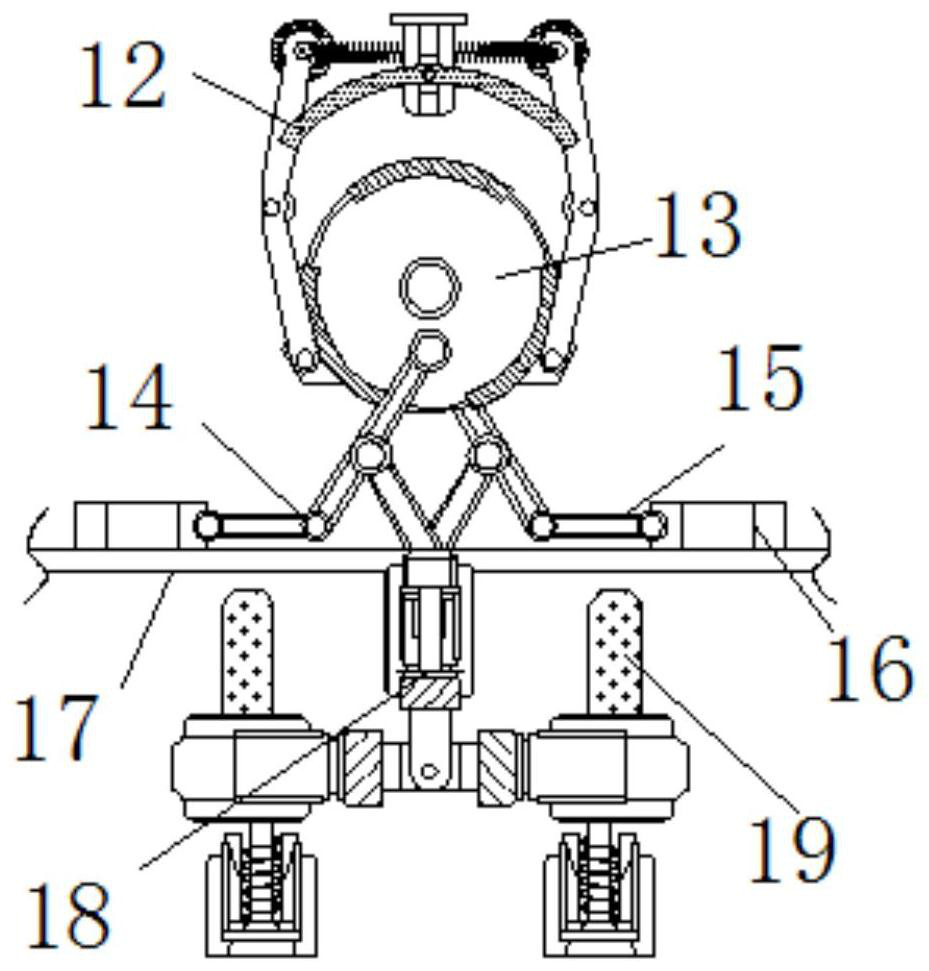

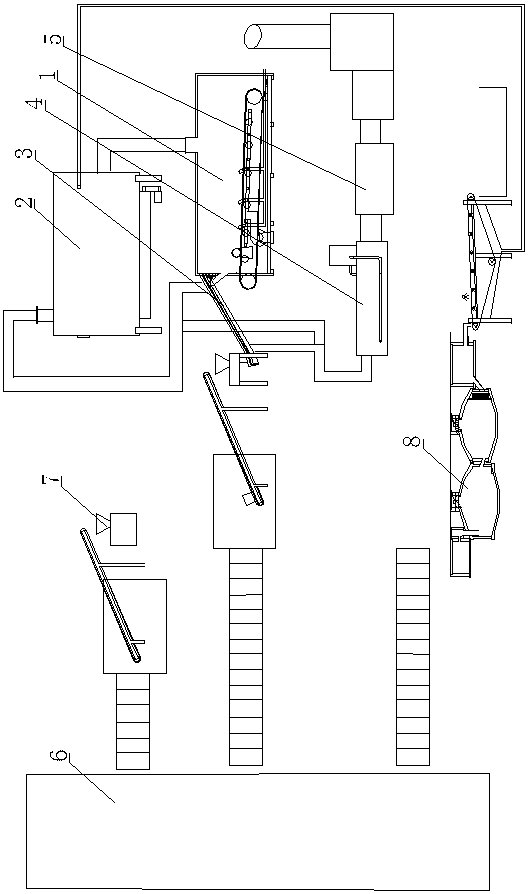

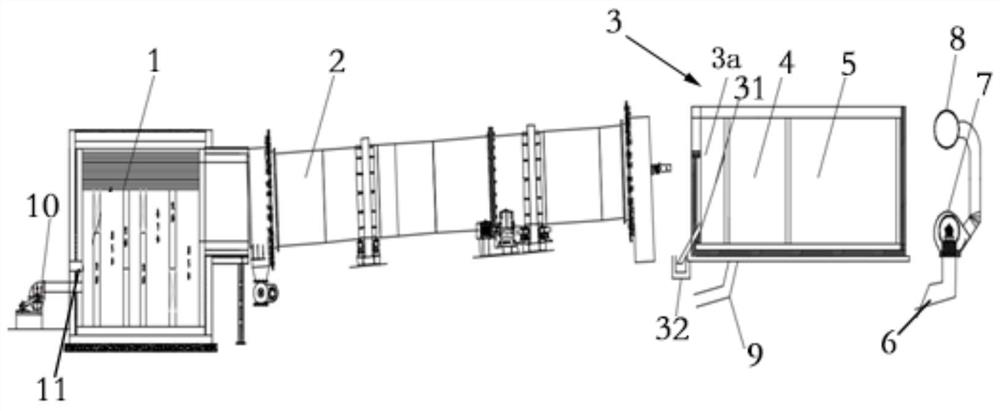

Waste incineration treatment system

ActiveCN106224974AReduce volumePromote fireIndirect carbon-dioxide mitigationAir/fuel supply for combustionCombustorCombustion chamber

The invention provides a waste incineration treatment system. The waste incineration treatment system comprises an incineration main furnace, an incineration auxiliary furnace and a feeding conveying device which are connected with the incineration main furnace, a flue gas cooling energy recovery device connected with the incineration auxiliary furnace, a dust remover connected with the flue gas cooling energy recovery device, an induced draft fan connected with the dust remover and an exhaust funnel connected with the induced draft fan. The incineration main furnace comprises a furnace body, a hearth located in the furnace body, a rotating platform connected with the furnace body, a round rotating grate connected with the rotating platform, a combustor connected with the furnace body, an air supply opening connected with the furnace body, an oxygen supply system connected with the furnace body, a slag discharging mechanism connected with the furnace body, an ash scraping device connected with the furnace body and an incineration main furnace flue communicating with the hearth. The incineration auxiliary furnace comprises an auxiliary furnace body, a first combustion chamber which is located in the auxiliary furnace body and connected with the incineration main furnace flue, a second combustion chamber communicating with the first combustion chamber, a third combustion chamber communicating with the second combustion chamber and an ash discharging mechanism connected with the auxiliary furnace body.

Owner:HENAN RUIXIN MACHINERY MFG CO LTD

Laser ranging sensor protection cover and laser range finder

InactiveCN104714219AIncrease rangeLess impact from sunlightWave based measurement systemsLaser rangingElectronic instrument

The invention discloses a laser ranging sensor protection cover, and relates to the technical field of an optical electronic instrument. The protection cover comprises a cover body and a bottom support seat, wherein the cover body comprises a groove-shaped lower bottom, an arc-shaped upper cover covering the upper part of the lower bottom, a laser panel fixedly arranged at the front end part of the lower bottom, and a rear cover fixedly arranged at the rear end part of the lower bottom; the lower bottom comprises a base plate and side plates which are arranged at two sides of the base plate and are integrally formed with the base plate; a hole is formed in the laser panel and laser can run through the hole; and a drainage device is arranged on the base plate of the lower bottom. The laser ranging sensor protection cover has the following beneficial effects that by replacing a conventional integral glass panel with the laser panel with the hole, the laser can run through the hole without barriers, so that the actual range of a sensor is improved, the interference degree of sunlight is reduced, and the waterproof performance of the protection cover is taken into consideration as well.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

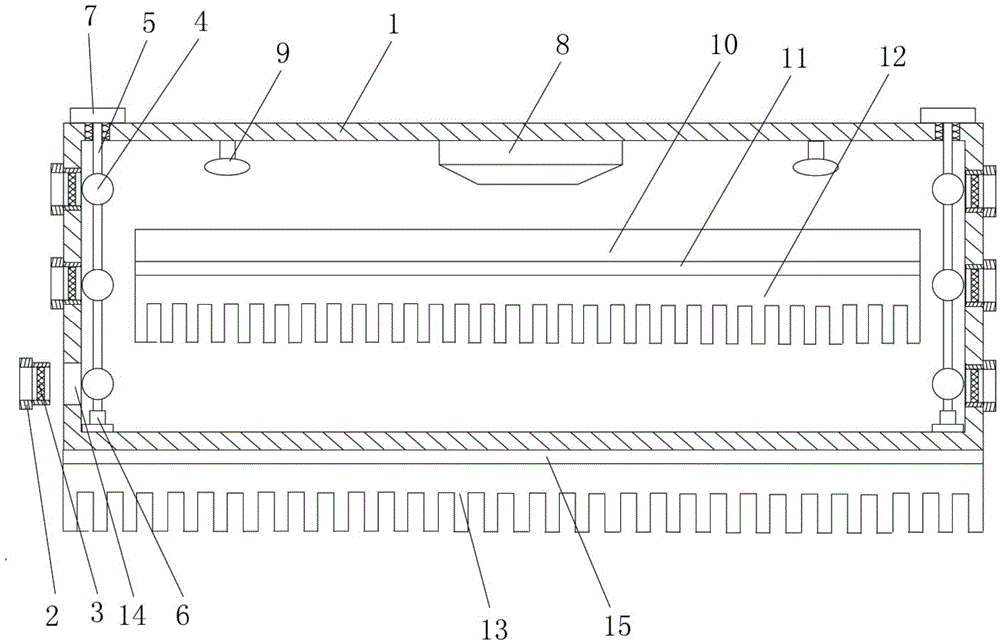

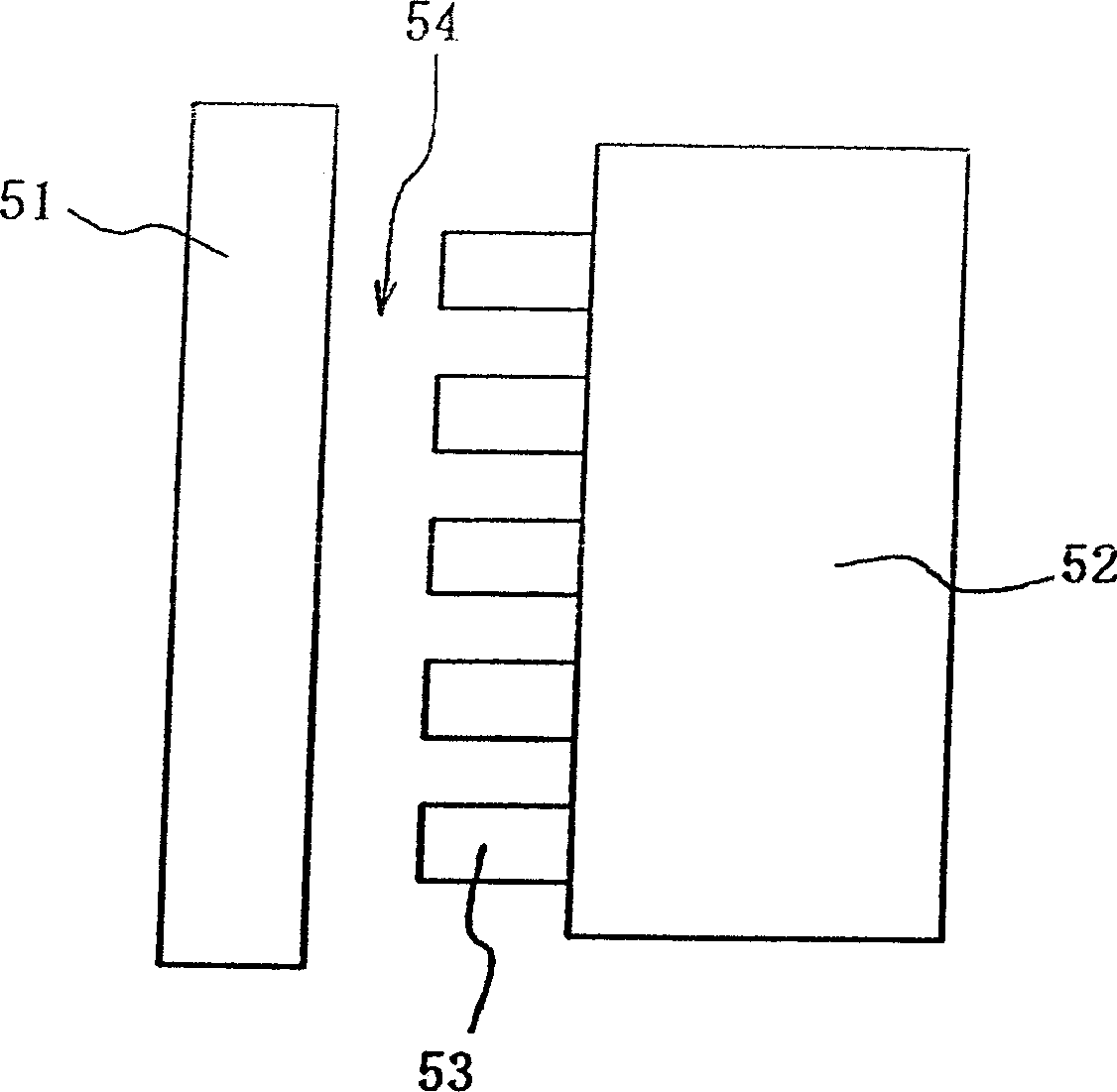

Solar module

ActiveCN105405905ASmall sizeImprove waterproof performancePhotovoltaic energy generationSemiconductor devicesLight transmissionJunction box

The invention discloses a solar module, and the module comprises a back plate, a light transmission substrate, a plurality of solar cells, a plurality of auxiliary wires, a sealing layer, a plurality of main wires, and a water-resisting insulating layer. The back plate is provided with a wire outgoing hole. The solar cell is disposed between the back plate and the light transmission substrate. The auxiliary wires are connected with the solar cells and are gathered to the main wires. The sealing layer is disposed between the back plate and the light transmission substrate, and covers the solar cells and the auxiliary wires. The main wires pass through the sealing layer and the wire outgoing holes to be connected to a junction box. The water-resisting insulating layer is embedded in a region, between the back plate and the solar cell, in the sealing layer, and is corresponding to the position of the wire outgoing hole, thereby enabling the projection of the water-resisting insulating layer towards the back plate to at least cover the wire outgoing hole.

Owner:ARCHERS

Device and method for air-drying meat products

InactiveCN103283807ANot perishableReduce the amount addedMeat/fish preservation by dryingTemperature controlSalt content

The invention discloses a device and a method for air-drying meat products. The device comprises a closed chamber, wherein an air draft dehumidifier is arranged outside the closed chamber, the air draft dehumidifier is provided with an air inlet pipe and an air outlet pipe, the air inlet pipe and the air outlet pipe are respectively communicated with the closed chamber, and the air draft dehumidifier is also provided with a temperature controller. The method for air-drying the meat products comprises the steps of: a, placing the meat products in the closed chamber; and b, carrying out air draft dehumidification on the meat products in the closed chamber, controlling the temperature of air in the closed chamber to be 8-12 DEG C and the air draft dehumidification time to be 40-50min. According to the device and method for air-drying the meat products, the meat products which are low in salt content and are not easily deteriorated at a normal temperature can be produced.

Owner:HUNAN QIZHI INGREDIENTS DEV

Electromagnetic shielding shell for power transmission line one-line monitoring device

InactiveCN102628881AGuaranteed uptimeReduce volumeInstrument screening arrangementsMeasurement instrument housingEngineeringHigh pressure

The invention relates to an electromagnetic shielding shell for a power transmission line one-line monitoring device. The electromagnetic shielding shell consists of an outer metal shell, an inner metal shell and a horizontal metal casing pipe, wherein the outer metal shell is shaped like a horizontal cylindrical tank; the metal casing pipe is sleeved on a high-voltage line and passes through the outer metal shell; the inner metal shell is positioned in the outer metal shell; and the power transmission line one-line monitoring device is arranged in the inner metal shell. The electromagnetic shielding shell has the advantages of small volume, low cost, convenience for mounting and the like, has a good shielding effect, and can guarantee normal operation of the power transmission line one-line monitoring device.

