Patents

Literature

36results about How to "Save workability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

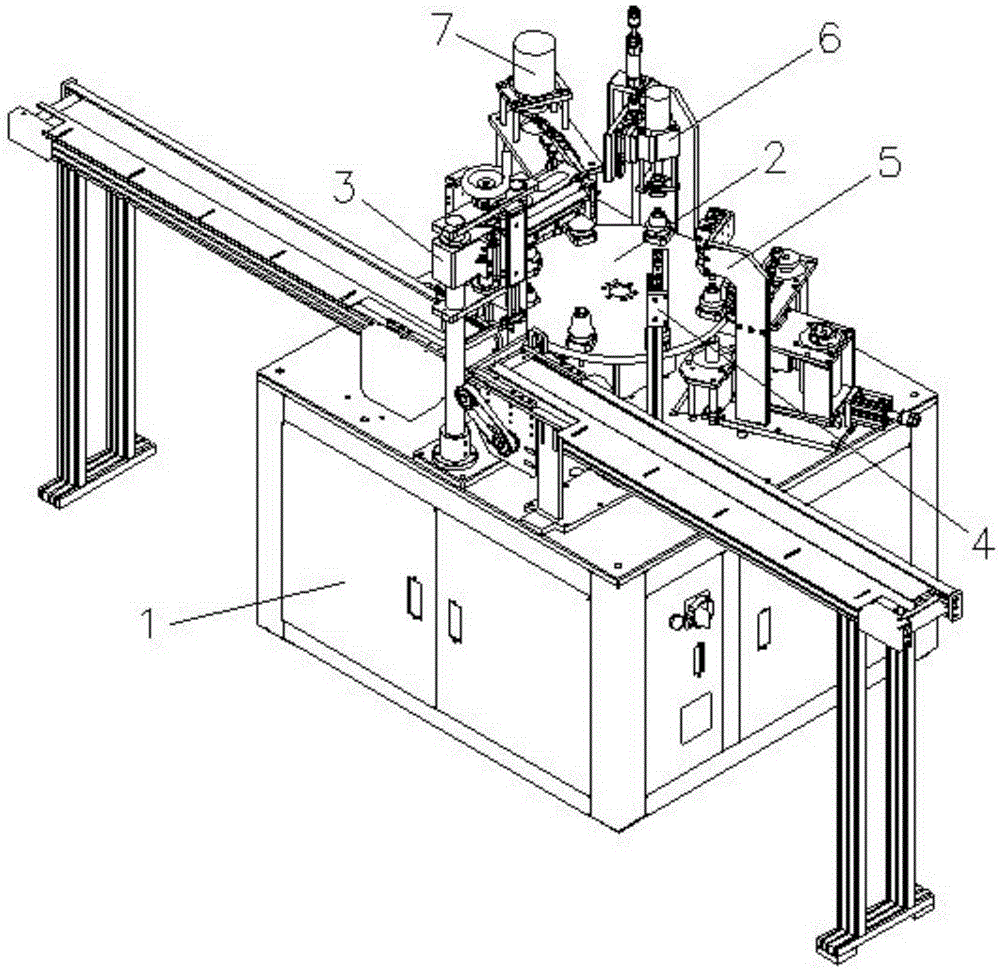

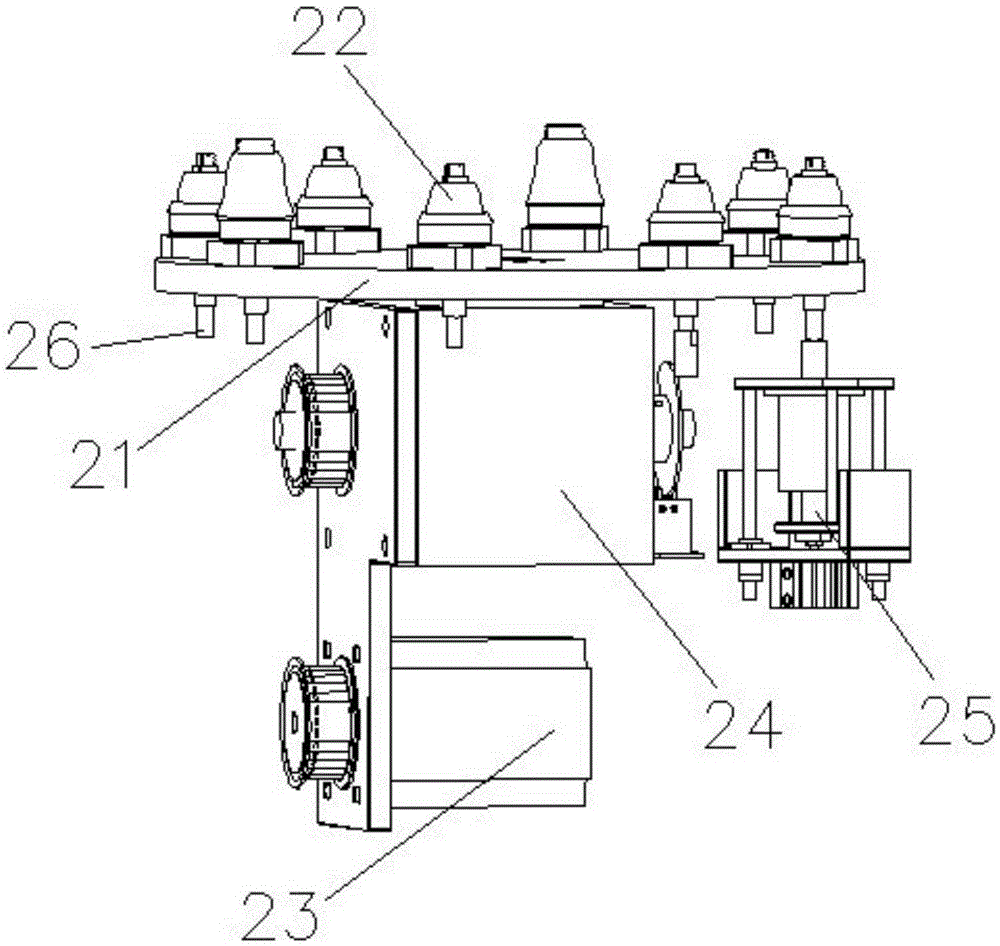

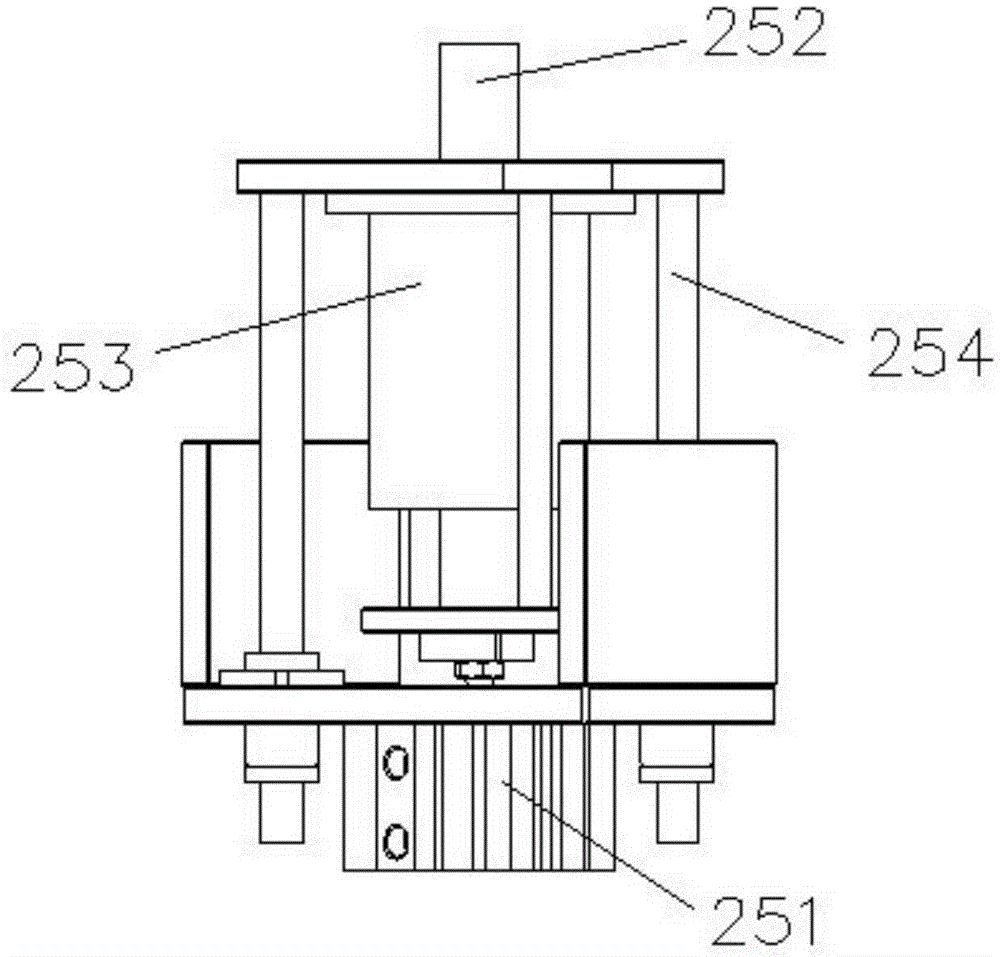

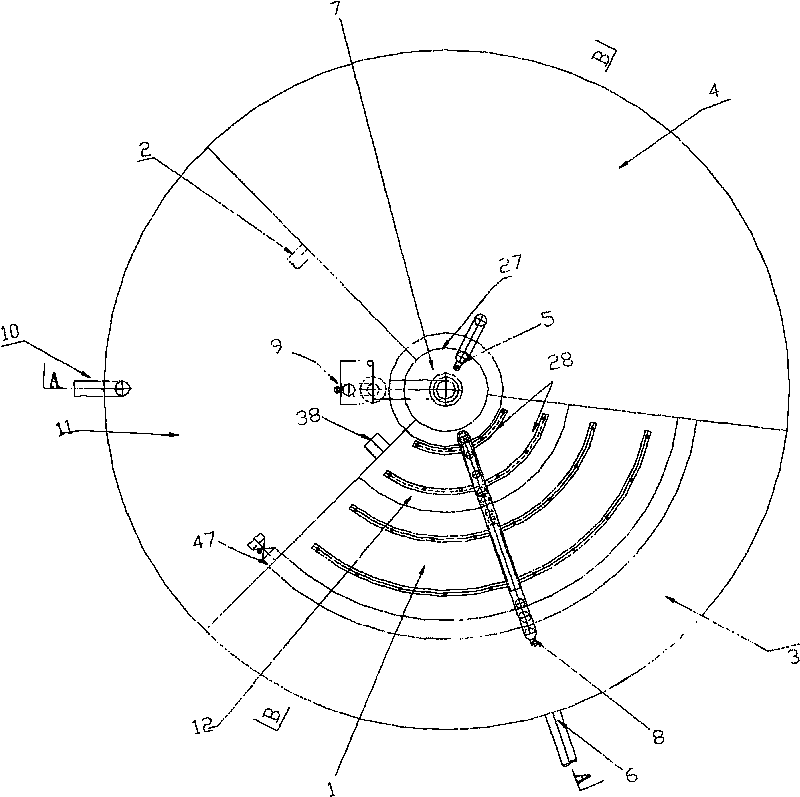

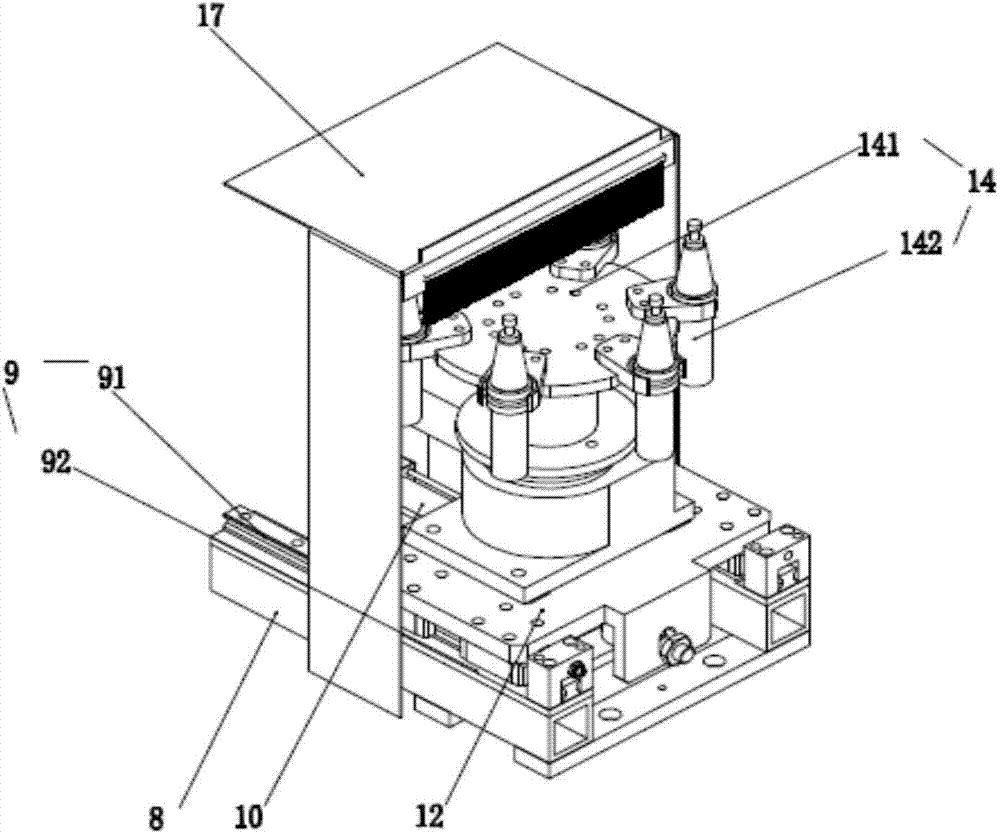

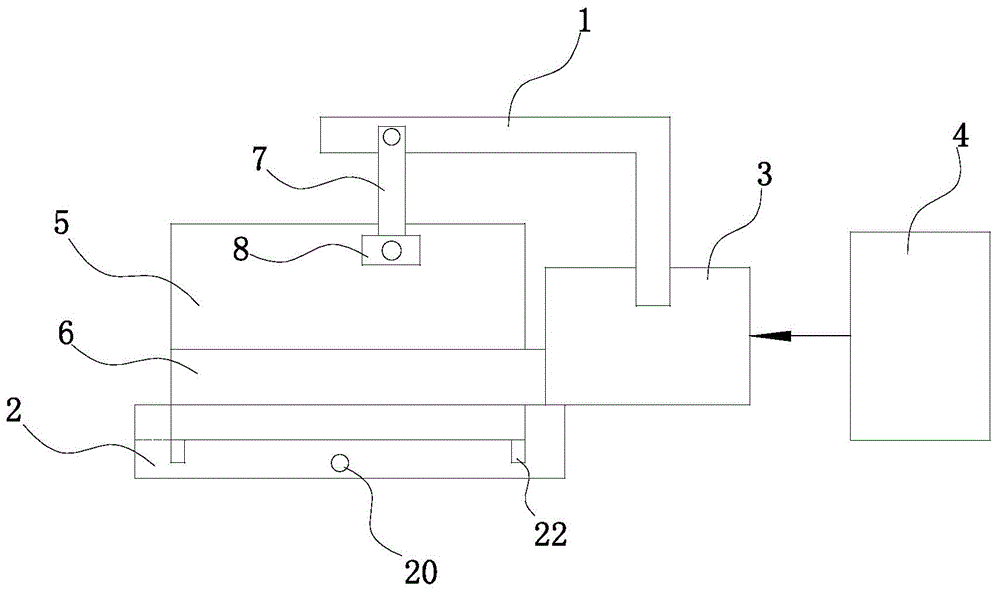

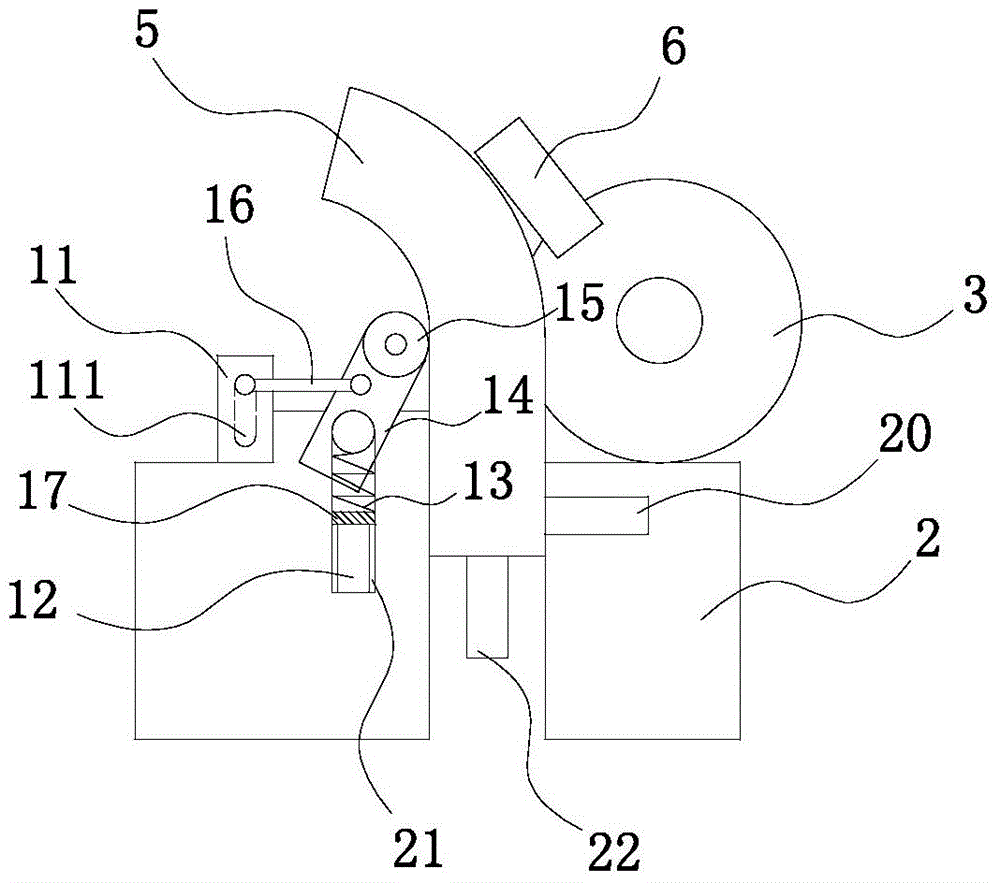

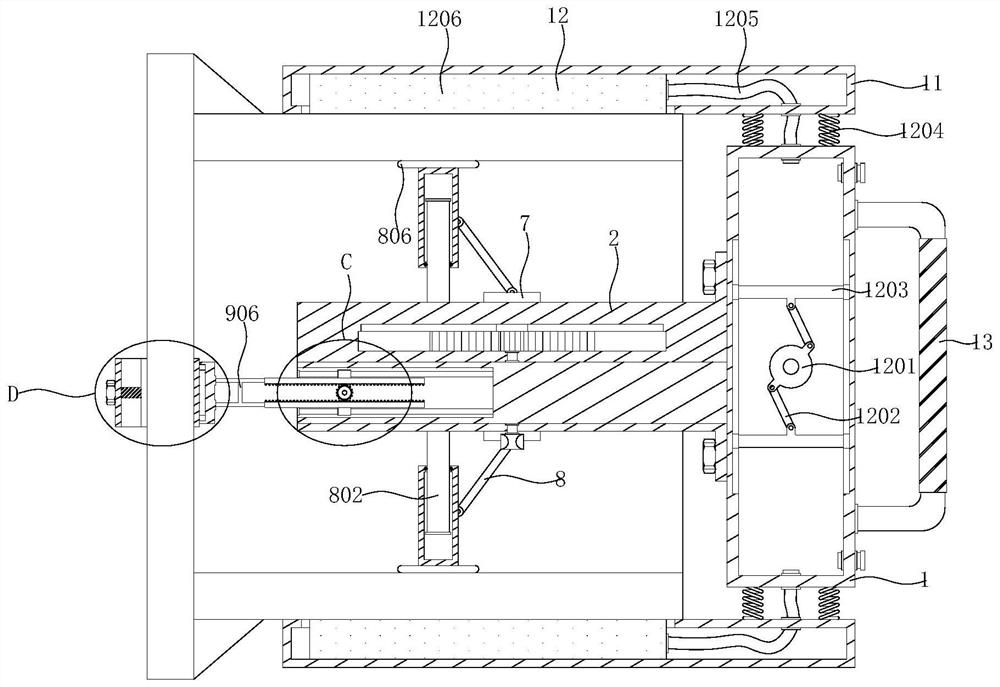

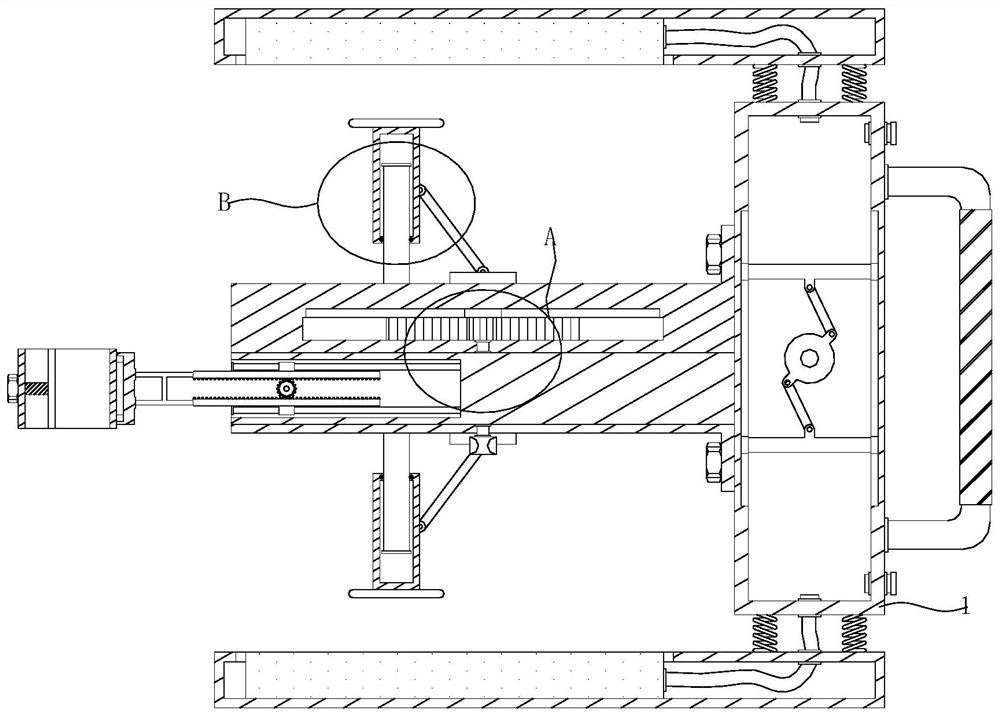

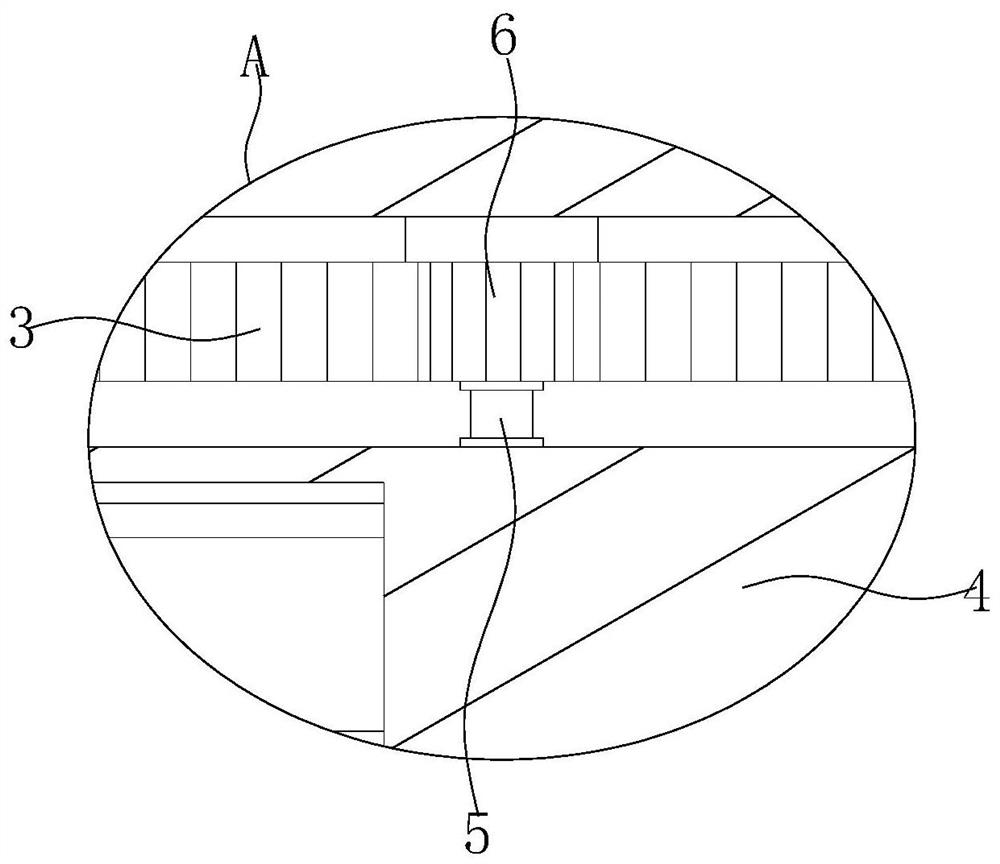

Multi-station automatic burr removal machine

ActiveCN105328548AReasonable designCompact structureEdge grinding machinesGrinding drivesReciprocating motionEngineering

The invention discloses a multi-station automatic burr removal machine. The multi-station automatic burr removal machine comprises a machine cabinet, a lifting and rotating index plate, a conveying mechanism, a pressing mold mechanism, a side surface burr removal mechanism, an in-hole burr removal mechanism and a top burr removal mechanism, wherein the lifting and rotating index plate is arranged in the center of the machine cabinet, and the conveying mechanism, the pressing mold mechanism, the side surface burr removal mechanism, the in-hole burr removal mechanism and the top burr removal mechanism are sequentially arranged in the periphery of the lifting and rotating index plate. The multi-station automatic burr removal machine is reasonable in design and compact in structure and can meet the requirements of removing burrs of different portions, the lifting and rotating index plate can accurately locate parts, brushes can make contact with the parts closely and do fast reciprocating motion so as to remove the burrs completely, the burrs in holes, on the side surfaces and on the tops can be removed at the same time, the number of machining steps can be reduced, the machining time can be saved, manual operation can be reduced, and the manpower cost can be lowered.

