Inclined plate sedimentation tank with bottom cavity sludge scraping function

A technology of inclined plate sedimentation and function, which is applied in the direction of sedimentation separation, settling tank, filtration separation, etc., can solve the problems of residual sludge and single function, and achieve the effect of improving function and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

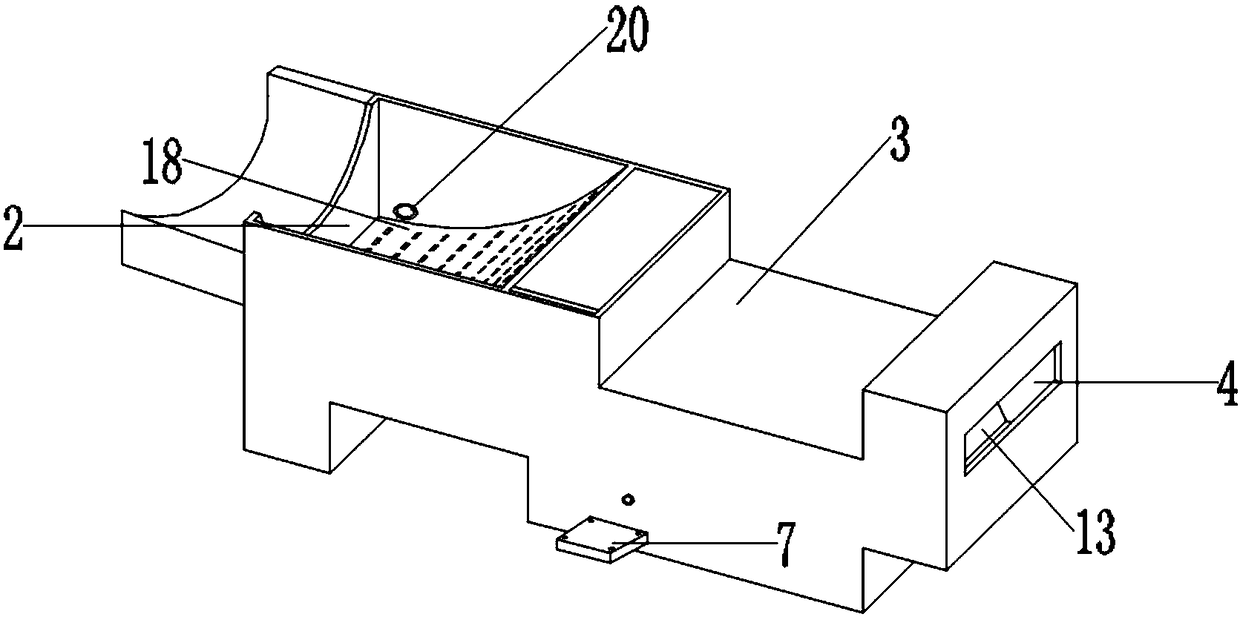

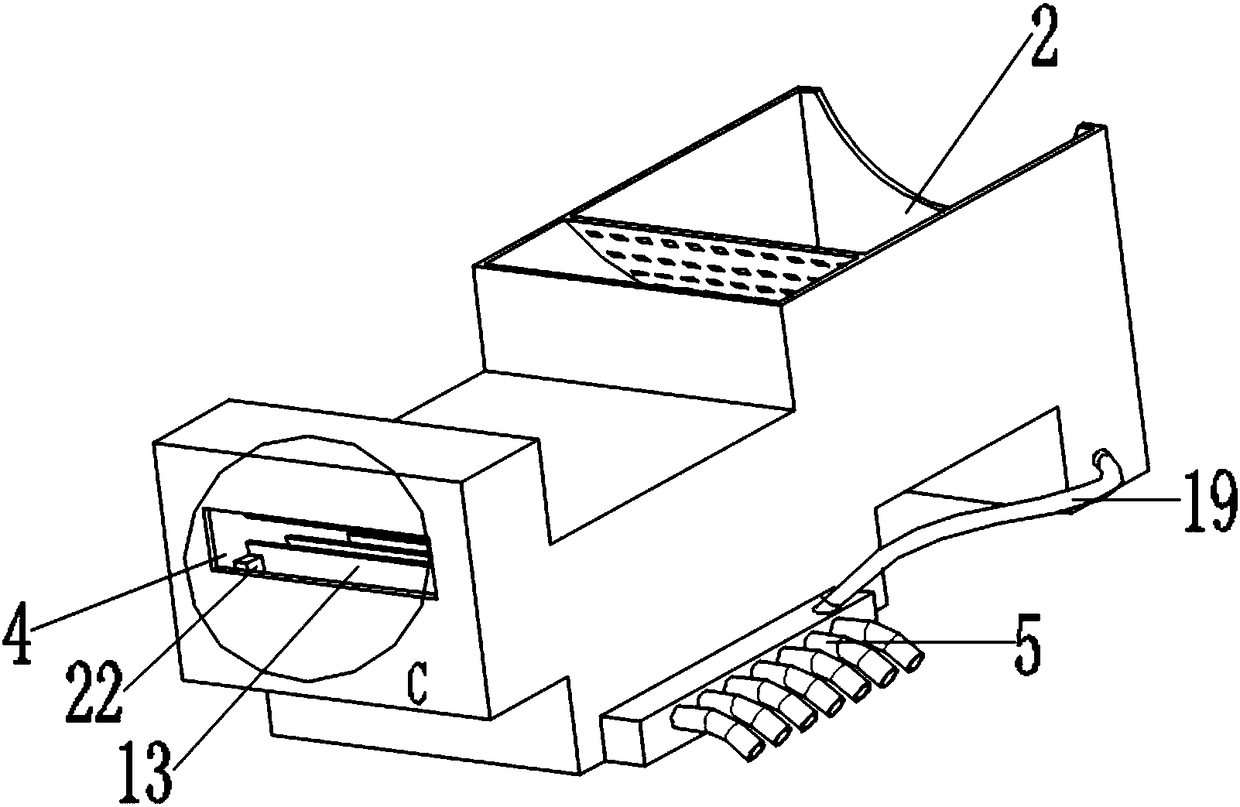

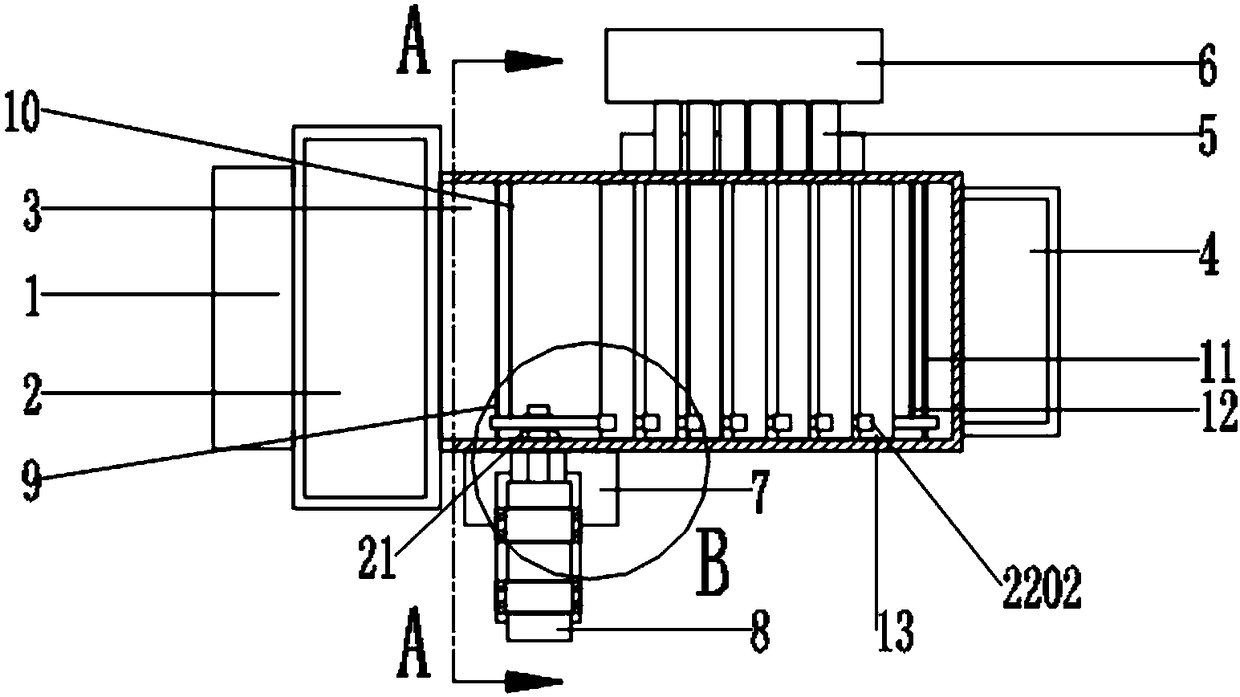

[0034] as attached figure 1 to attach Figure 8 Shown:

[0035]The invention provides an inclined plate sedimentation tank with a bottom chamber scraping function, including a water inlet 1, a coarse filter chamber 2, a sedimentation chamber 3, a clean water chamber 4, a sludge discharge pipe 5, a mud discharge system 6, and a support plate 7. Hydraulic cylinder 8, left guide rod 9, left rubber 10, right guide rod 11, right rubber 12, inclined plate 13, mud scraper 14, front scraper 15, rear scraper 16, guide groove 17, water-passing plate 18, diversion pipe 19, plug 20, rubber bag 21, mud cleaning plate 22, mud cleaning tank 2201 and rubber pad 2202; the left side of the coarse filter chamber 2 is connected with a water inlet 1 with a semi-arc structure, And in the chamber of the coarse filter chamber 2, a streamlined water filter plate 18 with a filter hole structure is welded; There is a clean water chamber 4 on the side, in which a row of sludge discharge pipes 5 for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com