Owner:TAIYUAN POWER SUPPLY OF SHANXI ELECTRIC POWER +1

Stickies control process in high wet strength paper making process

InactiveCN105672020AAvoid secondary deposition pollutionImprove cleanlinessPaper-making machinesFiberPapermaking

The invention relates to the field of papermaking, in particular to a stickies control process in a process of producing high wet strength paper for daily use. The stickies control process comprises the following steps: selecting pulp, dispersing pulp, removing residues, milling, mixing, diluting, screening, shaping on a net, dehydrating and squeezing, drying and wrinkling. Pulp with low ash content is selected, the condition that stickies are produced by cohesion of resins and PAE wet strength agents is avoided, the long fiber proportion is increased, separating and brooming of fibers can be improved, partial wet strength is improved by improving the winding function of finished paper, and usage of the wet strength agents is reduced; moreover, according to a dry strength agent, the utilization efficiency of the wet strength agents can be improved, the dry strength agent has a temporary wet strength agent effect, has no adhesiveness in water and cannot deposit, the wet strength agent is efficiently utilized, a glyoxal polyacrylamide dry strength agent is coordinated with a PAE wet strength agent, the utilization effect of the wet strength agent can be improved due to mixed utilization, and the glyoxal polyacrylamide dry strength agent has no adhesiveness under a wet condition, so that the problem that the wet strength agent is adhered to a felt to cause stickies is solved.

Owner:SHANDONG SUN HOUSEHOLD PAPER LTD

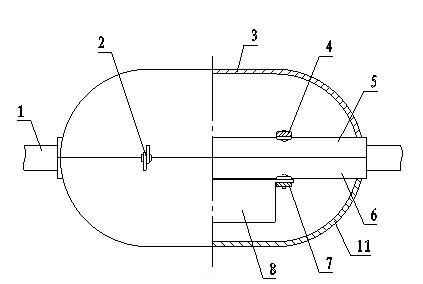

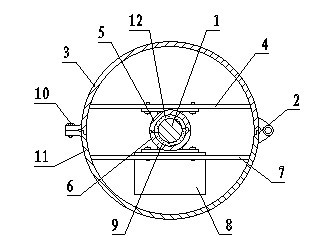

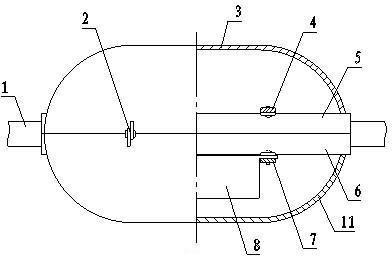

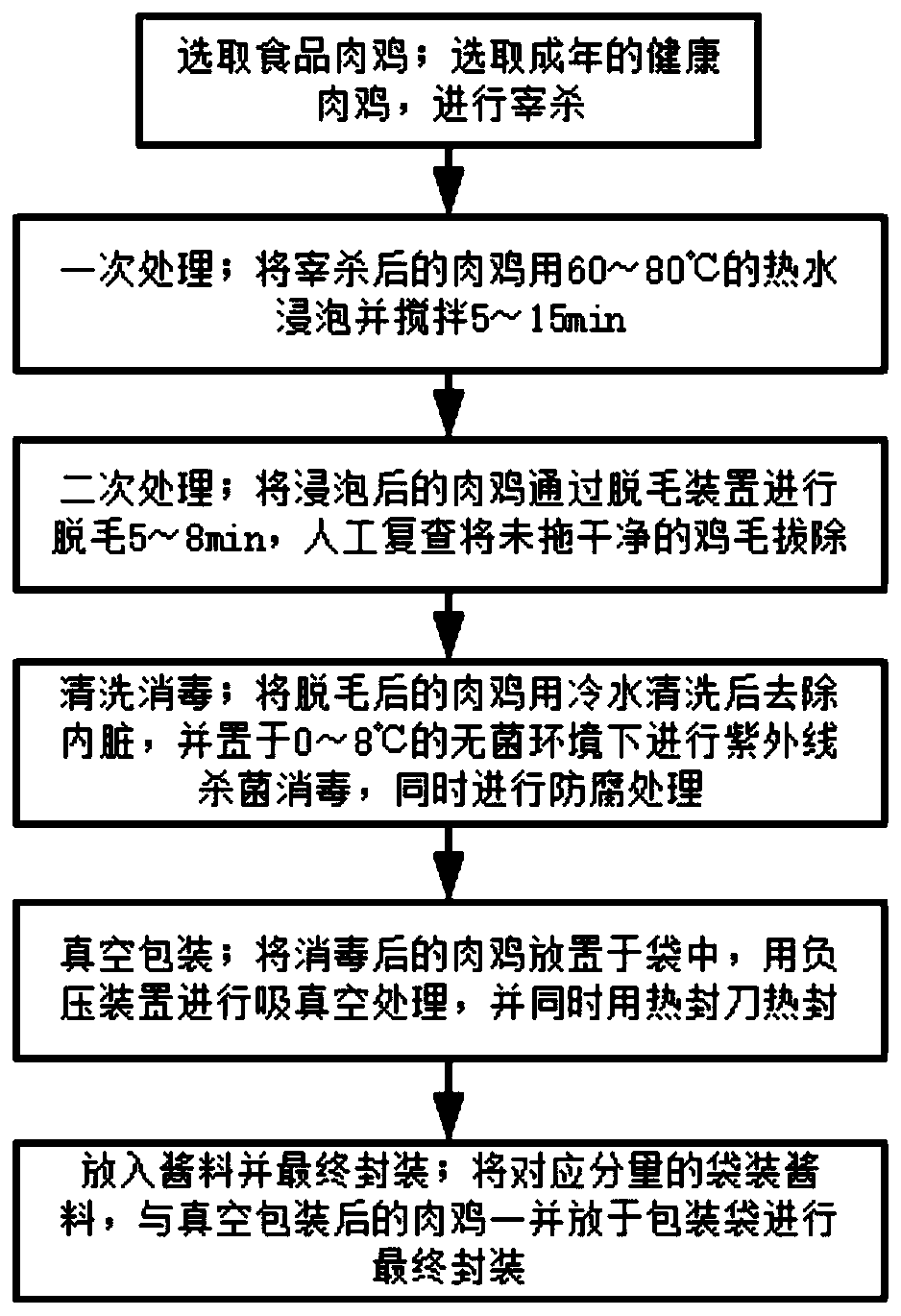

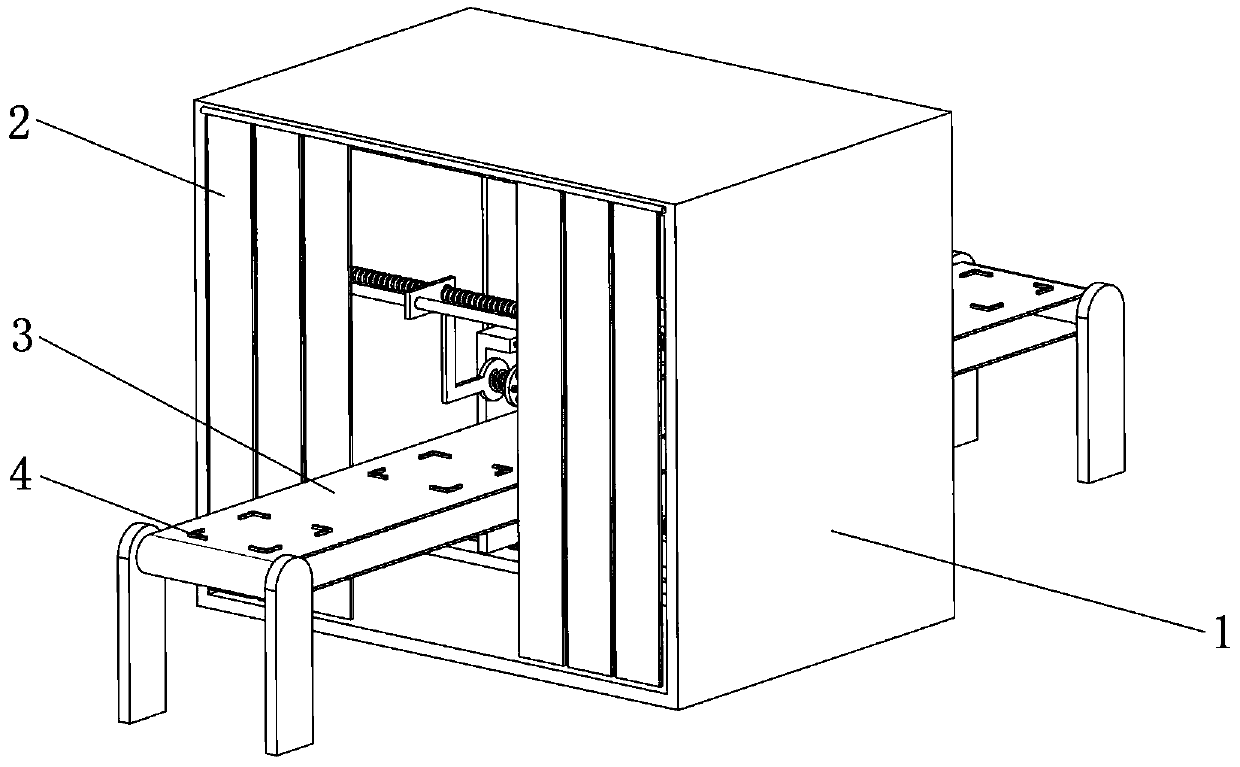

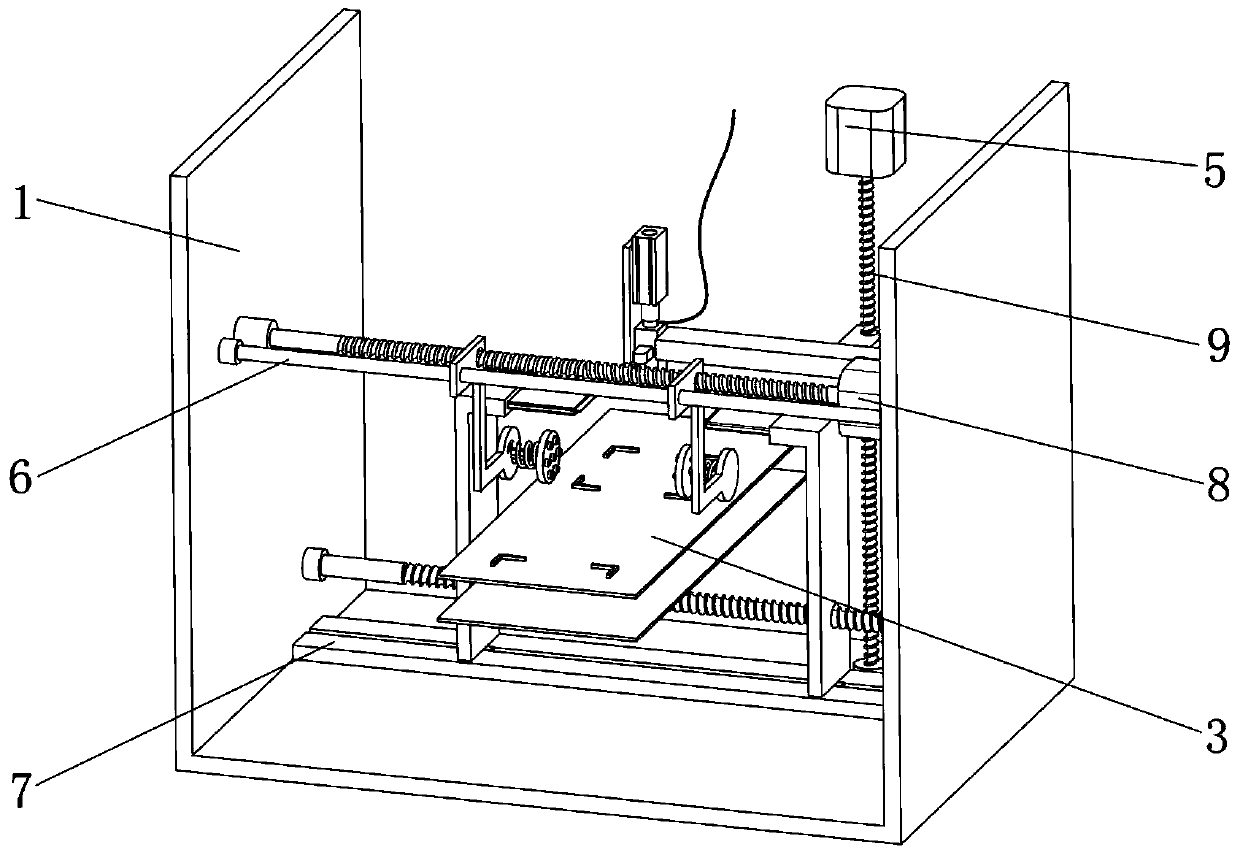

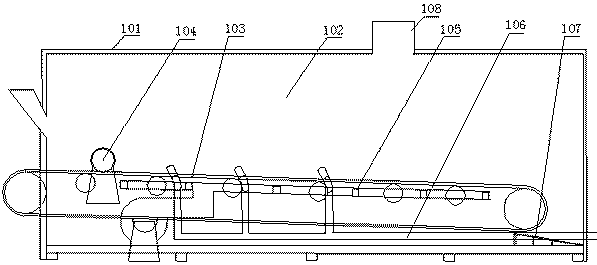

Processing technology and processing device for food broiler chickens

PendingCN111436479AMeet different needsConvenience for follow-up cooking workPoultry plucking mechanismsPackaging by pressurising/gasifyingProcess engineeringBroiler

The invention discloses a processing technology and a processing device for food broiler chickens, and relates to the technical field of food broiler chicken processing. In order to improve the convenience of cooking after purchasing, the processing technology comprises the following steps: selecting the food broiler chickens; selecting adult healthy broiler chickens, and slaughtering the selectedbroiler chickens; performing primary treatment; and soaking the slaughtered broiler chickens in hot water at 60-80 DEG C, and performing stirring for 5-15 minutes. The processing device comprises a packaging chamber, a conveying belt, an opening mechanism, a vacuum suction mechanism and a heat sealing mechanism, the vacuum suction mechanism comprises a vacuum suction motor, a vacuum suction threaded rod, a vacuum suction head and a vacuum suction air cylinder, the inner wall of one side of the packaging chamber is connected with a supporting column through a sliding block, and the inner wallof one side of the supporting column is connected with the outer wall of the vacuum suction threaded rod through threads. According to the method, by arranging the mode that a sauce is added and packaged together with the processed broiler chickens in a separated mode, different requirements of consumers can be met, meanwhile, convenience is provided for subsequent cooking work after purchasing, and time is saved.

Owner:江苏华斯达食品有限公司

Filtering structure of municipal drainage pipeline

ActiveCN110984337AAvoid submersionEffective drainageFatty/oily/floating substances removal devicesSewerage structuresSediment FilterStructural engineering

The invention provides a filtering structure of a municipal drainage pipeline. The filtering structure comprises a filtering pipe, a pipe cover and a drainage pipe, wherein an annular fixed block, a garbage filtering structure and a sediment filtering structure are arranged in the filtering pipe, the annular fixed block is fixed to the inner wall of the filtering pipe, the garbage filtering structure is arranged on the annular fixed block and comprises an inner cavity, a sand collection cavity and a sand collection groove, the sand collection cavity is formed in one side of the inner cavity and fixed to the filtering pipe, the side, close to the inner cavity, of the sand collection cavity is provided with an opening, and the sand collection groove is formed in the tops of the inner cavityand the sand collection cavity. The inner cavity runs through a first rotary shaft and a second rotary shaft, wherein the first rotary shaft is vertically arranged, the top end of the first rotary shaft is provided with a first blade arranged in the sand collection groove, the bottom end of the first rotary shaft is provided with a first bevel gear arranged in the inner cavity, one end of the second rotary shaft is provided with a second blade arranged outside the inner cavity, and the other end of the second rotary shaft is provided with a second bevel gear meshed with the first bevel gear. The pipe cover covers the top of the filtering pipe, the drainage pipe is installed at the bottom of the filtering pipe, sewage and garbage in rainwater are filtered out and cleaned away, and silt is also filtered out.