Owner:GUANGDONG GONGYE TECH CO LTD

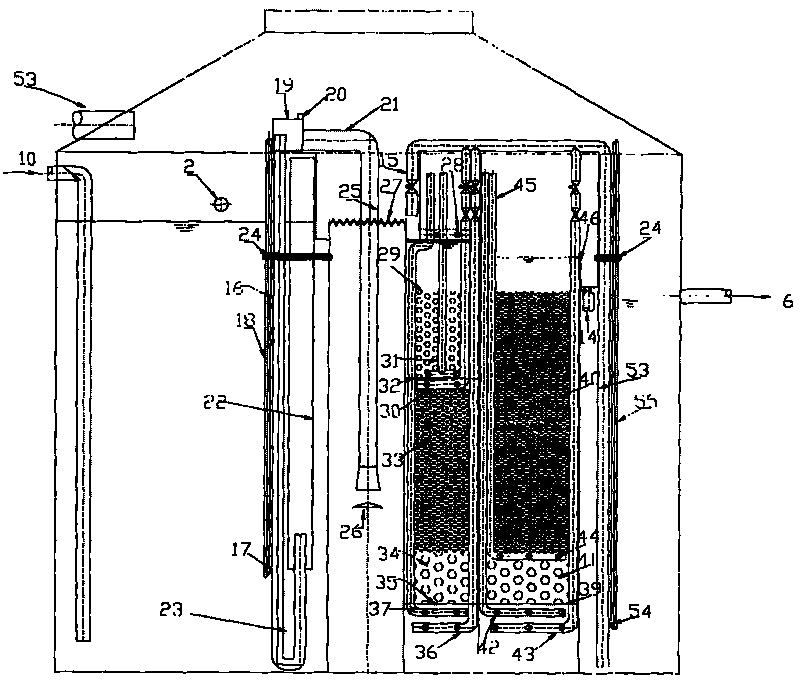

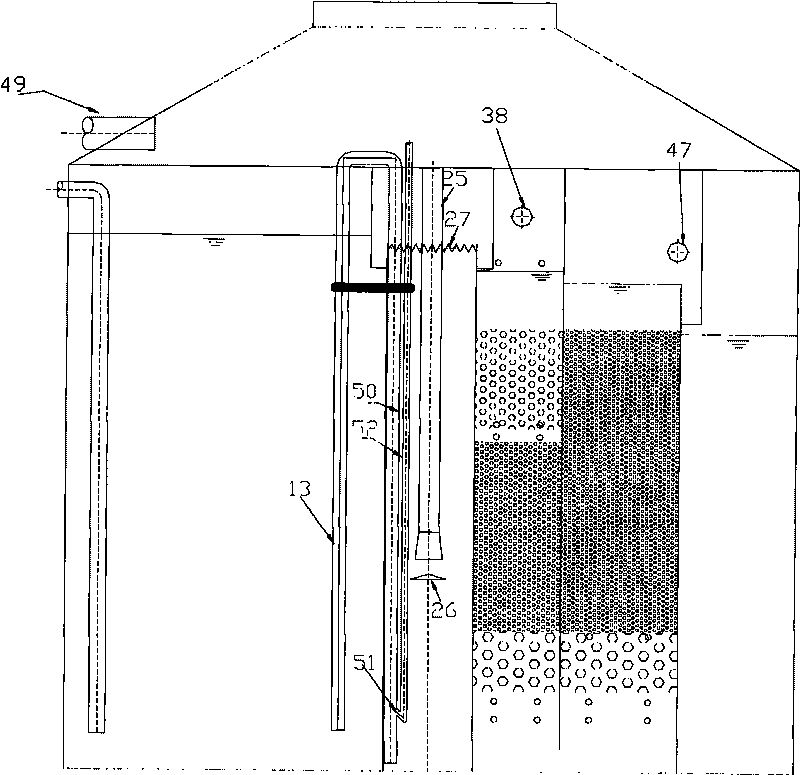

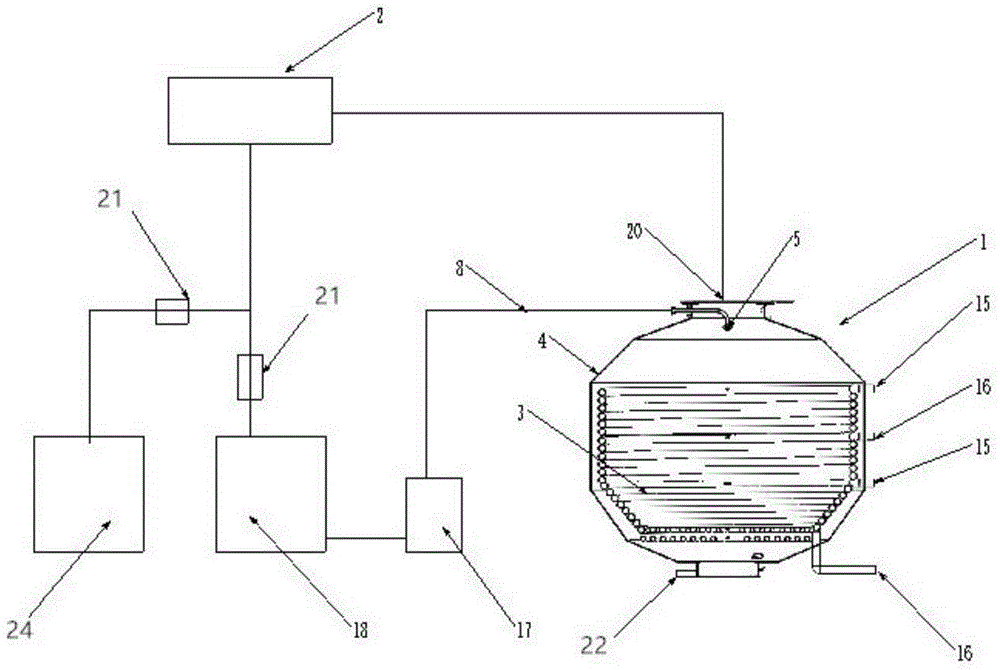

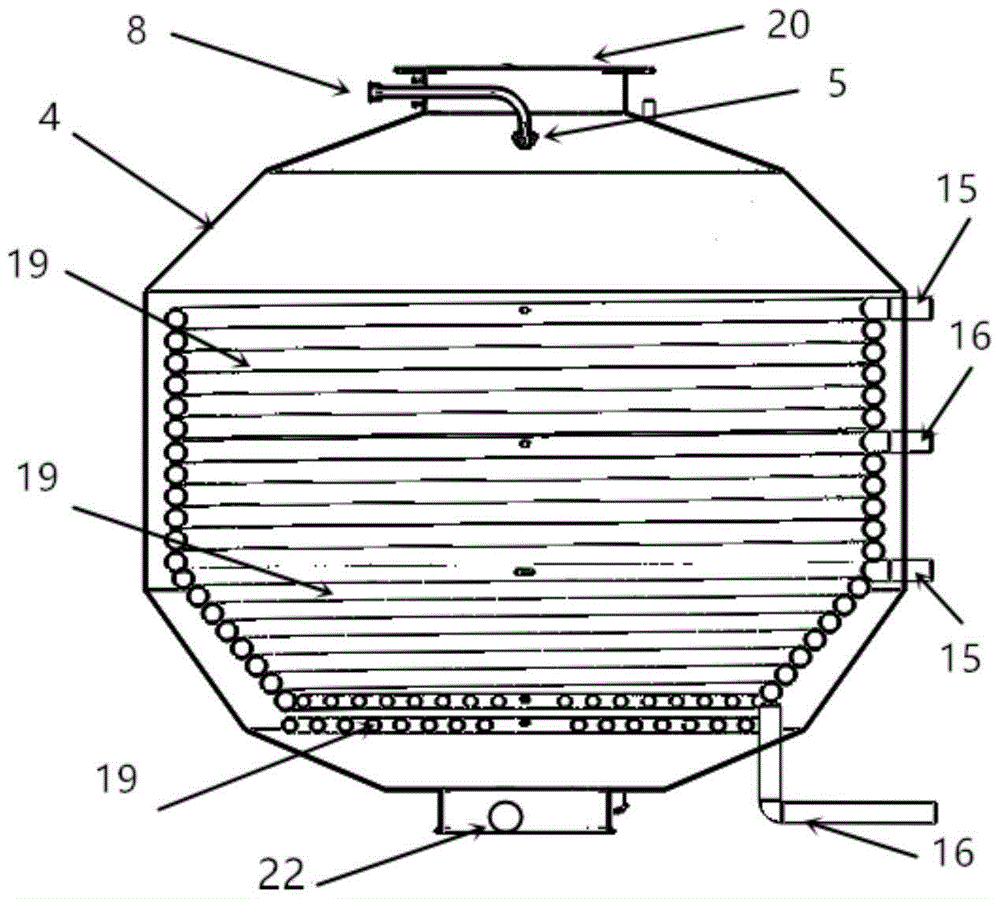

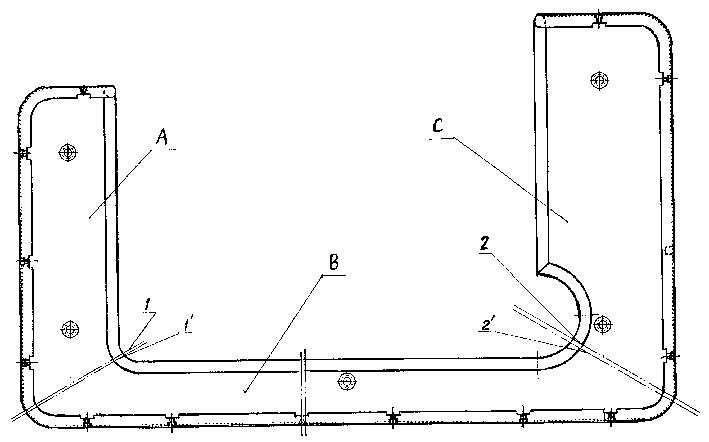

Integrated A/O bacteria filter device for treating dispersed wastewater

ActiveCN101723560ARealize integrationCompact structureTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentSludgeWastewater

The invention relates to an integrated A / O bacteria filter device for treating dispersed wastewater, which has a cylindrical structure in shape. The center of the integrated A / O bacteria filter device is provided with a cylindrical erect flow primary settling tank, a baffle wall is arranged between an inner cylinder body and an outer cylinder body, and a space is divided into an adjusting tank, a hypoxia bacteria filter, an aerobe filter, a clear water tank and a mud storage tank. The aerobe filter and the clear water tank are in a concentric circle arc structure. Wastewater in the adjusting tank is lifted into the primary settling tank through an air lifter, the settled wastewater and recycled nitrification liquor are together distributed into the hypoxia bacteria filter for denitrification, the bottom and the middle part of the hypoxia bacteria filter are provided with backwashing pipelines which can realize subsection washing; the hypoxia bacteria filter is communicated with the bottom of the aerobe filter, the denitrified wastewater overflows from the surface into the clear water tank for outputting after organic matters are removed and nitrification is carried out in the aerobe filter. The backwashing wastewater of the device flows into the adjusting tank per se, and mud in the primary settling tank is lifted into the mud storage tank through the air lifter. The invention has the advantages of less investment, little operation cost, longer mud discharge period and convenient management, thereby being suitable for treating the dispersed wastewater in countryside.

Owner:TONGJI UNIV

Forming method of titanium alloy oil tank shell

InactiveCN105033568AImproved precision forming processAchieving Precise FormingDrive wheelButt welding

The invention belongs to the field of precise panel machining, and discloses a forming method of a titanium alloy oil tank shell. The forming method comprises the following steps that firstly, the shape of an unfolded material of a component is calculated according to the theoretical diameter of the neutral plane of the titanium alloy oil tank shell, blanking is carried out in the direction of fiber of a rolled blank, and a panel material is obtained; secondly, the cold roll bending diameter of the oil tank shell is determined according to the structural parameters of a cold roll machine; thirdly, roll bending forming is carried out on the panel material through the cold roll machine according to the cold roll bending diameter of the oil tank shell; fourthly, butt welding is carried out on the panel material formed through roll bending; and fifthly, thermal correcting and stabilizing processing are carried out on a cylindrical piece formed through welding. The technology allowance and machining procedures needed by the thermal forming technology are greatly saved through unfolded material calculation, drive wheel pressing displacement compensation calculation, electron beam butt welding and the composite technology of thermal correcting and stabilizing processing; and according to the precise forming technology of the whole oil tank shell, the production efficiency is greatly improved, and the producing and manufacturing cost is reduced.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

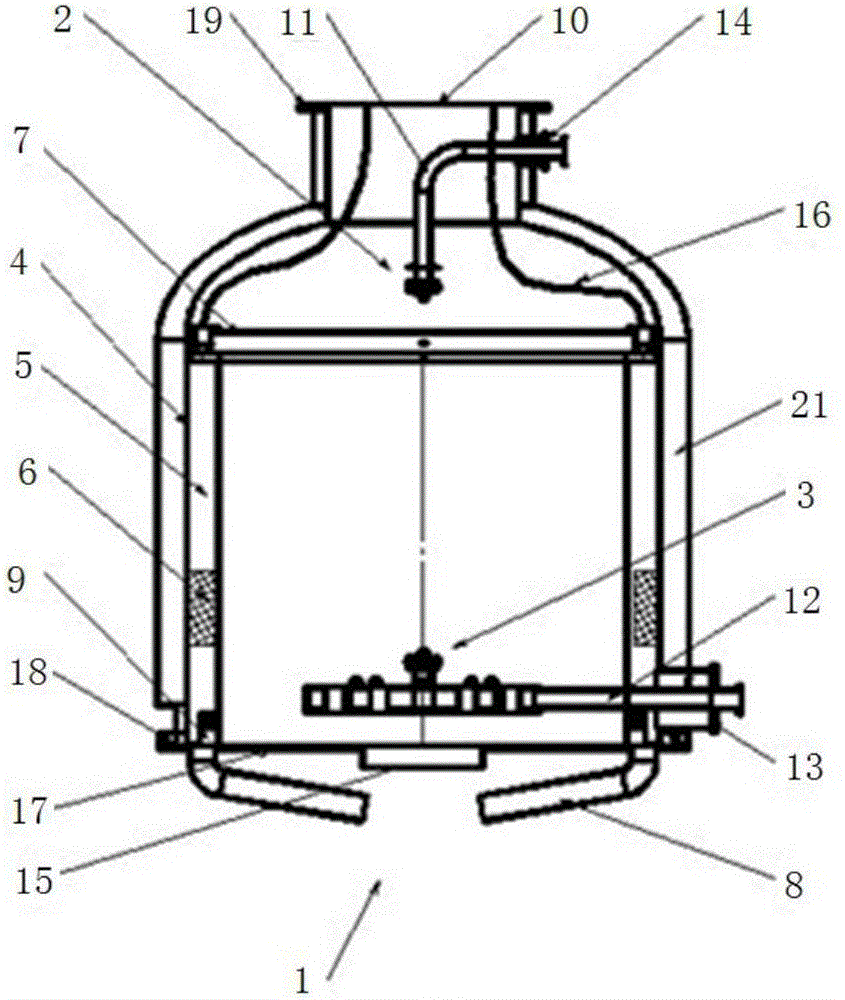

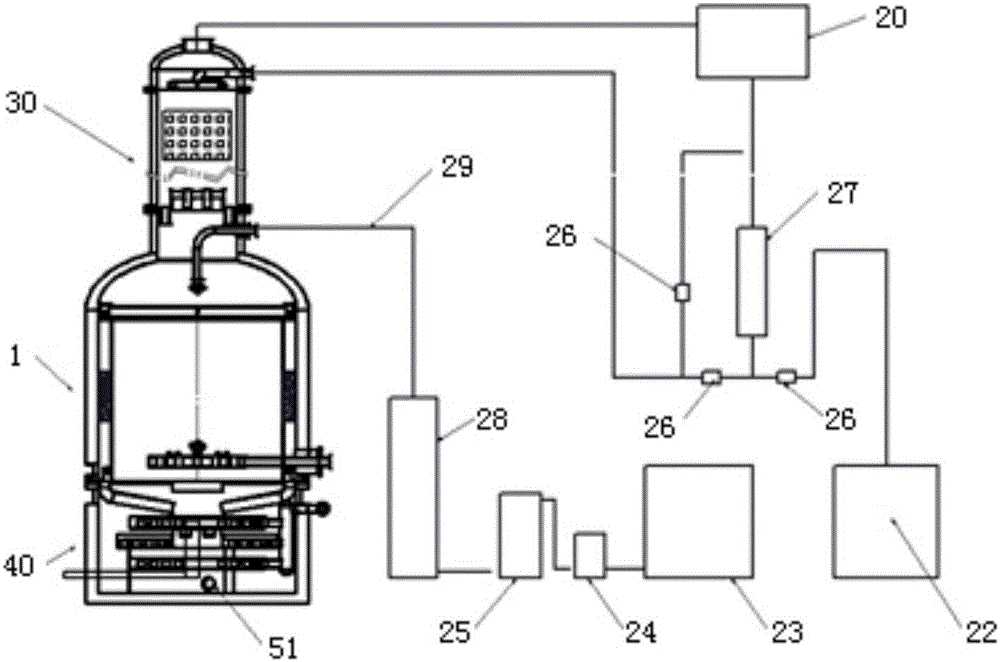

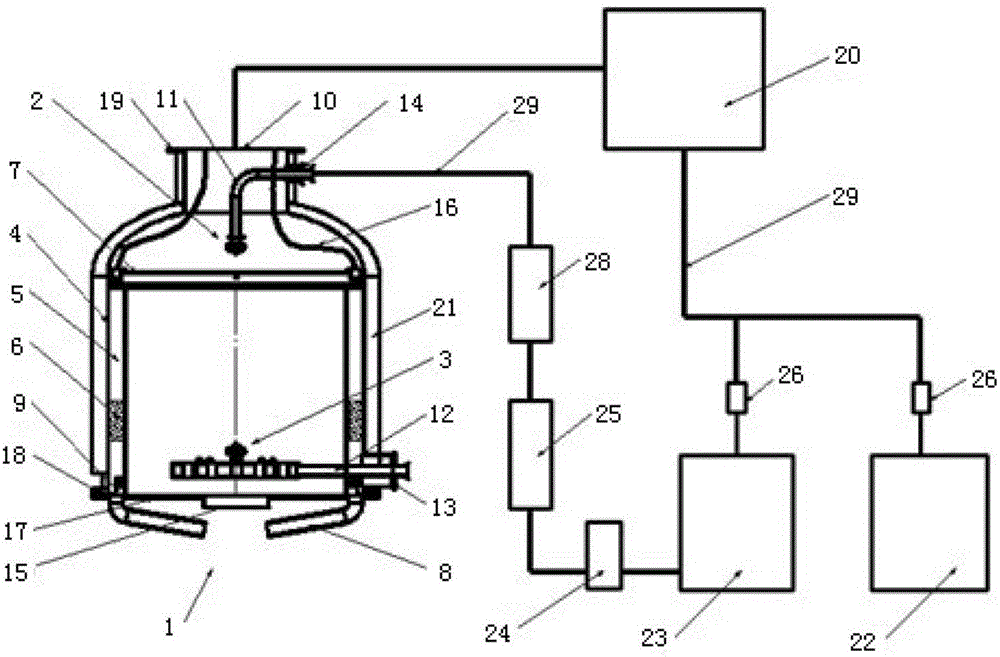

Spray distillation device

InactiveCN105920861AEasy to separateIncrease contact areaEvaporation by sprayingWater vaporDistillation

The invention discloses a spray distillation device, which comprises at least one evaporation chamber, a feed solution inlet pipe, a raw material preheater, a filter, a pump, a feed solution storage tank and a finished product storage tank, wherein the evaporation chamber comprises a shell, a feed solution atomizer, a water vapor distributor and a reflux treatment device; an easy-to-volatilize phase outlet is formed in the top of the shell, and a difficult-to-volatilize phase outlet is formed in the bottom; the feed solution atomizer and the water vapor distributor are mounted in the shell; the feed solution atomizer is connected with the feed solution inlet pipe; the water vapor distributor is connected with a water vapor inlet pipe; the reflux treatment device is mounted in the shell, and consists of a reflux conduit, a water spraying ring, a filler net loop, a residual liquid ventilation cap, a residual liquid discharge pipe and a mounting plate. According to the spray distillation device, a spray distillation technology is adopted instead of an existing mass and heat transfer distillation manner employing an orifice plate or a filler as a main condition, so that heat energy can be completely and effectively utilized, energy resources can be saved, waste liquid discharge reaches the standard, and prominent effects are achieved.

