Heat dissipation system of automobile charging pile

A heat dissipation system and car charging technology, applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of acceleration equipment, charging pile life shortening, aging, etc., to reduce noise, facilitate maintenance, and improve heat dissipation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

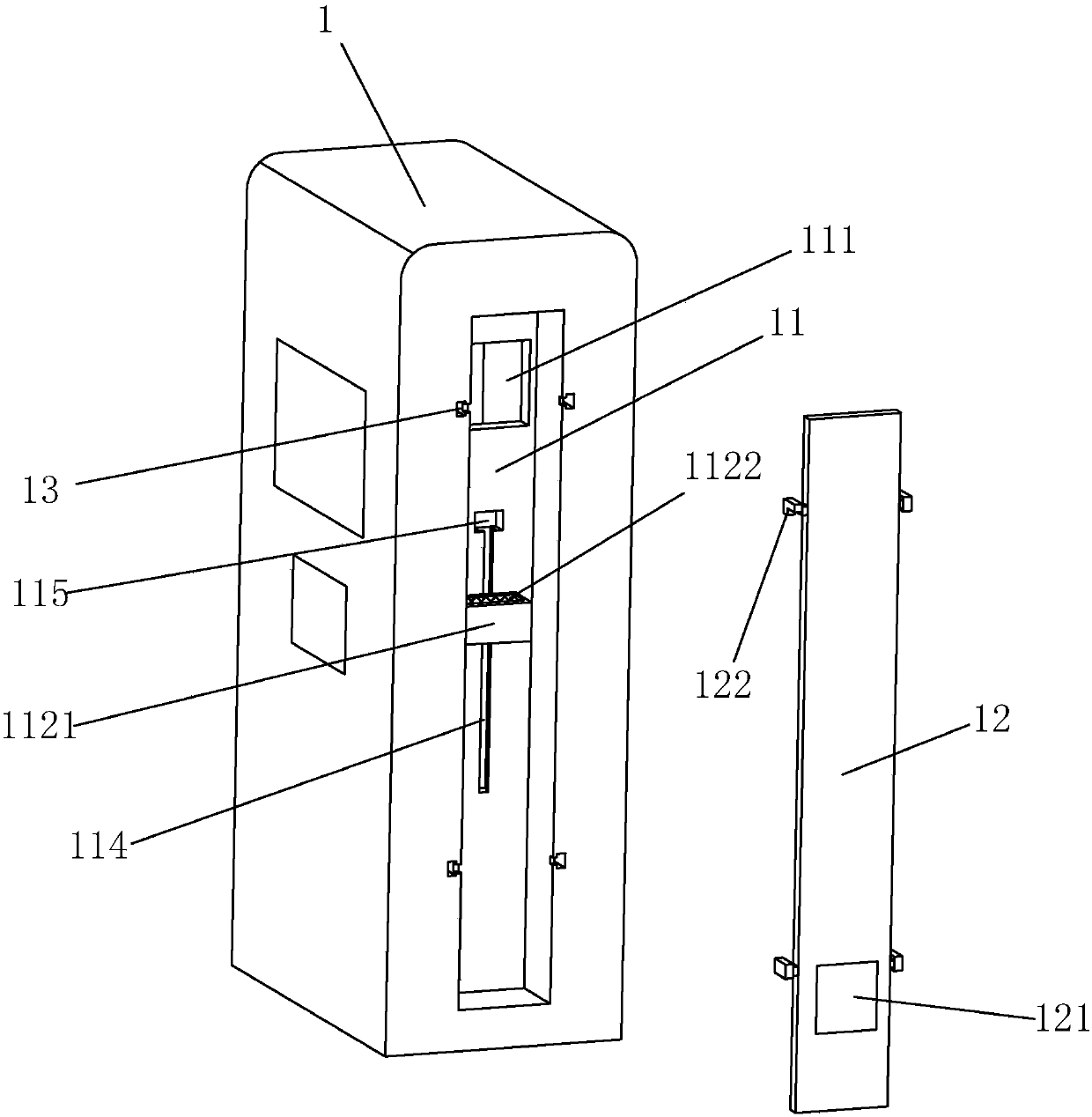

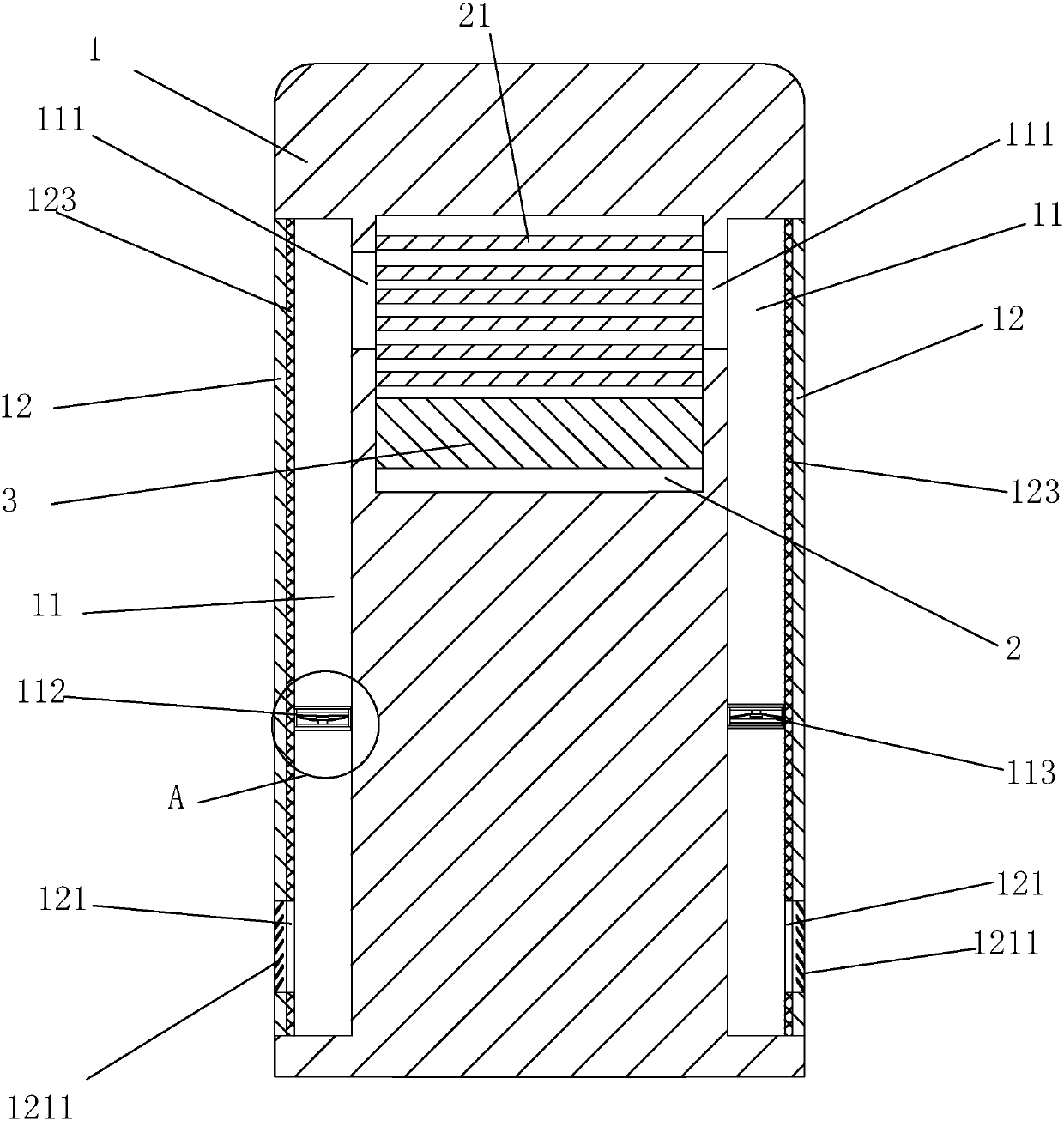

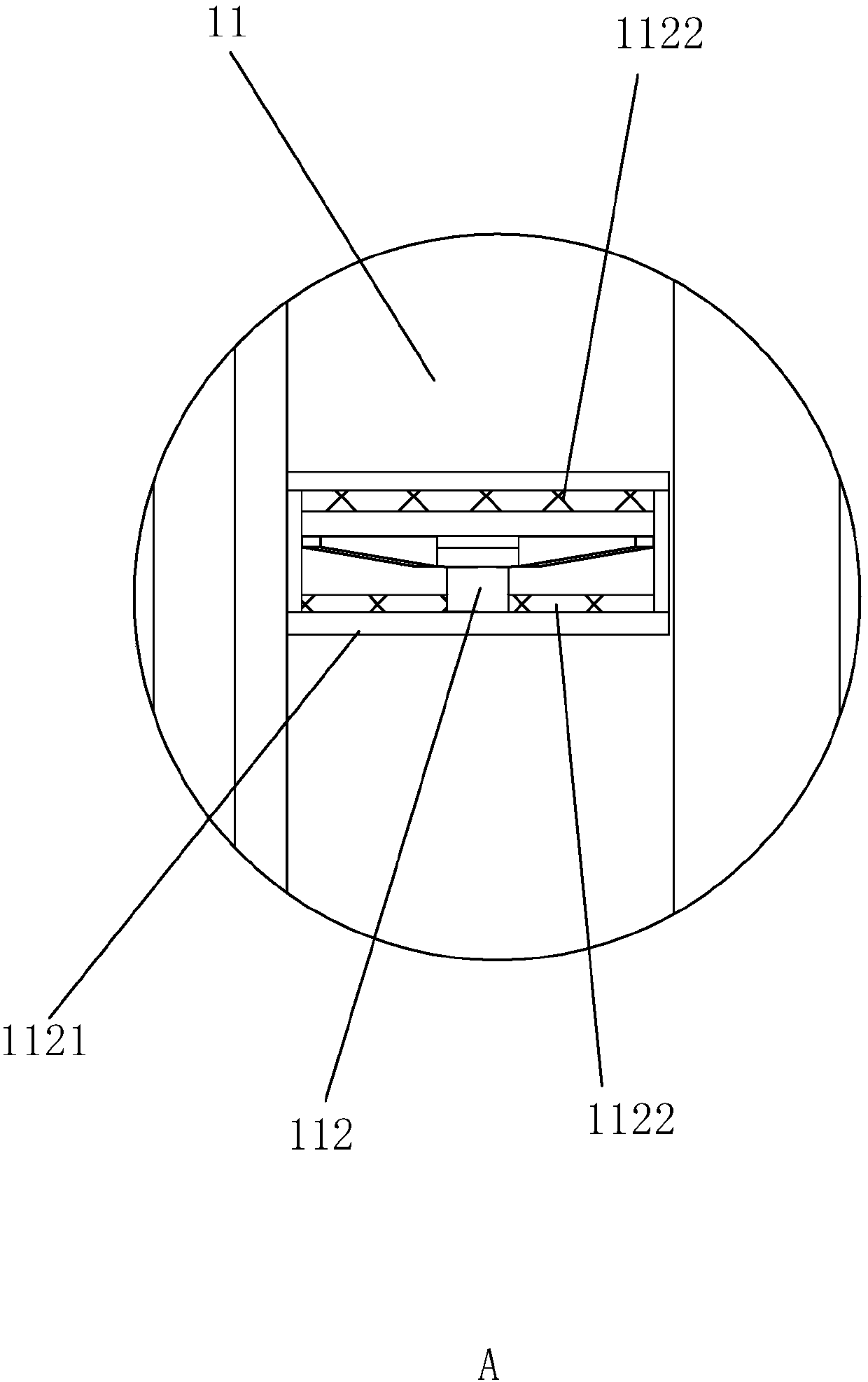

[0020] A heat dissipation system for a car charging pile, as shown in the figure, includes a charging pile body 1, an installation cavity 2, and a power module 3 located in the charging pile body 1, and a cooling fin 21 is arranged above the power module 3 in the installation cavity 2 The heat dissipation fins 21 are attached to the power module 3 to absorb the heat generated on the power module 3. The two side walls of the charging pile body 1 are recessed along its length direction to form a heat dissipation channel 11. The bottom wall of the heat dissipation channel 11 runs through Two ventilation holes 111 communicating with the installation cavity 2, the two ventilation holes 111 are located on both sides of the heat dissipation fins 21, two cover plates 12 covering the heat dissipation channel 11 are arranged on both sides of the charging pile body 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com