Patents

Literature

155 results about "Neutral plane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

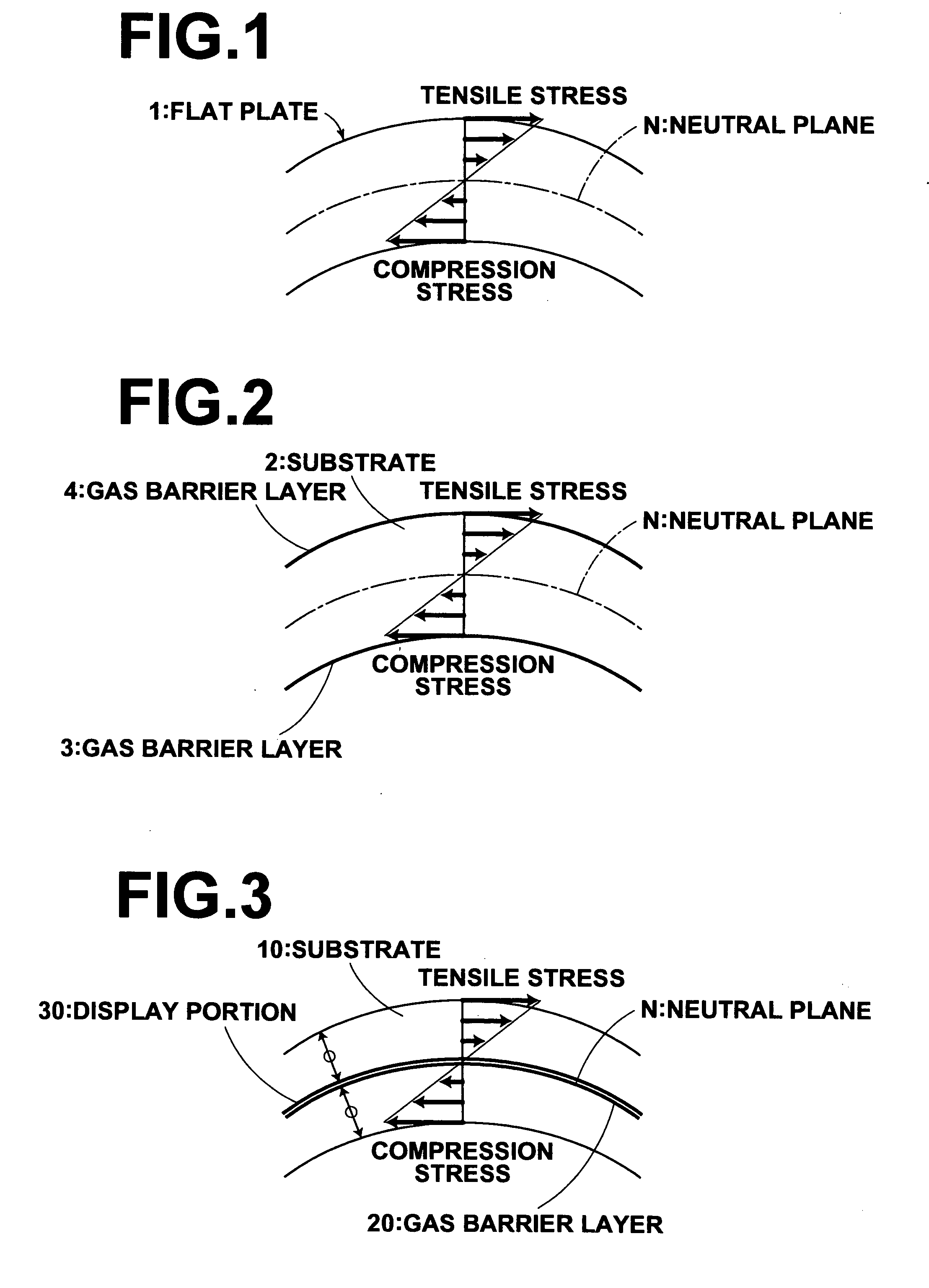

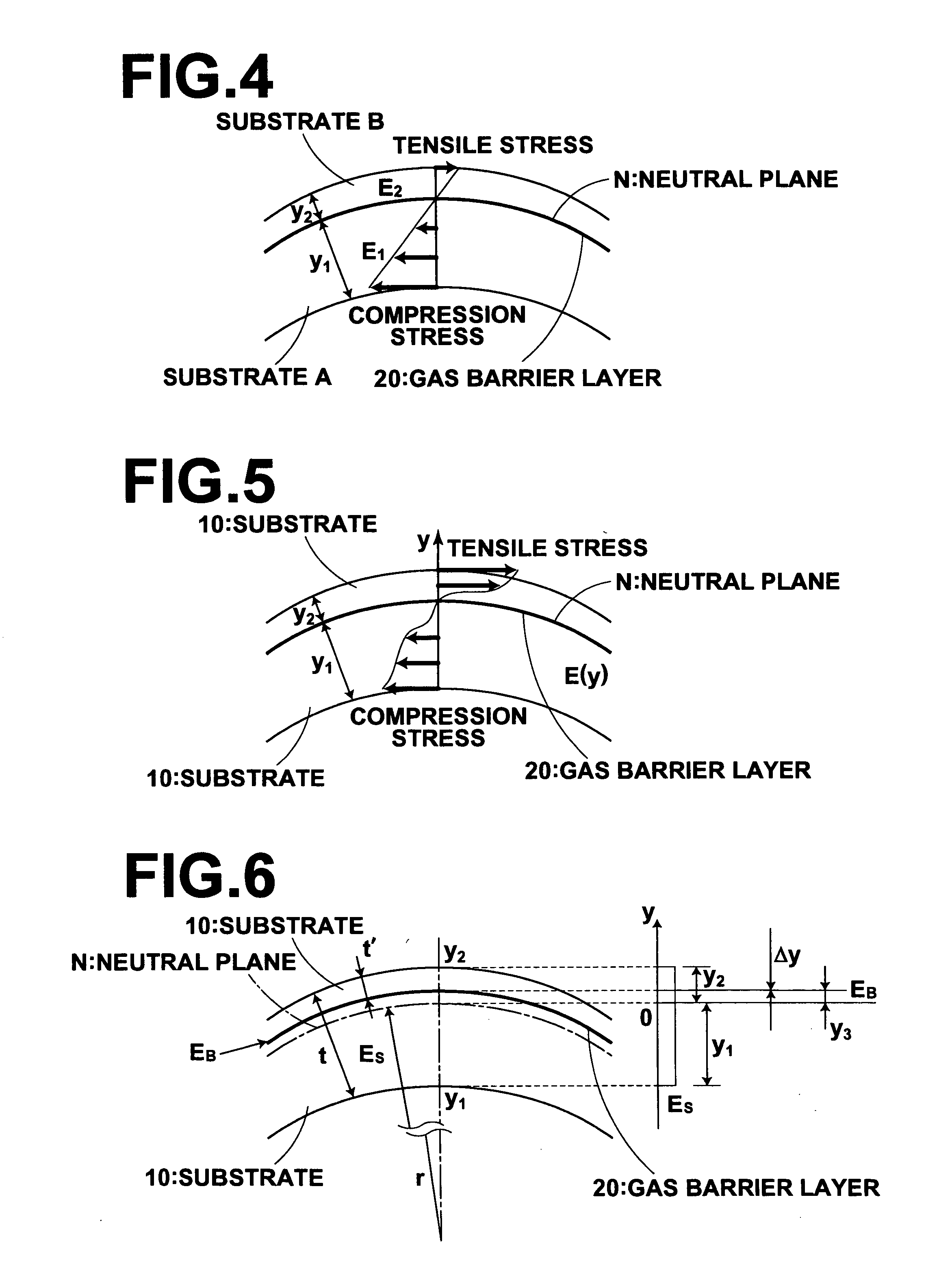