Owner:CHINA FIRST METALLURGICAL GROUP

Switch reducing dust entrance

InactiveCN105634749AAct as a primary filterEasy to disassembleData switching switchboardsRubber ringConductive paste

The invention belongs to the field of network maintenance equipment, and particularly relates to a switch reducing dust entrance. The switch is characterized in that a casing is provided with a radiating port, and a rubber ring is inserted into the radiating port; a mesh is fixed to the middle of the rubber ring; an air quantity adjusting plate is fixed to a connecting rod, and the air quantity adjusting plate is disposed at one side of the radiating port; a knob is arranged above the outside of the casing; the upper end of the connecting rod passes through the casing to be connected with the knob, and the lower end of the connecting rod is connected with a connecting rod rotating shaft; a PCB is mounted in the middle of the casing; a first radiating fin is mounted at the lower side of the PCB, and a first heat conductive paste layer is applied between the first radiating fin and the PCB; and a second radiating fin is mounted outside the casing, and a second heat conductive paste layer is applied between the second radiating fin and the casing. The invention provides a switch reducing dust entrance.

Owner:XINYU XUNCHI INFORMATION TECH TIANJIN

Cooling method of a direct reduction vertical furnace

InactiveCN103088182AReduce the amount of entryReduce the amount of waterShaft furnaceMetallurgyEnergy consumption

The invention relates to a cooling method of a direct reduction vertical furnace which is characterized in that cooling gas is divided into two parts, and the two parts enter a cooling section; one part of the cooling gas enters the vertical furnace from the upper part of the cooling section; the part of cooling gas is heated by hot sponge iron when cooling the sponge iron, and participates in a reduction reaction in a reduction section; the other part of the cooling gas enters the vertical furnace from the lower part of the cooling section, and further cools the sponge iron; the part of cooling gas is led out through a cooling gas outlet pipe arranged in the middle part of the cooling section. According to the invention, cooling gas is divided into two parts, and two-stage cooling is adopted, such that high-temperature section sponge iron energy is fully utilized, circulation cooling gas is reduced, tuyere-section reduction coal gas inlet amount is reduced, reduction coal gas needed to be heated is reduced, cooling gas outlet temperature is reduced, cooling gas washing water amount is reduced, gas amount for pressurization and dehumidification is reduced, energy consumption during the production process is reduced, and energy is saved.

Owner:CISDI ENG CO LTD +1

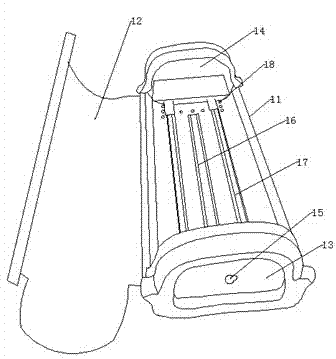

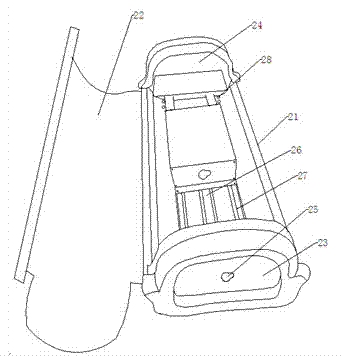

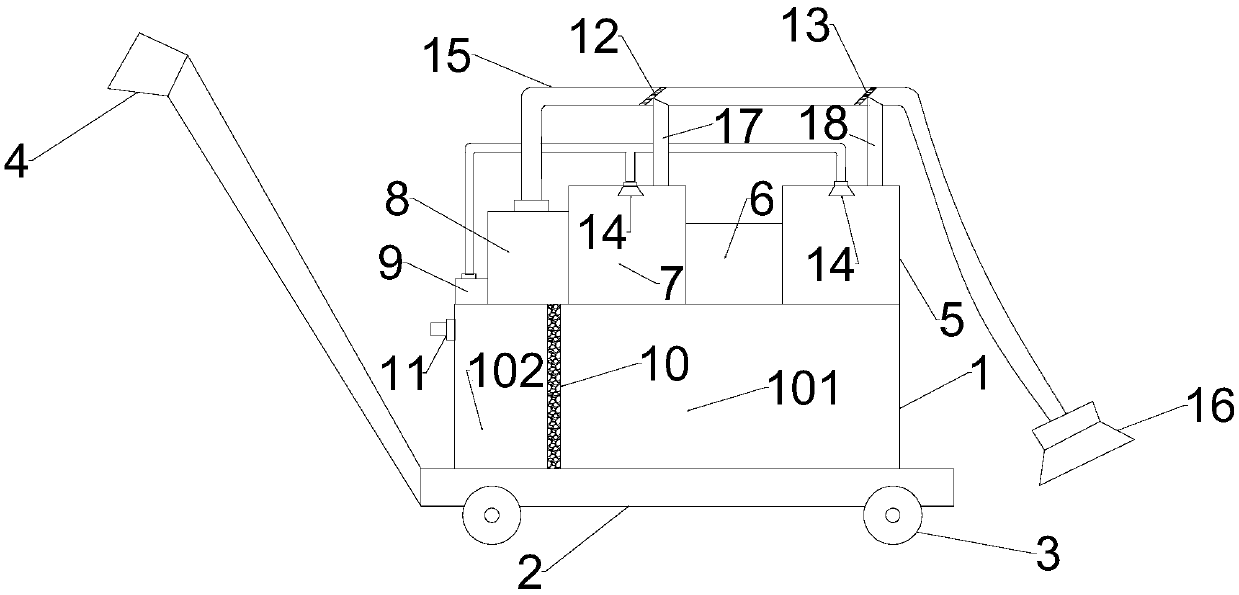

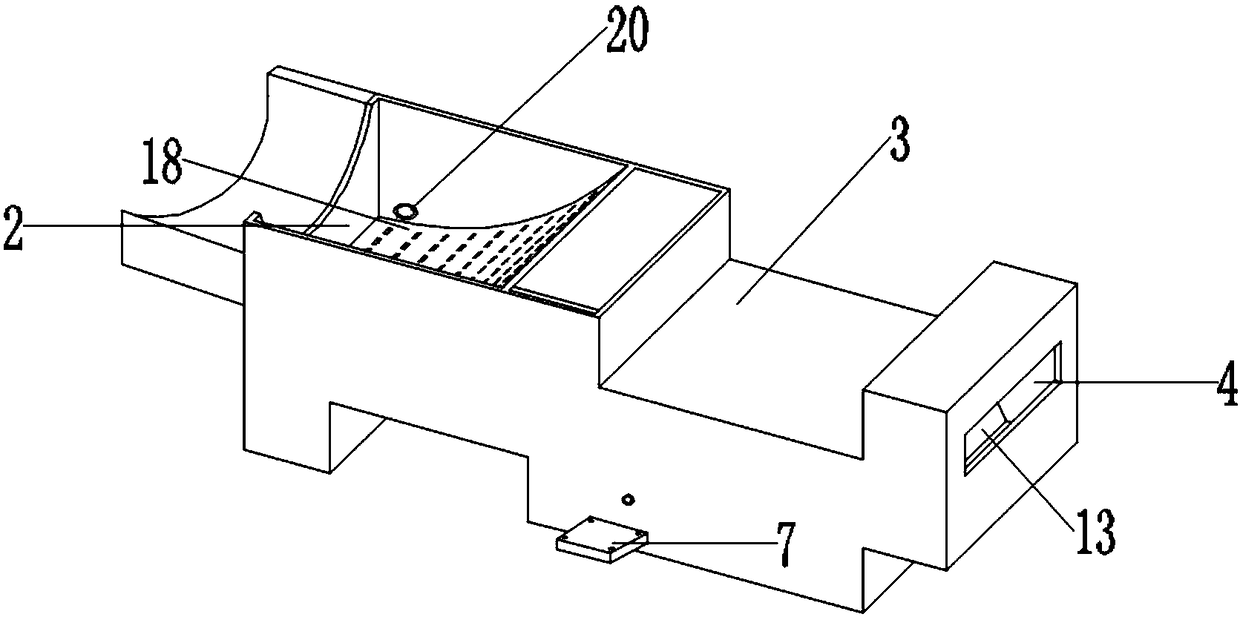

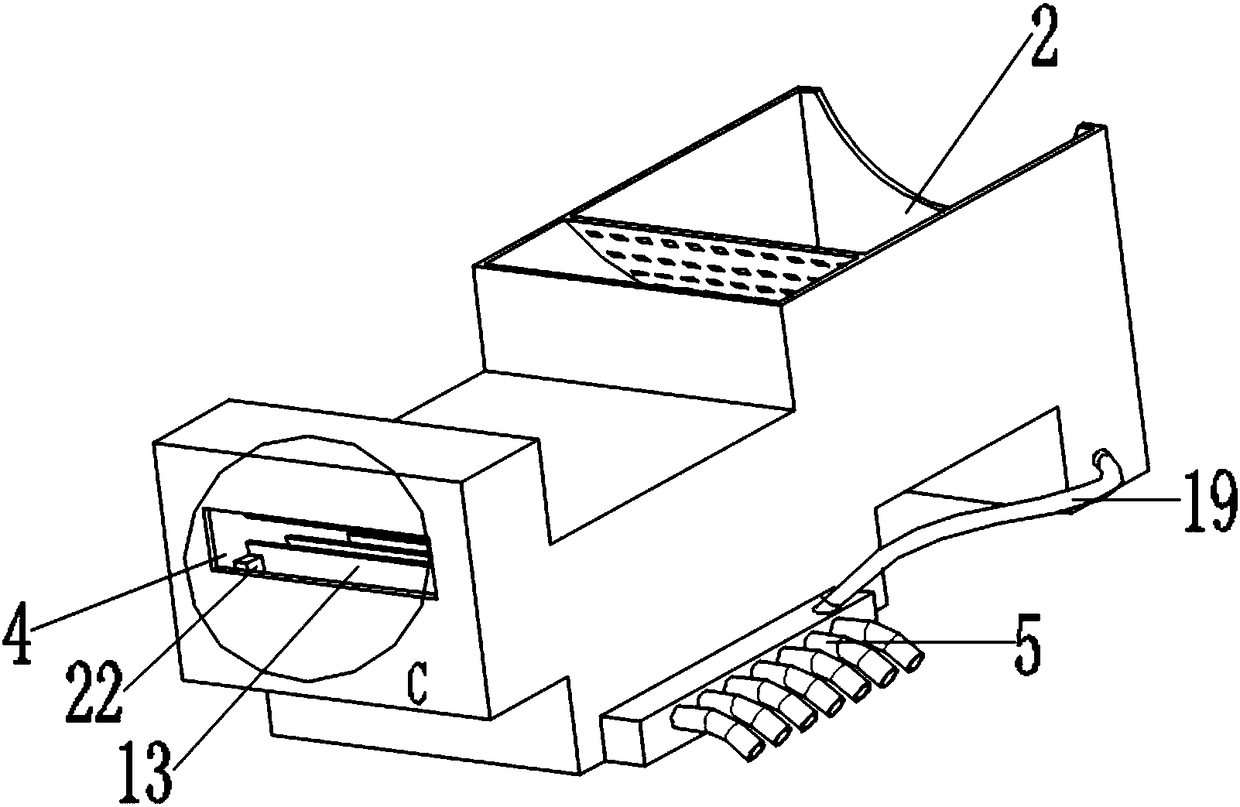

Ping-pong ball collection device with washing function

The invention discloses a ping-pong ball collection device with a washing function. The device comprises a base, a water collection box is arranged on the top of the base, a micro water pump, an air suction device, a second collection box, a driving device and a first collection box which are communicated with the water collection box are sequentially arranged on the top of the water collection box, a first air suction pipe is connected with an air inlet of the air suction device, a ball suction device is connected with an end of the air suction pipe, a first baffle and a second baffle are sequentially arranged in the air inlet direction in the air suction pipe, a first ball inlet pipe is arranged in the first collection box, a second ball inlet pipe is arranged in the second ball collection box, nozzles are arranged on the tops of the first and second collection boxes, and bottom plates are arranged at the bottoms of the first and second collection boxes. The ping-pong ball collectiondevice has the advantages of being excellent in mobility, and capable of meeting a demand of ball collection in school teaching and saving a large number of resources.