Owner:YANSHAN UNIV

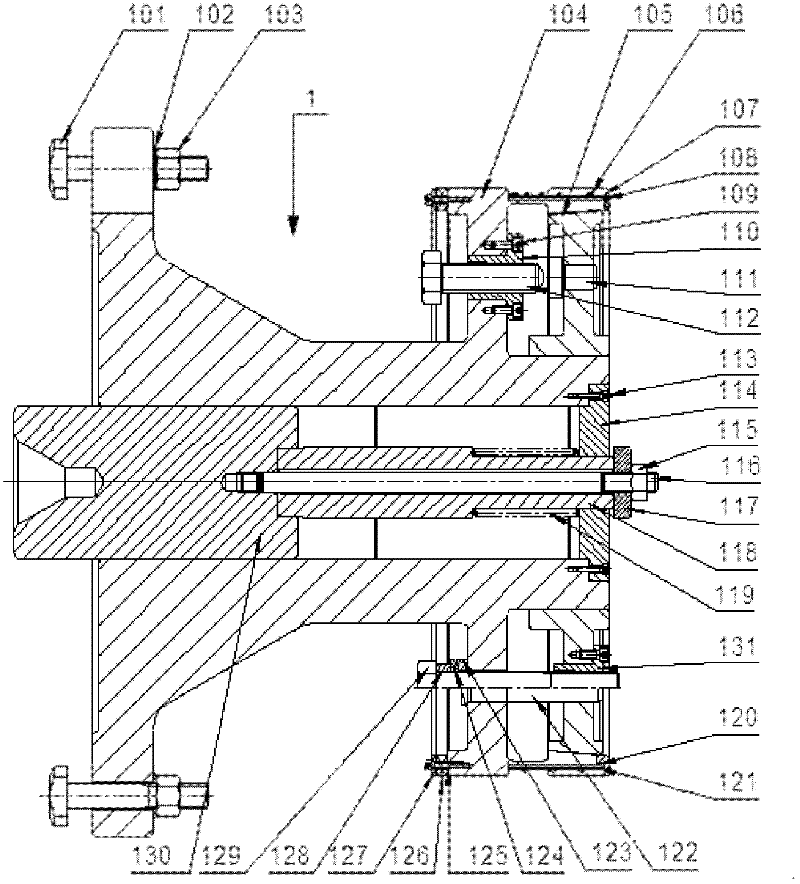

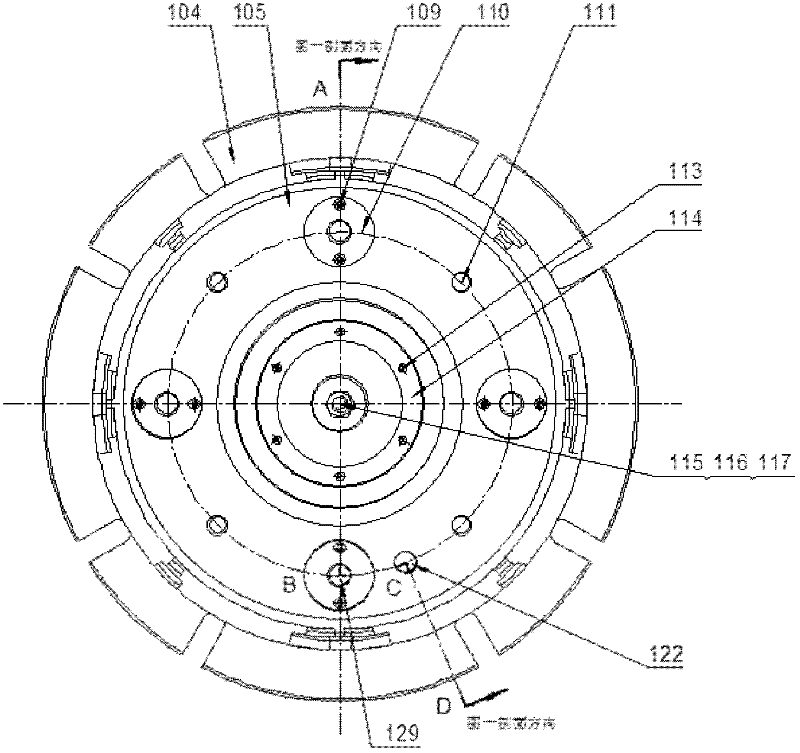

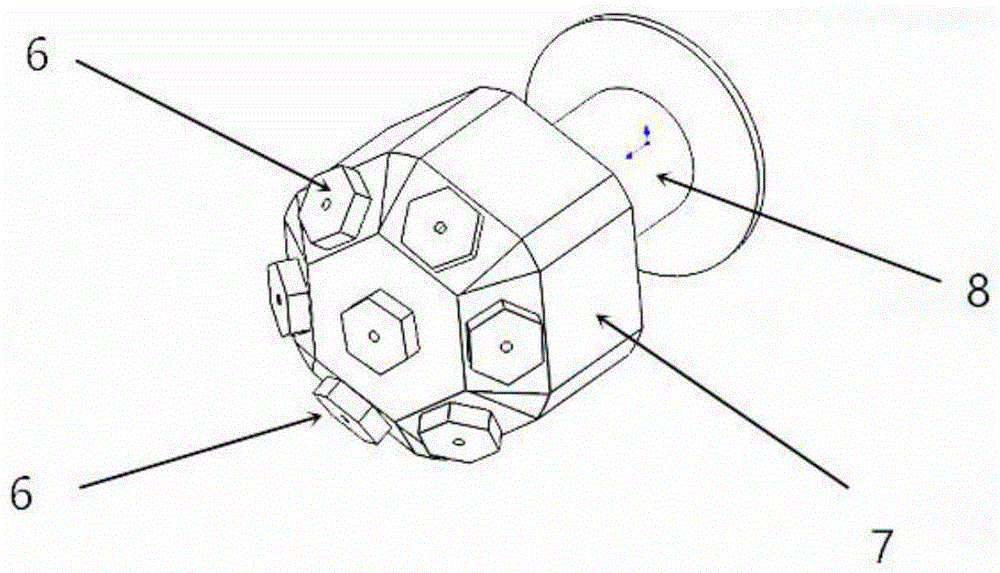

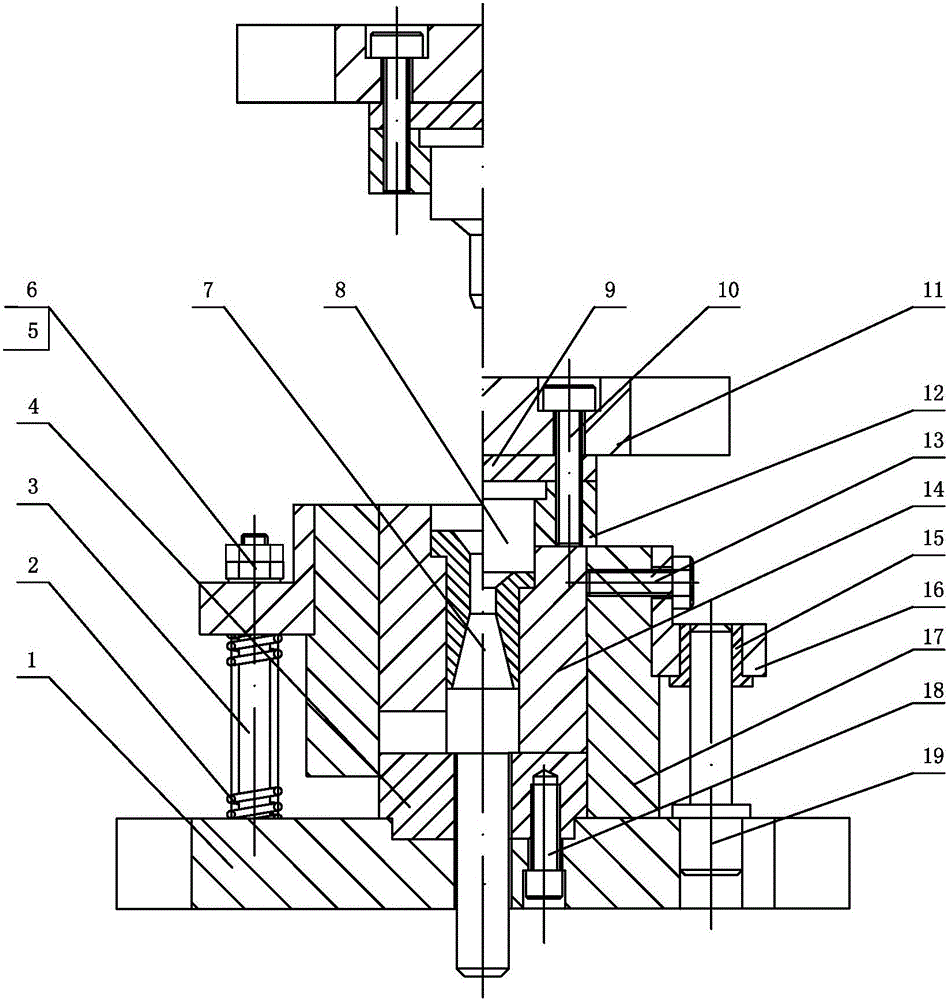

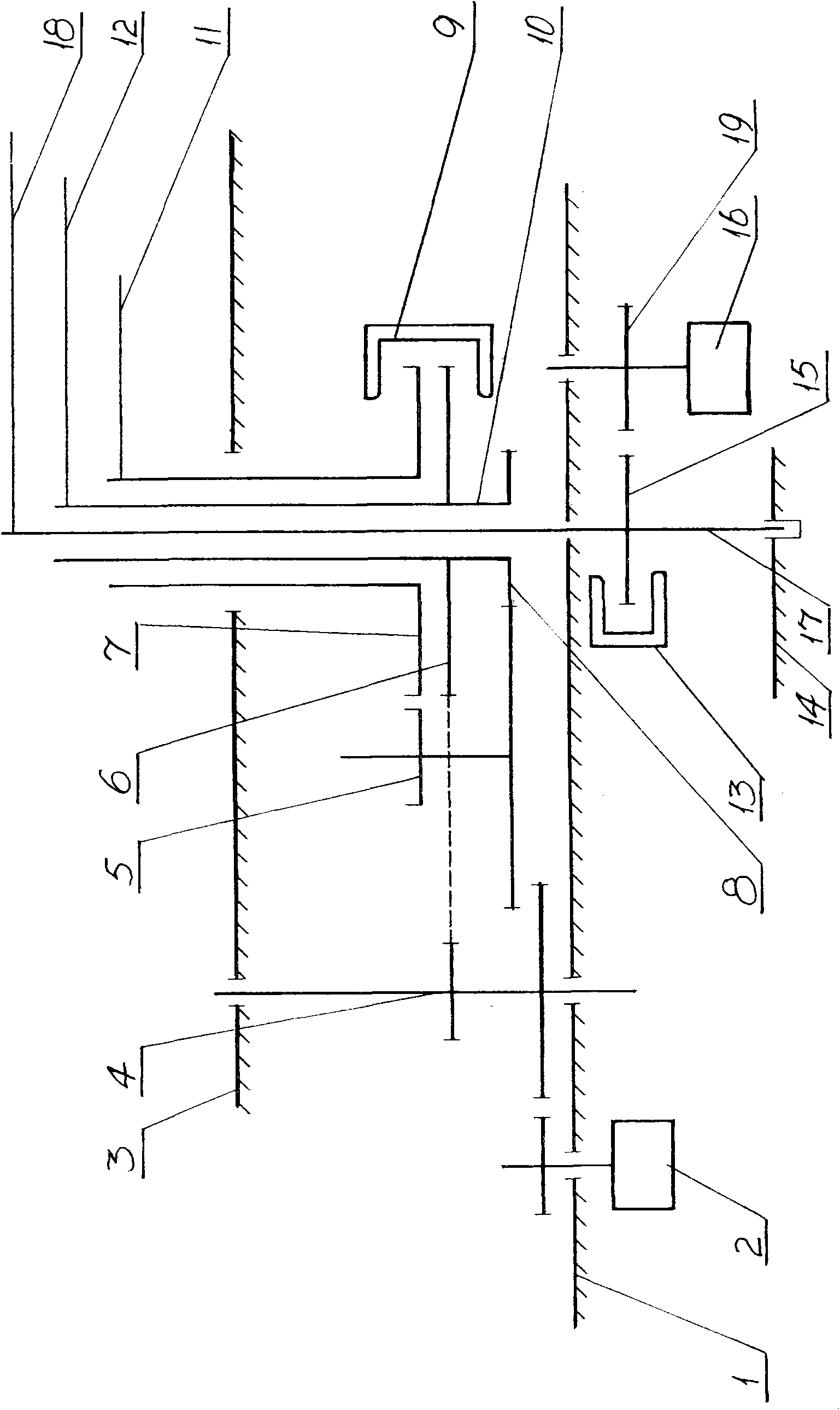

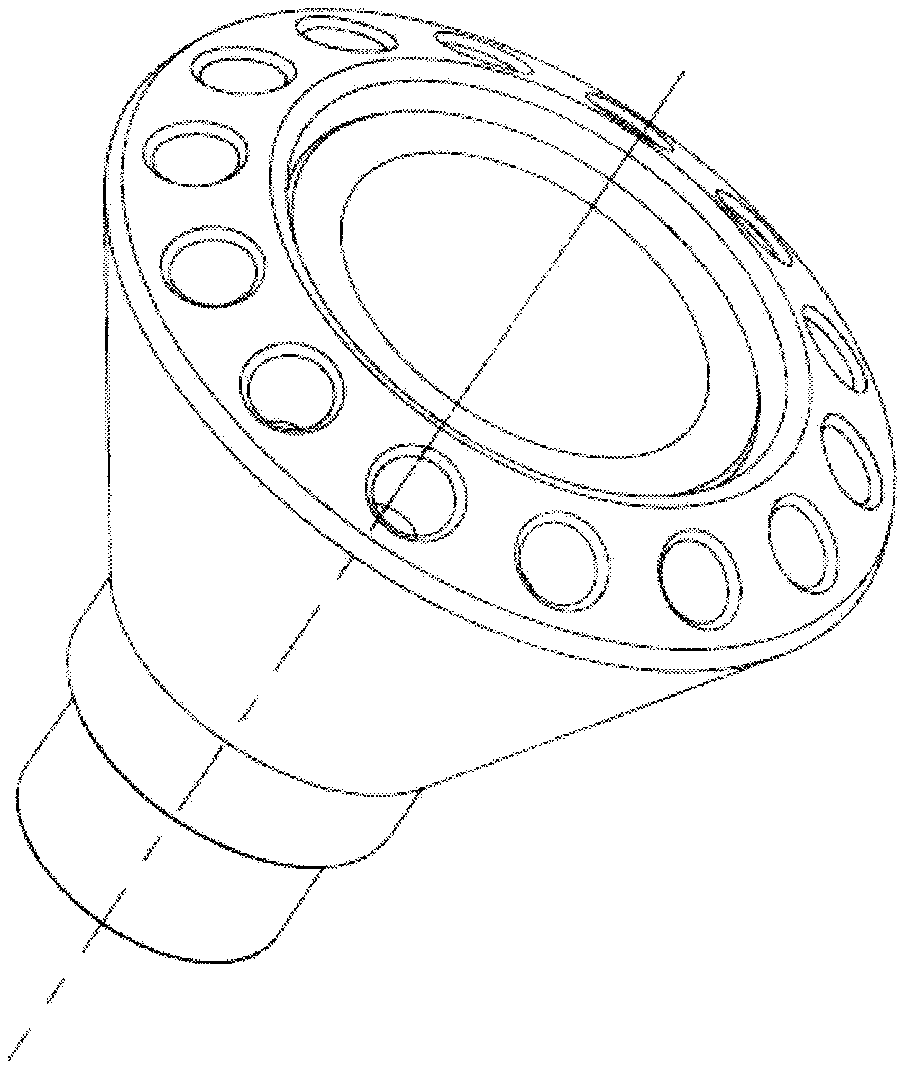

Internal expanding type centering fixture for turning large-scale sleeve parts

The invention discloses an internal expanding type centering fixture for large-scale sleeve parts. The internal expanding type centering fixture comprises a chuck fixture and a tail shaft base fixture which have a same shaft axis, wherein the chuck fixture comprises a fixture body, a cone body, a thread bushing and a spring base; the tail shaft base fixture comprises an elastic body, a cone body,a tail shaft, an expanding linking sleeve and an angular contact ball bearing; and the cone body is axially tensioned through bolts mounted on the fixture body or elastic body and the thread bushing on the cone body, so as to expand an elastic part of the fixture body or elastic body along the radial direction and tightly expand a workpiece. The internal expanding type centering fixture is suitable for processing the sleeve parts on a horizontal lathe. By once clamping and positioning the sleeve parts, the purpose of processing an external circle and two end faces of a cylinder jacket of a marine diesel can be realized. The internal expanding type centering fixture is characterized by compact structure, high rotating speed, high axiality, convenience in use and assembly, and the like. Theworkpiece is prevented from being repeatedly mounted on the lathe, so that the workpiece is processed more smoothly.

Owner:HUDONG HEAVY MACHINERY

Casting method of casting with machining reference

The invention relates to the field of casting, in particular to a casting method of a casting with a machining reference. The casting method is characterized in that when a mould is manufactured, the position of a pre-embedded special-shape nut is confirmed on a template and surrounded by a half movable block; a special-shape nut with a bolt is embedded into the half movable block during moulding; when a box is covered, the screwing depth of the bolt is slightly lower than the nut plane, the bolt is filled by refractory mortar, and the periphery of the nut is sealed by a box sealing strip so as to prevent molten iron from entering screw threads during pouring; the bolt is screwed out and the internal screw thread of the nut is tapped by a screw tap during finishing. Compared with the prior art, the invention not only can pre-embed the special-shape nut on the machining reference surface, but also can perform machining positioning by the nut, prevent the machining working procedure of machining the reference surface and save the machining time and cost.

Owner:太仓林飞铸造有限公司

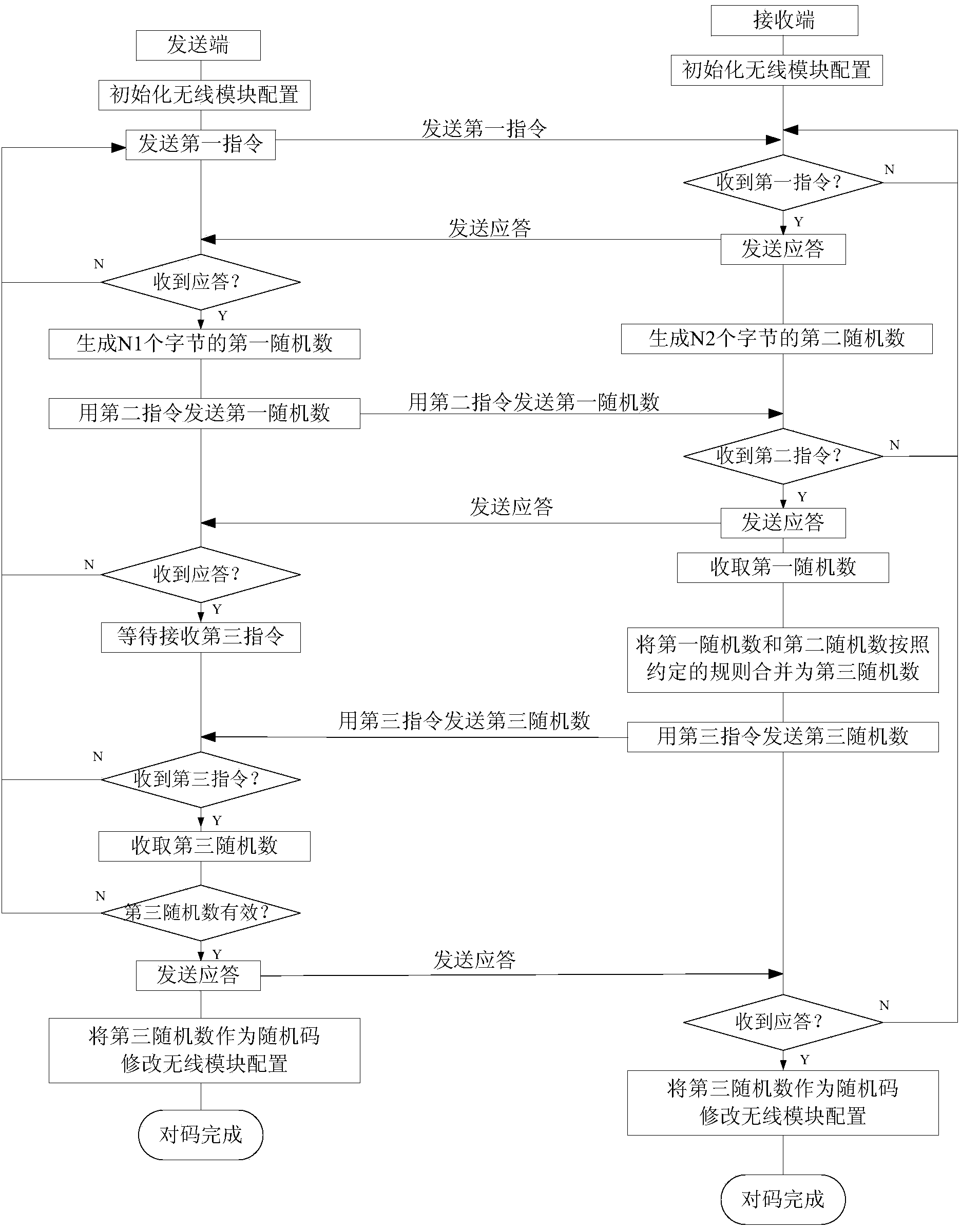

Automatic code matching method for wireless transceivers

The invention provides an automatic code matching method for wireless transceivers. Mainly, a transmitting end and a receiving end are adopted to carry out handshake response mutually so as to ensure mutual connectivity; the transmitting end and the sending end respectively generate random numbers; the respectively generated random numbers are merged according to rules appointed by both parties to generate a unique random code so as to ensure uniqueness of the random code. According to the automatic code matching method, any one pair of wireless transceivers can correspond to each other and do not interfere with each other. In the method, repeated handshake response of the transmitting end and the receiving end reduces an error rate generated by code matching. The transmitting end and the receiving end respectively have the own random numbers, correspond to each other, are not interfered by other wireless devices and also do not interfere other wireless devices.

Owner:无锡英斯特微电子有限公司

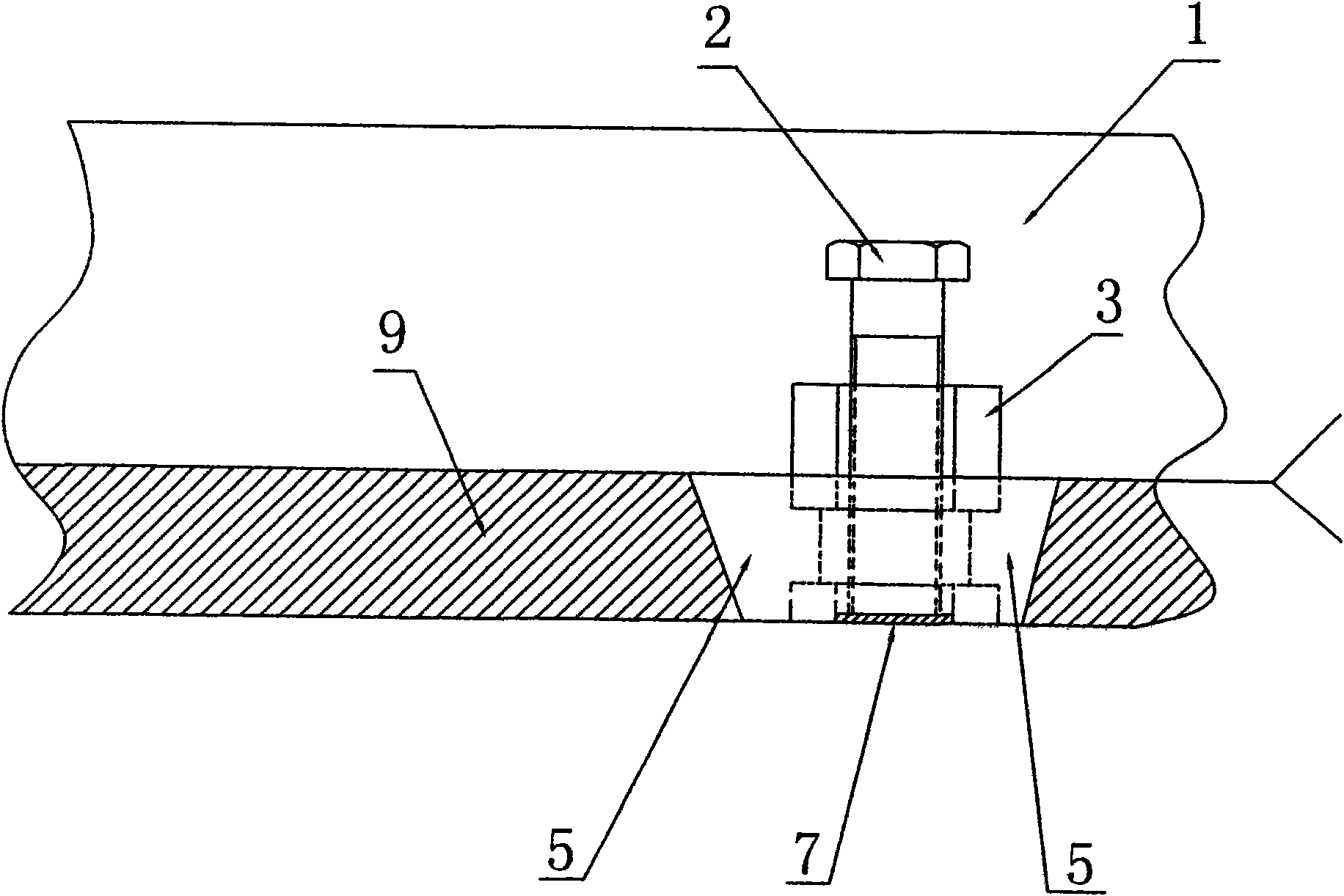

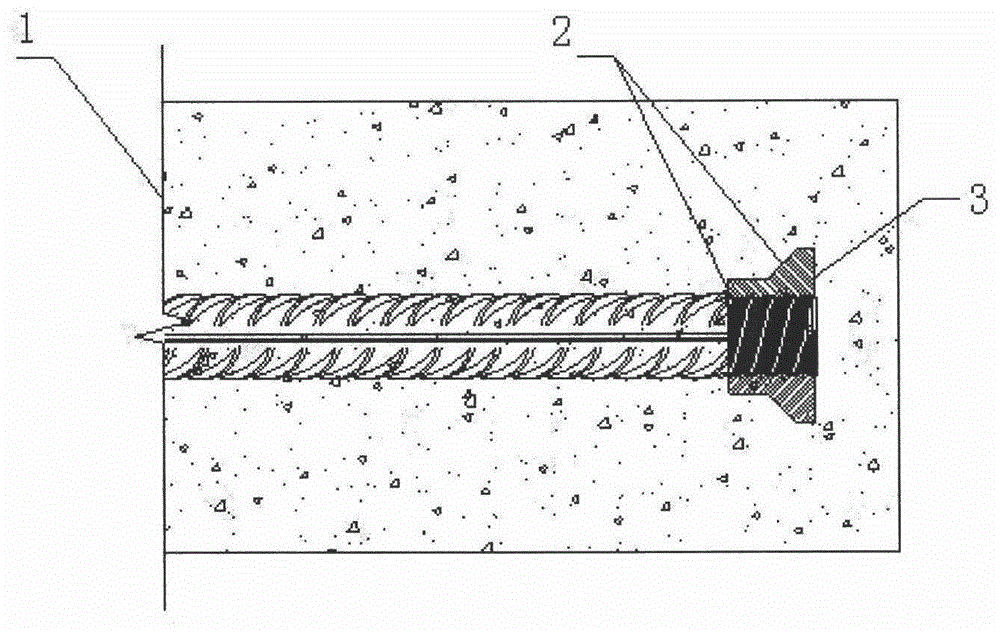

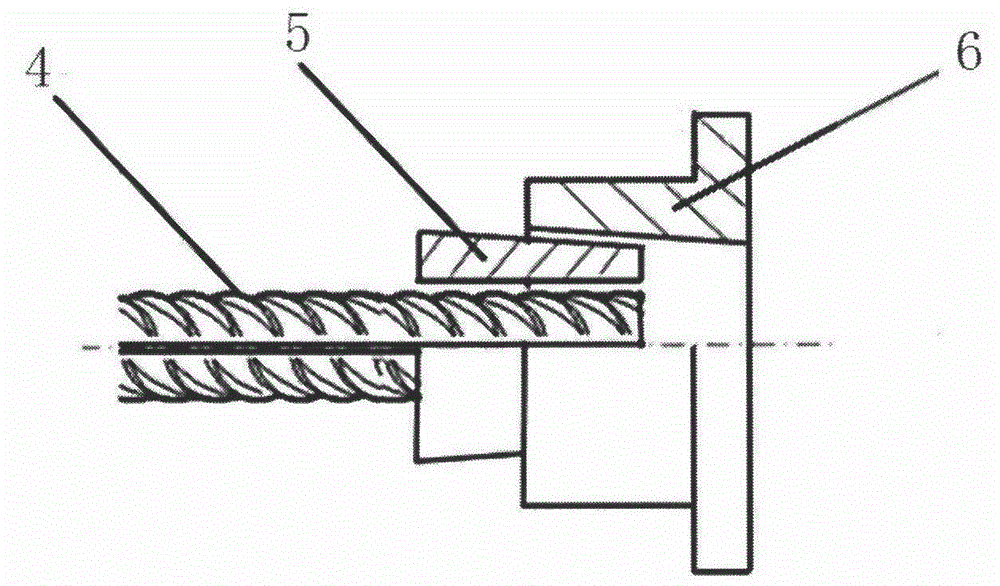

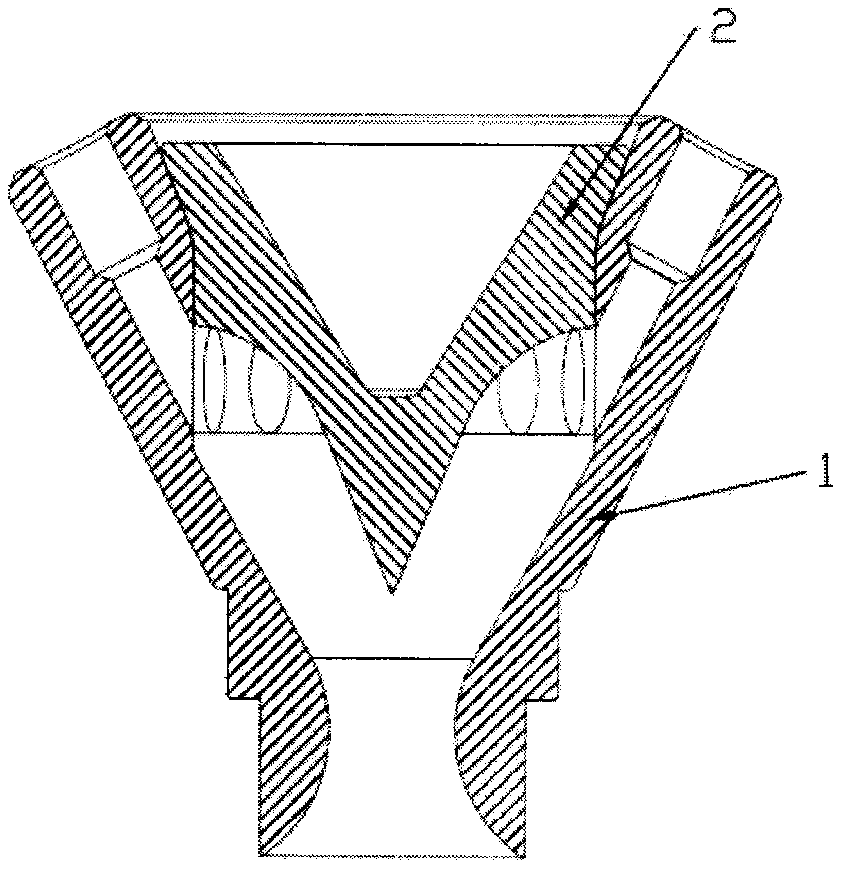

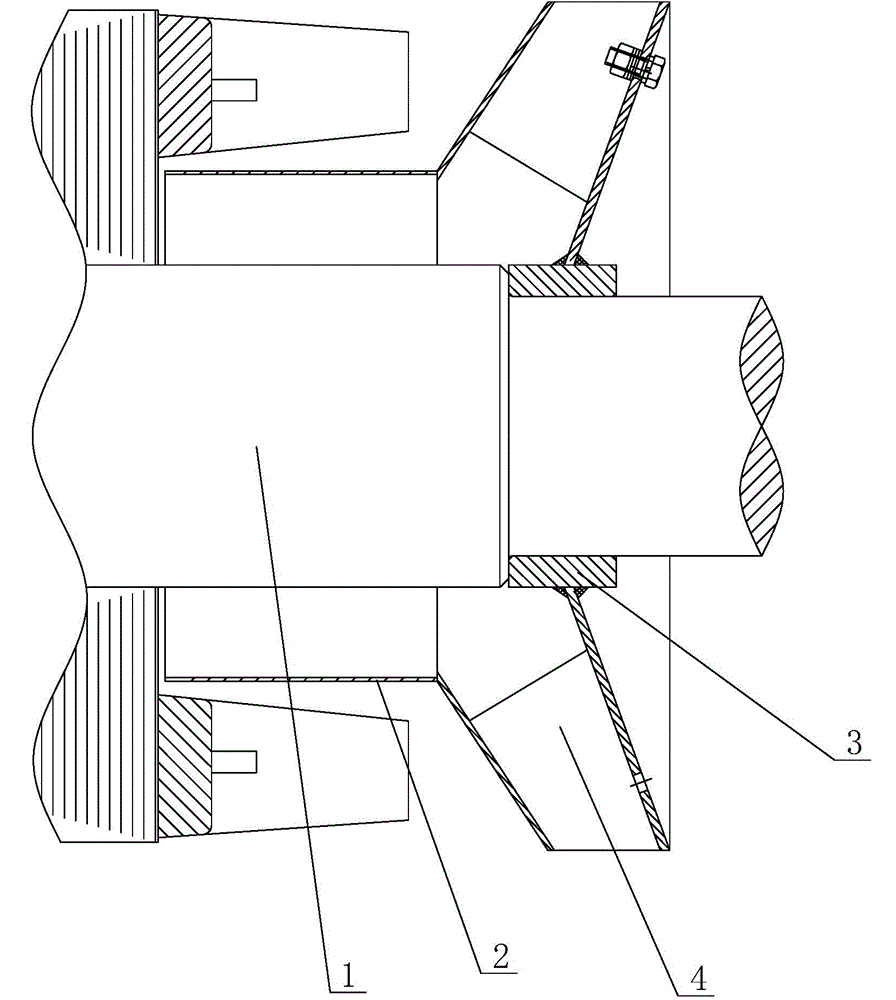

Anchoring device for taper sleeve-locking reinforcements and anchoring method thereof

InactiveCN104895252ASave workabilitySave processing costBuilding reinforcementsReinforced concreteControl quality

The invention relates to an anchoring device for a taper sleeve-locking reinforcements and an anchoring method thereof, and belongs to the technical field of reinforced concrete anchoring. The anchoring device comprises a plurality of clamping sheets and taper sleeve anchoring plates at the outer sides of the clamping sheets, wherein each clamping sheet is provided with a tooth-shaped inner surface and a single-conical-surface outer surface, and reinforcements to be anchored are wrapped and clamped through the tooth-shaped inner surfaces; each taper sleeve anchoring plate is in a head-shoulder integrated shape and provided with a conical hole at the centre, and the clamping sheets and the reinforcements to be anchored sequentially sleeve the inner centres of the conical holes and locked simultaneously through the taper sleeve anchoring plates; the tooth-shaped inner surface of each clamping sheet is provided with a plurality of spaced trapezoidal teeth, and threads for anchoring are not needed at the end parts of the reinforcements to be anchored. The anchoring device disclosed by the invention omits the prefabrication link of reinforcement thread machining, saves the machining structure and the machining cost of the prefabrication link, and is fast, convenient and reliable to install, and easy for control quality.

