A five-dimensional high-precision platform for large-scale grating installation and testing

An installation test, high-precision technology, applied in the direction of installation, optics, optical components, etc., can solve the problems that the large-scale grating installation test platform cannot realize five-dimensional adjustment, the overall stiffness of the four-dimensional adjustment device is low, and the stability is poor, so as to achieve a compact structure , Strong stability, strong security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

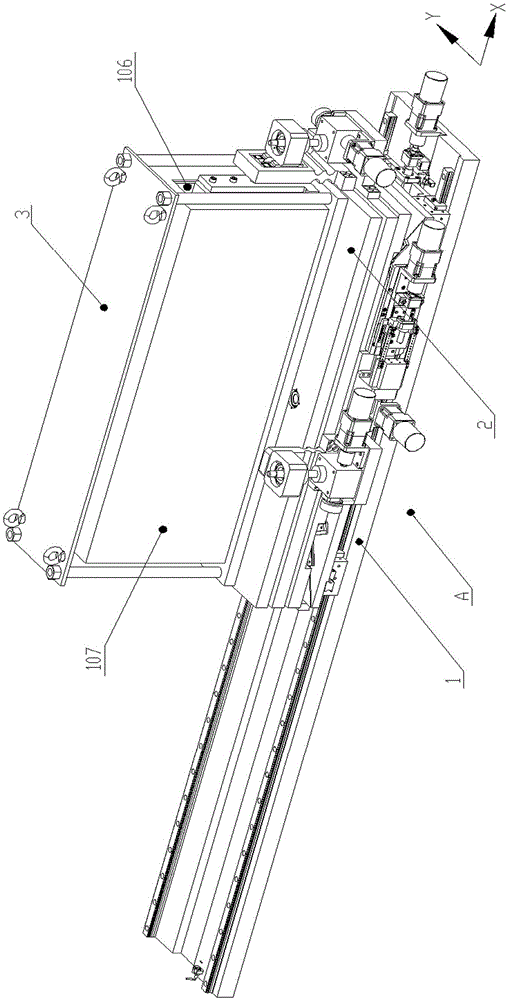

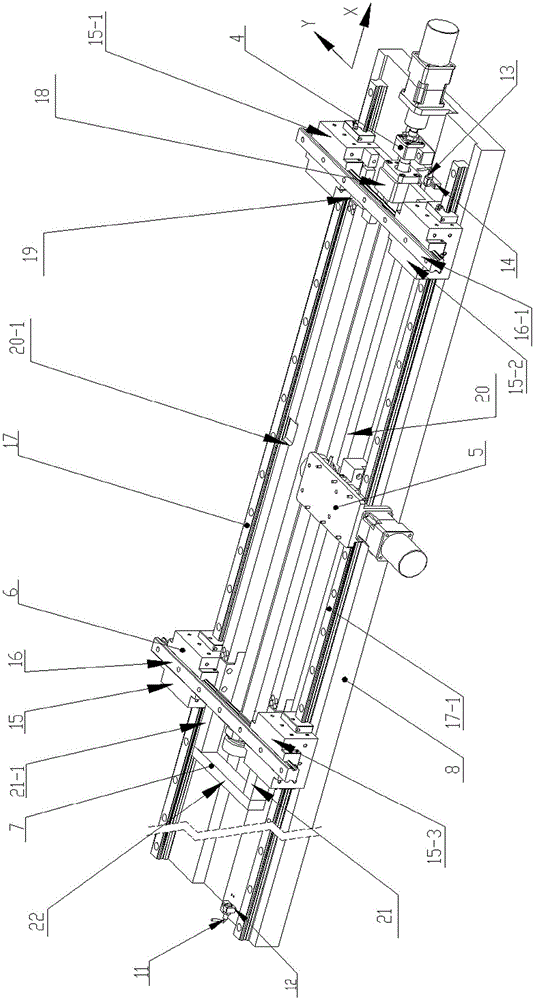

[0025] Specific implementation mode one: as figure 1 , figure 2 , Figure 5 and Figure 12 As shown, a five-dimensional high-precision platform for large-scale grating installation and testing involved in this embodiment includes a translation assembly 1, a grating installation assembly 3, and a rotation assembly 2 around the x, y, and z axes. The translation assembly 1 includes a translation base 8, an x-axis translation drive assembly 4, a y-axis translation drive assembly 5, a cross rail assembly 6, an inner slide assembly 7, an x-axis photoelectric proximity switch 11, and an x-axis photoelectric Proximity switch seat one 12, x-axis photoelectric proximity switch two 13 and x-axis photoelectric proximity switch seat two 14;