Owner:大竹县第十小学

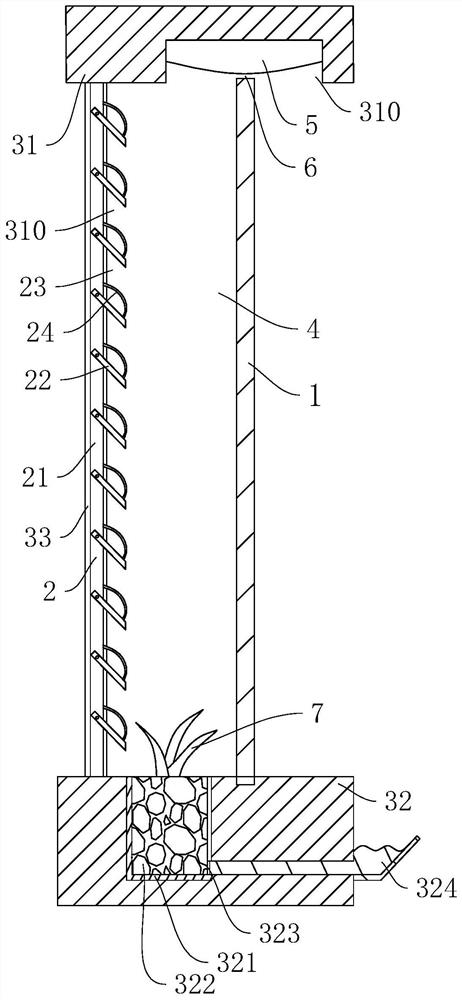

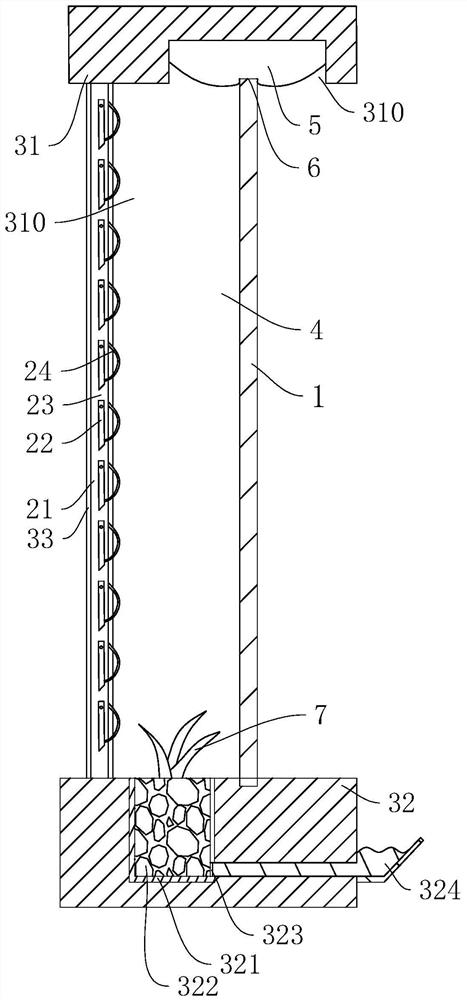

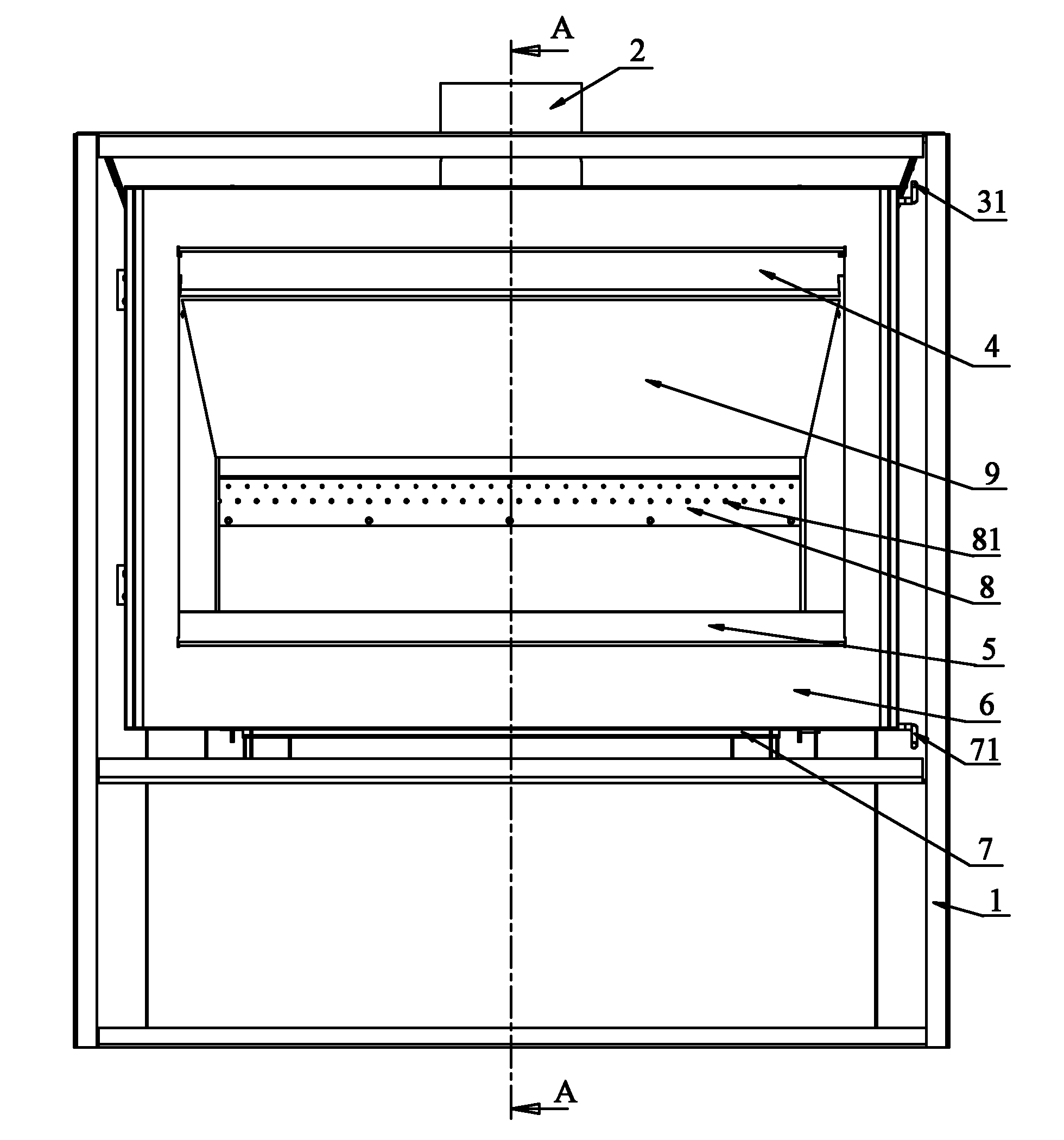

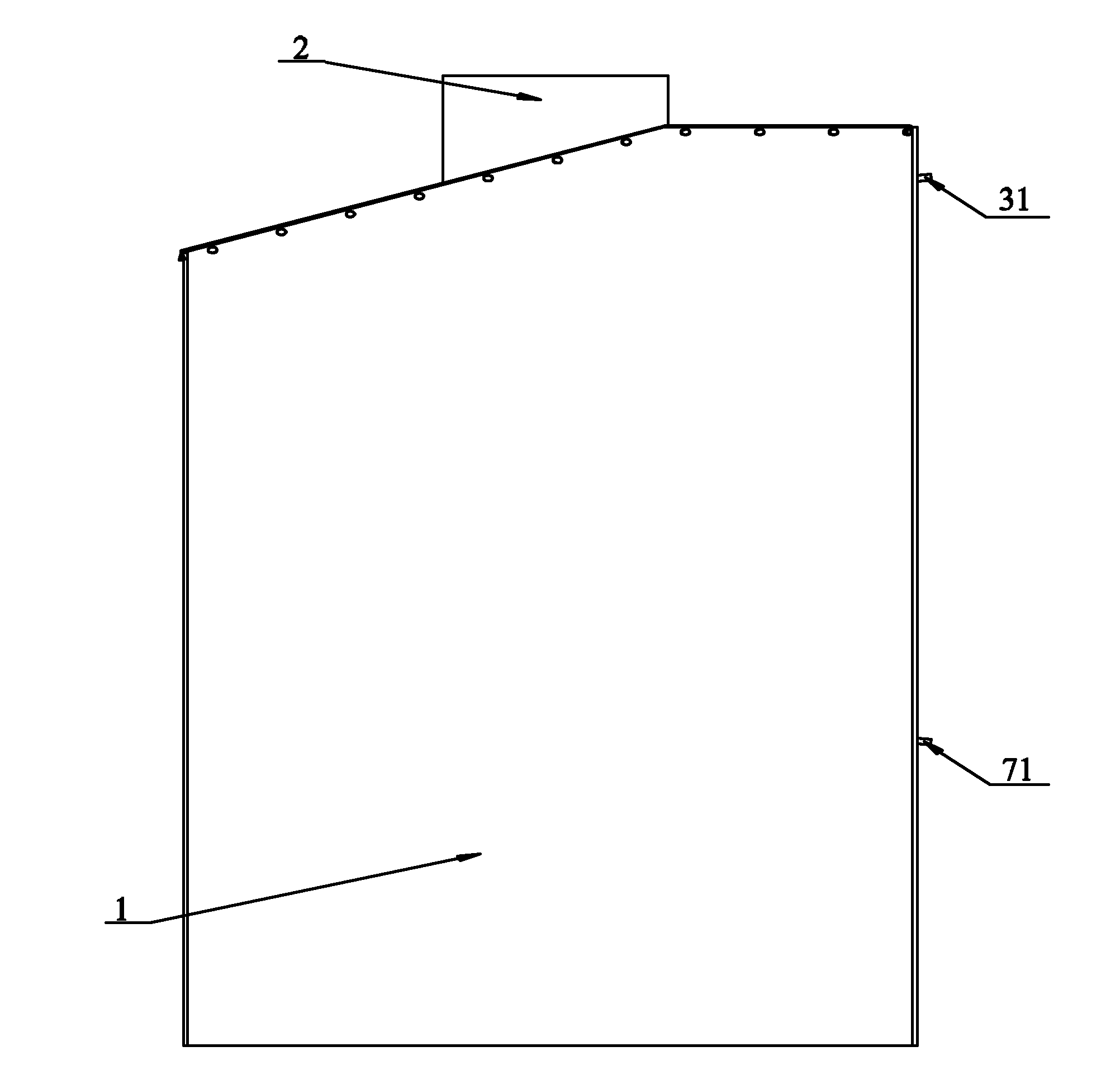

Ventilation type double-layer curtain wall system

InactiveCN112696747AIncrease temperatureReduce widthWallsLighting and heating apparatusIndoor air qualityEngineering

The invention relates to a ventilation type double-layer curtain wall system. The ventilation type double-layer curtain wall system comprises a light-transmitting outer wall, a ventilation inner wall and a heat transfer frame, the ventilation inner wall and the light-transmitting outer wall are oppositely installed in the heat transfer frame, the ventilation inner wall, the light-transmitting outer wall and the heat transfer frame are matched to form a containing cavity, and a communicating groove is formed in the position, connected with the light-transmitting outer wall, of the top of the heat transfer frame. The communicating groove communicates with the containing cavity and the outside, an elastic air bag is arranged at the groove bottom of the communicating groove, a communicating air gap is formed between the elastic air bag and the light-transmitting outer wall, the elastic air bag absorbs heat to expand and blocks the communicating air gap, the elastic air bag releases heat to contract and opens the communicating air gap, and green plants are planted in the containing cavity. A controllable air gap communicating the containing cavity with the indoor space is formed in the ventilation inner wall, and the width of the controllable air gap is in negative correlation with the temperature of the ventilation inner wall. The indoor and outdoor air exchange rate is regulated and controlled according to the environmental influence, and the indoor air quality is guaranteed.