Owner:青岛森林金属制品有限公司

Rectification device

InactiveCN105194898AGood mass and heat transferIncreased content of volatile phaseFractional distillationThermal energyEngineering

The invention relates to a rectification device which at least comprises an evaporation chamber, wherein the evaporation chamber comprises a heating device, a housing and a mistorizer; a volatile-phase outlet is formed in the upper part of the housing; the mistorizer is mounted in the housing, and is communicated with a feed pipe; the heating device is mounted in the housing; a non-volatile-phase outlet is formed in the lower part of the housing. The rectification device has the advantage that heat energy can be utilized sufficiently and effectively.

Owner:LIAONING TAOXIAN PHARMA MACHINERY CO LTD

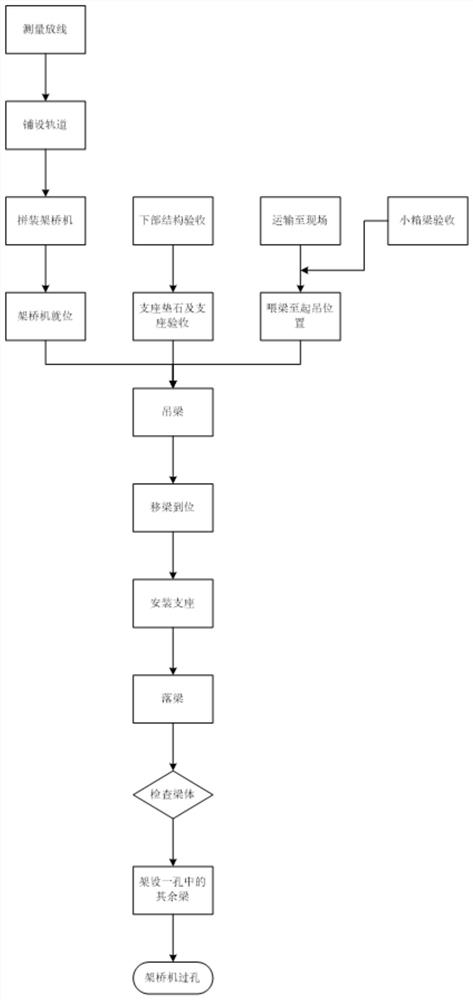

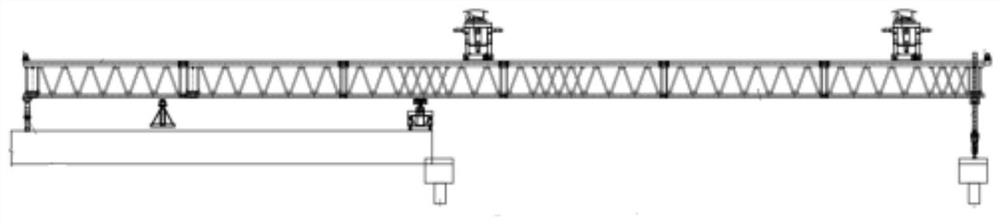

Construction method for prefabricated box girder support in complex city environment

PendingCN113957793AEasy to transportSimple structureBridge erection/assemblyBridge engineeringArchitectural engineering

The invention discloses a construction method for a prefabricated box girder support in a complex city environment, and belongs to the technical field of bridge engineering, and the construction method comprises the following steps: S1, carrying out surveying and setting out; S2, laying tracks, and assembling a bridge girder erection machine; S3, enabling the bridge girder erection machine to erect the box girder in a high-low mode; S4, mounting a support; S5, fixing the box girder; S6, carrying out bridge deck girder feeding and box girder erection of the bridge girder erection machine; and S7, performing crossing of the bridge girder erection machine. The truss double-beam bridge girder erection machine is adopted, a main truss of the bridge girder erection machine adopts standing rod pieces, transportation is convenient, the assembling and disassembling speed is high, the cost is saved, the machining period is shortened, high-low hoisting construction is adopted, a girder lifting station is not arranged, box girders are transported to the erection position through an offline transport vehicle, and the bridge girder erection machine directly lifts and erects the girders; a girder is lifted in the middle of an erection pier position, the mode that the front portion is high and the rear portion is low is adopted, box girders are lifted and longitudinally moved through a crane carriage, 1-2 spans are installed through a crane before a bridge girder erection machine is installed, and installation of the bridge girder erection machine is facilitated.

Owner:中能建建筑集团有限公司

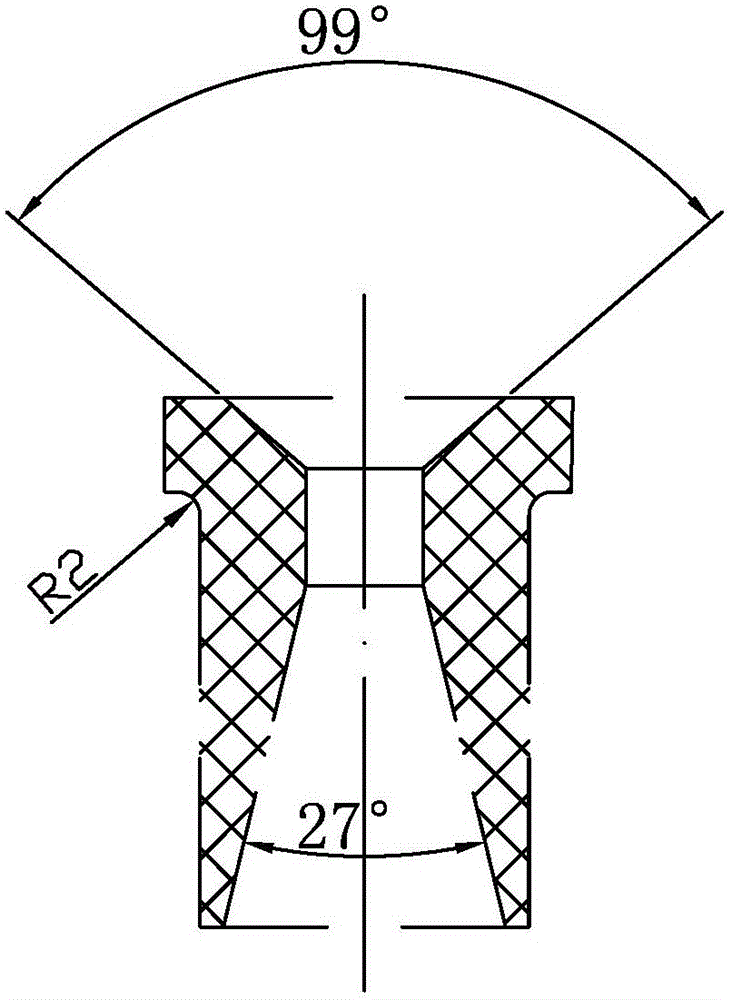

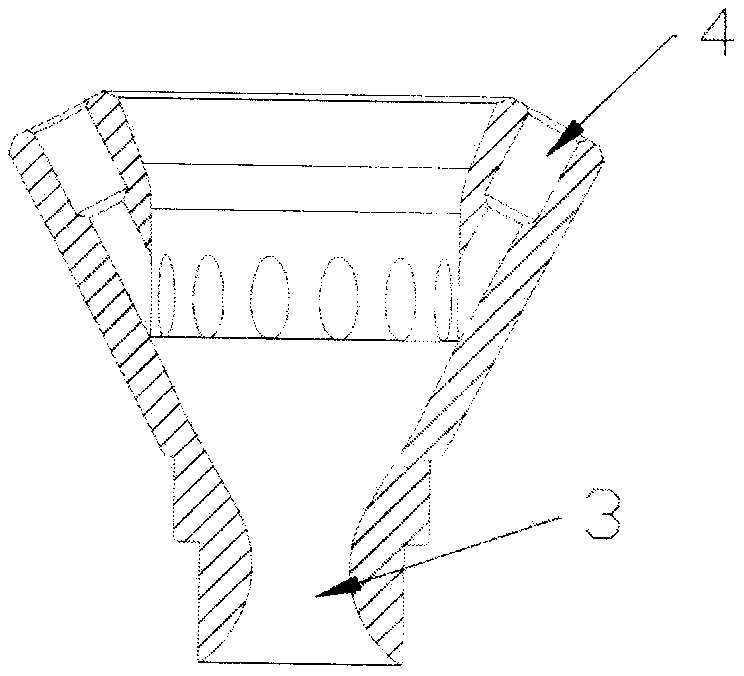

Forming technological method and forming mould for engine jet pipe

ActiveCN105880609AImprove mechanical performance indexImprove performance indicatorsTransportation and packagingMetal-working apparatusHigh pressureMachining

The invention discloses a forming technological method and a forming mould for an engine jet pipe, and relates to an extrusion forming method and a forming mould. The forming technological method and the forming mould are used for solving the problem that scouring burning loss on the neck of the spray pipe is caused by fuel gas as a result of poor high temperature resistance and poor high pressure resistance of parts of the engine jet pipe. The forming technological method comprises the following steps: I, preparing materials; II, preparing equipment; III, pre-forming; IV, sintering; V, carrying out hot extrusion forming; VI, carrying out quenching treatment; VII, carrying out low-temperature tempering; VIII, finish machining; and IX, phosphating. According to the forming mould, a cushion block is mounted in a groove of a lower mould base, wherein the lower mould base is connected with the cushion block; a reinforcing mould sleeve is mounted on the lower mould base; a return plate is clamped on a limiting table shoulder of the reinforcing mould sleeve; a plurality of return rods and a plurality of guide posts are separately arranged between the reinforcing mould sleeve and the lower mould base; a plurality of guide sleeves are mounted on the reinforcing mould sleeve in a plug-in manner; a concave mould is mounted in the reinforcing mould sleeve; a lower core mould is mounted in the concave mould; an upper core mould is clamped in a step hole of a clamping plate; and an upper molding board, a base plate and the clamping plate are sequentially arranged from top to bottom. The forming technological method and the forming mould are used for spray pipe extrusion forming.

Owner:HARBIN JIANCHENG GRP

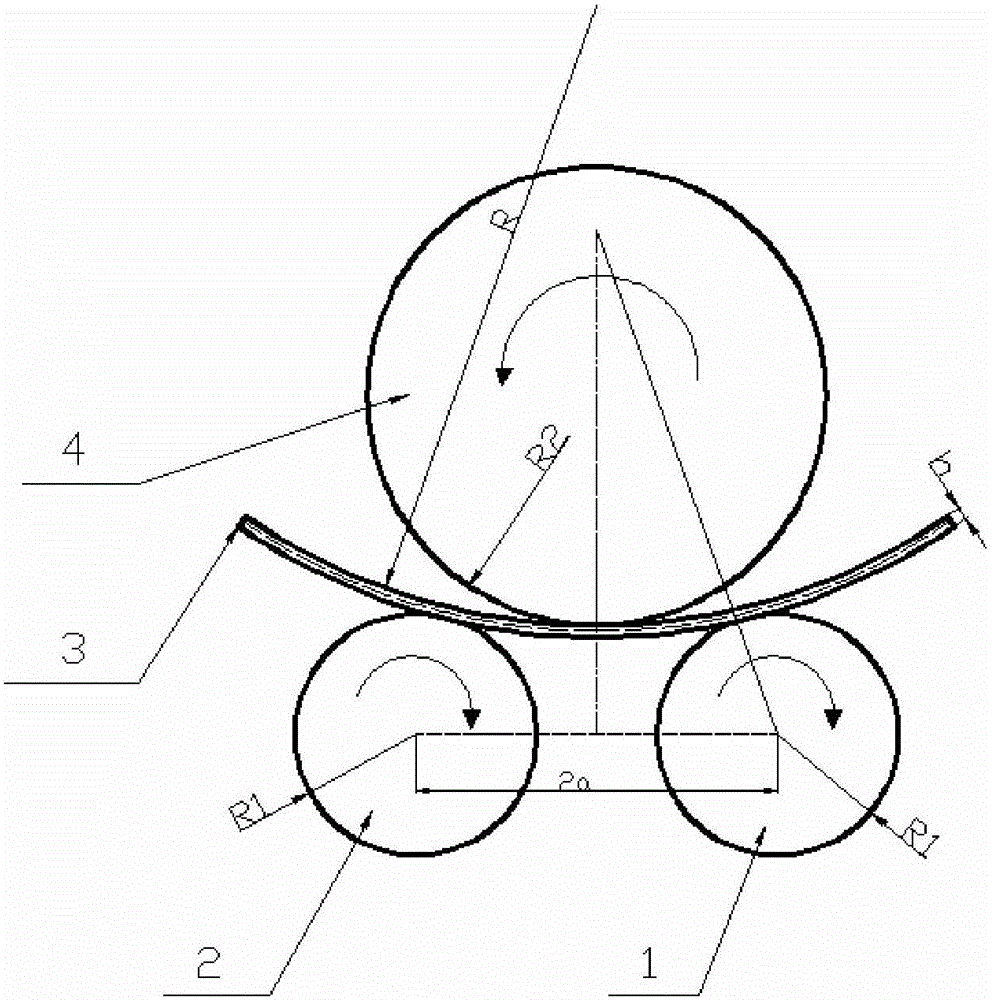

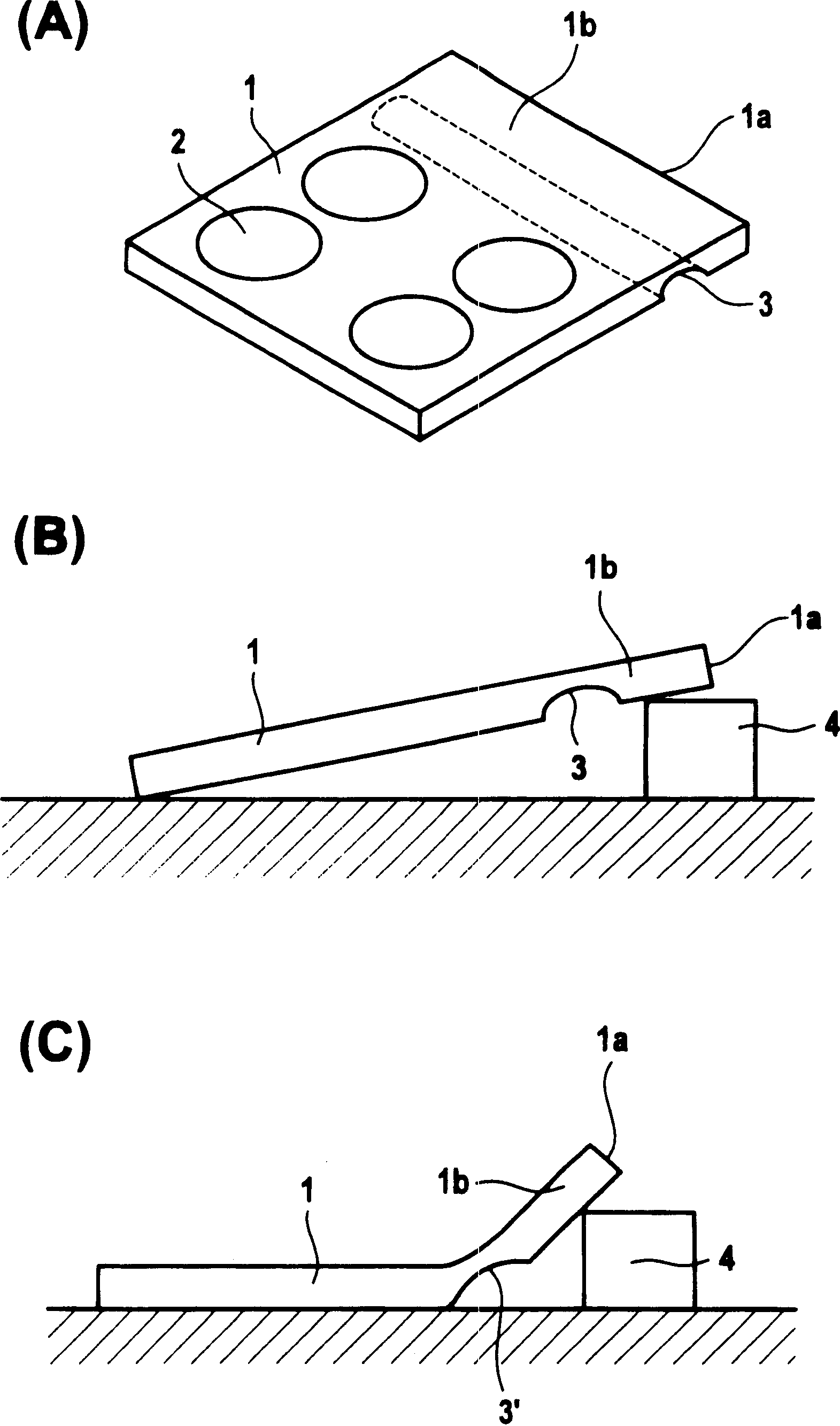

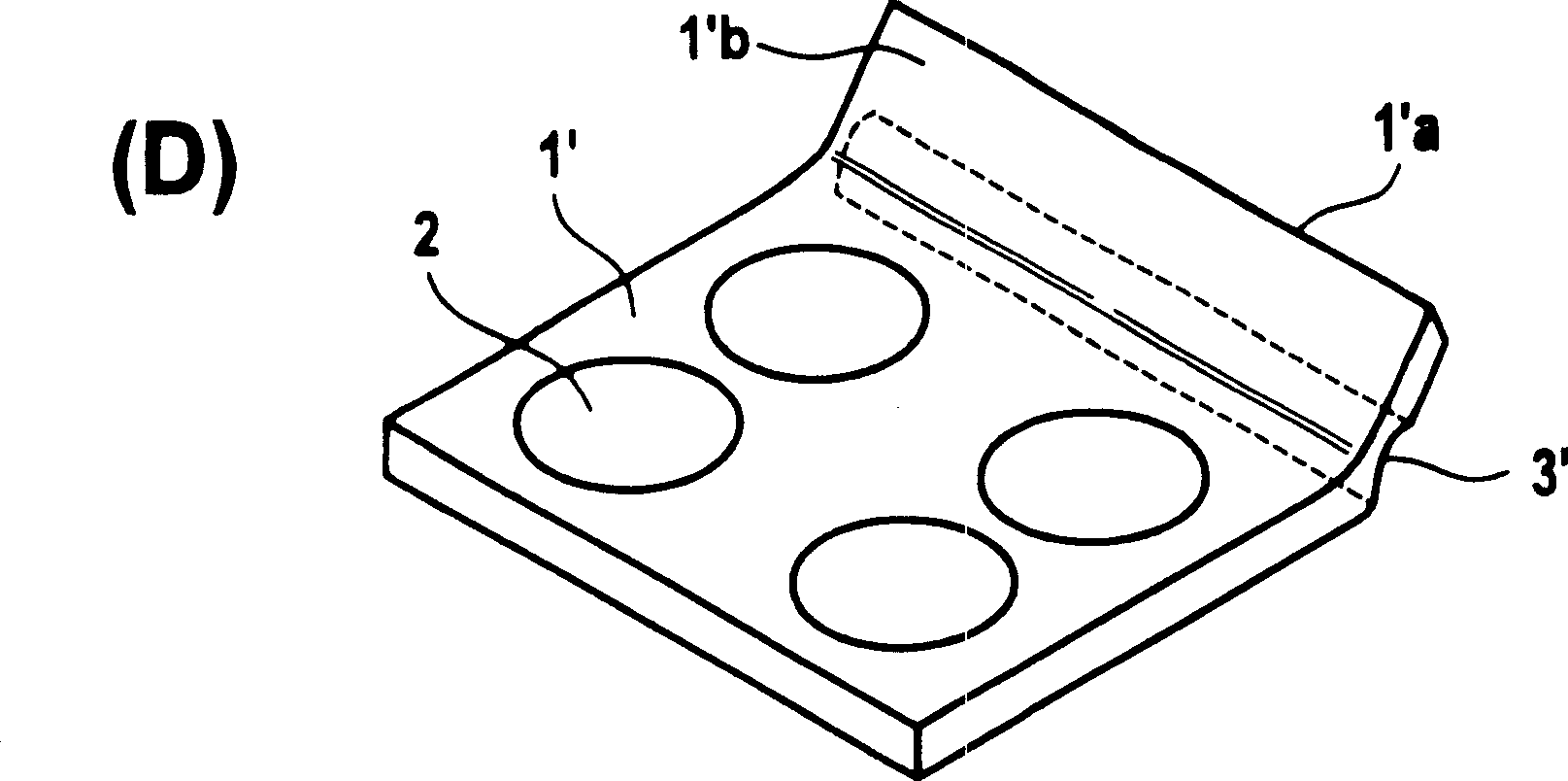

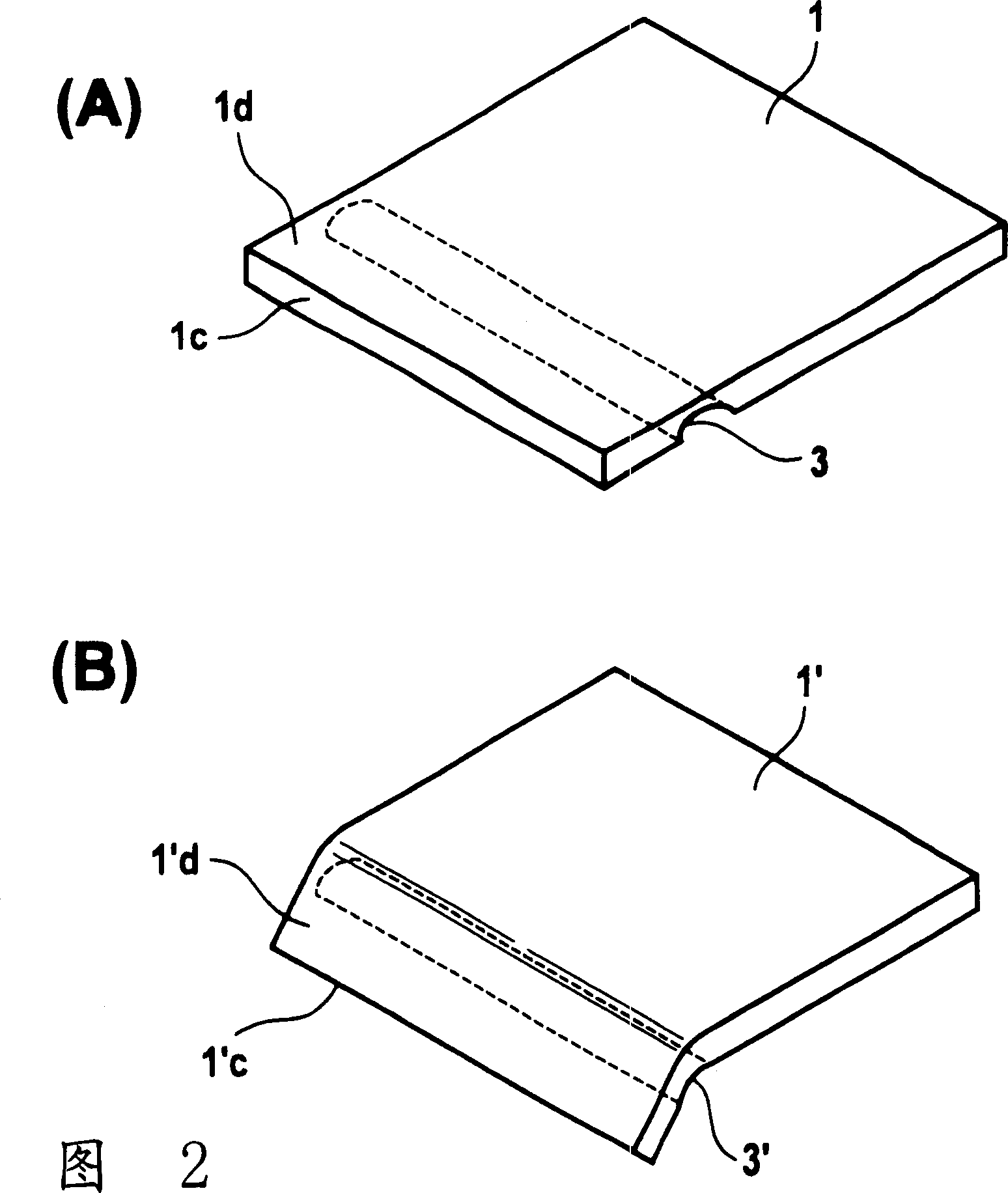

Method for locally shaping of glass sheet and glass sheet or glass ceramic sheet having locally deformed zone

InactiveCN1600717ASave energySave workabilityGlass rolling apparatusGlass reforming apparatusMetallurgyGlass-ceramic

Disclosed are various deforming methods for carrying out partial deformation of glass plate which can be selectively changed to glass ceramic plate, wherein deformation caused by gravity is also provided. In order to execute deformation with high deformation ratio by the method, a thinning of the material corresponding at the contour is realized before the partial deformation in predefined zone of the glass plate (1). The thinning of the material is beneficial to the deformation in great extent. The glass plate or transformed glass ceramic plate produced by the method of the invention can be used as cooling panel or fireplace glass window.

