Connection structure of draining valve for washer

A connection structure and washing machine technology, which can be applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of high processing and material costs, complex forming process of guide plate hole and fixed part, cumbersome installation process, etc., to achieve Save processing costs and material costs, simple structure, and easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

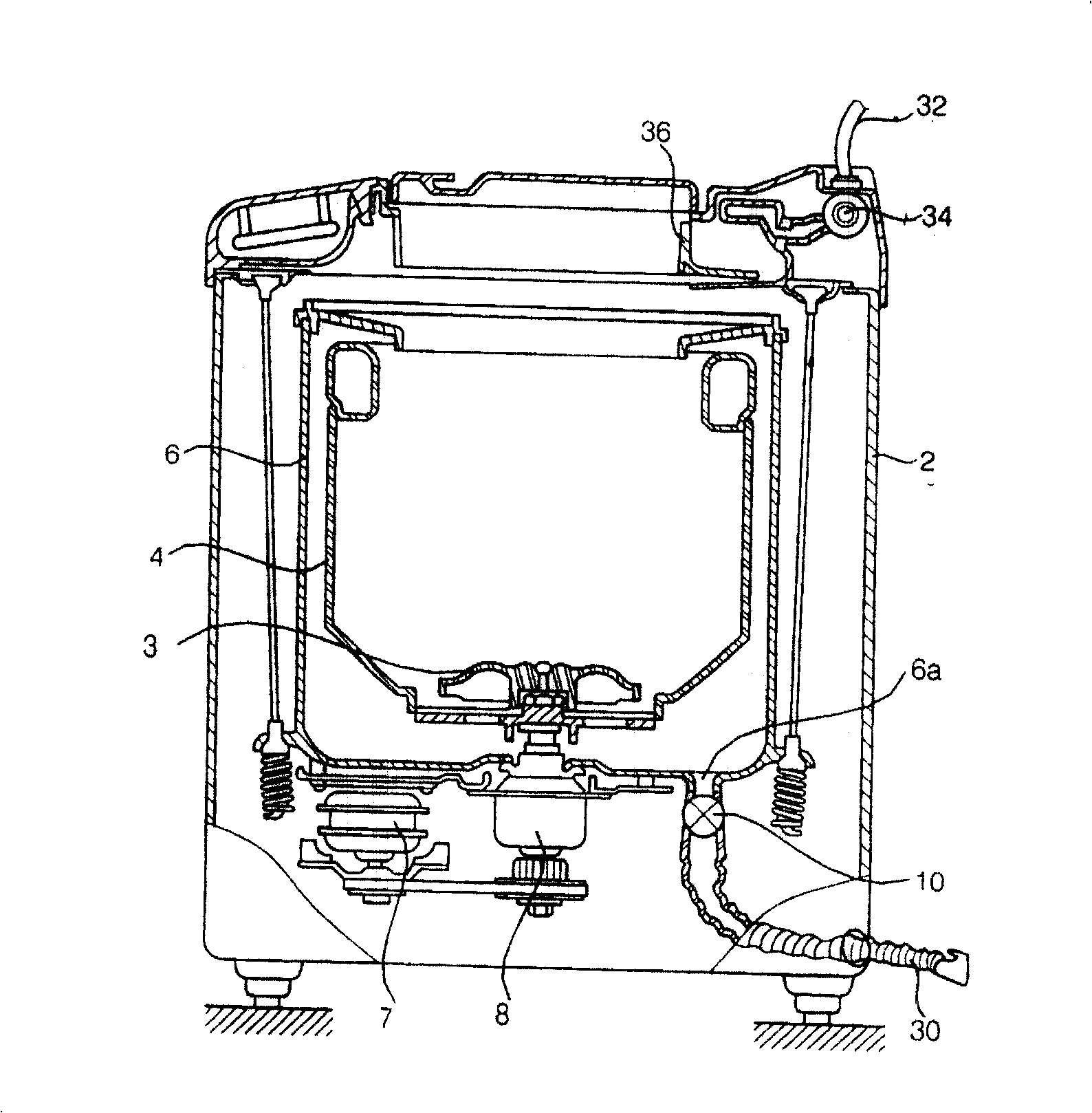

[0032] The specific implementation, structure, features and effects of the two-way connection structure of the washing machine drain pump according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