Owner:SHENZHEN YIJINGSHENG DECORATION ENG

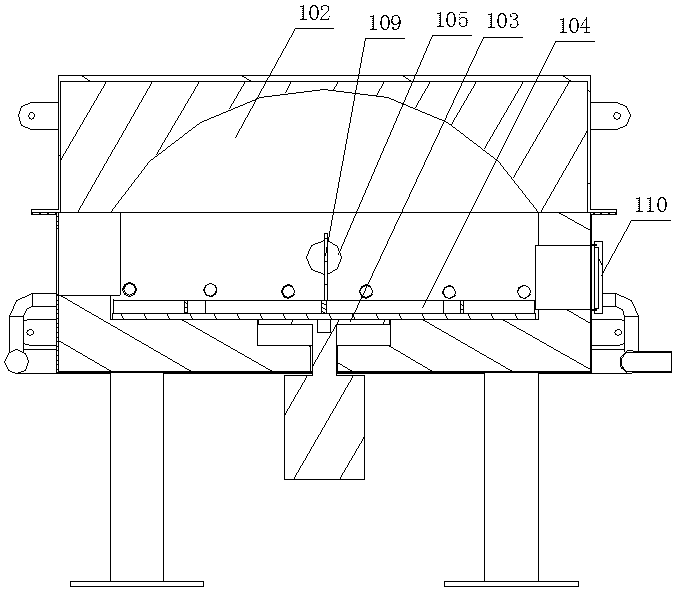

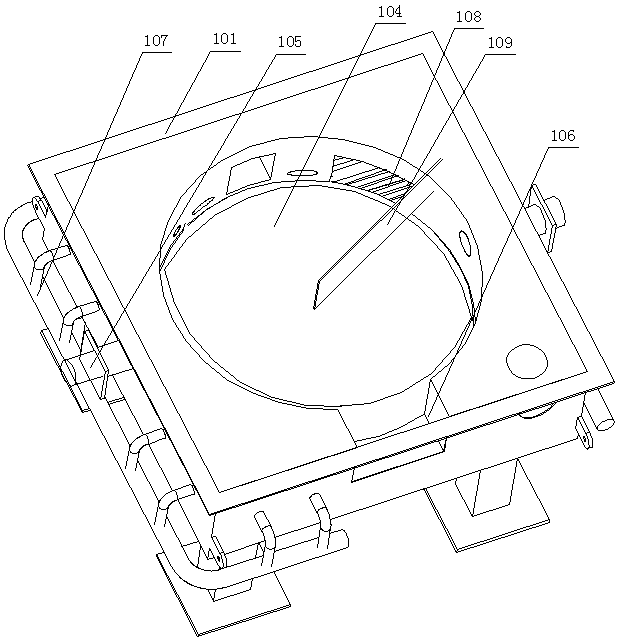

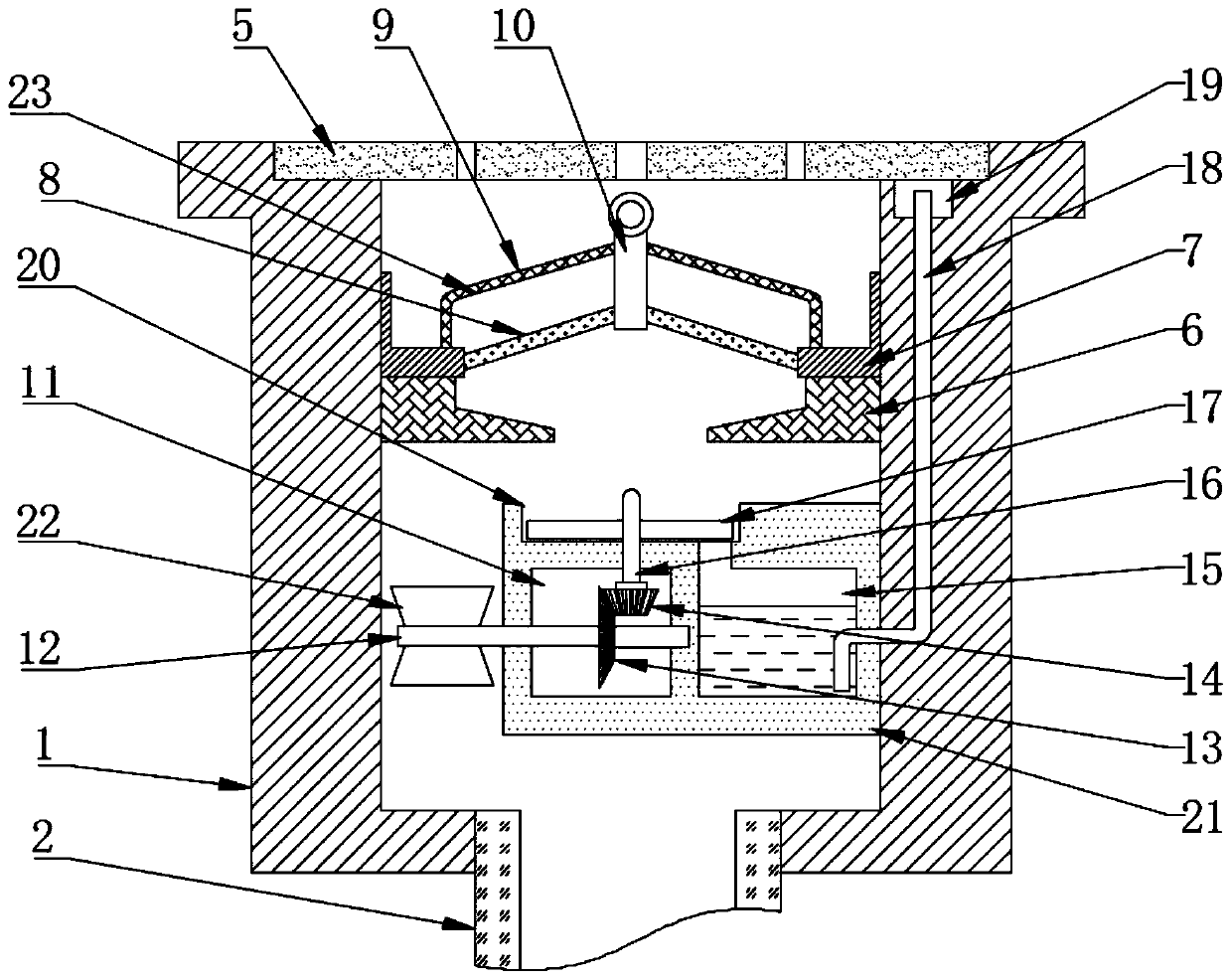

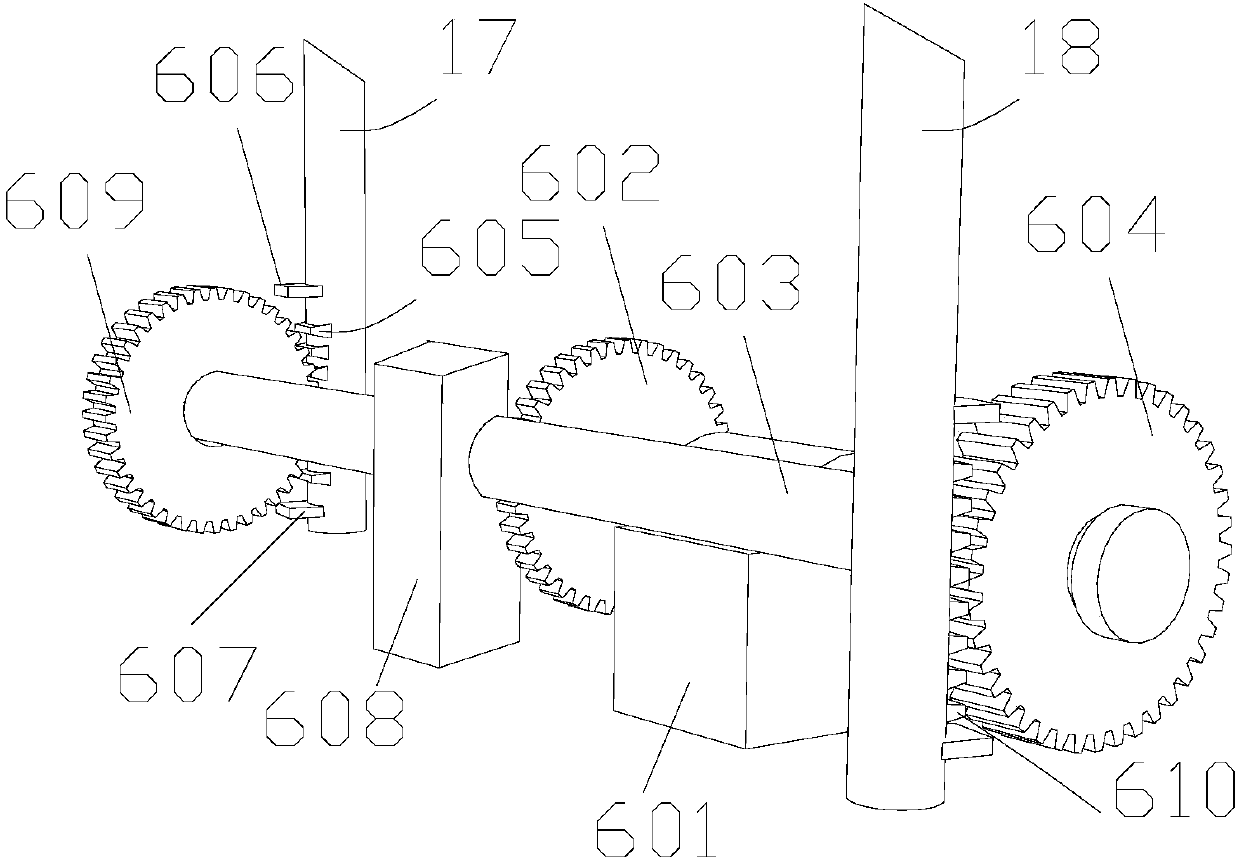

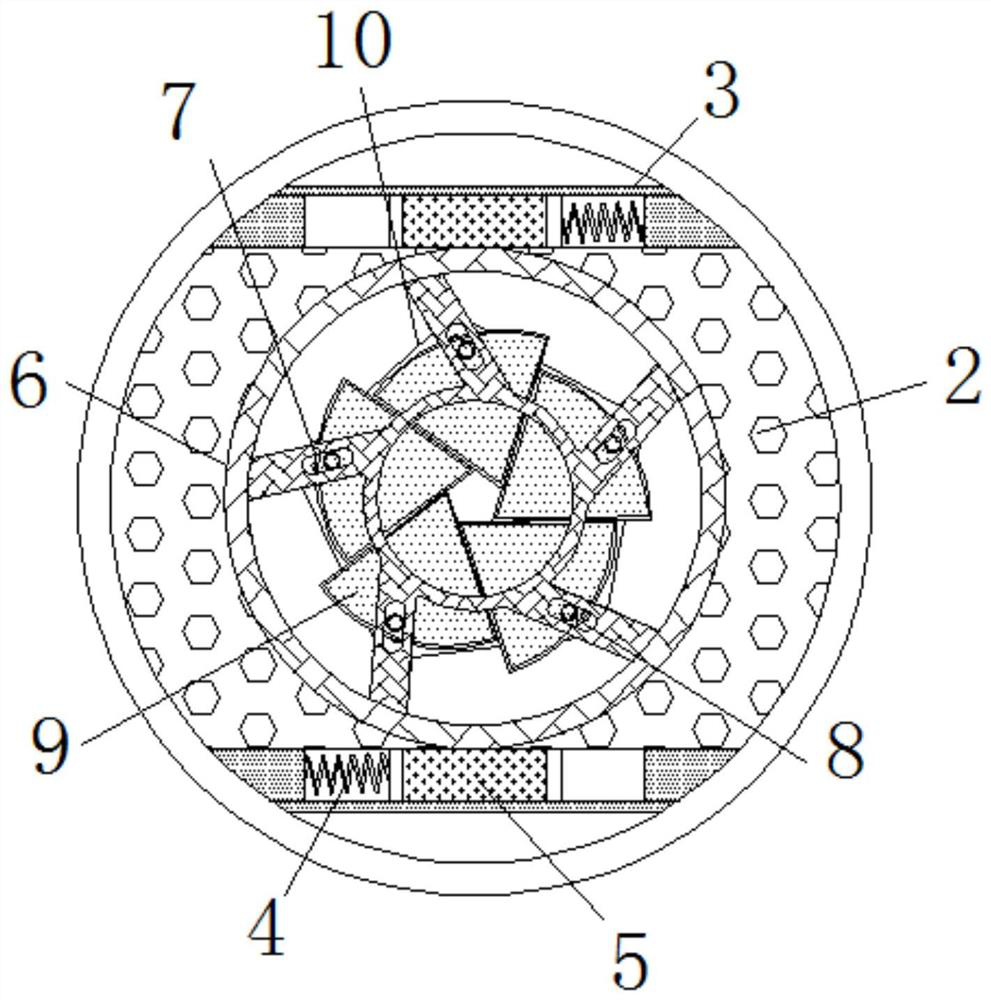

Vertical shaft type sand making device capable of fully crushing raw materials

InactiveCN112246350AIncrease pressureReduce the amount of entryGrain treatmentsCentrifuge rotorEngineering

The invention relates to the technical field of gravel preparation, and provides a vertical shaft type sand making device capable of fully crushing raw materials. The vertical shaft type sand making device comprises a body, an inner wall of the body is movably connected with a feeding rotating disc, an inner wall of the feeding rotating disc is provided with a track, and an inner wall of the trackis elastically connected with a spring. According to the vertical shaft type sand making device capable of fully crushing the raw materials, when the feeding speed is higher than the discharging speed, the raw materials in the sand making machine are continuously accumulated, the pressure borne by the sand making machine is increased, the rotating speed of a centrifugal rotor is reduced, the centrifugal force borne by the raw materials is reduced, and the phenomenon of incomplete crushing occurs; and at the moment, the rotating speed of the centrifugal rotor is reduced, the centrifugal forceborne by a rack block in the feeding rotating disc is reduced, the rack block moves under the tension of the spring, the rack block drives a conversion wheel to enable a baffle to rotate and move, a feeding inlet is reduced, the feeding amount of the raw materials in unit time is reduced, incomplete crushing and machine damage are caused, the size of the feeding inlet is changed through the changeof the centrifugal force, and the raw materials are completely crushed.