Owner:SCHOTT AG

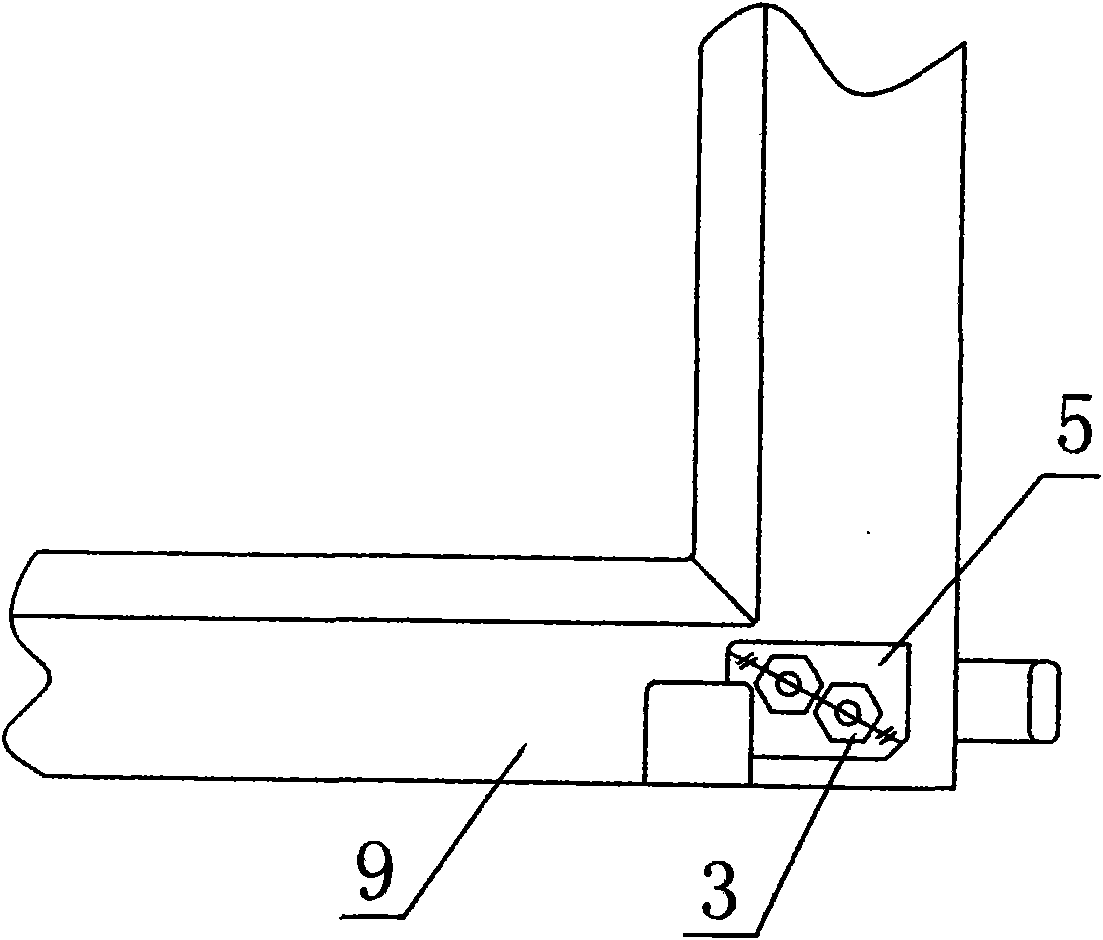

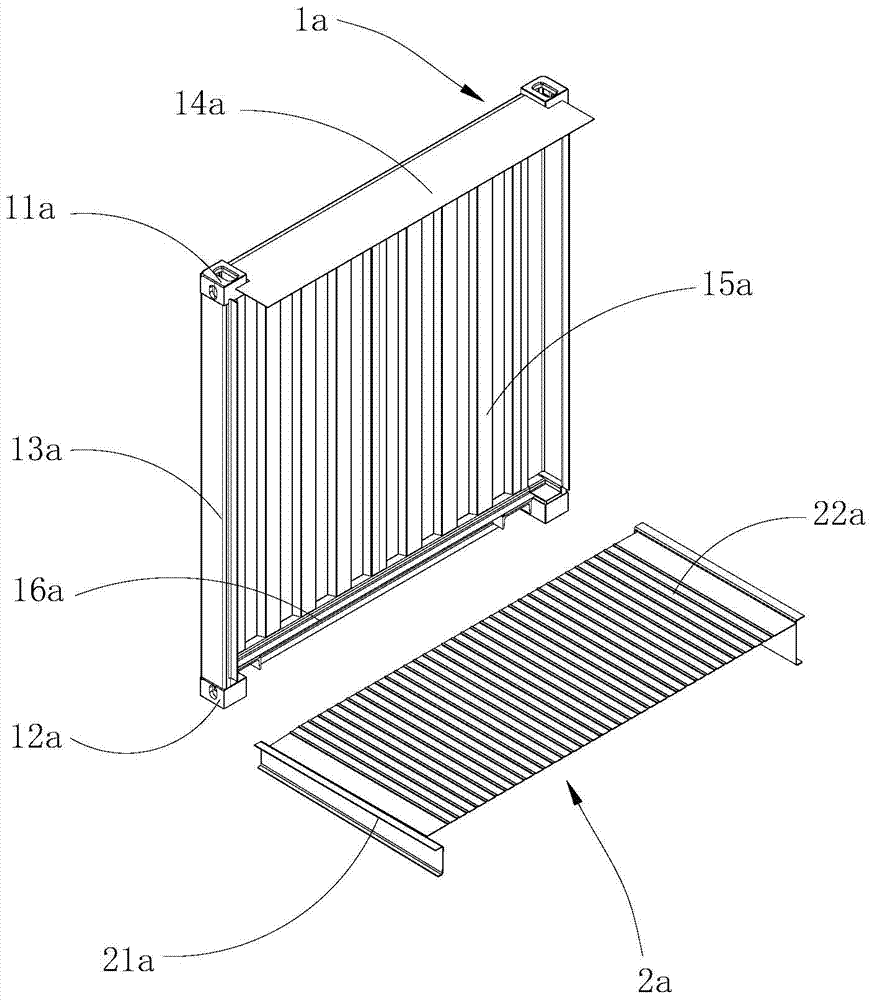

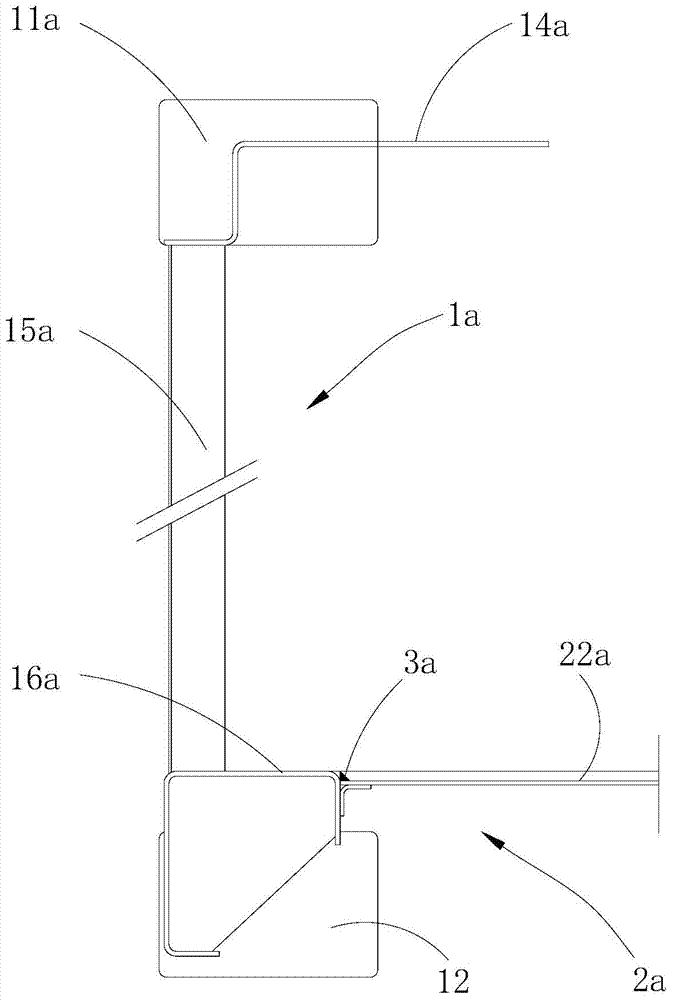

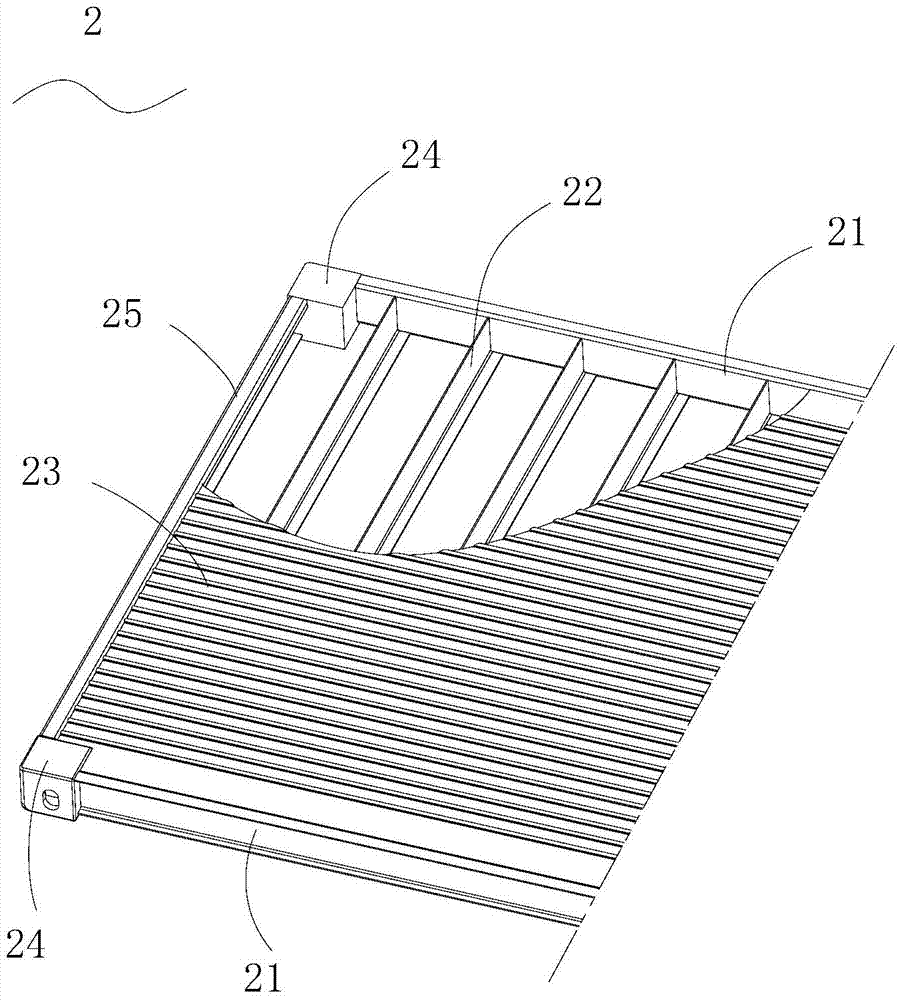

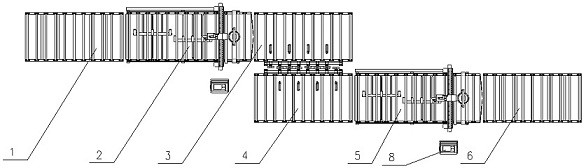

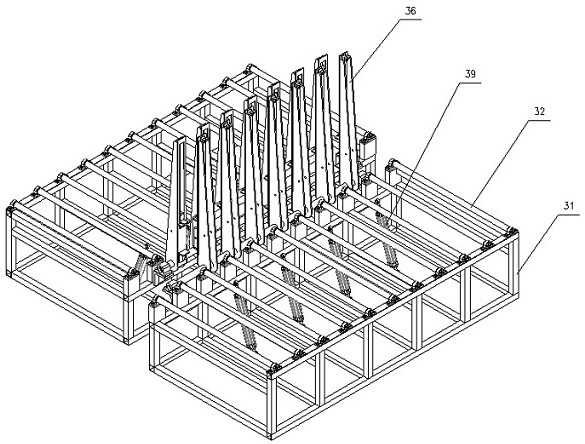

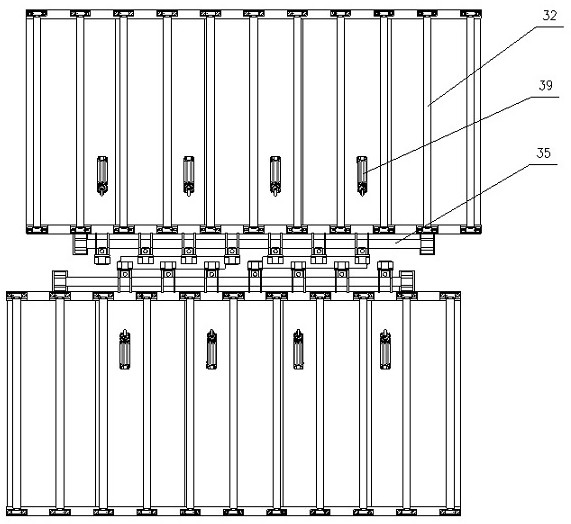

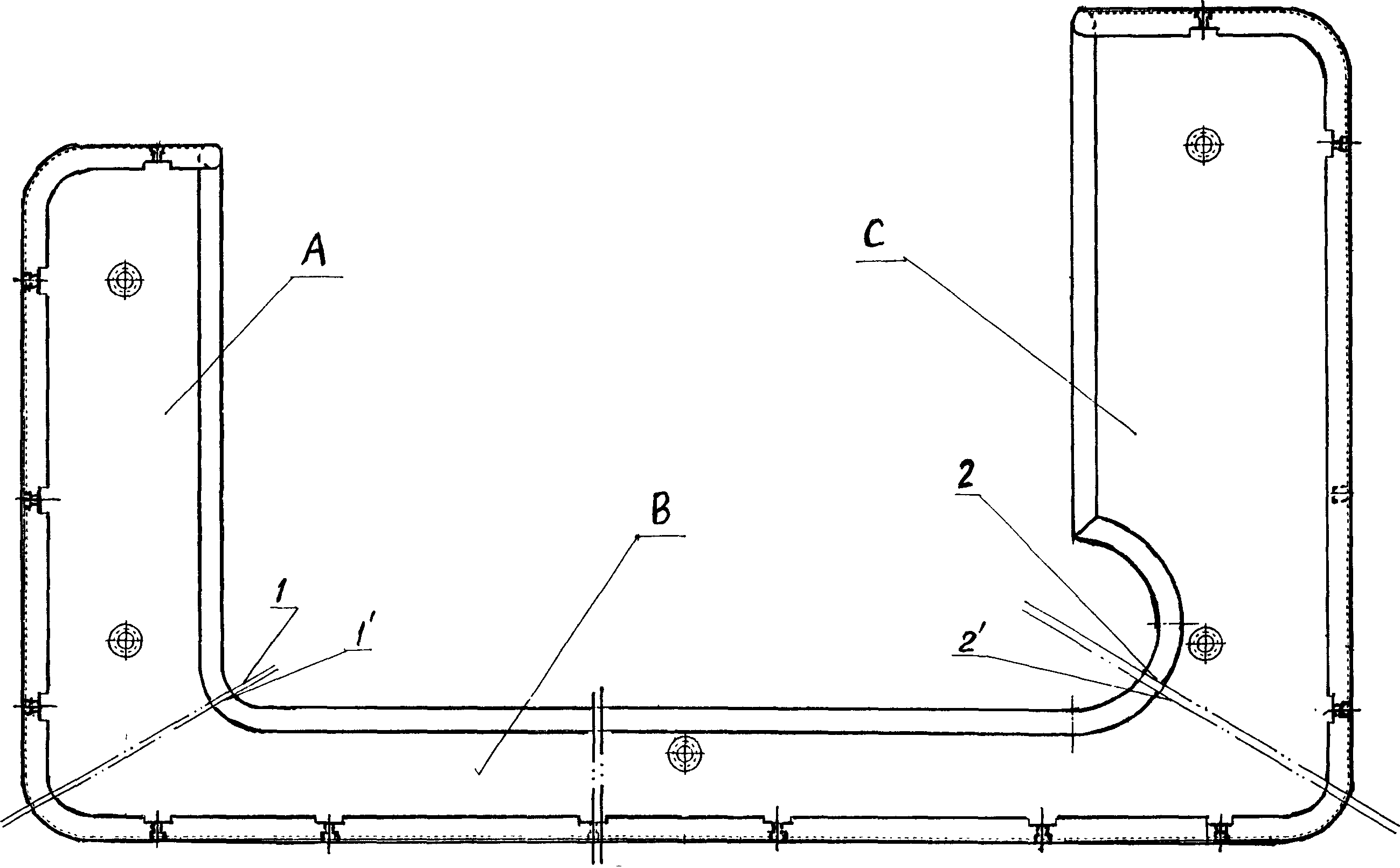

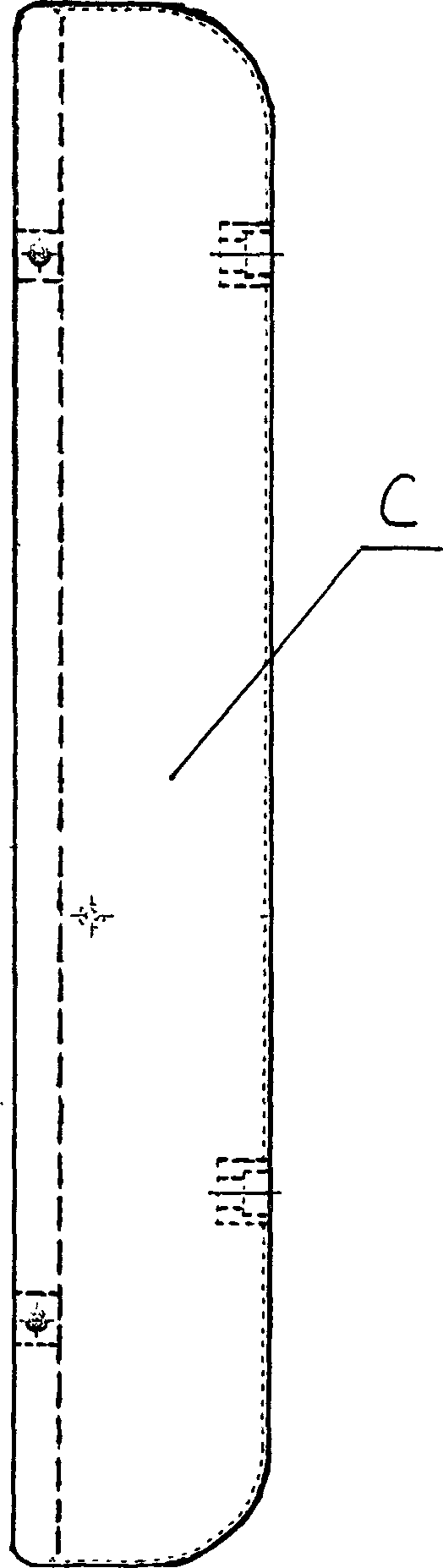

Dry cargo container underframe part, dry cargo container and processing method thereof

InactiveCN104760786ASave consumptionSave workabilityLarge containersMaterial consumptionCargo container

The invention discloses a dry cargo container underframe part, a dry cargo container and a processing method thereof. The underframe part comprises two longitudinally-extending bottom side beams, bottom cross beams fixed between the two bottom side beams, a steel floor positioned on the bottom cross beams, two corner parts positioned at the end parts of the same ends of the two bottom side beams and a bottom end cross beam connected with two corner parts transversely, wherein the two corner parts and the upper end face of the bottom end cross beam are used for being assembled and fixed to a front end part of the dry cargo container. The front end part, matched with the underframe part, of the dry cargo container does not include a front underbeam and a front corner part, and piercing processing of a front corner post and a sealing plate at the front corner part are eliminated, so that material consumption and processing amount are reduced. In the dry cargo container, the upper surface of the underframe part is assembled to the lower end face of the front end part, and welding and fixation are carried out outside the container, plane combined assembly is simple, and fixation is firm, so that welding operation and sanding are facilitated by welding outside the container, therefore, the production efficiency and product quality are improved.

Owner:DALIAN CIMC SPECIAL LOGISTICS EQUIP CO LTD

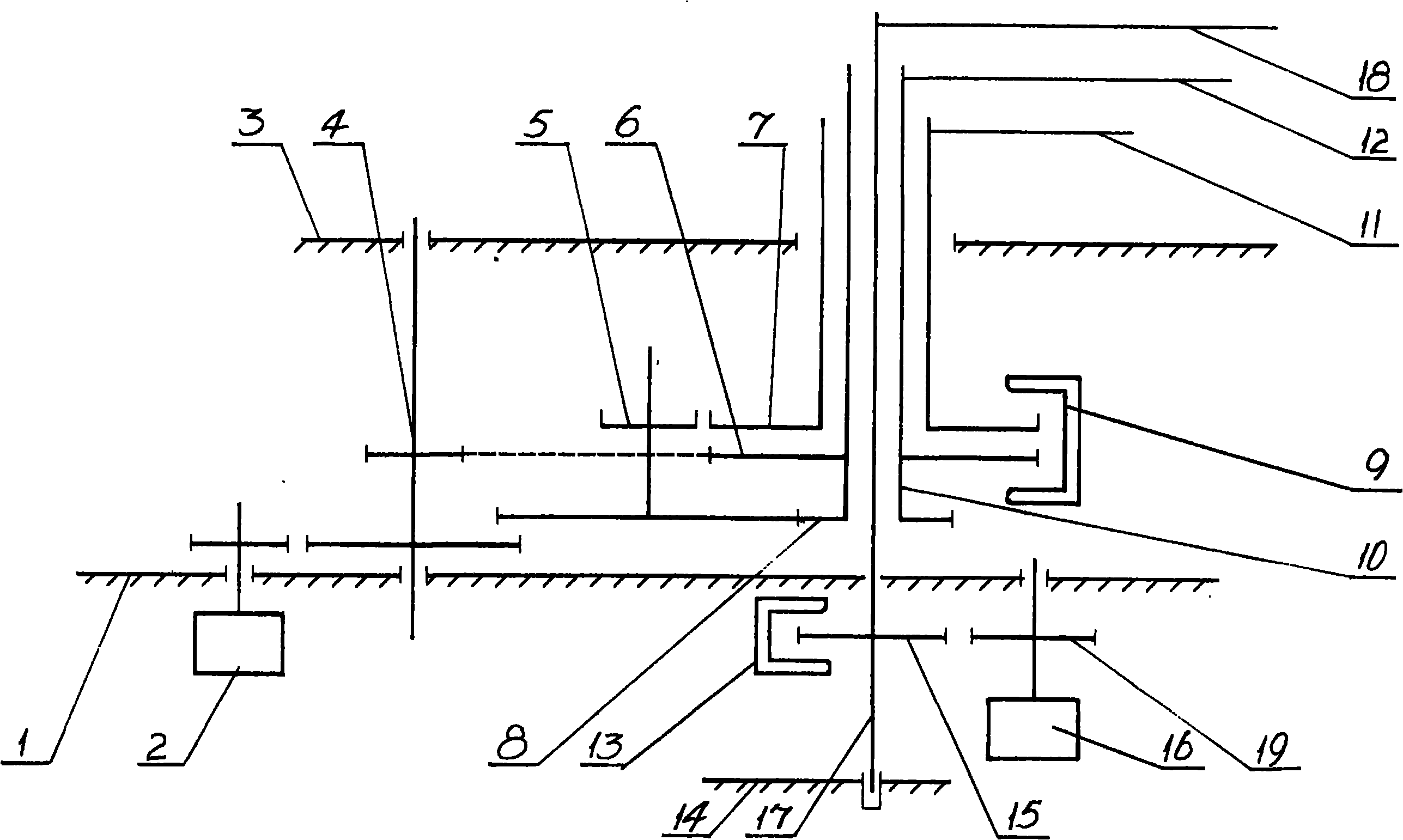

Automatic turnover double-sided gluing production line for doors and windows as well as processing method thereof

PendingCN112777281AIncrease productivitySave human effortConveyor partsProduction lineIndustrial engineering

The invention discloses an automatic turnover double-sided gluing production line for doors and windows as well as a processing method thereof. The automatic turnover double-sided gluing production line comprises a feeding conveying device, a first automatic gluing machine, a turnover machine, a second automatic gluing machine and a discharging conveying device, wherein the feeding conveying device, the gluing machine, and the discharging conveying device are arranged into a production line according to the gluing sequence of the doors and the windows; the turnover machine is arranged between the first automatic gluing machine and the second automatic gluing machine; and a left turnover device and a right turnover device of the turnover machine are the same in structure, are oppositely arranged in the Y direction, and can transmit the doors and windows in a relayed mode for turning over the doors and windows 7 by 180 degrees. Each turnover frame of the turnover machine is equipped with a door-window Y-direction positioning plate, so that the turnover machine can be suitable for doors and windows with greater dimensions as well as doors and windows with smaller dimensions, and is great in processing range. The production line can realize automatic operation, saves labor power, greatly improves production efficiency, reduces a product unqualified rate, is convenient to operate, is low in production cost, is stable in gluing quality, and is high in product qualification rate.

Owner:济南唐林智能科技有限公司

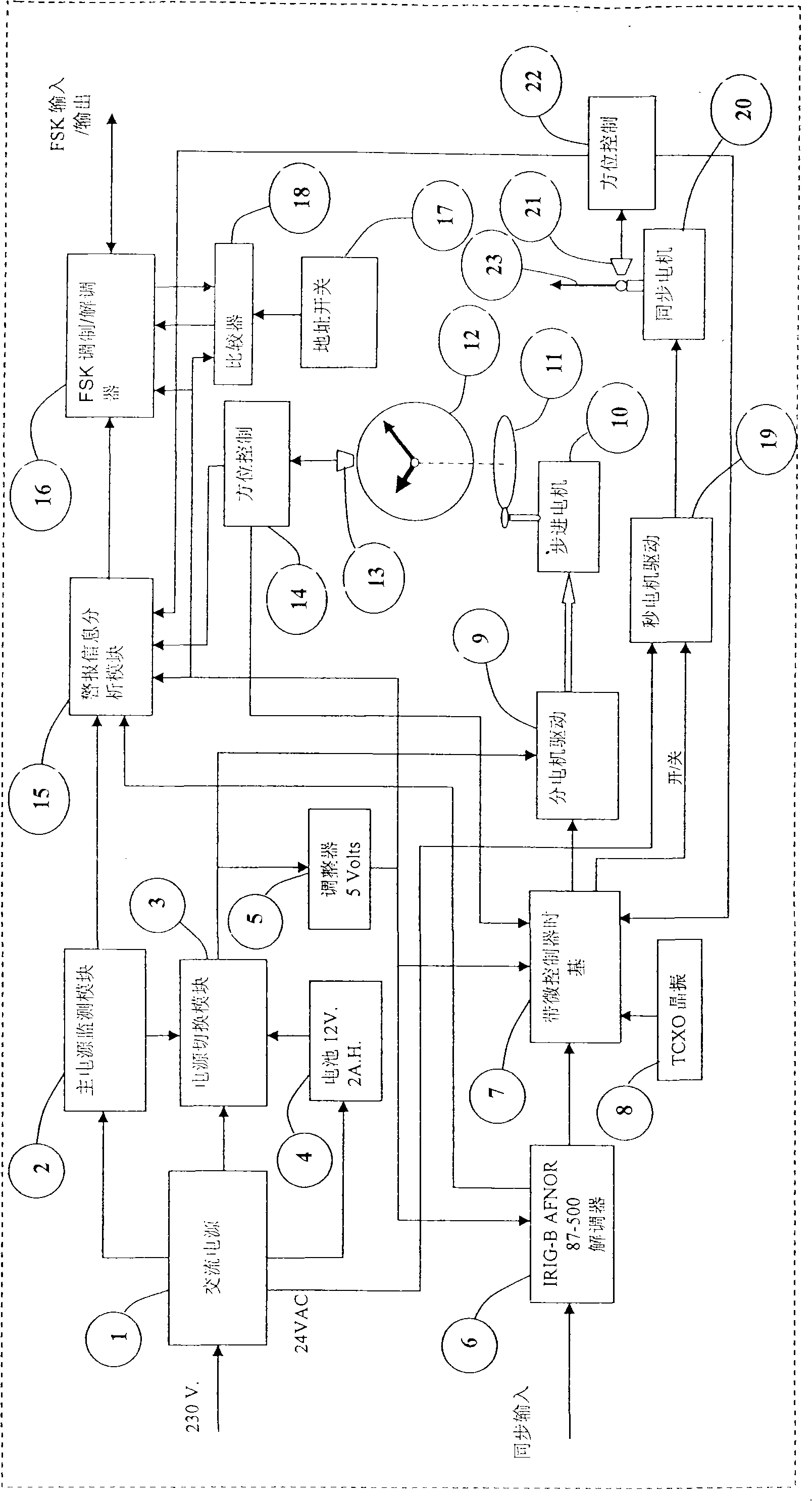

Regional clock movement and control design method

InactiveCN101813913ASave workabilitySave material costGearworksElectric windingGear wheelElectric machine

The invention discloses a regional clock movement and a control design method, and belongs to the technical field of time instruments. The regional clock movement comprises movement clamping plates, a stepping motor, a clock pointer assembly and a gear reducing transmission mechanism, and is characterized in that: the regional clock movement comprises a synchronous reducer motor; a gear at the output end of the synchronous reducer motor is directly meshed with a secondwheel which is fixedly arranged on a secondwheel shaft; and the secondwheel is provided with a hole and a photoelectric switch is arranged at two ends of the hole. The control design method comprises setting and control of power supply of the clock movement, time base, hour hand and minute hand driving, second hand driving, and alarm information feedback items. Compared with the prior art, the clock movement and the control design method have the prominent substantive characteristics and obvious progress that: the second hand continuously moves, and the clock is ensured to work for 3 hours to wait for connecting a main power supply after the 220V main power supply is cut off; when the clock movement is not powered by the main power supply, the hour hand and the minute hand automatically return to twelve clock, so passengers notice alarm information that the clock is failed and cannot delay the travel; and the like.