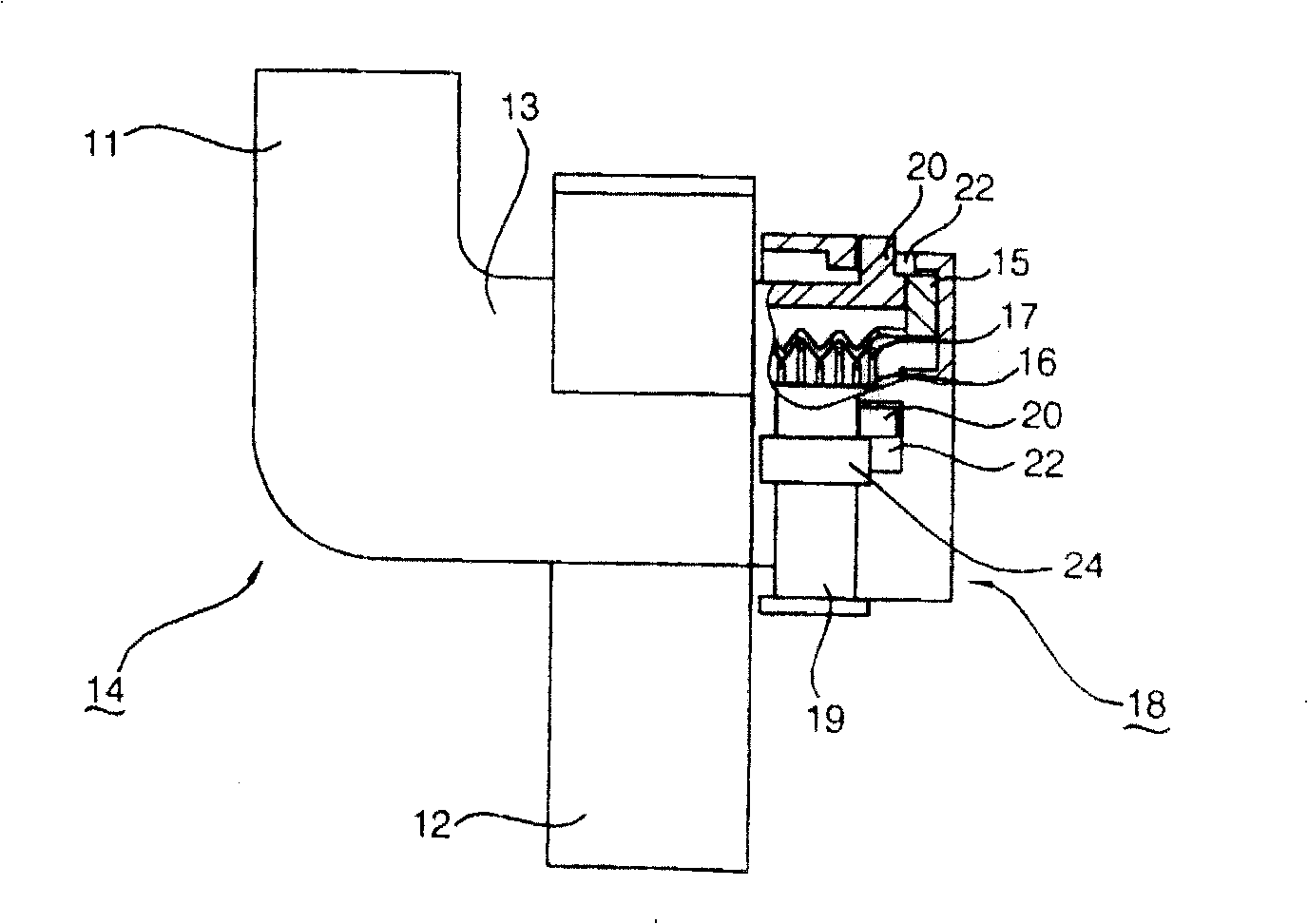

[0033] According to the connection structure of a washing machine valve proposed by the present invention, a hook is protruded on the valve shell; a hook hole is formed on the edge of the valve cover and can be inserted into the hook; and a hook hole is formed on the valve shell. There is a broken groove that can hang the end of the hook inserted into the hook hole, so that the valve cover can be combined with the valve housing at one time.