Owner:怀化明达建材有限公司

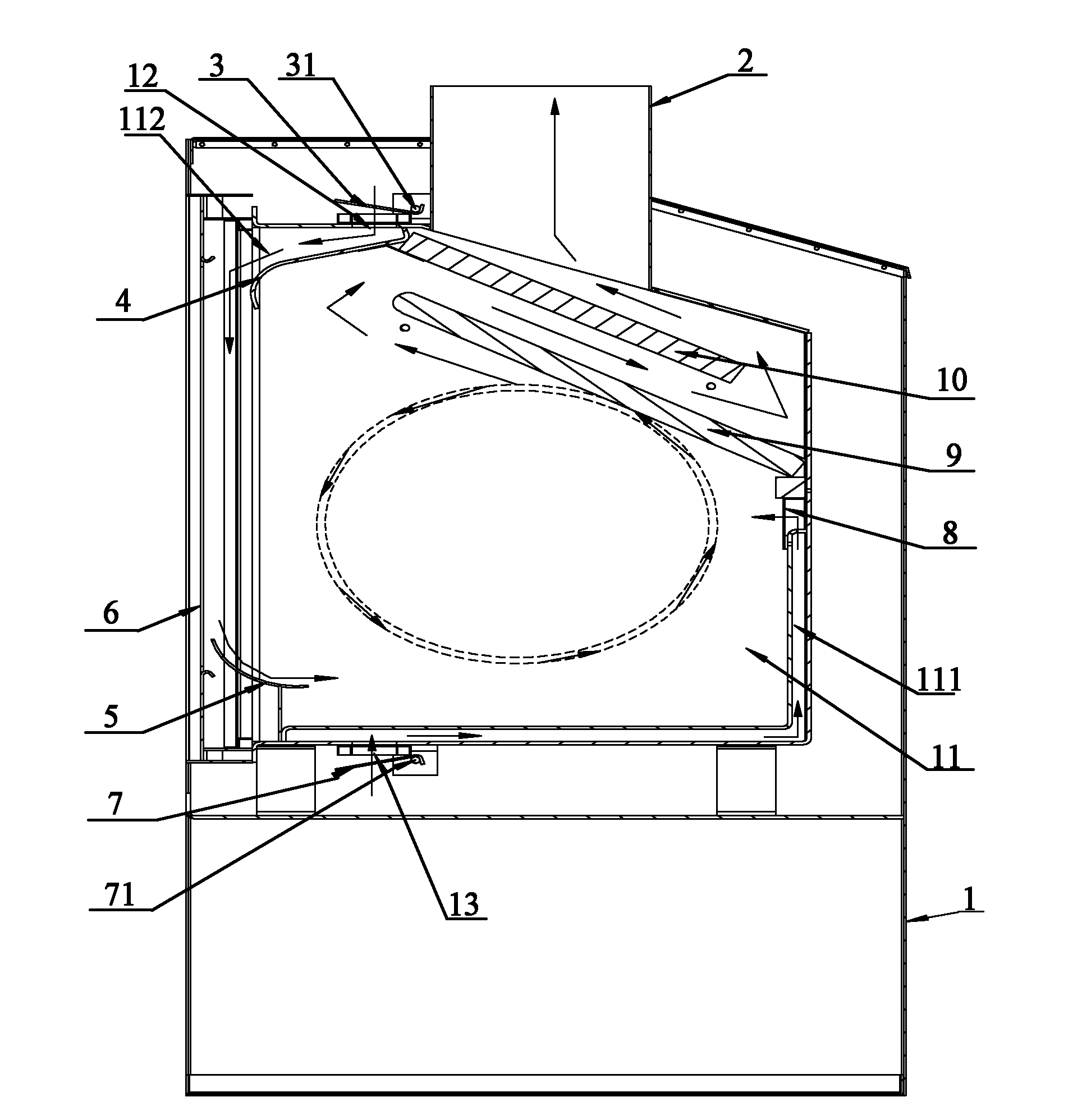

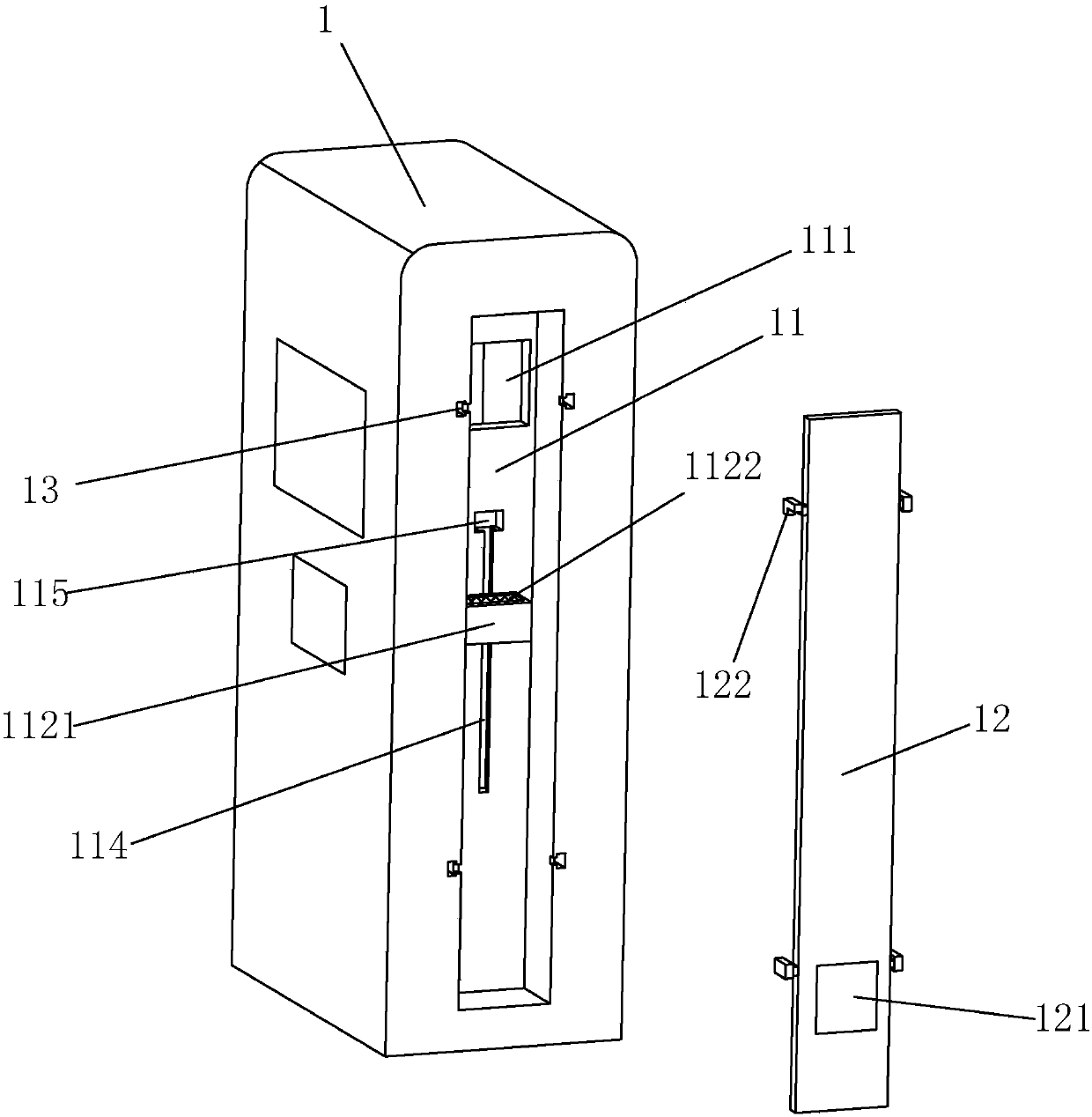

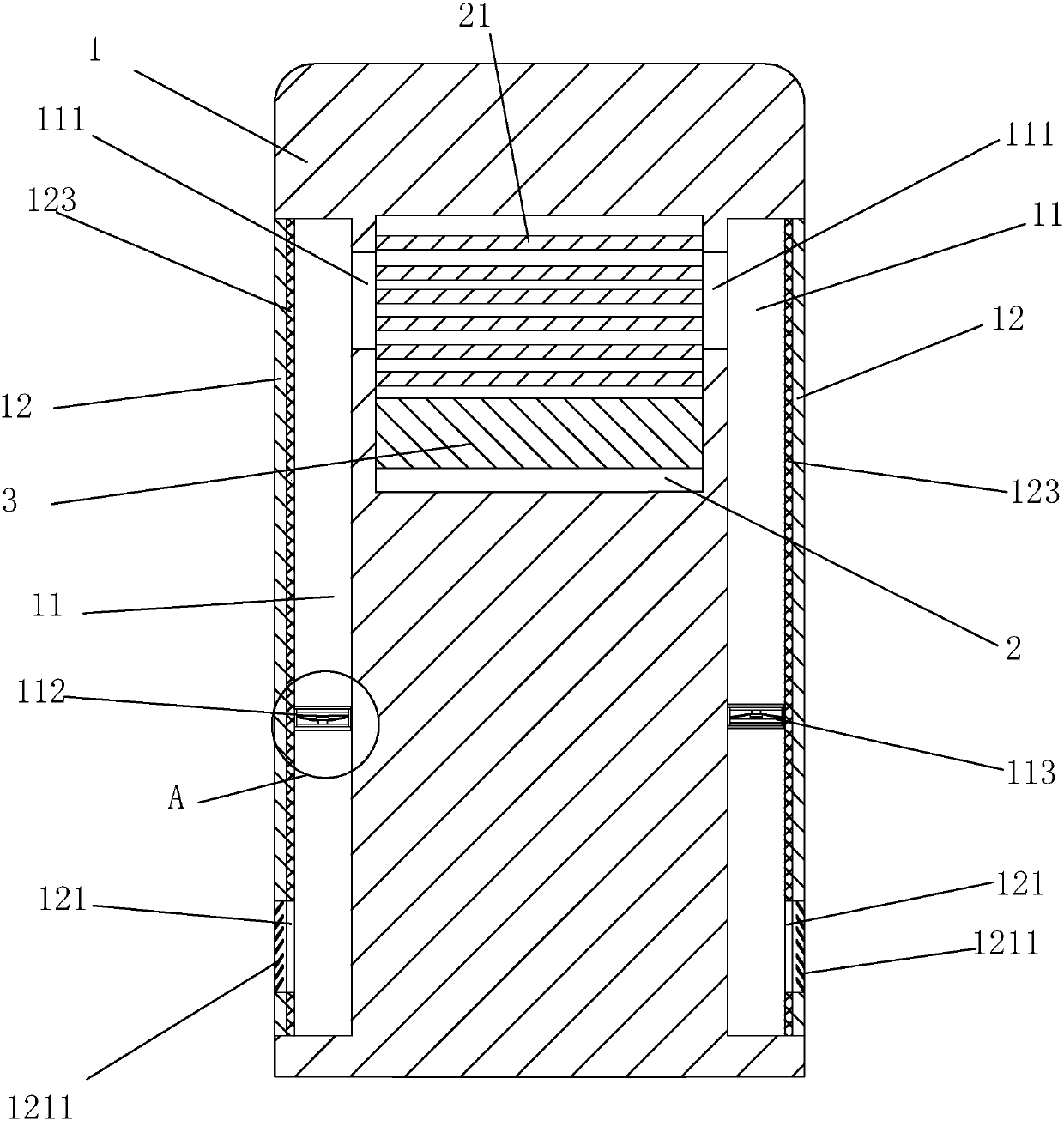

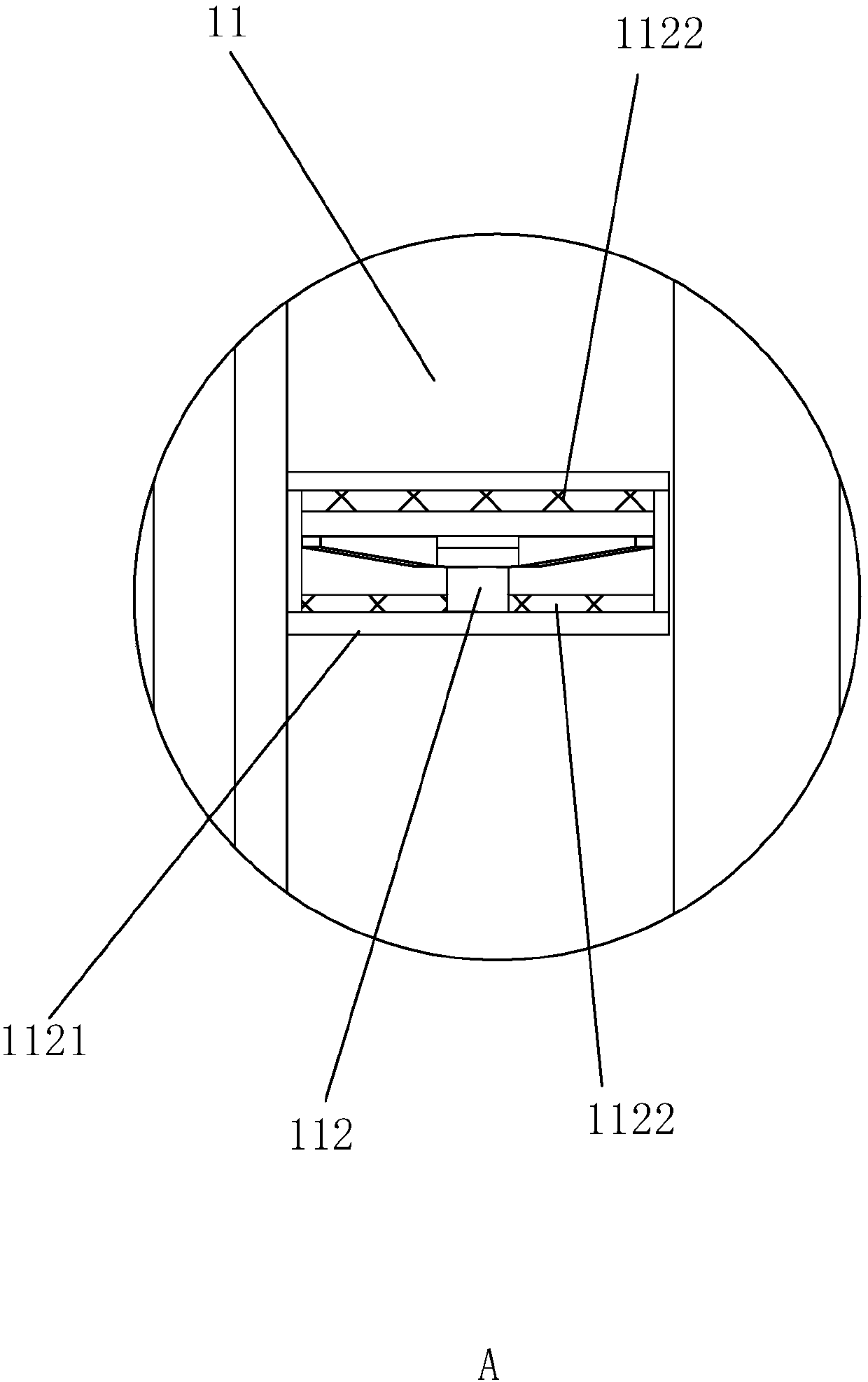

Fireplace

InactiveCN102116502AImprove the perturbation effectBurn fullyEnergy efficient heating/coolingSpace heating and ventilation detailsFirewoodHearth

The embodiment of the invention discloses a fireplace which comprises a hearth, an upper deflector, a lower deflector and a second air inlet passageway, wherein the upper deflector is arranged at the top of the hearth; a lower air inlet is arranged at the bottom of the hearth; the upper deflector is arranged at the front end of the top of the hearth and forms a first air inlet passageway together with a door of the fireplace; the first air inlet passageway is communicated with an air inlet; an outlet end of the first air inlet passageway faces towards the bottom end of the hearth; the lower deflector is arranged on the bottom end of the hearth and is a concave plate; the concave surface of the lower deflector faces towards the back wall of the hearth; the second air inlet passageway is arranged on the back wall of the hearth and is communicated with the lower air inlet; and an air inlet hole communicated with the second air inlet passageway is arranged in the back wall of the hearth. Air flow entering the fireplace through the first air inlet passageway and the second air inlet passageway forms an annular air flow in the hearth; as an inlet air flow entering the hearth has very large disturbance, the inlet air flow is sent to each corner in the hearth, and dead angles of air supply are avoided, therefore, firewood is burnt more sufficiently in the working process of the fireplace.

Owner:朱宏锋 +1

Heat dissipation system of automobile charging pile

PendingCN107708386AImprove cooling effectEasy maintenanceCharging stationsModifications for power electronicsComputer engineeringComputer module

The invention discloses a heat dissipation system of an automobile charging pile. The heat dissipation system comprises a charging pile body, a mounting cavity and a battery module positioned in the charging pile body; the heat dissipation system is characterized in that heat dissipation fins are arranged, above the power supply module, in the mounting cavity; heat dissipation channels are formedin the two side walls of the charging pile body in a concave manner in the length direction; two ventilating holes, connected with the mounting cavity and formed in the two sides of the heat dissipation fins, run through the bottom walls of the heat dissipation channels; two cover plates for covering the heat dissipation channels are arranged on the two sides of the charging pile body; heat exchange holes run through the space below the cover plates; and an upward suction fan and a downward exhaust fan are arranged, above the heat exchange holes, in the two heat dissipation channels. The heatdissipation system is characterized in that rotation of the suction fan and the exhaust fan drives the external air to flow through the heat dissipation channels, so that a quick heat dissipation effect on the power supply module in the mounting cavity is realized.

Owner:SUZHOU JURUI MECHANICAL & ELECTRICAL TECHCO LTD

Garbage treatment system

InactiveCN106568087AEasy to handleEmission reductionIndirect carbon-dioxide mitigationIncinerator apparatusCombustionWastewater

The invention discloses a garbage treatment system. The garbage treatment system comprises a garbage sorting device, a garbage crushing device, a garbage combustion device and a garbage biogas fermentation device; the garbage sorting device divides garbage into solids capable of directly embedding and incapable of burning, solids capable of directly burning and organic matters incapable of directly burning; the solids capable of directly embedding and incapable of burning are crushed by the garbage crushing device for backfilling; the solids capable of directly burning are sent to the garbage combustion device for burning; the organic matters incapable of directly burning are treated by the garbage biogas fermentation device to generate biogas as a fuel; generated biogas residues are pressed, filtered and dried as organic fertilizers; and at least one part of generated waste water is sent to the garbage combustion device for burning. The garbage treatment system classifies the garbage, facilitates quick and effective treatment of the garbage, and recycles useful resources.

Owner:HENAN RUIXIN MACHINERY MFG CO LTD

Method of purifying aluminium alloy melt

A process for cleaning the molten Al-alloy by removing hydrogen features that the inertial gas is sprayed onto top surface of molten Al-alloy contained in a degassing case via rotating nozzle while onto the bottom of the molten Al-alloy via the air-permeable bricks on the bottom of the degassing case.

Owner:江西金达通新材料科技有限公司

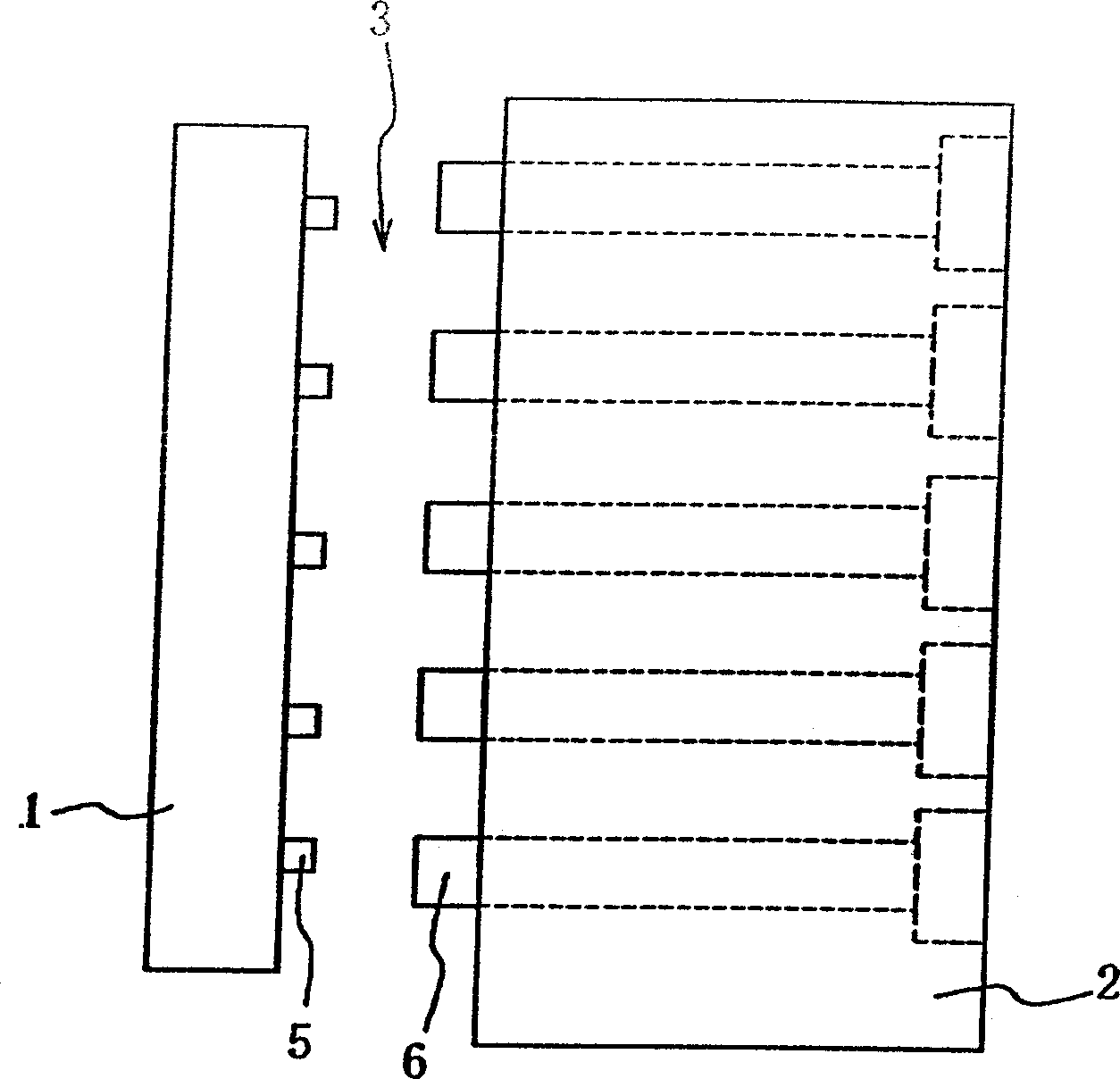

Shaping mould device

InactiveCN1504316AImprove flatnessIncreased durabilityTelephone set constructionsSurface finishMaterials science

Provided is a mold assembly which improves the surface finish properties and durability of a molded object and can be manufactured simply at a low cost. This mold assembly is used for manufacturing a molded object with an opening by clamping a cavity-side part 1 and a core 2 and injecting a molten resin into the cavity 3 formed between the cavity-side part 1 and the core 2. In this mold assembly, projected parts 5 and 6, which are projected into the cavity 3 to collide with each other in the clamped state of the cavity-side part 1 and the core 2, are provided to the respective parts of the cavity-side part 1 and the core 2 for molding the opening and at least the opposed end areas of the paired projected parts 5 and 6 are differentiated.

Owner:FUJISU I NETWORK SYST

Flue gas utilization system, flue gas utilization process and high-temperature combustion treatment system

PendingCN111692877AReduce the amount of entryAvoid fireCarbon compoundsRotary drum furnacesCombustion chamberCarbonization

The invention relates to a flue gas utilization system, a flue gas utilization process and a high-temperature combustion treatment system. The flue gas utilization system is applied to the high-temperature combustion treatment system, the high-temperature combustion treatment system comprises a combustion chamber and a rotary kiln, wherein the combustion chamber is provided with a natural gas burner and an air distribution device. The flue gas utilization system comprises a flue gas settling device, a discharge flue, a high-temperature induced draft fan, an outlet flue, a return flue and a return fan, wherein the return flue communicates with the flue gas settling device, and the return fan arranged on the combustion chamber introduces part of flue gas in the flue gas settling device intothe combustion chamber of the high-temperature combustion treatment system from the return flue to combust combustible volatiles in the flue gas so as to generate heat. The flue gas utilization systemcan effectively solve the problems that an existing rotary kiln is high in energy consumption, a combustion chamber needs to be continuously provided a heat source, flue gas in an incineration chamber is insufficient in combustion, flue gas is not effectively utilized, and flue gas enters the combustion chamber and is difficult to ignite, and can be applied to the carbonization process of activated carbon to produce activated carbon.

Owner:INNER MONGOLIA PURUIFEN ENVIRONMENTAL SCI ANDTECH

Inclined plate sedimentation tank with bottom cavity sludge scraping function

ActiveCN108525393AReasonable structureImprove functionalityFiltration circuitsSedimentation settling tanksWire brushEngineering

The invention provides an inclined plate sedimentation tank with bottom cavity sludge scraping function. The inclined plate sedimentation tank comprises a support plate, a hydraulic cylinder, a left guiding rod, a guiding groove, a water filter plate, a guiding tube, a plug, a rubber bag, a sludge cleaning plate, a sludge cleaning tank and a rubber pad, wherein the left side of a coarse filter chamber is connected with a semi-arc-shaped water inlet pipe opening, and the streamlined water filter plate with a filter hole structure is welded in the coarse filter chamber; a sludge scraping plate unique to the structure is installed on the bottom surface of a sedimentation chamber, and a row of brush and a scraper plate are installed at the front and the rear of the lower end of the sludge scraping plate, respectively. The bottom surface of the sedimentation chamber is first hardly cleaned by the scraper plate, and then the steel wire brush is used for fine cleaning; with the inclined chamber bottom structure, residual sludge at the bottom of the chamber is regularly cleaned up together, so as to prevent a large amount of residual sludge from forming at the bottom of the sedimentation chamber after long-term use; the structure is more reasonable.

