Processing method of profiled screening cover

A shielding cover and special-shaped technology, which is applied in the field of mechanical processing, can solve the problems of unmanufacturability and high cost, and achieve the effects of saving manufacturing material costs and processing costs, high production efficiency, and reducing product manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

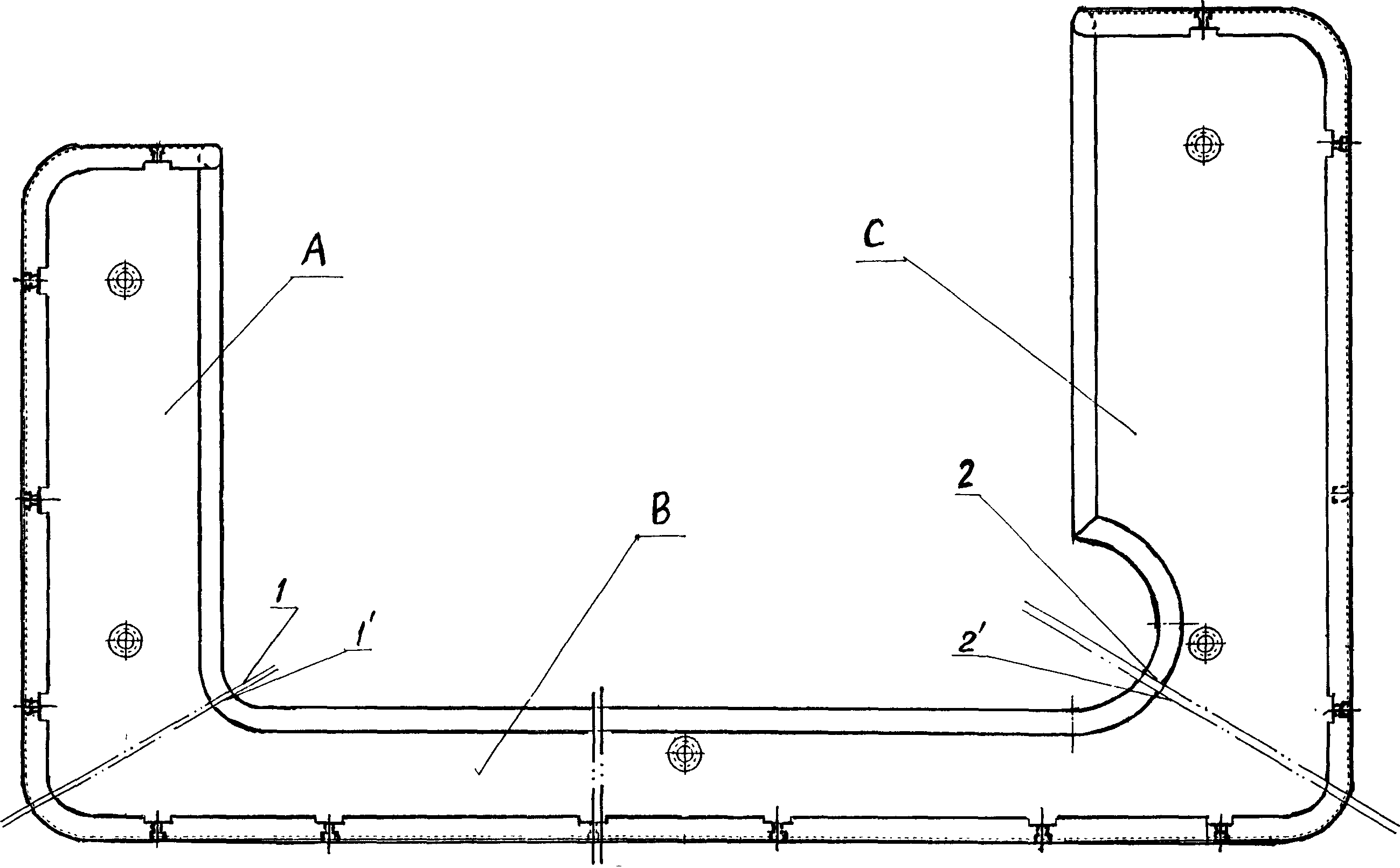

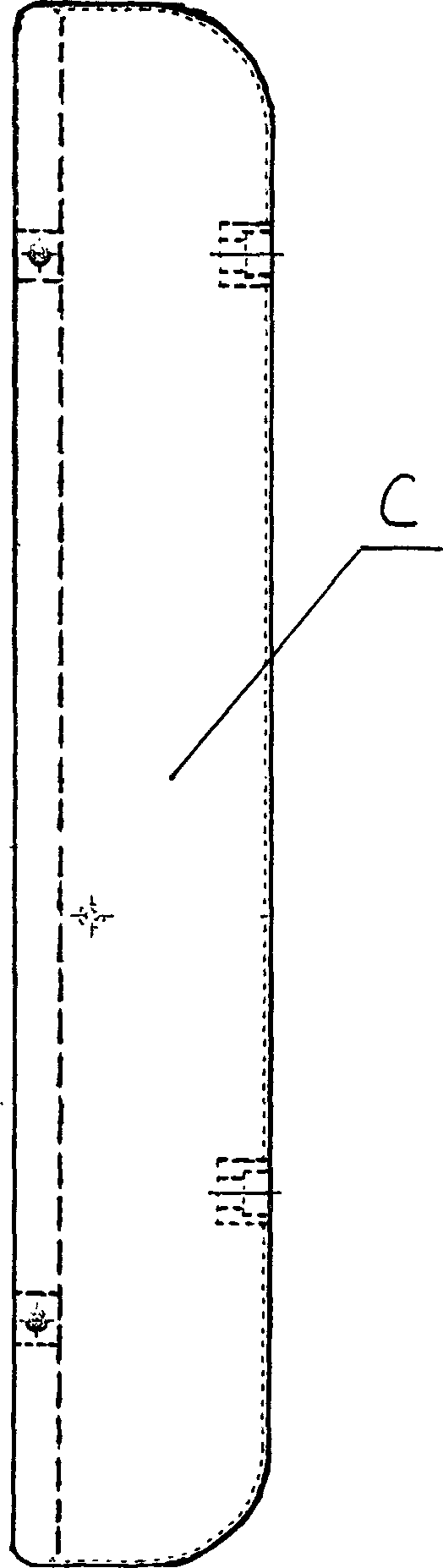

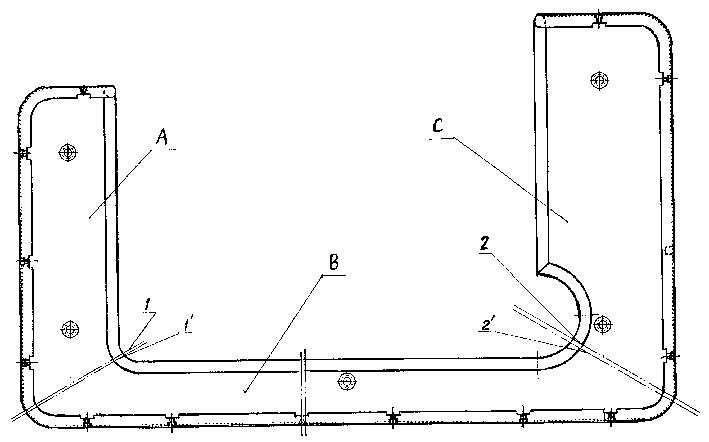

[0016] 1. Press figure 1 As shown, the product is divided into three blocks A, B, and C on the drawing, and divided into three blocks 1, 1', 2, and 2' at the rounded corners.

[0017] 2. Computer graphics, draw the cardboard diagram according to the ratio of 1:1, and make the cardboard, the thickness of the cardboard is 1mm metal sheet.

[0018] 3. Press figure 1 A, B, and C dimensions on the above are respectively processed into actual products.

[0019] 4. Splice A, B, and C three physical products according to the pallet, and weld the welds 1, 1' and 2, 2'.

[0020] 5. Use a special abrasive tool - the electric grinding head is equipped with a file to rotate to remove the scars of the weld seam, and then use the sandpaper disc on the electric grinding head to polish the weld seam.

[0021] The invention is applicable to the processing of small batch, multi-variety and large-size thin plate parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com