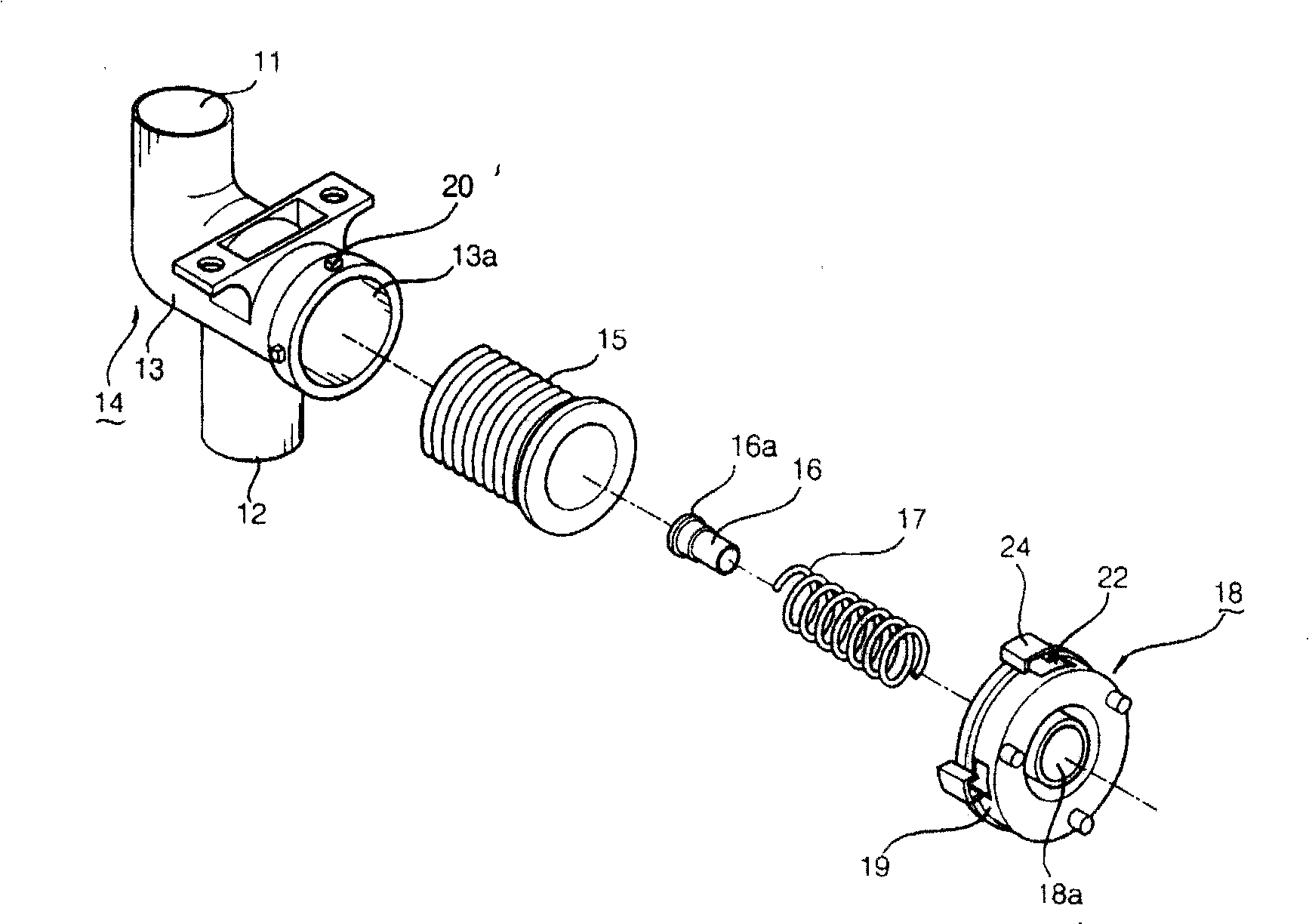

[0034] Please refer to FIG. 4 and FIG. 5 . FIG. 4 is an exploded schematic view showing the main structure of the drain valve according to the present invention, and FIG. 5 is a partial cross-sectional side view of the drain valve according to the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com