Owner:HENAN ZEHENG ENVIRONMENTAL PROTECTION TECH CO LTD

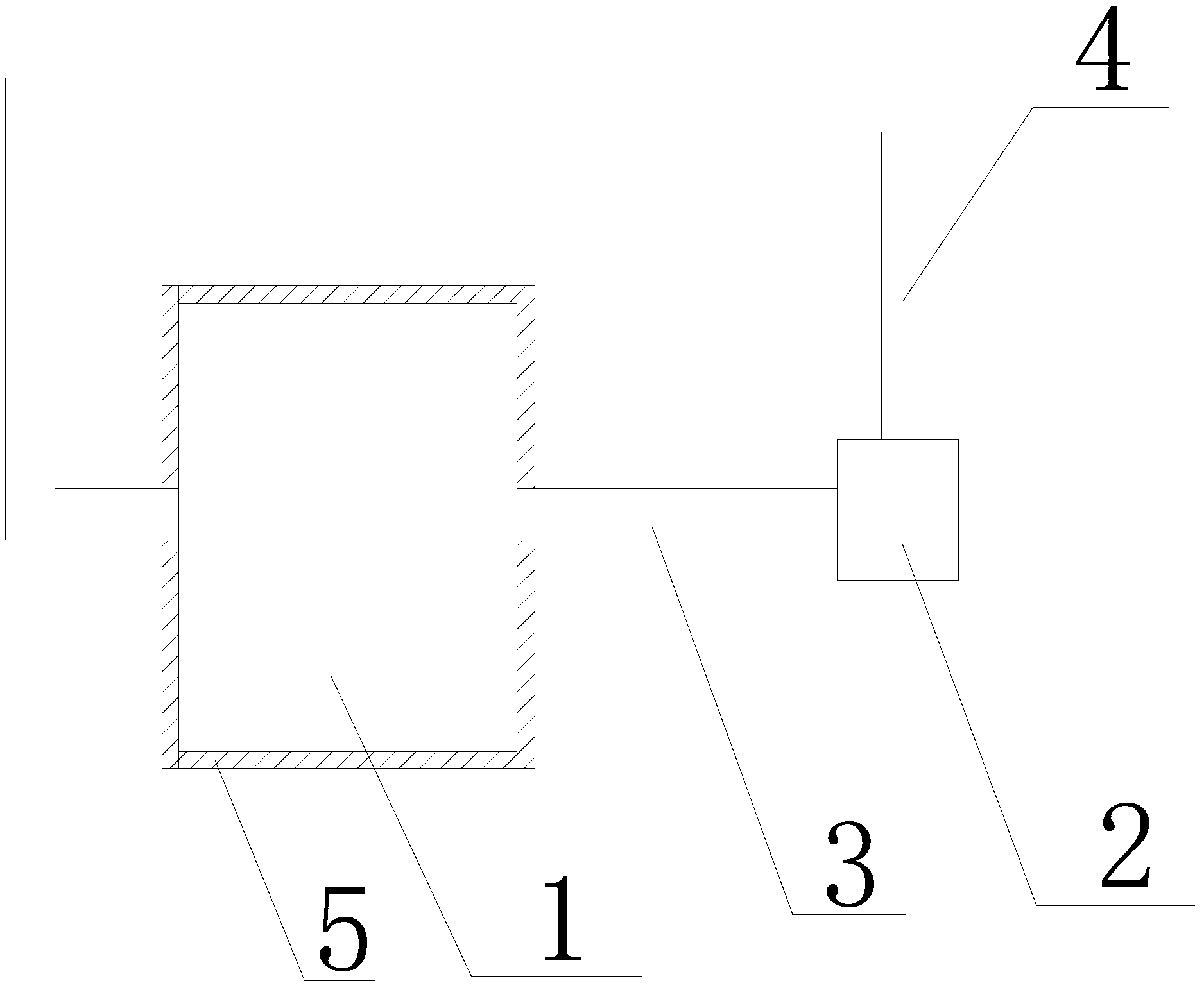

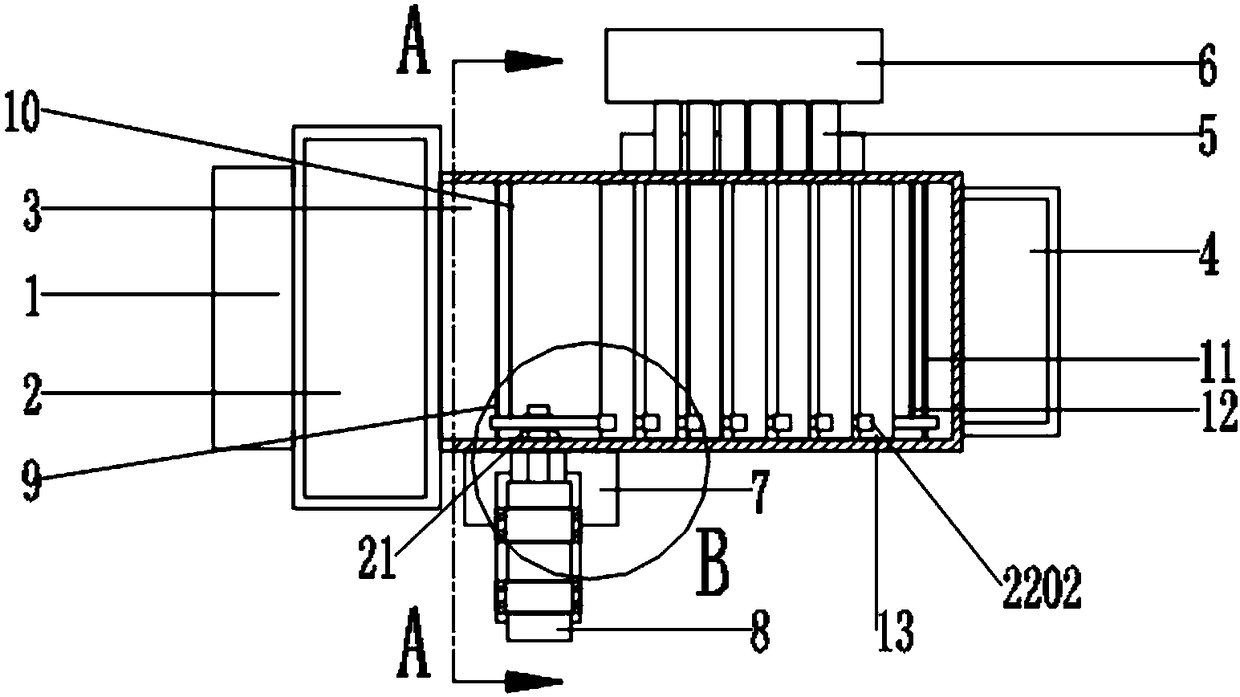

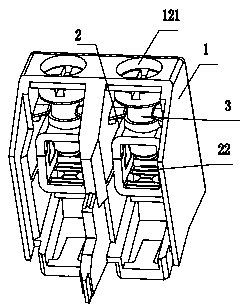

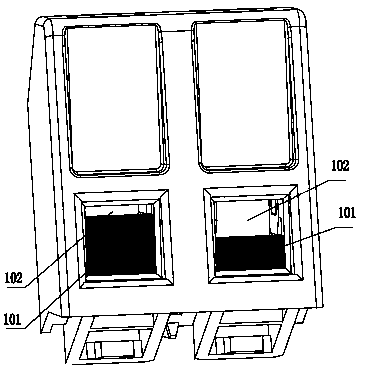

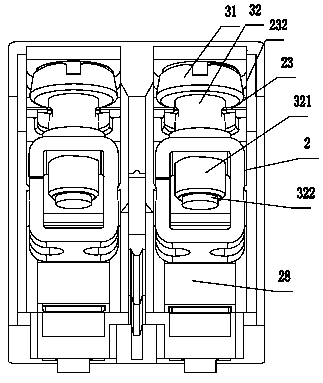

Wiring module for low-voltage electrical appliance and contactor

The invention provides a wiring module for a low-voltage electrical appliance and a contactor. The problem that most wire inlet slots of a low-voltage electrical appliance on the market are not blocked and dust easily enters a casing is solved. The wiring module is characterized in that a liftable wiring frame (2) is arranged in the seat body, a crimping groove (22) for crimping a wire is arrangedin the wiring frame, one side of the seat body is provided with a wire inlet slot (10) which is used for inserting the wire and communicates with the crimping groove, one side of the wiring frame isprovided with a baffle plate (28) which rises and falls with the wiring frame, and the baffle plate is used for partially blocking the wire inlet slot when the wire is connected to the wiring frame. The invention provides the wiring module for the low-voltage electrical appliance and the contactor, the baffle plate partially blocks the wire inlet slot when the wire is connected to the wiring frame, and the amount of entering dust is reduced.