Owner:烟台钟表研究所有限公司 +1

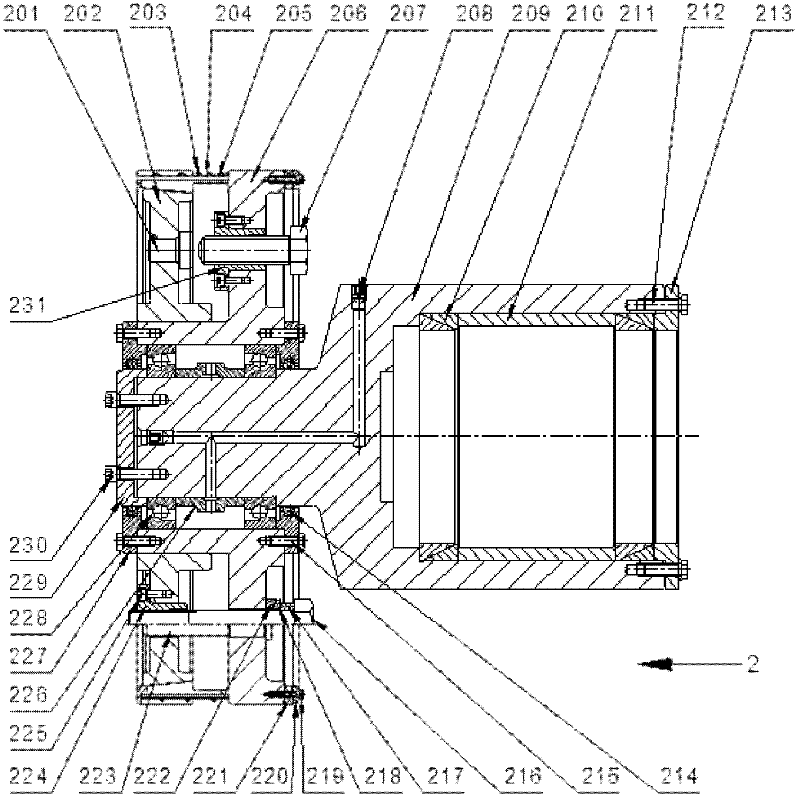

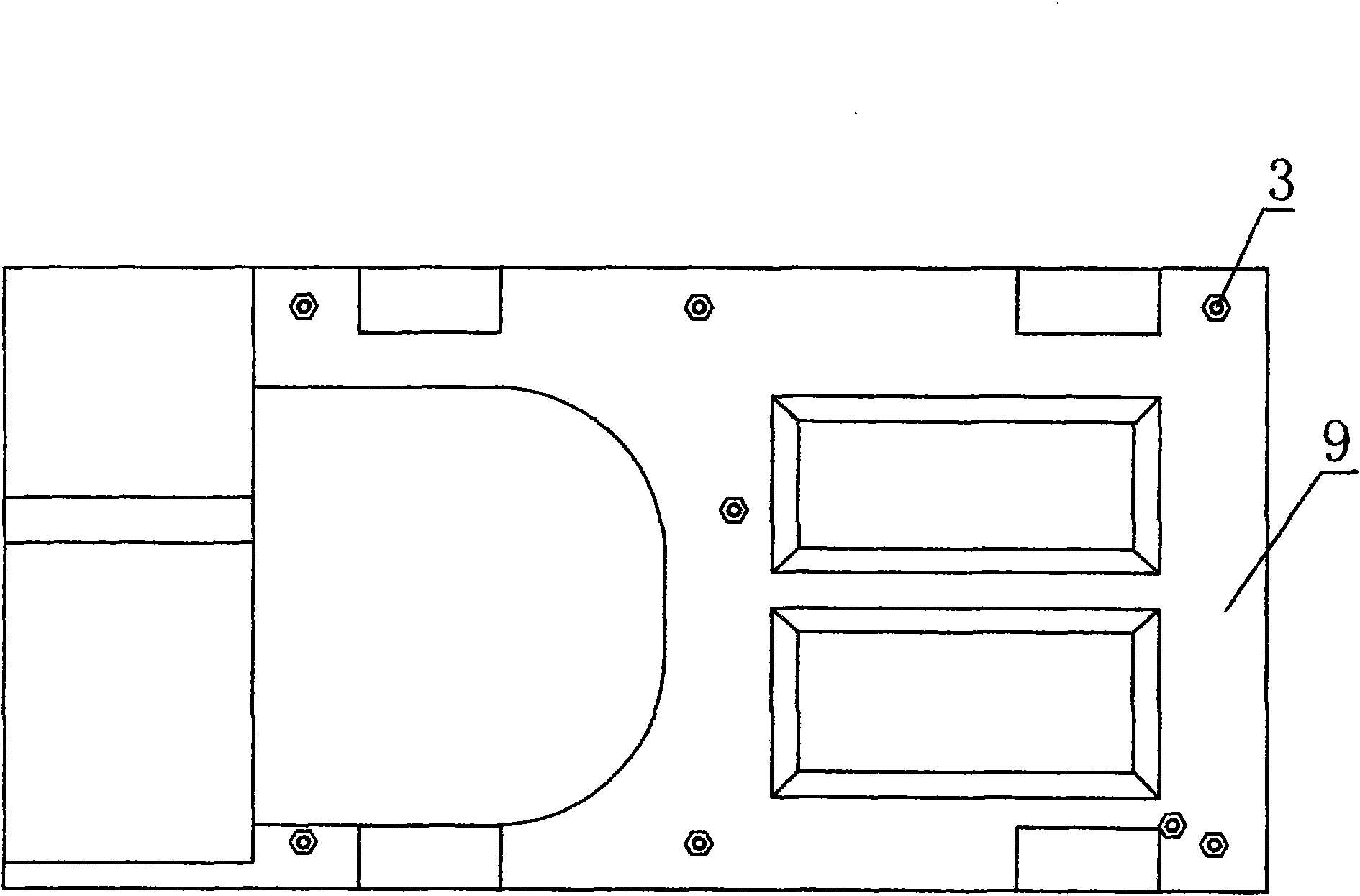

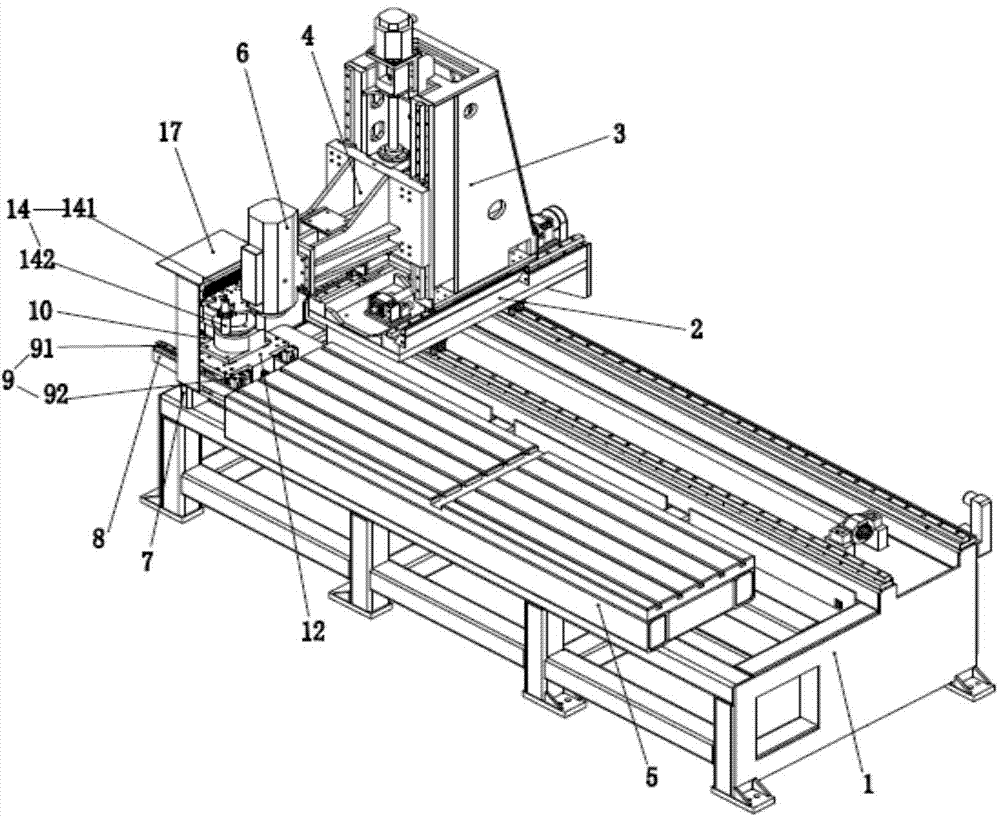

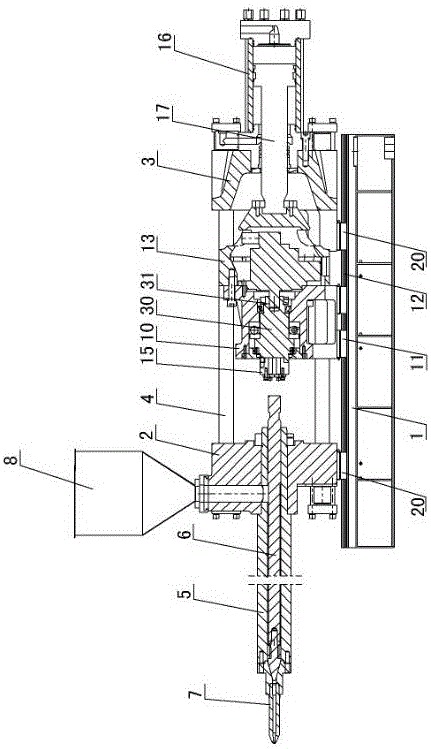

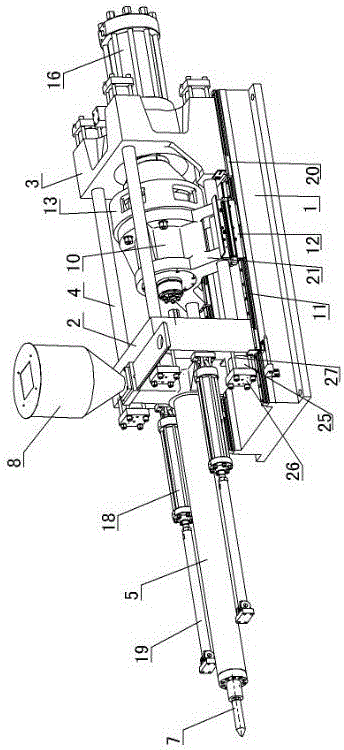

Machining center using turntable type tool magazine

InactiveCN104842200AShorten the lengthSave lengthPositioning apparatusMetal-working holdersEngineeringMachining

A machining center using a turntable type tool magazine comprises a tool body, a tool saddle, a column, a machine head, a worktable, a spindle, a tool magazine moving guide rail, a tool magazine installing plate, a tool and a driving device. The tool saddle and the worktable are installed on the tool body, and the column is installed on the tool saddle. The machine head is installed on the column. The spindle is installed on the machine head. The tool magazine moving guide rail is installed on the tool body. The tool magazine installing plate is installed on the tool magazine moving guide rail, the tool is installed on the tool magazine installing plate, and the driving device drives the tool magazine installing plate to move on the tool magazine moving guide rail. The tool magazine moving guide rail and the driving device are added to enable the length of the worktable of the machining center to be the same as the X-axis stroke of the machining center, tool change and machining are not mutually influenced without an additionally-added tool change stroke or length increase of the worktable, the stroke of the machining center is saved, occupied area of a device is decreased, manufacturing cost is reduced, and the application range of the whole machining center is widened.

Owner:FOSHAN PRATIC CNC SCI & TECH

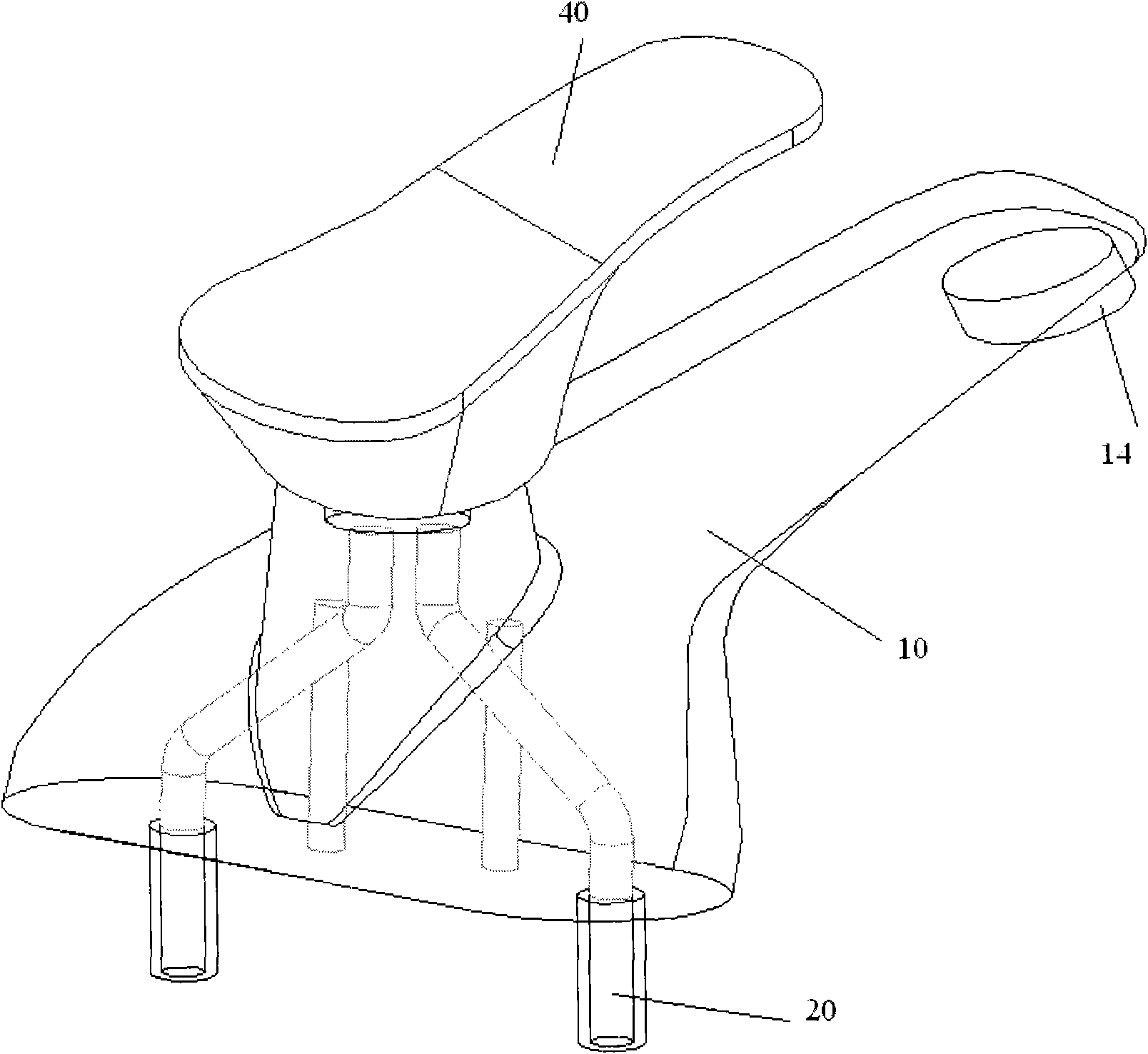

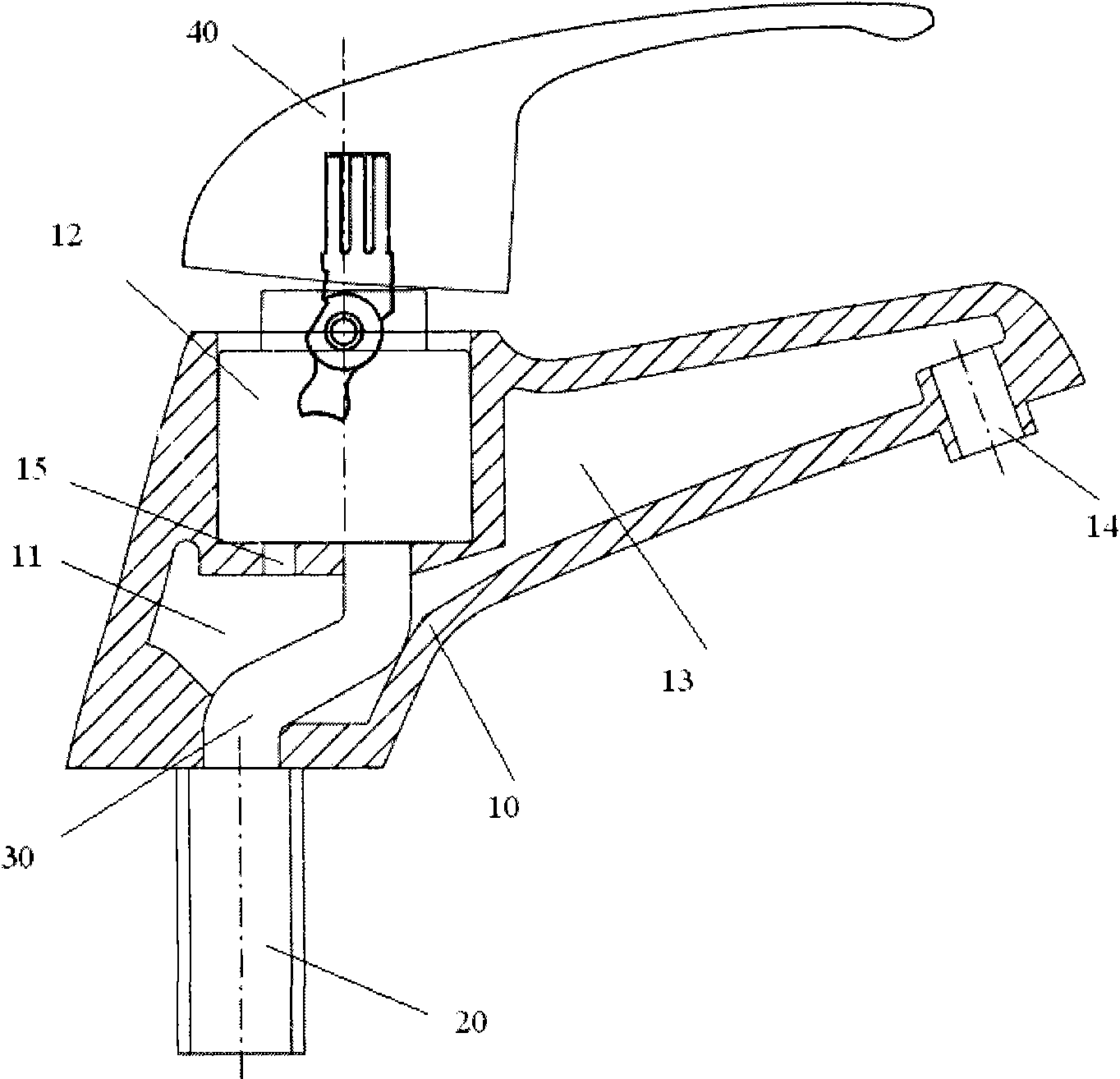

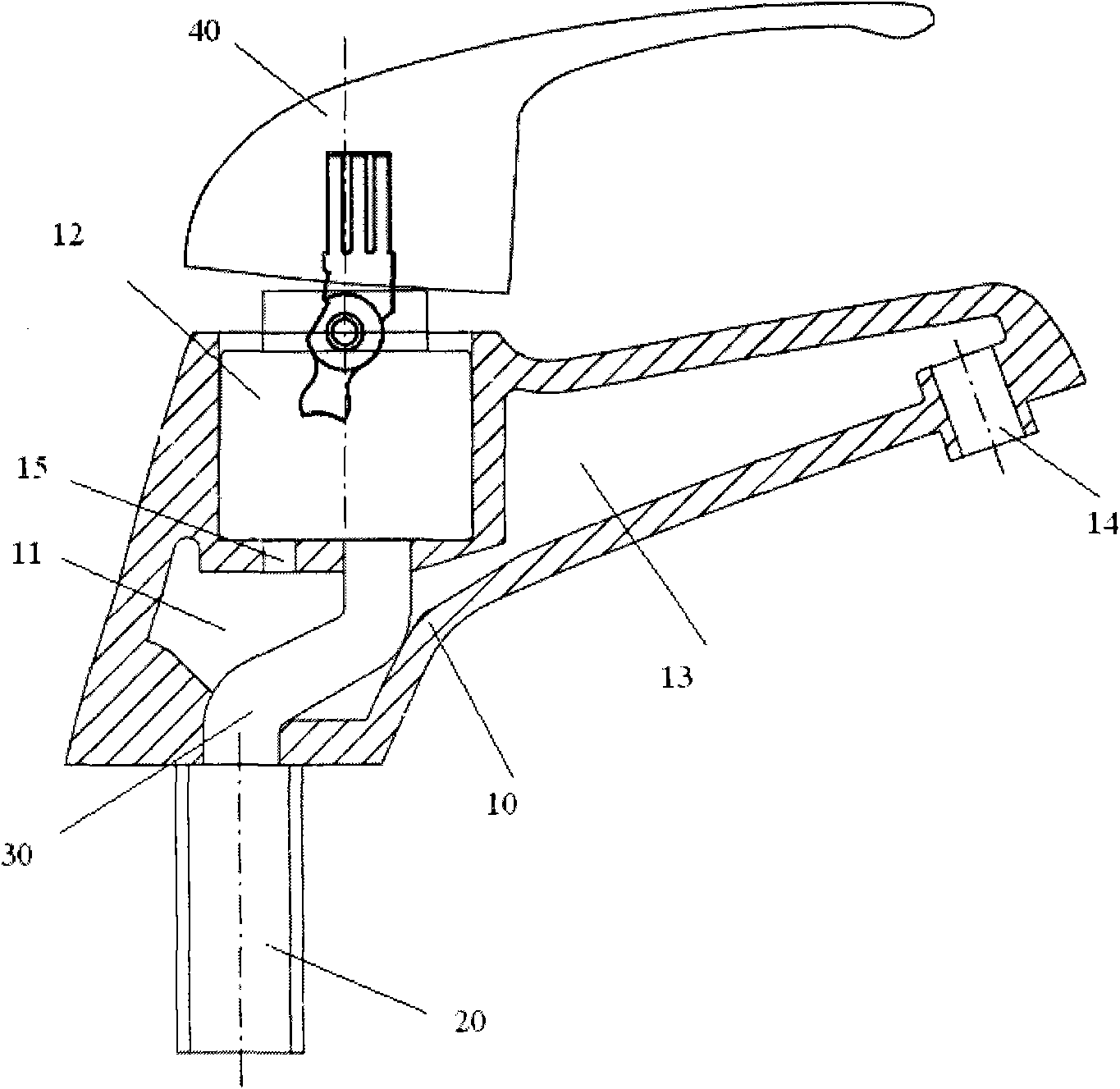

Water faucet

InactiveCN101788080ASave processing timeSave workabilityOperating means/releasing devices for valvesMultiple way valvesSatiationsWater flow

The invention provides a water faucet, which comprises a main body, a water inlet pipe and a switch valve, wherein the water inlet pipe is connected with the main body, the switch valve is arranged on the upper part of the main body for controlling the inlet and outlet of the water flow, the main body protrudes forward, the tail end of the main body is provided with a water outlet, the material of the main body is plastic, and the main body is provided with a cavity molded by plastic extruding. In the technical scheme, since the material of the main body of the water faucet is plastic and the cavity part is processed by means of plastic extruding molding of the compressed gas, the processing time and the processing material are saved. Moreover, the defects of un-satiation and out-of-flatness caused by product shrinkage due to the too thick product wall, and the like are resolved.

Owner:章森文

Processing method of profiled screening cover

A technology for machining the shaped shielding case by plate-type copying method includes computer aided drawing by ratio of 1:1, preparing metallic plate, driving it into several blocks, assembling, welding, polishing welded seams, and cleaning. Its advantages are high productivity and quality and low cost.

Owner:JIANGSU YONGLONG ELECTRIC +1

Sheet metal bending device based on clamping and positioning and feedback bending

The invention relates to a sheet metal bending device based on clamping and positioning and feedback bending. The device comprises a drive motor on a rack, a clamping and fixing base and a main machine. A bending shaft is installed on the drive motor, and a machined part is arranged on the clamping and fixing base. The device further comprises an ultrasonic thickness detector, an ultrasonic crack detector, a pressure sensor, a rolling shaft and a controller connected with the main machine. The ultrasonic thickness detector, the ultrasonic crack detector and the pressure sensor are connected with the main machine through a DSP data processing module. Staged bending and feedback control are combined, the quantity of cracks is greatly reduced, and machining quality is improved. The rolling shaft is arranged to extrude and rub with the inner concave face of the machined part, protruding burrs and the cracks are effectively removed, and the subsequent machining process is omitted. By means of the pressure sensor, clamping pressure and positioning are controlled, plates are prevented from deforming or disengaging, and machining reliability is improved.

Owner:SUZHOU BIANTONG SENSING TECH

Liquid separating head

PendingCN110068176ASmooth entryInto the uniformFluid circulation arrangementCircular coneEngineering

The invention discloses a liquid separating head. The liquid separating head consists of a liquid separating head body and a flow dividing block, the liquid dividing head body and the flow dividing block are combined and welded into a whole to form a complete liquid separating head, a plurality of flow dividing holes are formed in the bottom of the liquid separating head body, and the sizes of theflow dividing holes are equal and are uniformly distributed in a circular cone shape; the flow dividing block is embedded into the interior of the liquid separating head body and is welded into a whole with the liquid separating head body; and the liquid separating head body and the flow dividing block and the liquid separating hole and the liquid distributing pipe can simultaneously weld into the liquid separating head component. The liquid separating head has the beneficial effects that the processing material and the processing time can be saved, the liquid separating head can also be usedas a refrigerant, and can smoothly and uniformly enter each flow dividing hole, so that the flowing resistance and the flowing sound are reduced, uniformly distributing refrigerant flowing to each set of coiled tubes, and providing temperature uniformity of each path outlet of an evaporator, the heat transfer area of the evaporator is fully utilized, the operation efficiency of the evaporator isimproved, and therefore the performance and reliability of the refrigeration system are improved.

