A uniform drying device for electroplating parts

A technology for drying devices and electroplating parts, which is applied in drying, dryers, heating devices, etc., which can solve the problems of low heat utilization and no hydrogen ion diffusion, and achieve good water and hydrogen removal effects and strong adsorption performance, speed-up effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

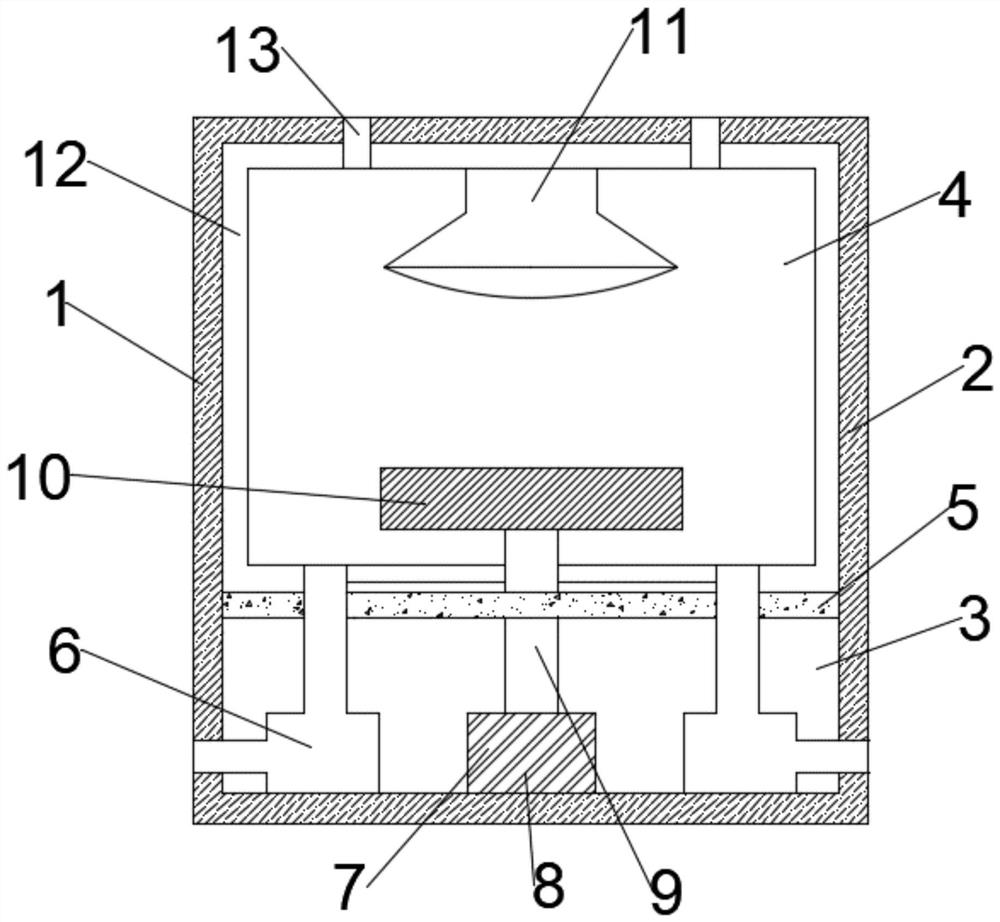

[0045] A device for uniform drying of electroplated parts, such as figure 1 As shown, the drying device body 1 is included, and the outer shell 2 of the drying device body 1 is separated by a thermal insulation layer 5 to form a heating cavity 3 and a constant temperature cavity 4. The heating cavity 3 and the constant temperature cavity 4 pass through the thermal insulation layer 5. Separated; the heating cavity 3 is provided with a blowing device 6 and a rotating device 7, the rotating device 7 is fixed at the bottom of the heating cavity 3, and the blowing device 6 is arranged on both sides of the rotating device 7; one end of the blowing device 6 The side wall of the heating cavity 3 communicates with the outside world, and the other end communicates with the constant temperature cavity 4 through the thermal insulation layer 5; the rotating device 7 includes a motor 8 and a rotating shaft 9, and the rotating shaft 9 passes through the thermal insulation layer 5 and extends ...

Embodiment 2

[0061] A device for uniform drying of electroplated parts, such as figure 1 As shown, the drying device body 1 is included, and the outer shell 2 of the drying device body 1 is separated by a thermal insulation layer 5 to form a heating cavity 3 and a constant temperature cavity 4. The heating cavity 3 and the constant temperature cavity 4 pass through the thermal insulation layer 5. Separated; the heating cavity 3 is provided with a blowing device 6 and a rotating device 7, the rotating device 7 is fixed at the bottom of the heating cavity 3, and the blowing device 6 is arranged on both sides of the rotating device 7; one end of the blowing device 6 The side wall of the heating cavity 3 communicates with the outside world, and the other end communicates with the constant temperature cavity 4 through the thermal insulation layer 5; the rotating device 7 includes a motor 8 and a rotating shaft 9, and the rotating shaft 9 passes through the thermal insulation layer 5 and extends ...

Embodiment 3

[0077] A device for uniform drying of electroplated parts, such as figure 1 As shown, the drying device body 1 is included, and the outer shell 2 of the drying device body 1 is separated by a thermal insulation layer 5 to form a heating cavity 3 and a constant temperature cavity 4. The heating cavity 3 and the constant temperature cavity 4 pass through the thermal insulation layer 5. Separated; the heating cavity 3 is provided with a blowing device 6 and a rotating device 7, the rotating device 7 is fixed at the bottom of the heating cavity 3, and the blowing device 6 is arranged on both sides of the rotating device 7; one end of the blowing device 6 The side wall of the heating cavity 3 communicates with the outside world, and the other end communicates with the constant temperature cavity 4 through the thermal insulation layer 5; the rotating device 7 includes a motor 8 and a rotating shaft 9, and the rotating shaft 9 passes through the thermal insulation layer 5 and extends ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com