Method of purifying aluminium alloy melt

A technology for aluminum alloy melt and aluminum alloy, which is applied in the field of aluminum alloy melt purification for removing gas in aluminum alloy and metal melt purification, and can solve the problem of high degassing cost, increased oxidation, unfavorable uniform degassing of molten pool, etc. problem, to achieve a good effect of removing hydrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

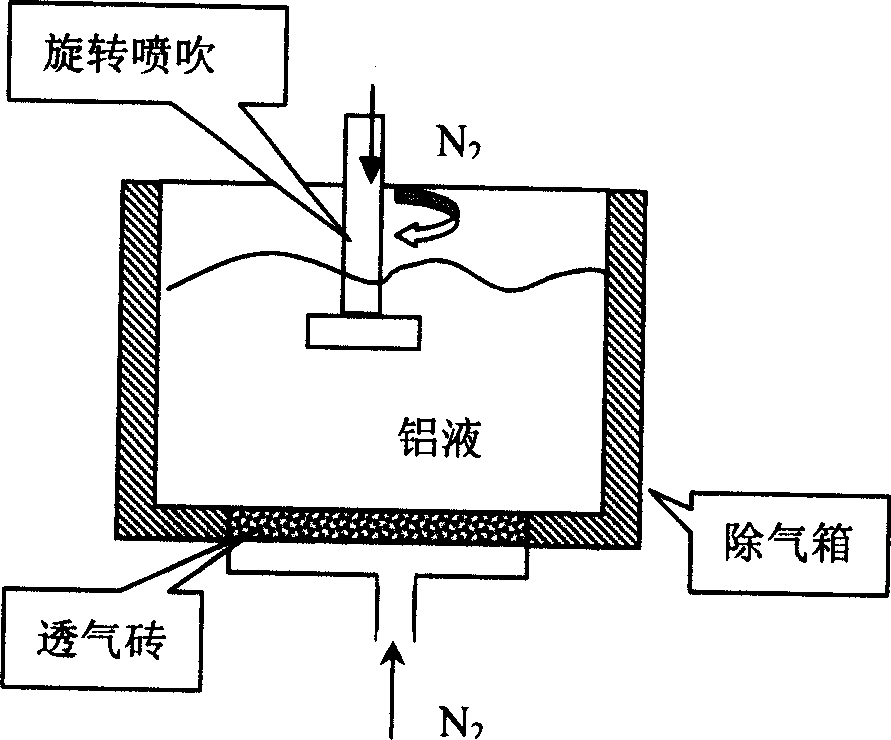

[0017] Spray from the top in the degassing box: the rotor speed of the rotary blowing is 200 rpm, the gas used is N2, and the flow rate is 0.2m 3 / h, gas pressure 0.1MPa,

[0018] Blow into the melt from the bottom of the degassing box: the gas N2 used in the breathable brick, the gas pressure is 0.1MPa, and the flow rate is 0.03m 3 / h, the hydrogen content in the purified aluminum melt is 0.10ml / 100gAl, and the metal gas consumption ratio is 0.31L / kg.

Embodiment 2

[0020] Spraying from the top in the degassing box: the rotational speed of the rotary blowing rotor is 200 rpm, the gas used is N2, and the flow rate is 0.2m 3 / h, gas pressure 0.15MPa,

[0021] Blow into the melt from the bottom of the degassing box: the gas N2 used in the breathable brick, the gas pressure is 0.1MPa, and the flow rate is 0.03m 3 / h, the hydrogen content in the purified aluminum melt is 0.12ml / 100gAl, and the metal gas consumption ratio is 0.31L / kg.

Embodiment 3

[0023] Spraying from the top in the degassing box: the rotary blowing rotor speed is 200 rpm, the gas used is N2, and the flow rate is 0.3m 3 / h, gas pressure 0.1MPa

[0024] Blow into the melt from the bottom of the degassing box: the gas N2 used in the breathable brick, the gas pressure is 0.05MPa, and the flow rate is 0.05m 3 / h, the hydrogen content in the purified aluminum melt is 0.09ml / 100gAl, and the metal gas consumption ratio is 0.46L / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com