Owner:上海昶协实业有限公司

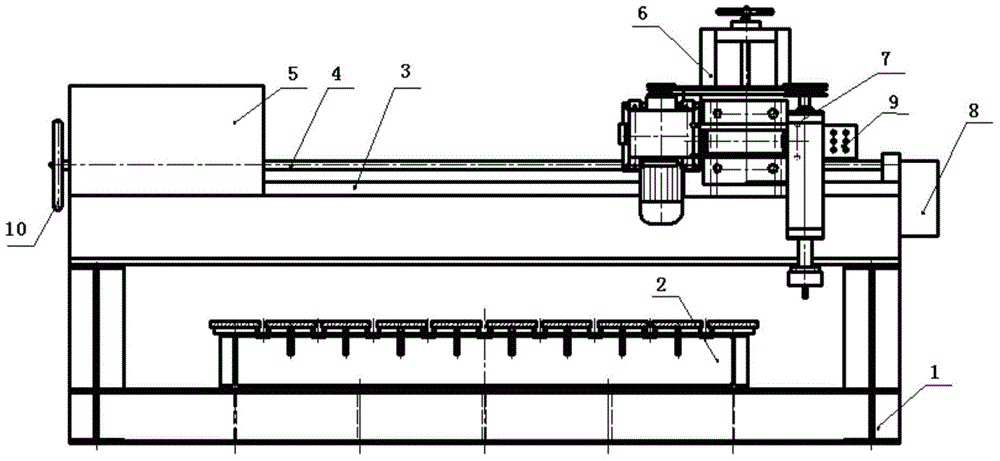

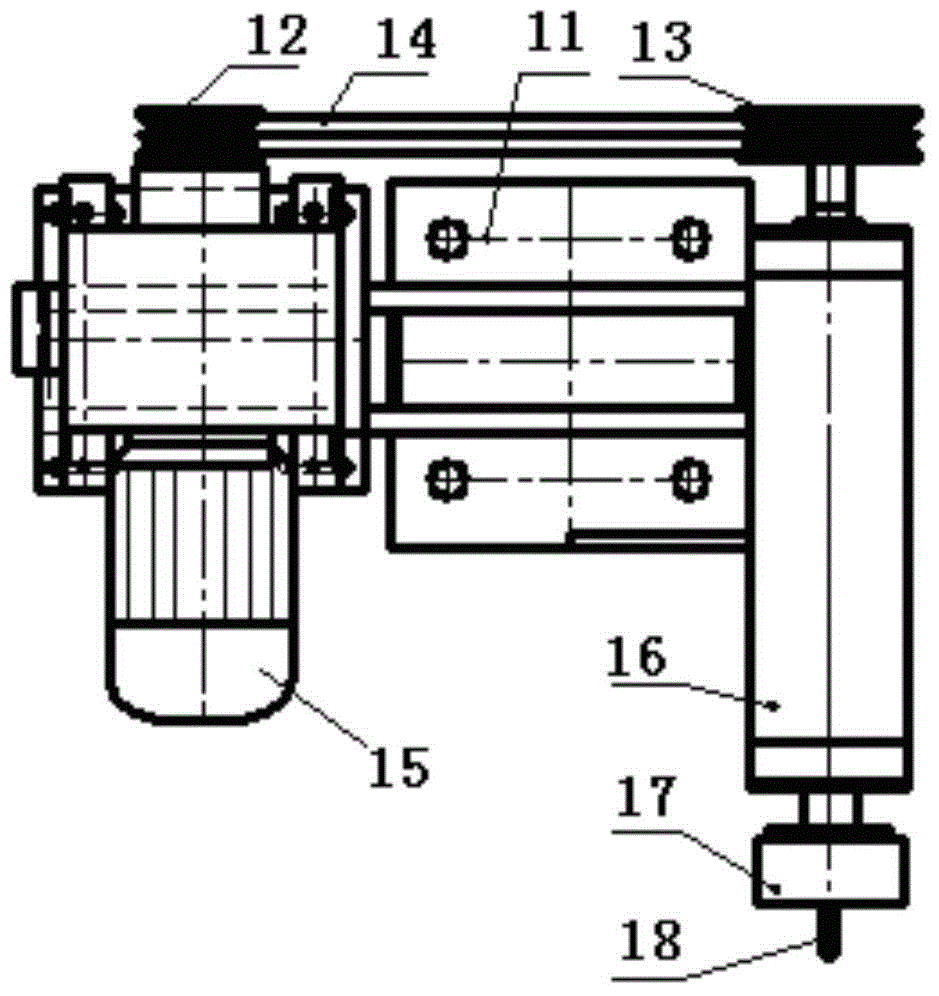

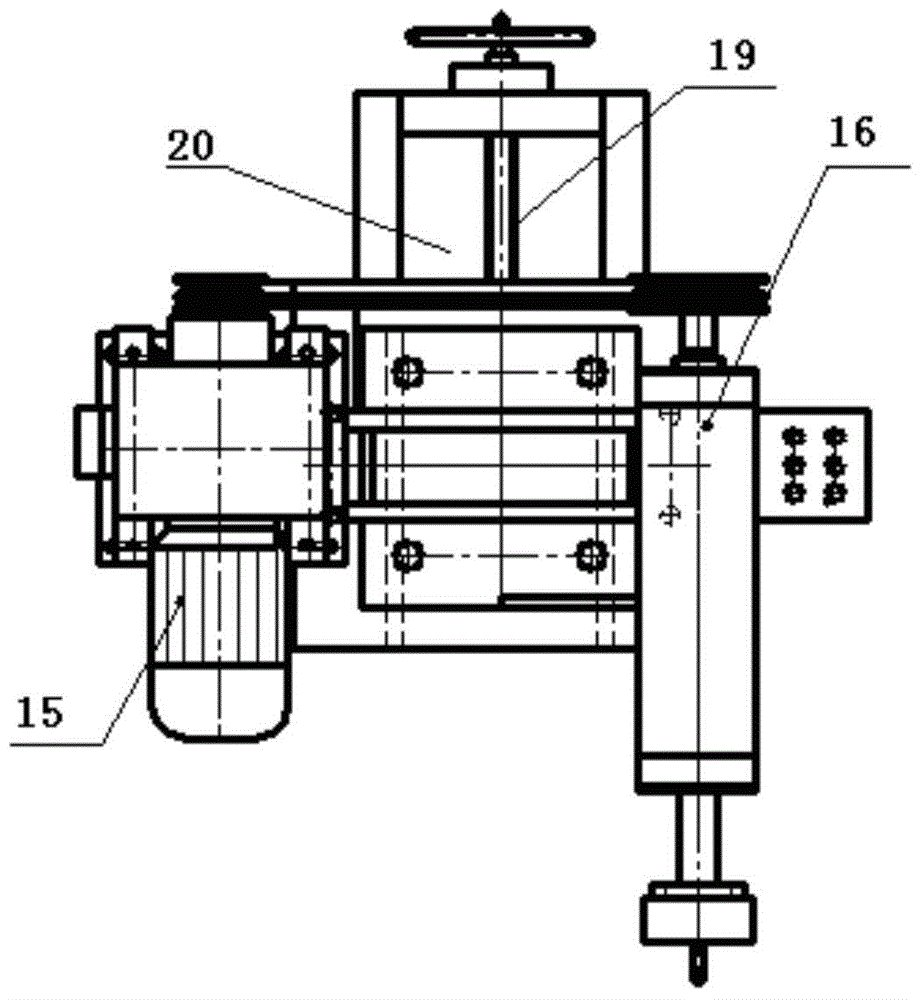

Special milling machine for machining separation plates of tube plates

InactiveCN103600111ASave workabilityCost savingsFeeding apparatusLarge fixed membersSurface roughnessEngineering

The invention discloses a special milling machine for machining separation plates of tube plates. The milling machine comprises a bracket, wherein a working table is arranged on the bracket; a guide rail and a screw are arranged at the upper end of the bracket; the guide rail is matched with a horizontal traveling mechanism and a vertical height adjustment mechanism; the screw is spirally matched with the horizontal traveling mechanism; a hand wheel is arranged at the other end of the screw; a milling mechanism is arranged on the vertical height adjustment mechanism; the horizontal traveling mechanism props against the vertical height adjustment mechanism. After the special milling machine for machining the separation plate grooves of the tube plates is manufactured, three plate grooves of three tube plates with the nominal diameters of DN800mm, DN1200mm and DN1800mm are selected for trial machining, the operation situation of the milling machine and the machining quality of a workpiece are evaluated, and the machining quality, accuracy and surface roughness of the workpiece can meet requirements of a drawing.

Owner:傅贵轩

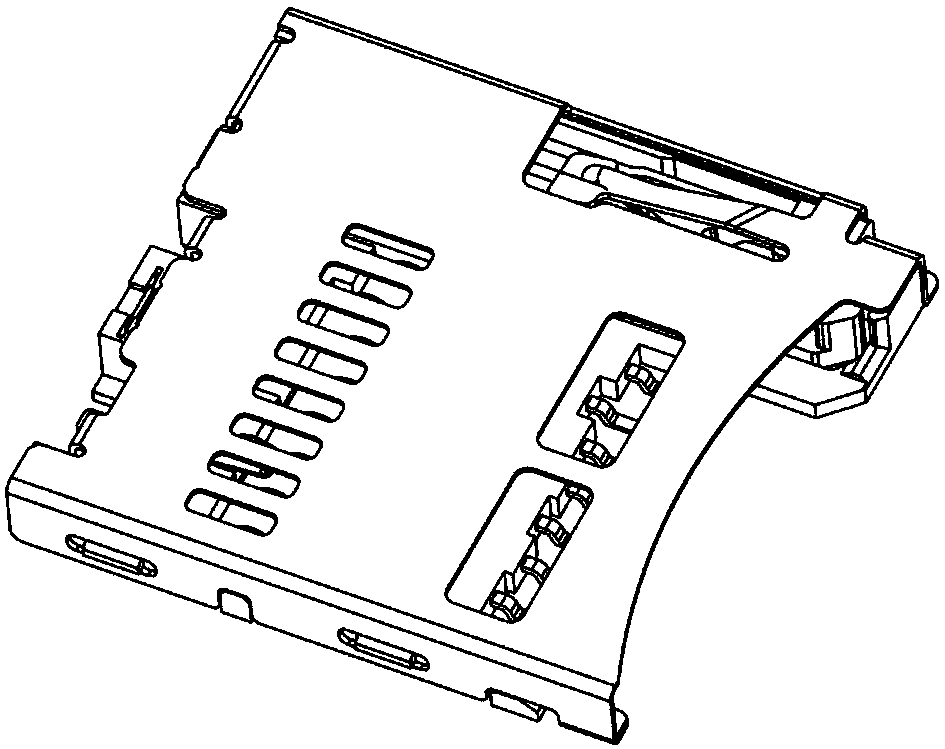

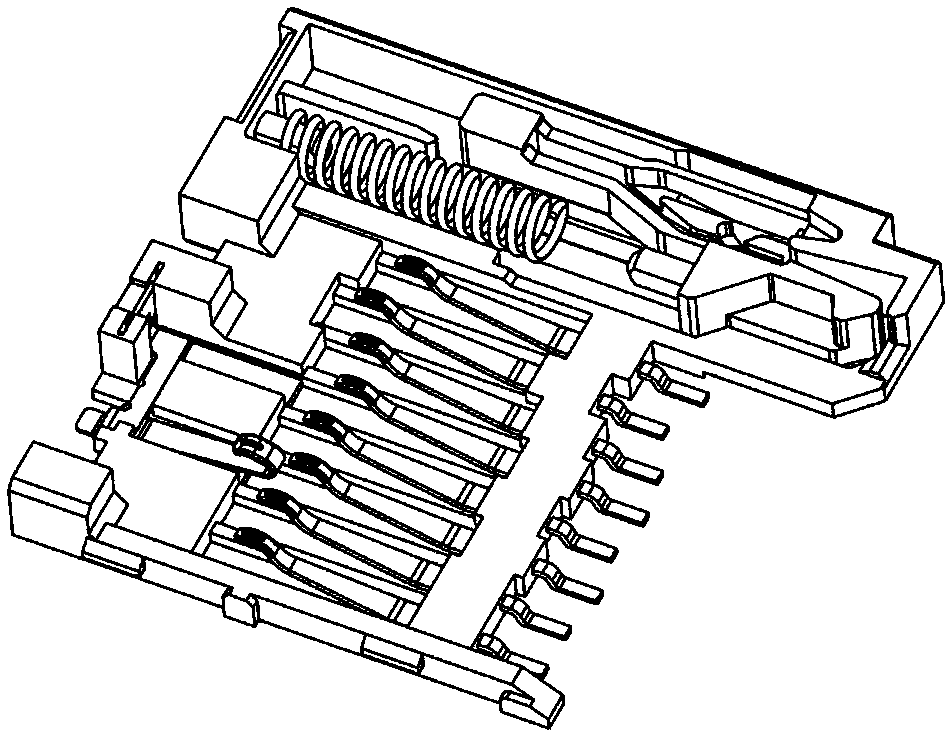

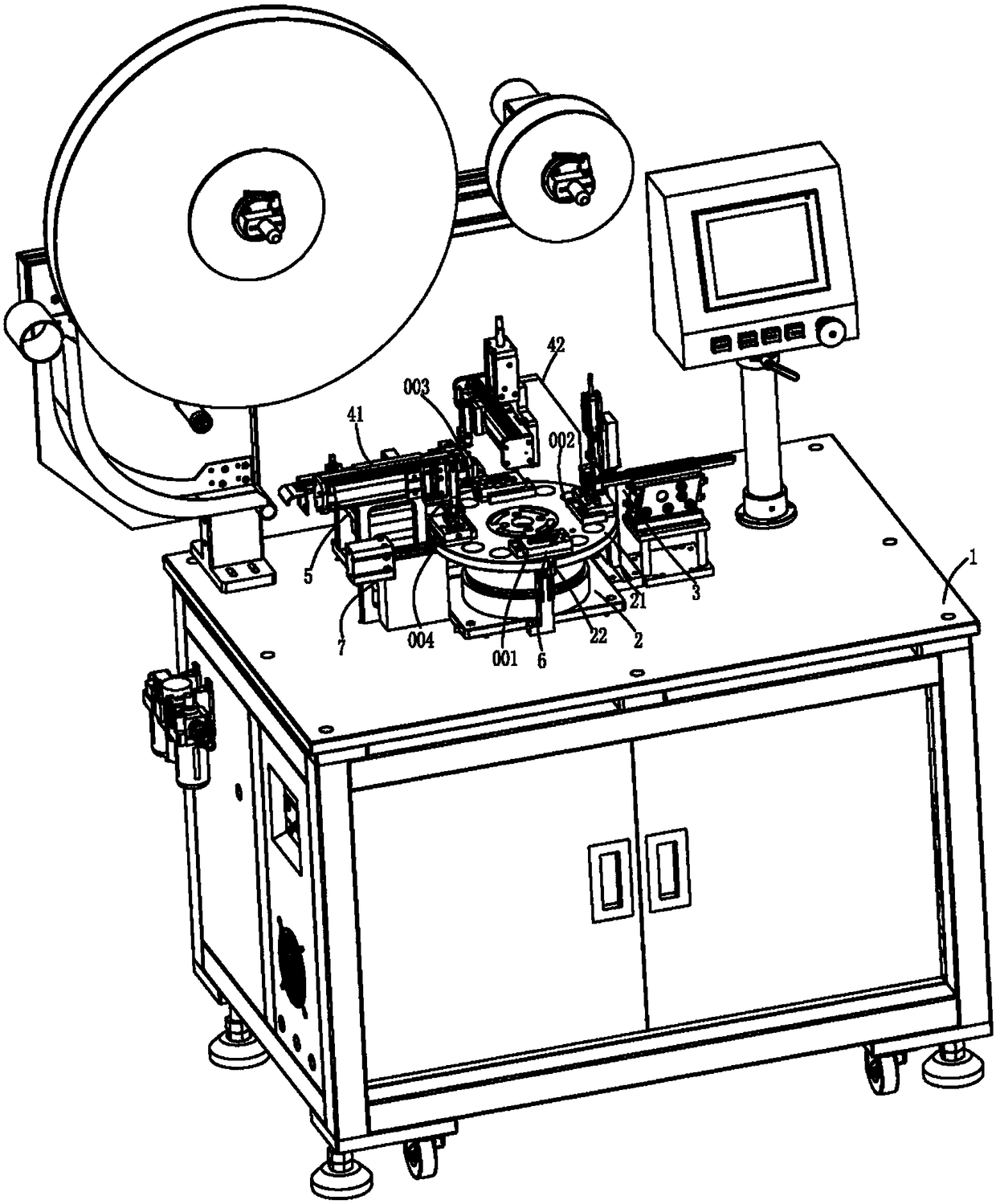

TF card connector assembling machine

ActiveCN108466045AAssembly precisionQuick assemblyAssembly machinesMetal working apparatusWork in processCam

The invention discloses a TF card connector assembling machine. The TF card connector assembling machine comprises a rotating disc component, a cam needle assembling component, an iron shell assembling component and a discharging component which are arranged on a machine case, wherein station fixtures used for the laying and loading of TF card connectors are circumferentially arrayed on the rotating disc component, and can be driven by the rotating disc component to intermittently rotate among a feeding station, a cam needle assembling station, an iron shell assembling station and a discharging station as well as to be butted with the cam needle assembling component, the iron shell assembling component and the discharging component; a cam needle can be fed by the cam needle assembling component to the matched station fixture and assembled with a semi-finished product of the corresponding TF card connector; the iron shell assembling component comprises a conveying device and a blanking-feeding device; the conveying device is used for conveying a conjoined iron shell coil material to a blanking station; the blanking-feeding device is used for manufacturing a single iron shell throughblanking, conveying the single iron shell to the matched station fixture, and assembling the single iron shell with the semi-finished product of the corresponding TF card connector into a finished product of the corresponding TF card connector; and the discharging assembly is used for sucking and discharging the finished product of the corresponding TF card connector on the matched station fixture to a receiving box.

Owner:东莞市科晟电子有限公司

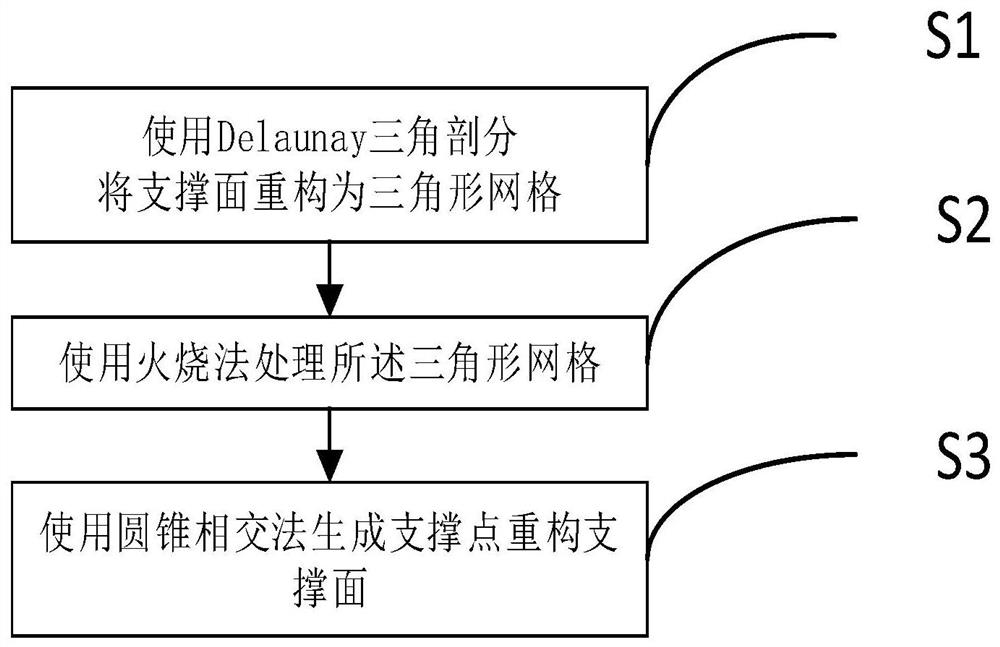

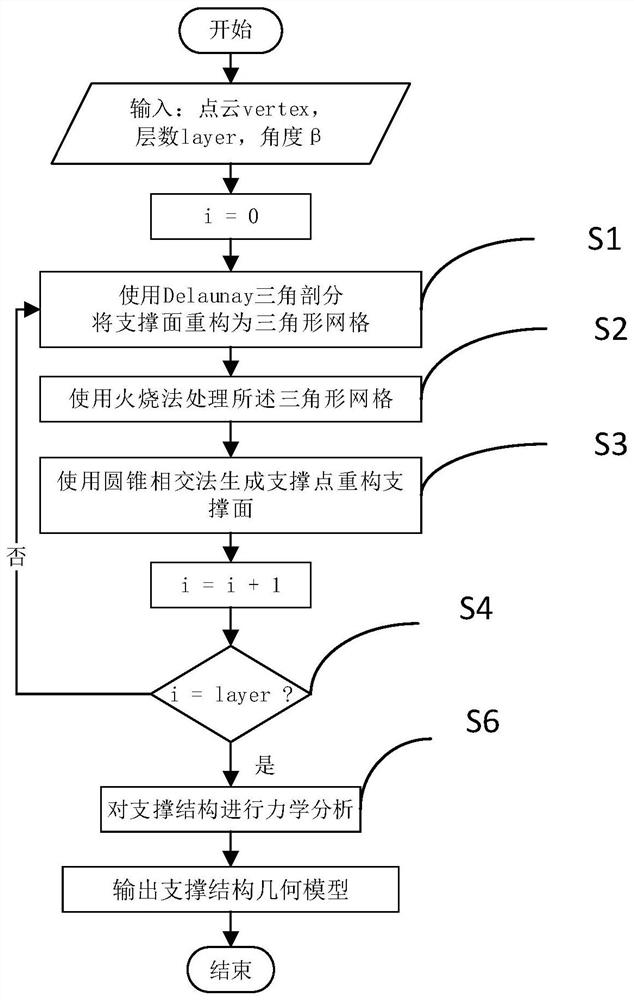

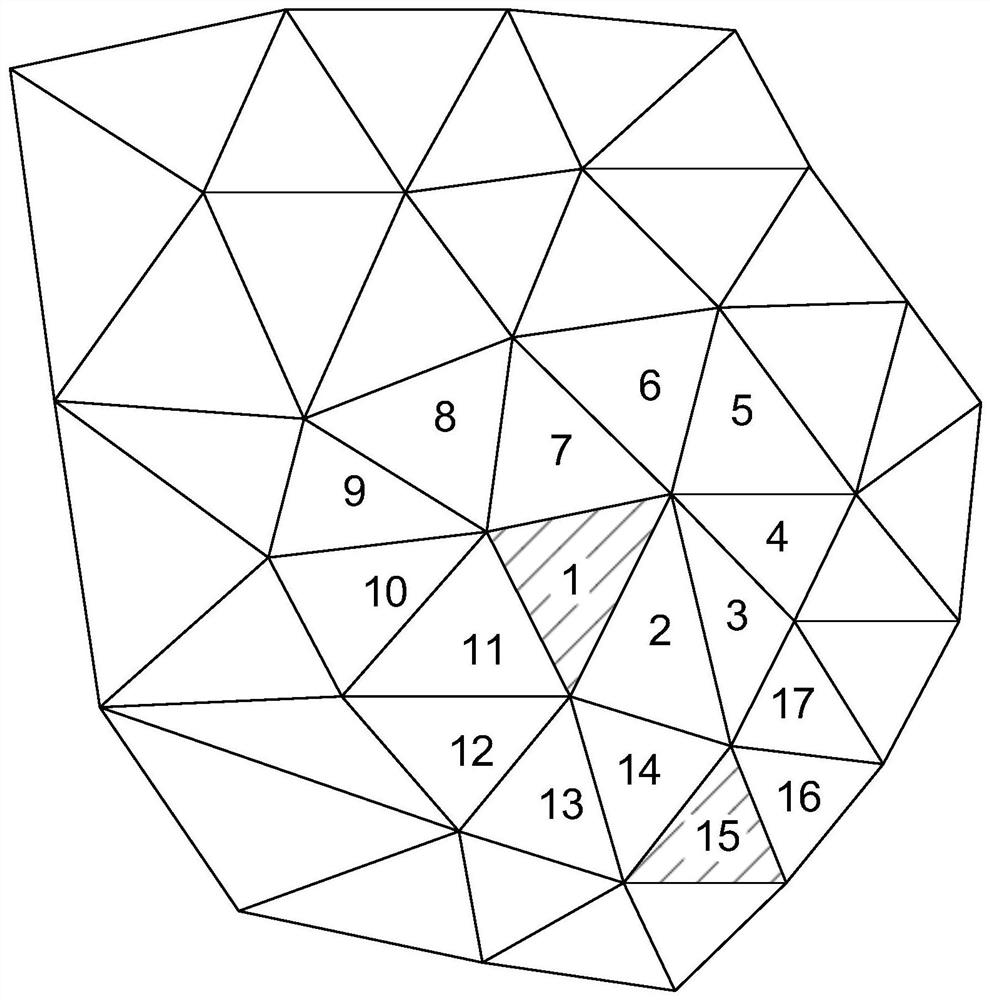

Method for generating 3D printing supporting structure

ActiveCN113255021AReduce contact areaSave workabilityGeometric CADAdditive manufacturing apparatusComputational scienceAlgorithm

The invention relates to a method for generating a 3D printing support structure. The method comprises the following steps: reconstructing a support surface into a triangular mesh by using a Delaunay triangle subdivision method; performing classification extraction on the triangular grids by using a burning method to generate a unit set; and processing the unit set by using a cone intersection method to generate supporting points to reconstruct the supporting surface. Optimization of the supporting structure can be further realized. According to the generated supporting structure, the contact area between the supporting structure and the printing model is reduced, rapid separation of the supporting structure and the model is achieved, and the printing model is not prone to being damaged.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

