Shaping mould device

A technology for forming molds and molds, applied to the structure of telephones, etc., can solve problems such as rising costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

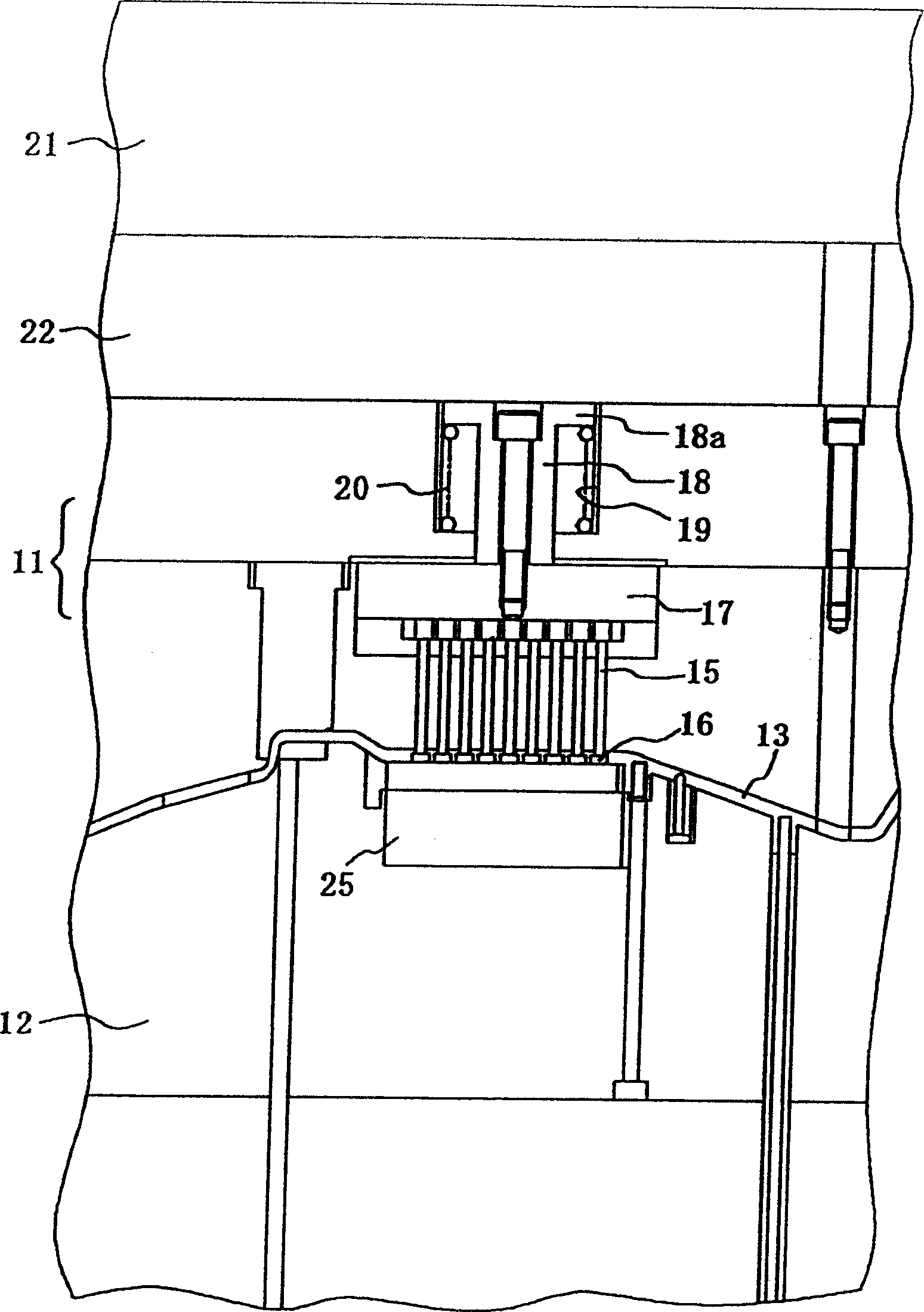

[0025] Hereinafter, referring to the figures, embodiments of the molding die device of the present invention will be described in detail.