Owner:ZHEJIANG TENGEN ELECTRIC

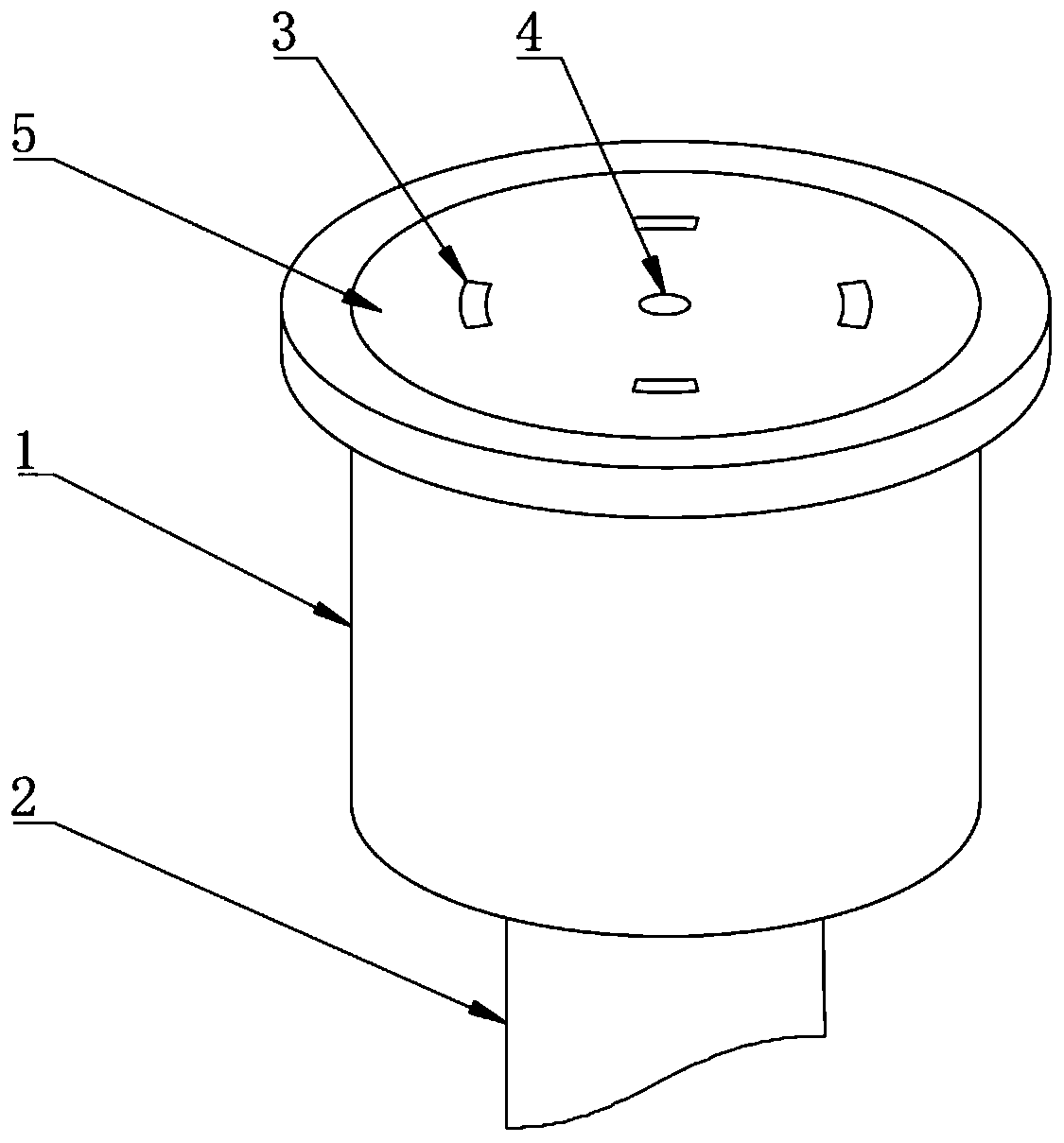

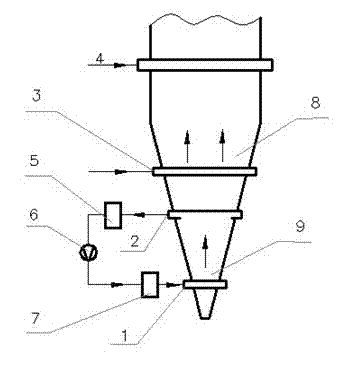

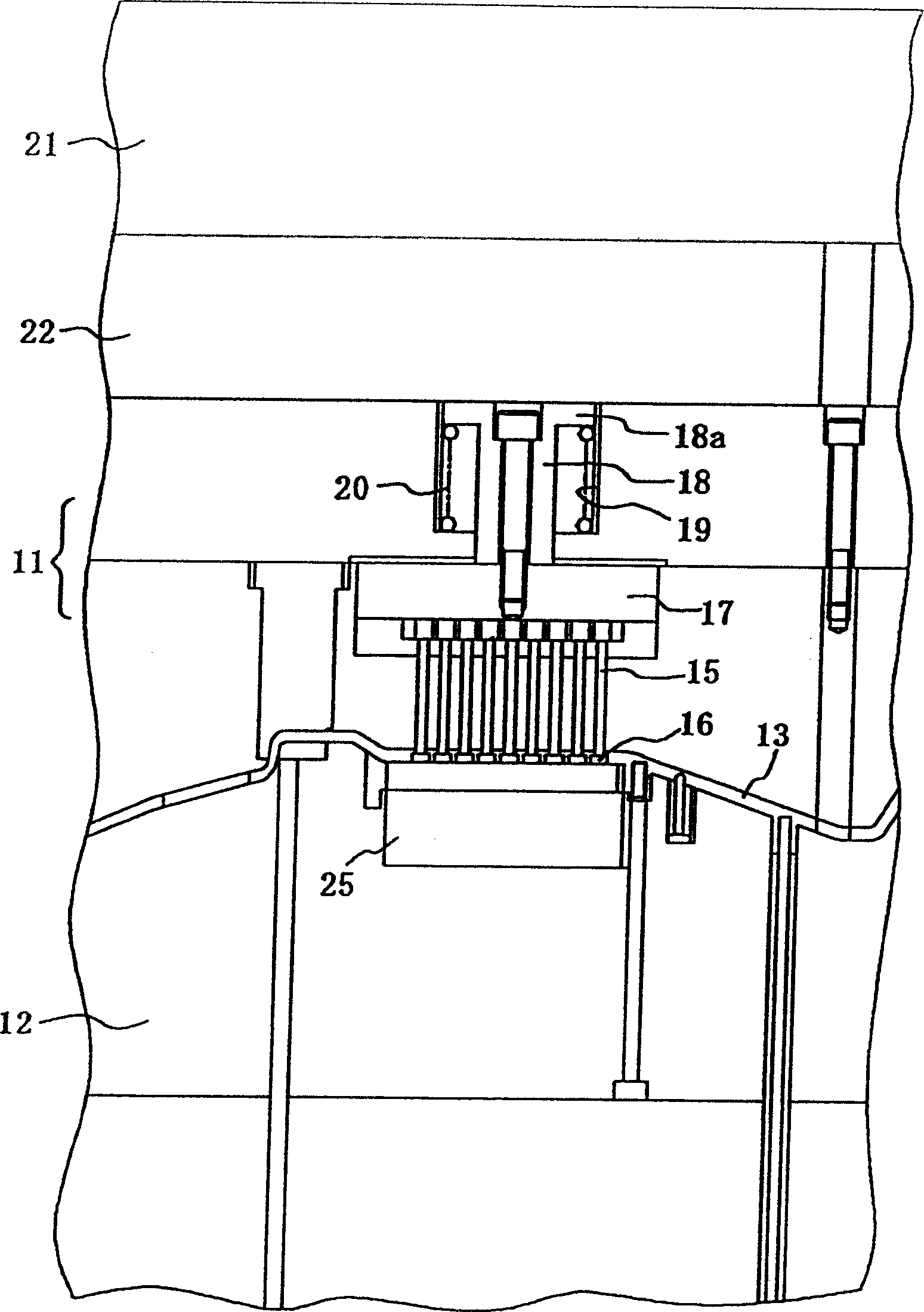

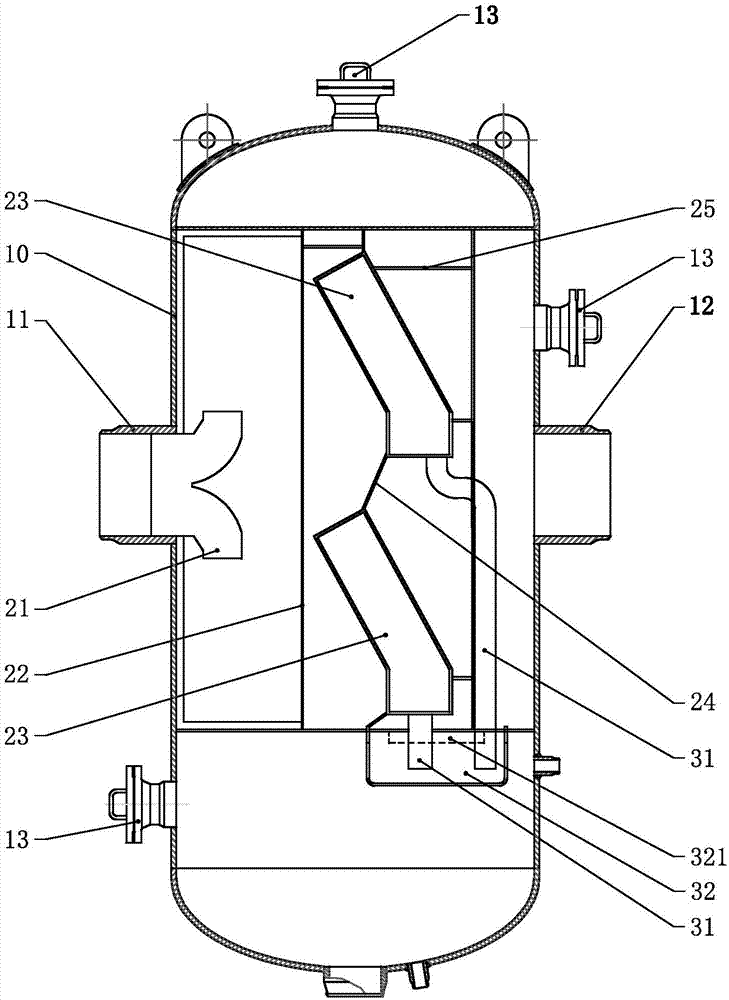

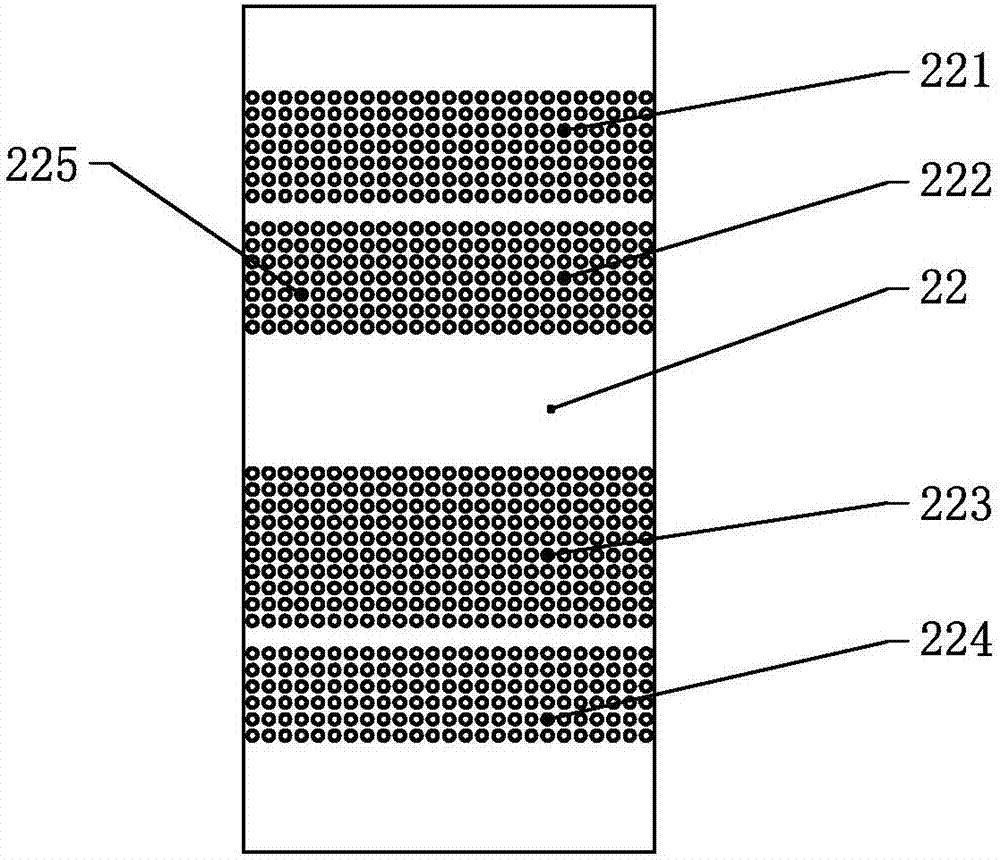

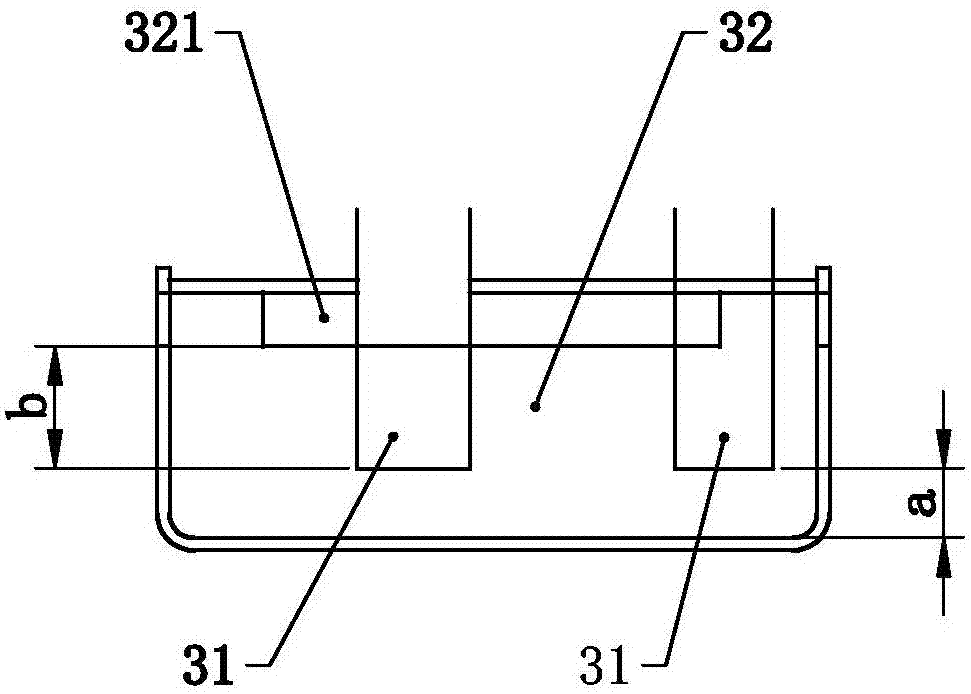

Steam-water separation equipment

ActiveCN107504362AResolve height constraintsHighly restricted problem mitigationSteam trapsEngineeringDistributor

Steam-water separation equipment comprises a barrel with a steam-water separation cavity. The steam-water separation cavity comprises a flow distributor and a steam-water separator which communicate with each other in sequence. A steam inlet communicating with the flow distributor and a steam outlet communicating with the steam-water separator are formed in the side wall of the barrel. The steam-water separator comprises a plurality of obliquely arranged steam-water separation units, the steam-water separation units are arranged longitudinally, and a connecting plate is connected between the end portions of every two adjacent steam-water separation units. By obliquely arranging the steam-water separation units, the contact area of steam and the steam-water separation units is effectively enlarged, and the steam-water separation efficiency is improved. Besides, as the steam-water separation units are disposed layer by layer longitudinally, the problem that the height of a single steam-water separation unit is limited is solved, and meanwhile by adoption of the layering arrangement mode, the steam entry amount and the drainage volume of each steam-water separation unit can be reduced, and reliable running of the steam-water separation units is ensured.

Owner:DONGFANG (GUANGZHOU) HEAVY MASCH CO LTD

Straw pretreatment method for cellulosic ethanol in straw

InactiveCN106834362AGuarantee hydrolysisGuarantee the fermentation environmentBiofuelsFermentationPretreatment methodHigh energy

The invention discloses a straw pretreatment method for cellulosic ethanol in straw. Pretreatment technologies for agricultural wastes such as the industrially produced straw mainly comprise acidic hydrolysis, alkaline hydrolysis, adding of chemicals for explosion and other pretreatment processes at the present, and have the problems of complicated treatment process, relatively high energy consumption and pollution to the environment to different extends. The straw pretreatment method for the cellulosic ethanol in the straw comprises the following steps: pre-soaking: removing sand from the straw through a sand remover to remove impurities; dewatering: pressurizing and heating a plug flow reactor through steam with pressure of 15 kg / cm<2> till the pressure is 13.5 kg / cm<2> and the temperature is 190 DEG C, retaining the pressure for 20 minutes, then discharging the straw, and carrying out two-stage flash distillation in a material discharging process of the plug flow reactor; gas production in the second stage of flash distillation during flash distillation: recycling steam from the first stage of flash distillation, producing gas from the second stage of flash distillation, cooling the gas through a cooler, and discharging the gas into a sewage treatment device. The straw pretreatment method is applied to the field of bio-refinery.

Owner:黑龙江中丹建业生物能源有限公司

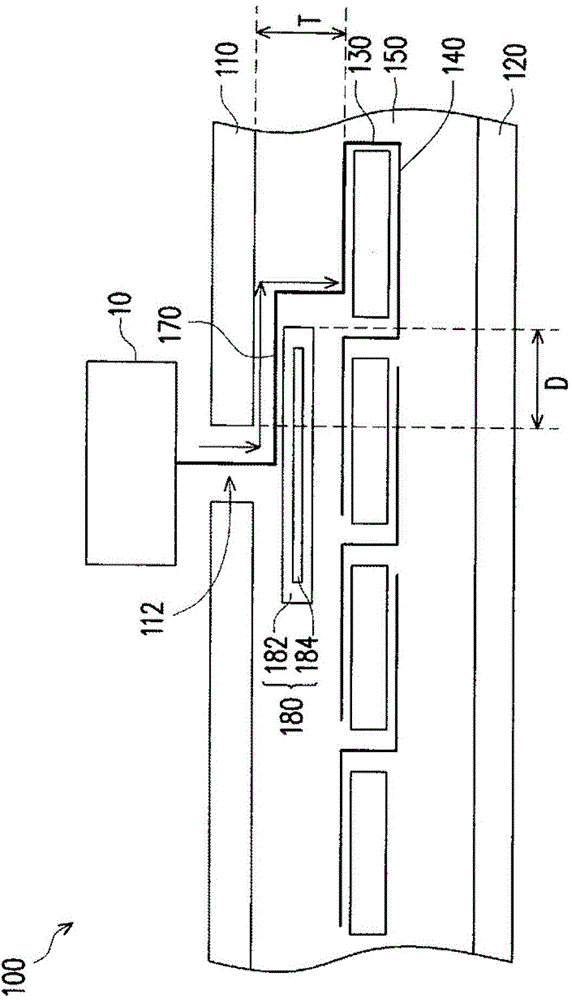

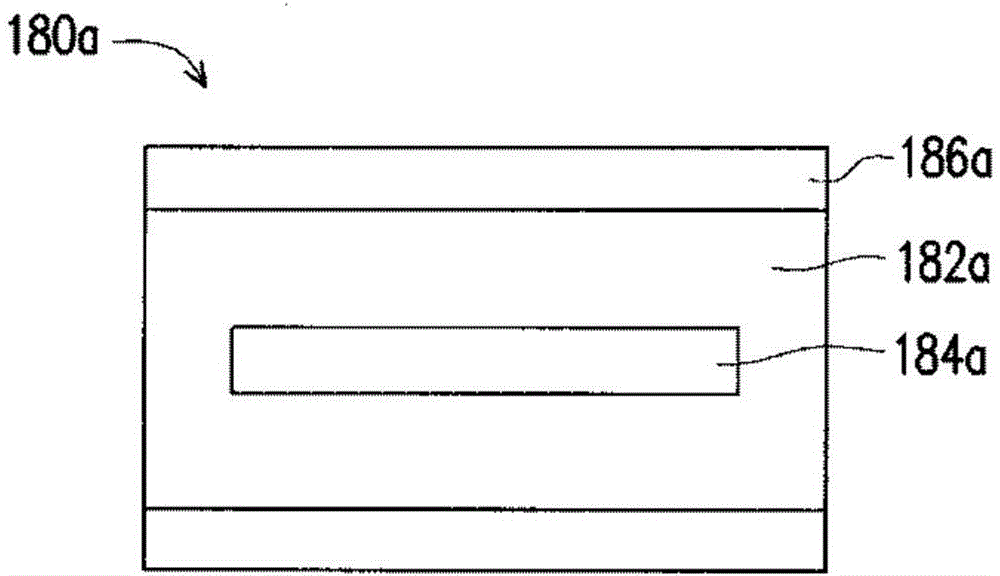

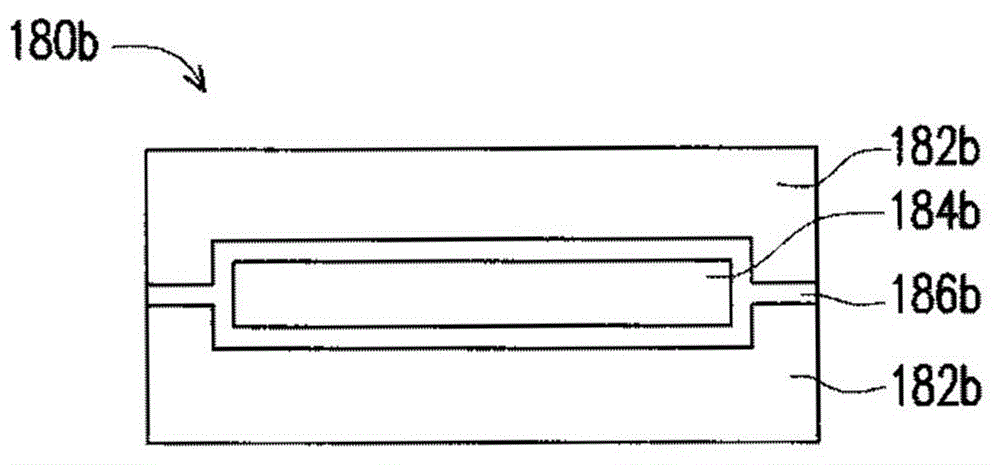

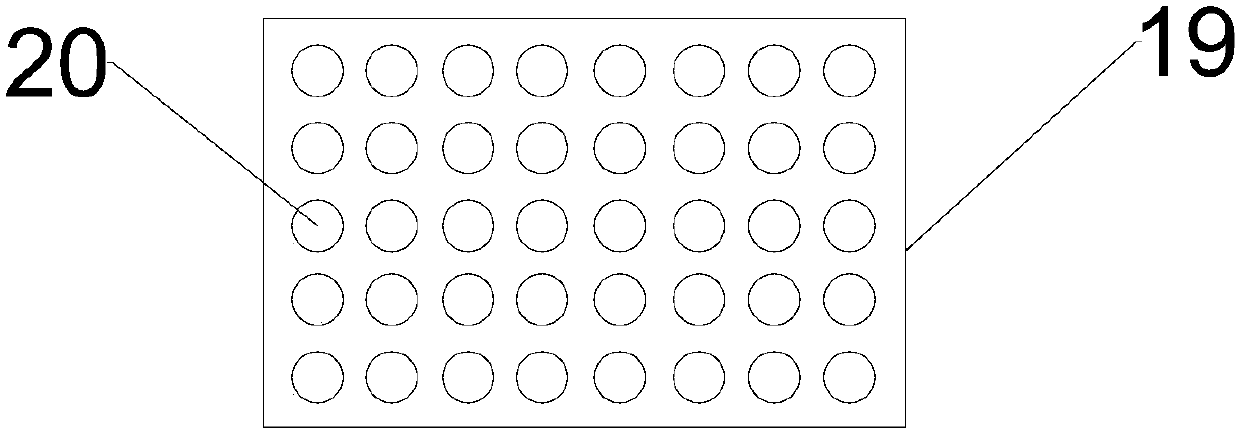

Backlight module and display device

ActiveCN103899989AReduce the amount of entryQuality improvementPoint-like light sourceStatic indicating devicesDisplay deviceBlock structure

The invention belongs to the technical field of display, and discloses a backlight module and a display device. The backlight module comprises a plurality of first light sources and a diffusion plate. In the 3D display mode, the multiple first light sources belong to different scanning regions, and each scanning region corresponding to one display region. The backlight module further comprises blocking structures which are arranged corresponding to the scanning regions, wherein the blocking structures are used for blocking light emitted by the first light sources in other scanning regions except the current scanning region from being transmitted to the display region corresponding to the current scanning region. According to the backlight module, the blocking structures are arranged corresponding to the scanning regions, the light emitted by the first light sources in other scanning regions is blocked from being transmitted to the display region corresponding to the current scanning region, the light inlet amount of the light turning-on scanning region to the light turning-off scanning region is reduced when a backlight source conducts scanning in the 3D display process, crosstalk in the 3D display process is reduced, and 3D display quality is improved.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com