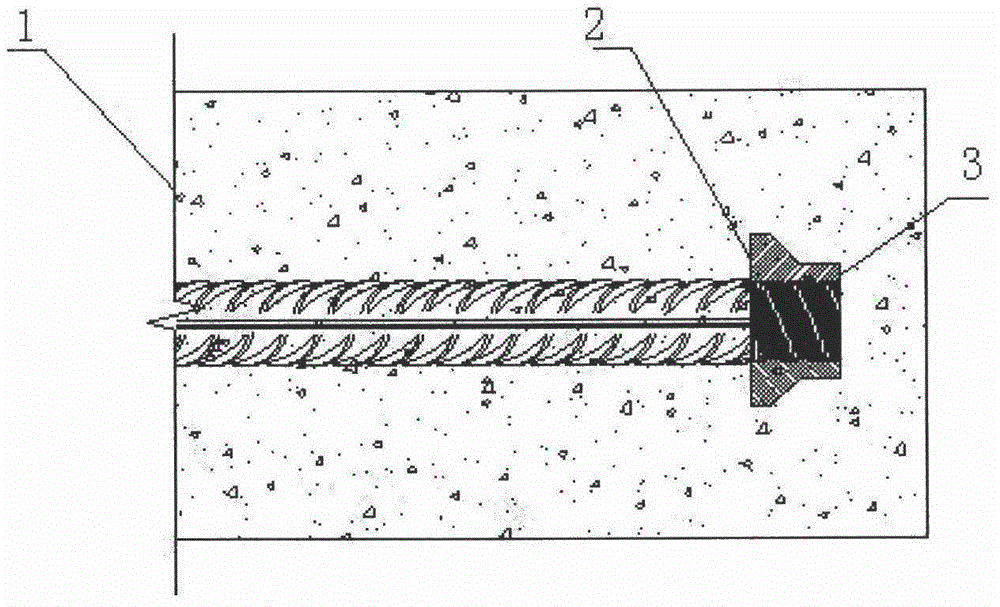

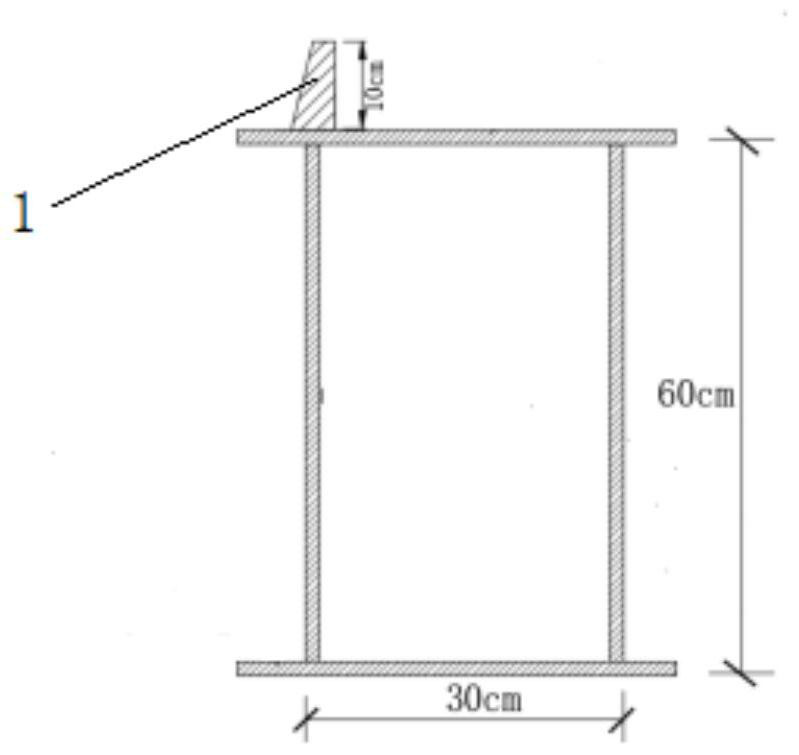

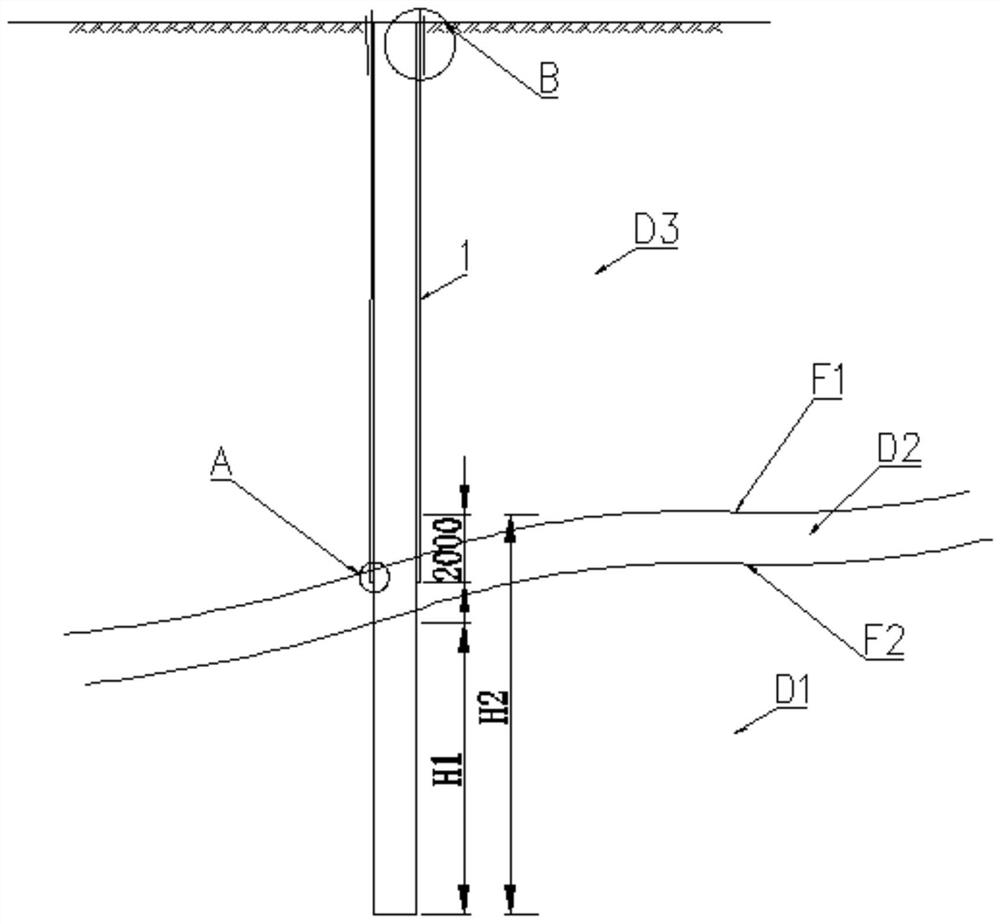

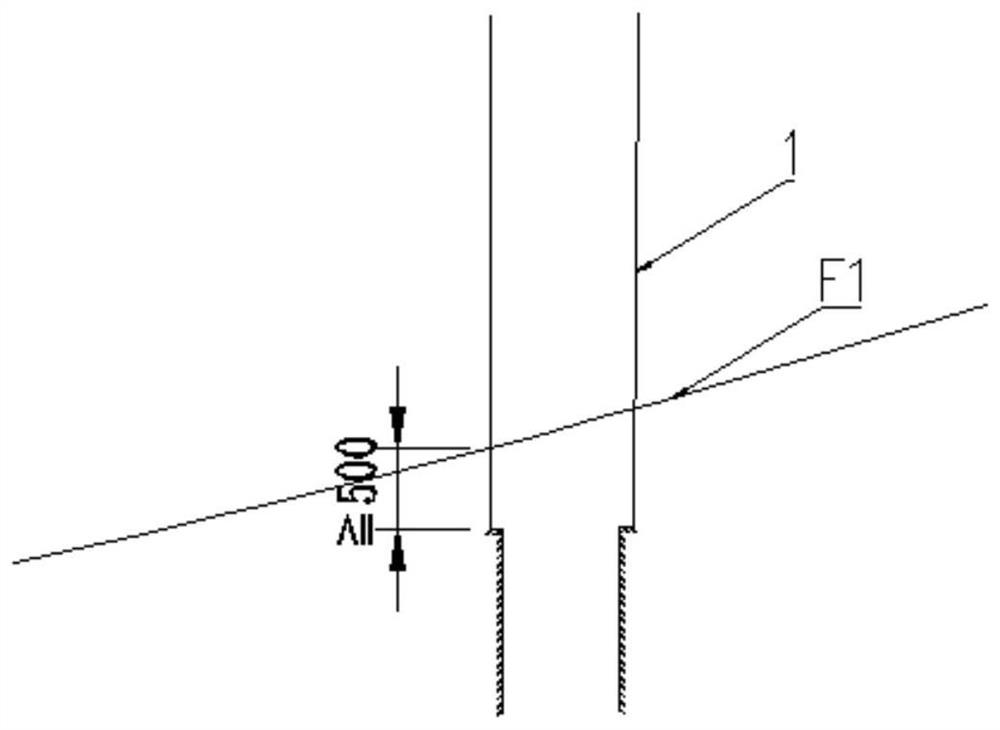

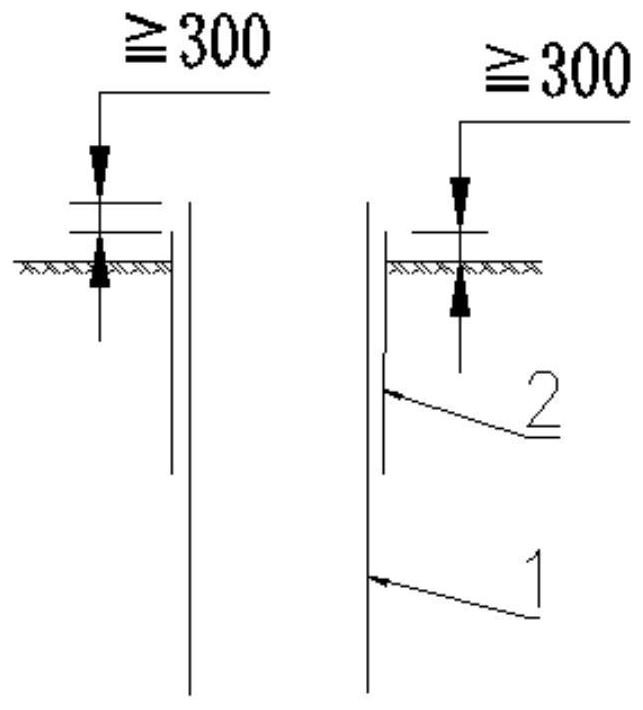

Water-rich sandy gravel geological pile group hole forming construction method

PendingCN114753354AThe amount of unearthed increasedSave workabilityDirectional drillingSealing/packingMaterials preparationRebar

The invention discloses a water-rich sandy gravel geological pile group hole-forming construction method which comprises the following steps of construction investigation, paying-off and pile position fixing, mounting of a positioning pile casing, primary drilling, mounting of a protection pile casing (1), secondary drilling, hole cleaning and hoisting and placing of a reinforcement cage lamp.The method includes the following steps that firstly, construction investigation is sufficient, pile casing materials are prepared in advance, material preparation can be optimized in combination with construction organizations, and the construction efficiency is improved; the pile casing machining and coring time is saved, and under the general condition, the whole pile casing is installed, and the protection wall forming efficiency is high; 2, drilling is performed twice, and the hole forming part influenced by rich water follows the protective casing, so that the mounting time of the protective casing is greatly saved; and (3) the steel wire mesh can effectively reduce the time for lowering steel bar holes and cleaning sediments at the bottom of the pile. The method is high in construction efficiency, small in environmental pollution, large in safety coefficient, capable of guaranteeing quality and suitable for hole forming construction of the rock-socketed rotary excavating pile in the water-rich sandy gravel geology.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

Mobile phone P+R (Plastic + Rubber) key structure

InactiveCN107749913AImprove injection molding to production efficiencyIncrease productivityElectric switchesTelephone set constructionsKey pressingMobile phone

The invention discloses a mobile phone P+R (Plastic + Rubber) key structure. The mobile phone P+R key structure comprises a face shell, key brackets, silicone keys and plastic key sleeves, wherein thekey brackets are integrally molded on the face shell; the key brackets are arranged at intervals; the silicone keys are arranged between adjacent key brackets; the plastic key sleeves sleeve the silicone keys; and lower surfaces of the plastic key sleeves are fixed to upper ends of the key brackets by sticking. According to the mobile phone P+R key structure disclosed by the invention, the face shell and the key brackets are connected integrally, so that a procedure of repeatedly processing and molding for conventional keys is omitted; relevant cost is saved; the injection molding to production efficiency of mobile phone keys can be increased effectively; and the cost is lowered.

Owner:重庆市量劲科技有限公司

Manufacturing process for high-precision cold-drawn tube

InactiveCN112157431AReduce processing stepsSave workabilityOther manufacturing equipments/toolsCold treatmentProcess engineering

The invention discloses a manufacturing process for a high-precision cold-drawn tube. The manufacturing process comprises the following steps of heating, piercing, annealing, first-time pickling, cold-rolling, stress-relief annealing, second-time pickling, phosphating, saponifying, cold-drawing, normalizing and air-cooling, quenching, honing, thermal strengthening and detecting. Related detectingand screening steps are added, so that unqualified products can be timely detected and removed, and therefore, the unqualified products are prevented from being further processed, processing energy and labor operation are saved, and unnecessary investment processing cost is reduced; and in the manufacturing process, rust-removal and cold-drawn tube crystallization refining are added to remove dimples in surfaces, so that an integral qualification rate is increased after the high-precision cold-drawn tube is manufactured.

Owner:无锡市腾茂液压机械有限公司

Inner fan installing structure of motor

InactiveCN104319943AShorten the lengthEasy to processCooling/ventillation arrangementEngineeringControl theory

The invention discloses an inner fan installing structure of a motor. The inner fan installing structure of the motor comprises a motor rotation shaft, an inner fan and an air guide barrel, wherein the inner fan and the air guide barrel are arranged on the motor rotation shaft, the inner fan comprises a shaft sleeve located at the center, fan blades are arranged outside the shaft sleeve, and the shaft sleeve is fixed to the motor rotation shaft in a hot jacket mode. The shaft sleeve of the inner fan of the inner fan installing structure of the motor is fixed to the motor rotation shaft in the hot jacket mode, so that the length of the shaft sleeve of the inner fan is appropriately shortened, machining of the inner diameter of a shaft hole of the inner fan and fan gears in the shaft is simplified, and the problem that a lamination bounces off to push away the air guide barrel, the inner fan is inaccurately positioned and accordingly keys and a retainer ring cannot be installed is completely avoided. The whole installation process is simple and clear, and a large amount of machining work and installation time are saved. In addition, multiple-time tests prove that no adverse influence on wind path circulation is produced.

Owner:无锡欧瑞京机电有限公司

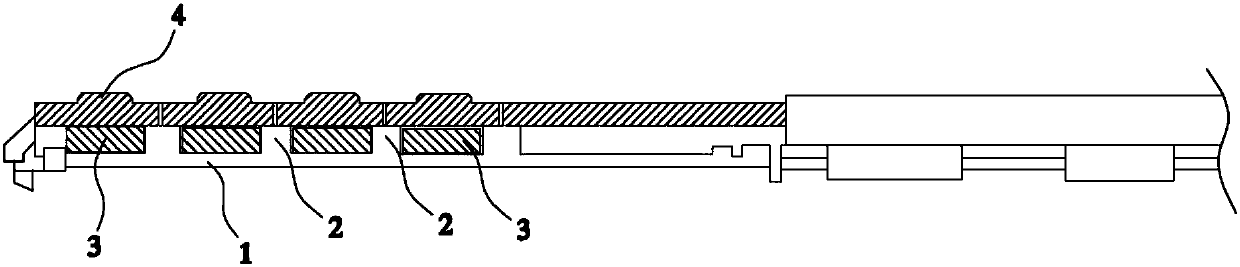

Straight line type high-speed single-cylinder injection mechanism

The invention discloses a straight line type high-speed single-cylinder injection mechanism which comprises an injection base, wherein a front injection plate and a rear injection plate are arranged on the injection base; the front injection plate and the rear injection plate are connected through four guide rods up and down; a charging barrel is mounted on the front injection plate; a screw is mounted in the charging barrel; an injection head is mounted at the head of the charging barrel; a hopper is mounted on the charging barrel; a middle injection plate is arranged between the front injection plate and the rear injection plate; a sliding block is arranged on the bottom surface of the middle injection plate; a linear guide rail is mounted on the injection base; the sliding block is matched with the linear guide rail; an oil motor is mounted on the rear wall of the middle injection plate; a screw connector is arranged on the front wall of the middle injection plate and is connected with the screw; a single-cylinder injection oil cylinder is mounted on the rear wall of the rear injection plate; and a piston rod of the single-cylinder injection oil cylinder penetrates through the rear injection plate to be connected with the oil motor. According to the scheme, the straight line type high-speed single-cylinder injection mechanism is small in occupied area and energy consumption, low in cost and high in efficiency.

Owner:浙江力松机械有限公司

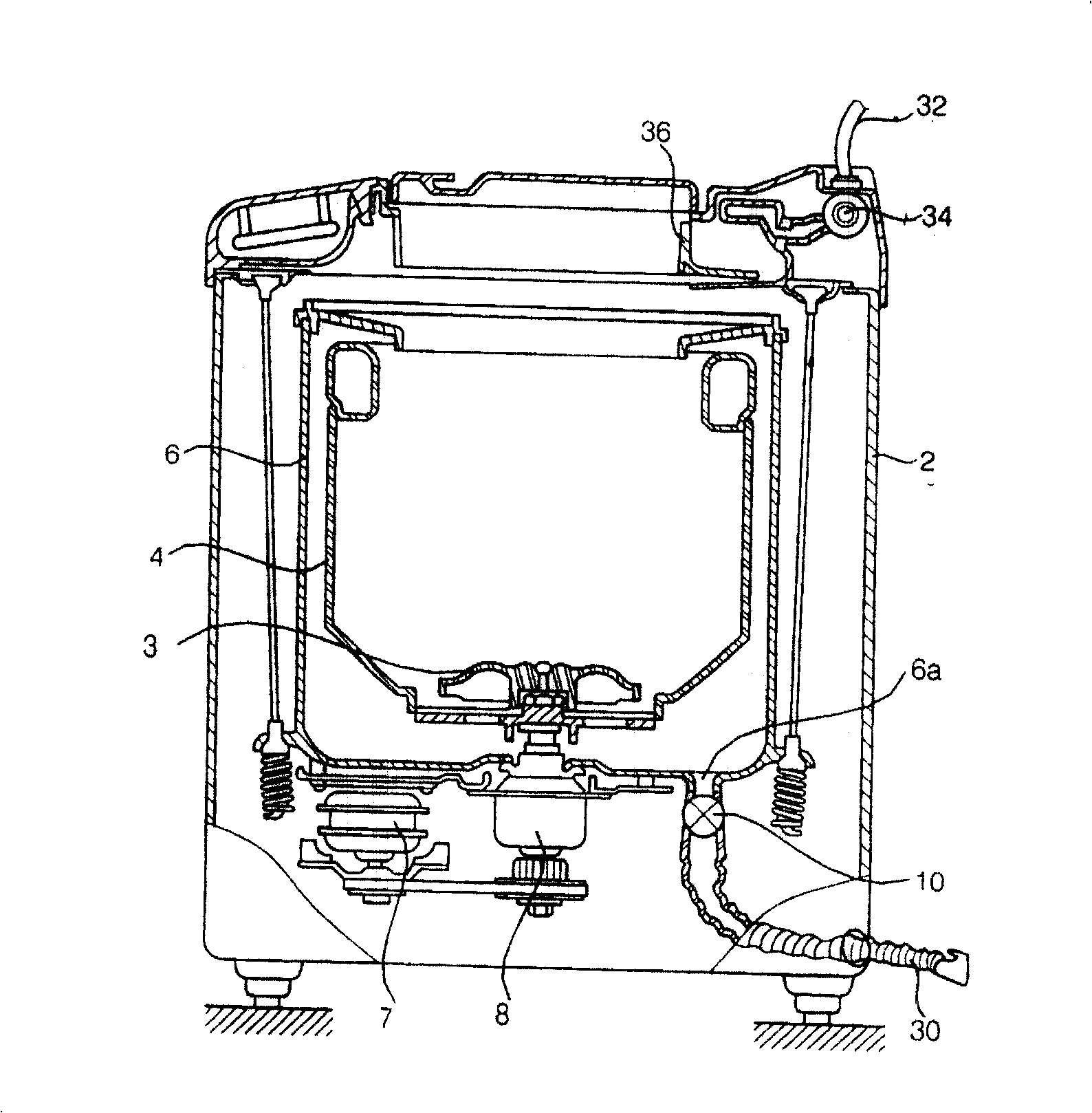

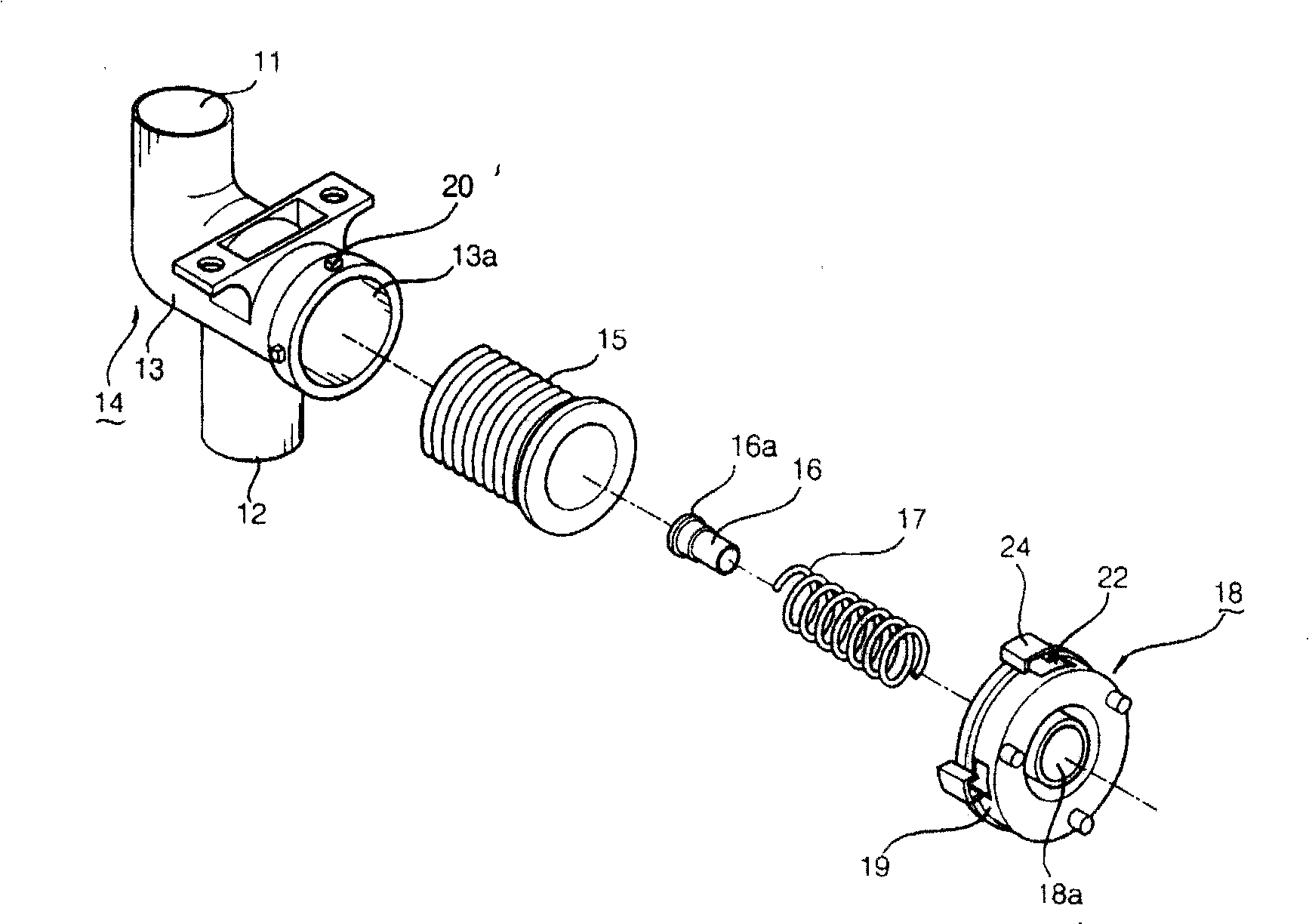

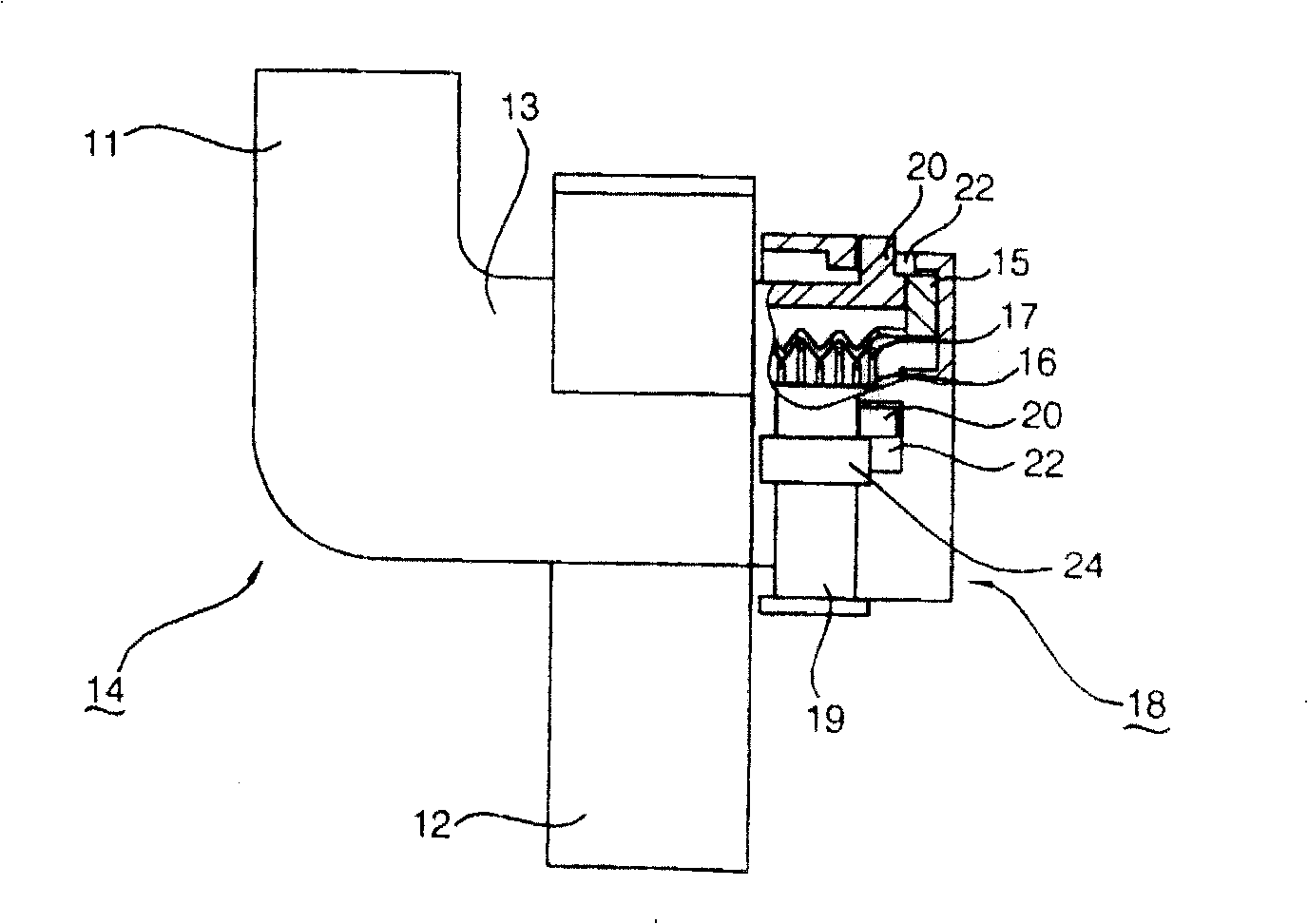

Connection structure of draining valve for washer

InactiveCN100455713CFirmly connectedSimple structureOther washing machinesTextiles and paperVALVE PORTEngineering

The connection structure of draining valve for washer has easy connection between the valve casing and valve hood and low manufacture and material cost. The connection structure includes valve casing with raised hook and valve hood with hole for the hook to be inserted in. The valve casing has also slot for the end of the inserted hook to be inserted in, so that the valve hood can be combined with the valve casing via simple operation. The present invention makes the connection of draining valve easy and the connection structure is simple and low in cost.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Anti-deformation device for steel structure

PendingCN113478125AAnti-deformation for controlQuick supportWelding/cutting auxillary devicesAuxillary welding devicesPull forceGear wheel

The invention discloses an anti-deformation device for a steel structure, and relates to the technical field of steel structures. The anti-deformation device for the steel structure comprises a water box, a back plate is fixedly mounted on the outer wall of the other side of the water box through bolts, a long opening is formed in the back plate, a short toothed plate is arranged in the long opening, and the outer surface of the rear side of the short toothed plate extends to the outer surface of the rear side of the back plate and is fixedly connected with a vertical plate. According to the anti-deformation device for the steel structure, through cooperative use of a thin sliding rod, a thin sliding rod sleeve, a long toothed plate, a short rotating rod, a second gear and an H-shaped rod, the steel structure can be pulled, and the pulling force can be mutually balanced with the deformation trend of the steel structure, so that the deformation force is reduced, the situation that the transverse rigidity of the steel structure is insufficient is avoided, the situation of welding deformation of the steel structure is effectively reduced, the surface of the obtained steel structure is straight and reliable, machining steps and correction cost are saved, the quality of the steel structure is improved, and the stability of the steel structure is guaranteed.

Owner:浙江正豪钢结构工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com