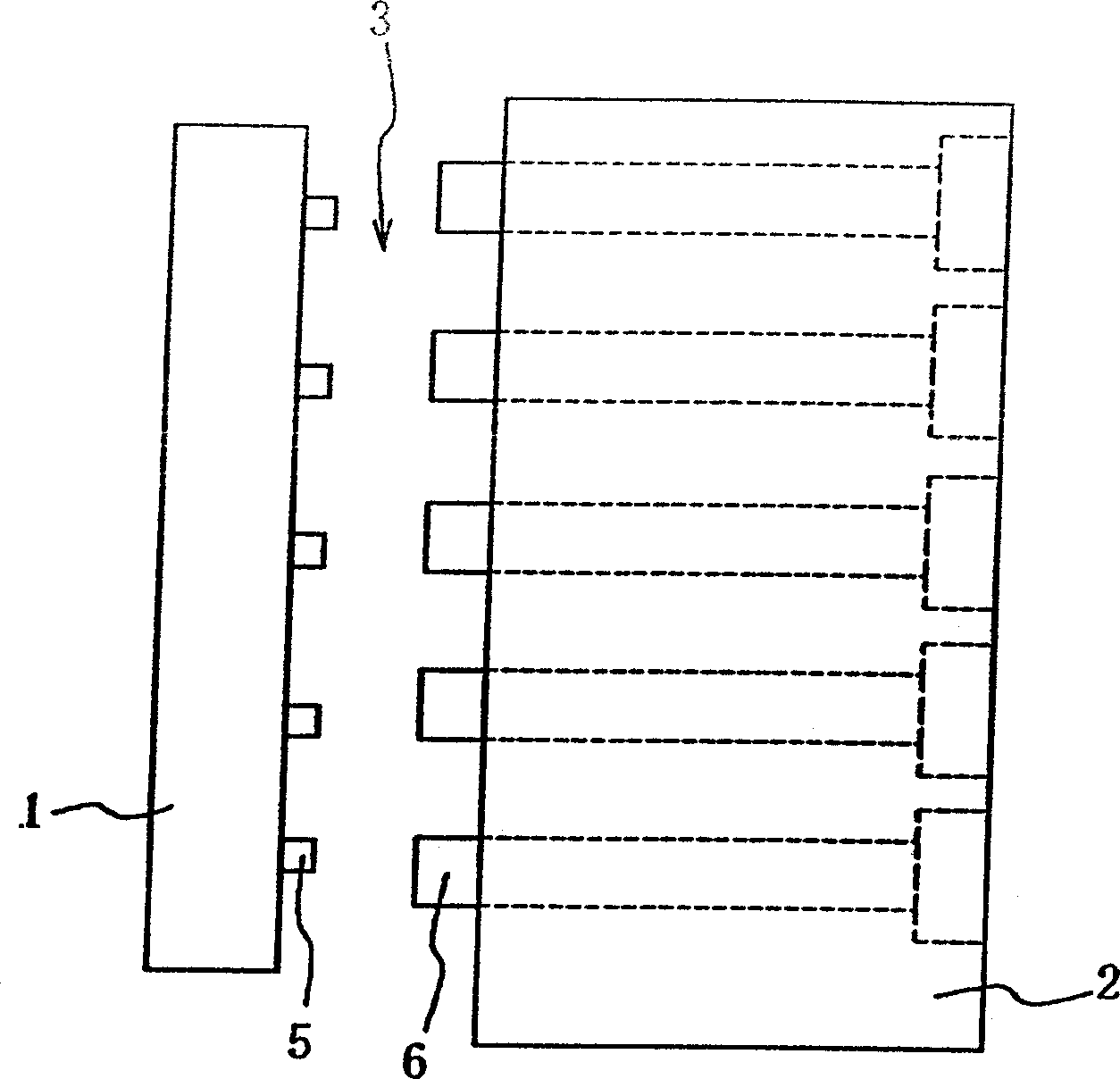

[0026] figure 1 What is shown is a schematic structural view of the forming mold device of the first embodiment of the present invention. In this embodiment, in order to make a plastic film molded body with a large number of openings with dense openings, the female mold side contact plug 5 and the male mold 2 are set on each part of the female mold 1 and the male mold 2 that shape the opening of the molded body. Die side touch pin 6. The touch pin 5 on the female mold side and the touch pin 6 on the male mold side are protrusions protruding into the mold cavity 3 and touching each other.

[0027] The front surface area of the touch pin 5 on the female mold side is smaller than that of the touch pin 6 on the male mold side, and the length of the touch pin 5 on the female mold side protruding into the mold cavity 3 is also smaller than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com