[0026] The translation base 8 is a rectangular translation base, the x-axis photoelectric proximity switch 11 is fixedly connected to one end of the translation base 8 through the x-axis photoelectric proximity switch seat 12, and the x-axis photo...

specific Embodiment approach 2

[0027] Specific implementation mode two: as figure 1 , figure 2 with Figure 4 As shown, a five-dimensional high-precision platform for large-scale grating installation and testing described in the first embodiment, the x-axis translation drive assembly 4 includes an x-axis translation adjustment motor base 27, an x-axis translation Stepper motor 23, x-axis translational reducer 24, x-axis translational coupling 25, x-axis ball screw nut 28, x-axis ball screw 29, x-axis translational bearing seat 26, x-axis translation Bearing seat 2 30 and x-axis electromagnetic brake 31; the x-axis translation stepper motor 23 is affixed to the x-axis translation adjustment motor seat 27 through the x-axis translation reducer 24, and the x-axis ball screw One end of 29 is supported by the x-axis translation bearing seat-26, and the x-axis translation bearing seat-26 is affixed to the upper surface of the x-axis translation adjustment motor seat 27, and the one end of the x-axis ball screw...

specific Embodiment approach 3

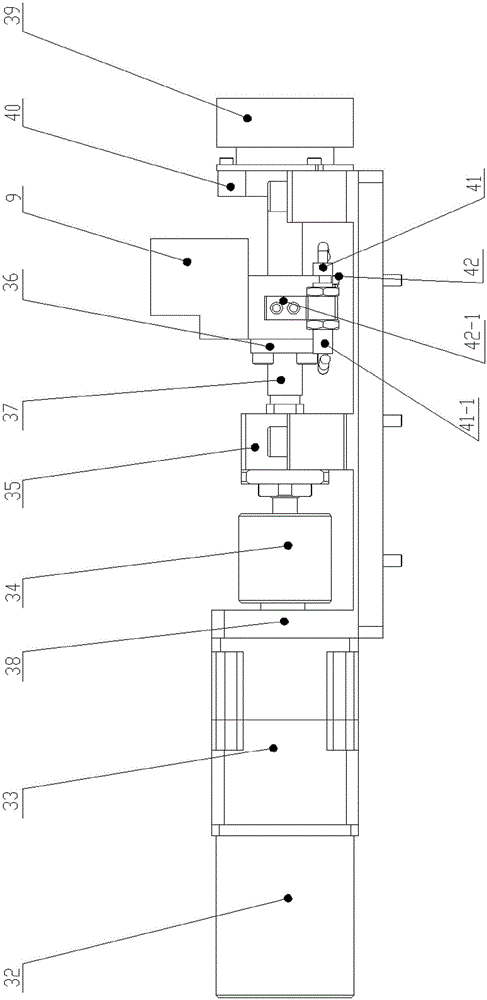

[0028] Specific implementation mode three: as Figure 1 ~ Figure 3 As shown, the five-dimensional high-precision platform for large-scale grating installation and testing described in the second embodiment, the y-axis translation drive assembly 5 includes a y-axis translation adjustment motor base 38, a y-axis translation Stepping motor 32, y-axis translation reducer 33, y-axis translation coupling 34, y-axis ball screw 37, y-axis ball screw nut 36, y-axis translation bearing seat 35, y-axis translation Bearing seat 2 40, y-axis electromagnetic brake 39, y-axis translational connection bending plate 9, y-axis photoelectric switch seat 1 42, y-axis photoelectric proximity switch 1 41, y-axis photoelectric switch seat 2 42-1 and y-axis photoelectric proximity Switch two 41-1; the y-axis translation stepper motor 32 is fixedly connected to the y-axis translation adjustment motor seat 38 through the y-axis translation speed reducer 33, and the two ends of the y-axis ball screw 37 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com