Steam-water separation equipment

A steam-water separation and steam-water separator technology, applied in mechanical equipment, steam traps, etc., can solve the problems of equipment safety or efficiency impact, low separation efficiency, and failure to reach the dryness of high-pressure cylinder equipment, so as to improve efficiency, Increase the contact area and ensure the effect of reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

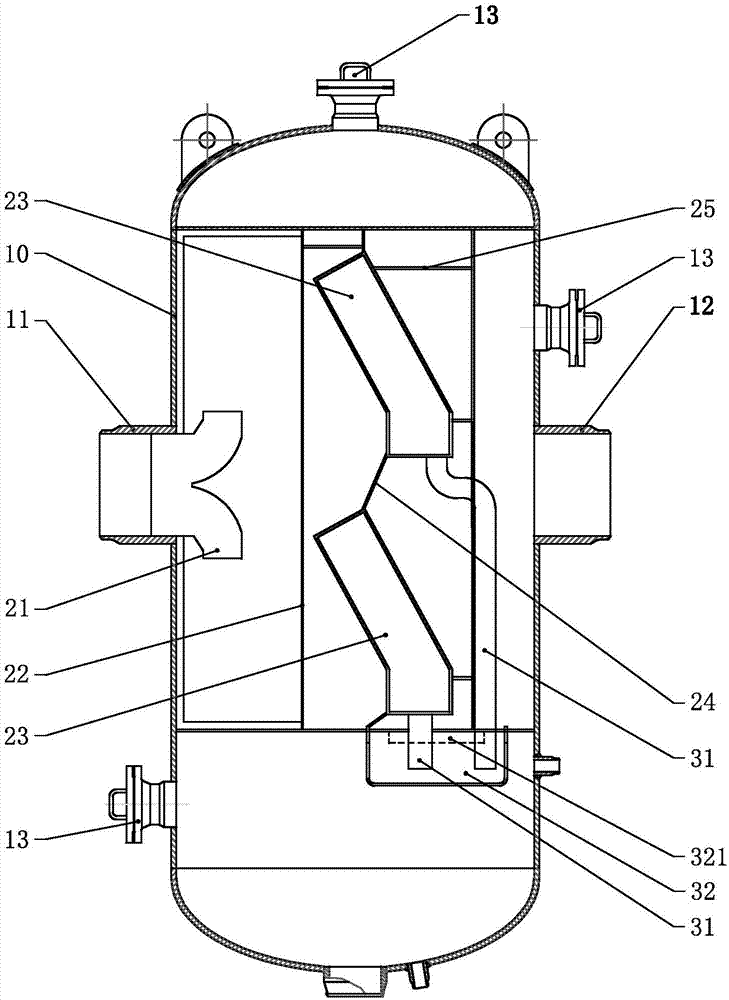

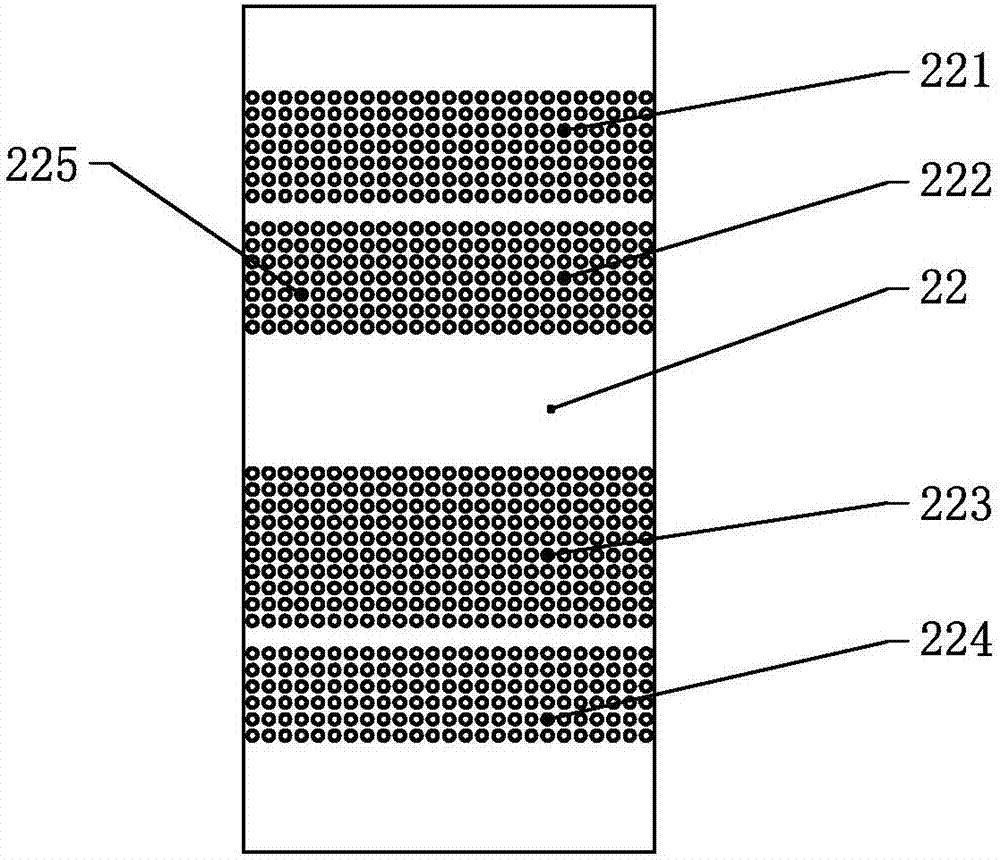

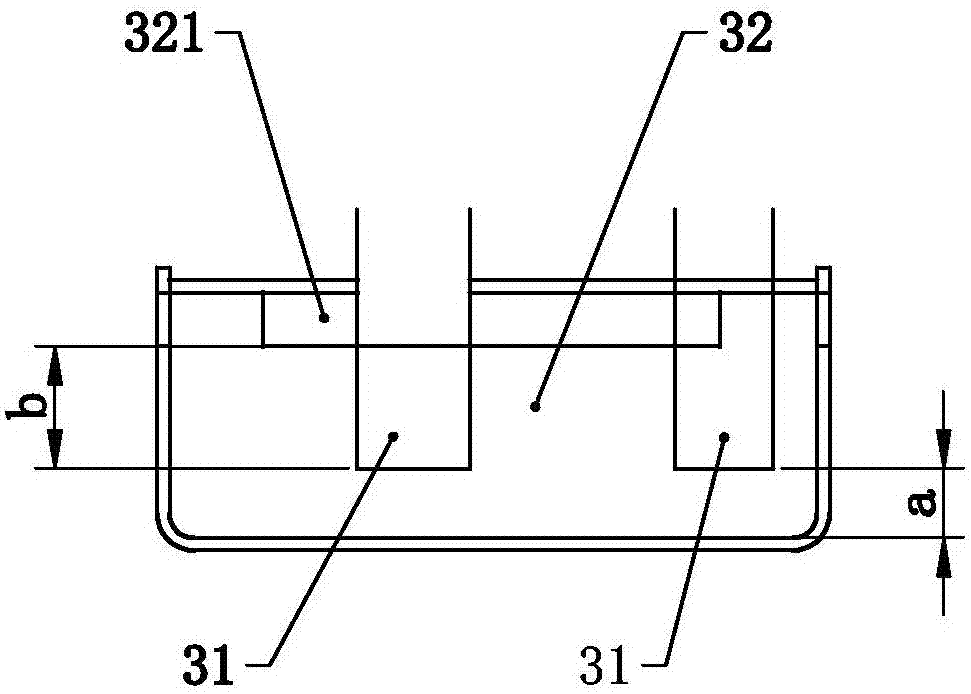

[0017] refer to Figure 1 to Figure 5 , a steam-water separation device in this embodiment, the device includes a cylinder 10, the side wall of the cylinder 10 is respectively symmetrically provided with a steam inlet 11 and a steam outlet 12, and the lower part of the cylinder 10 is fixedly equipped with two supporting feet 14. The support foot 14 and the anchor piece 15 are connected by bolts to fix the steam-water separation device. A steam-water separation cavity is formed inside the cylinder 10, and a flow distributor and a steam-water separator are respectively fixedly installed in the steam-water separation cavity. Under the action of the flow distributor, the steam flowing in from the steam inlet 11 enters the steam-water separation evenly The steam-water separator includes two steam-water separation units 23 distributed in the upper and lower layers. The steam-water separation unit 23 is obliquely fixed in the steam-water separation chamber through a fixed bracket 25,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com