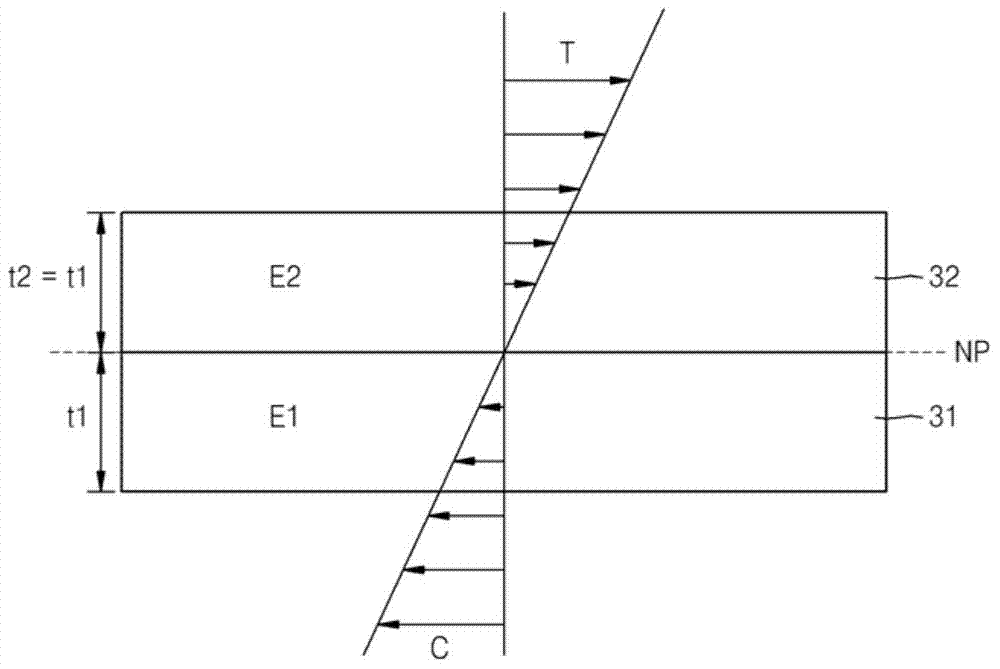

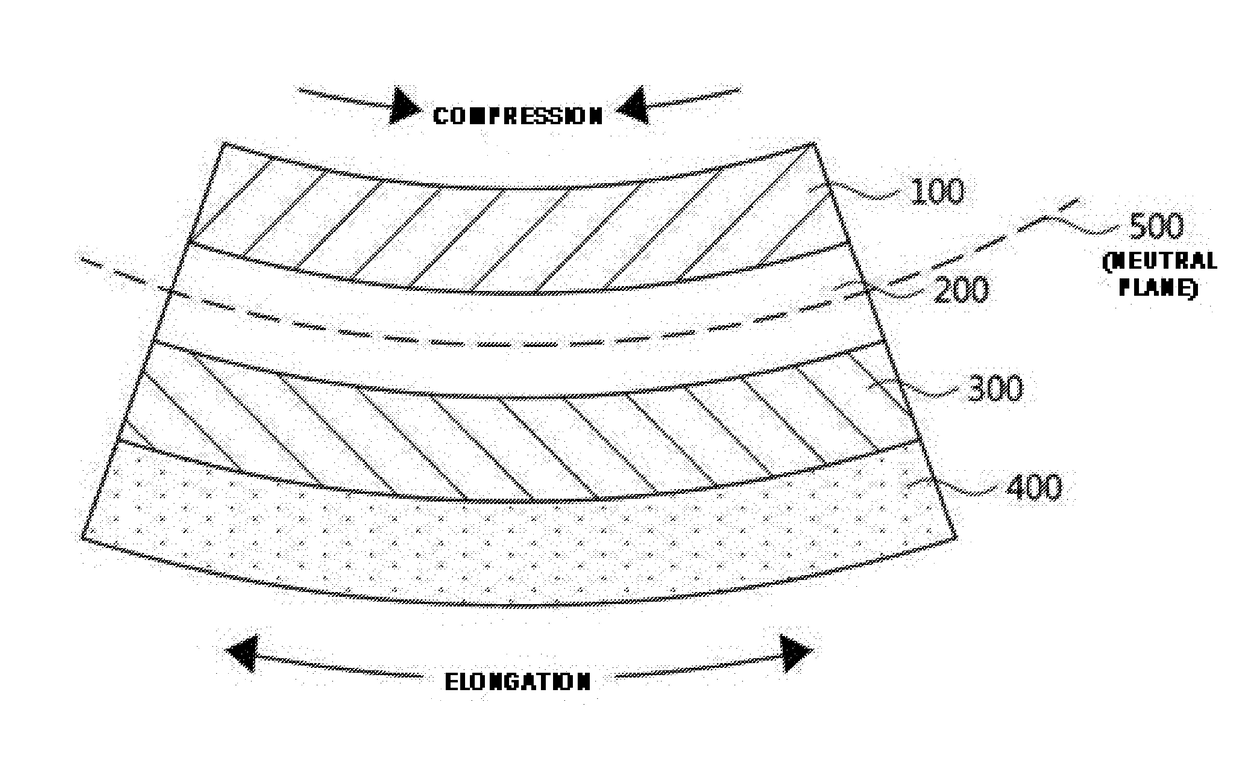

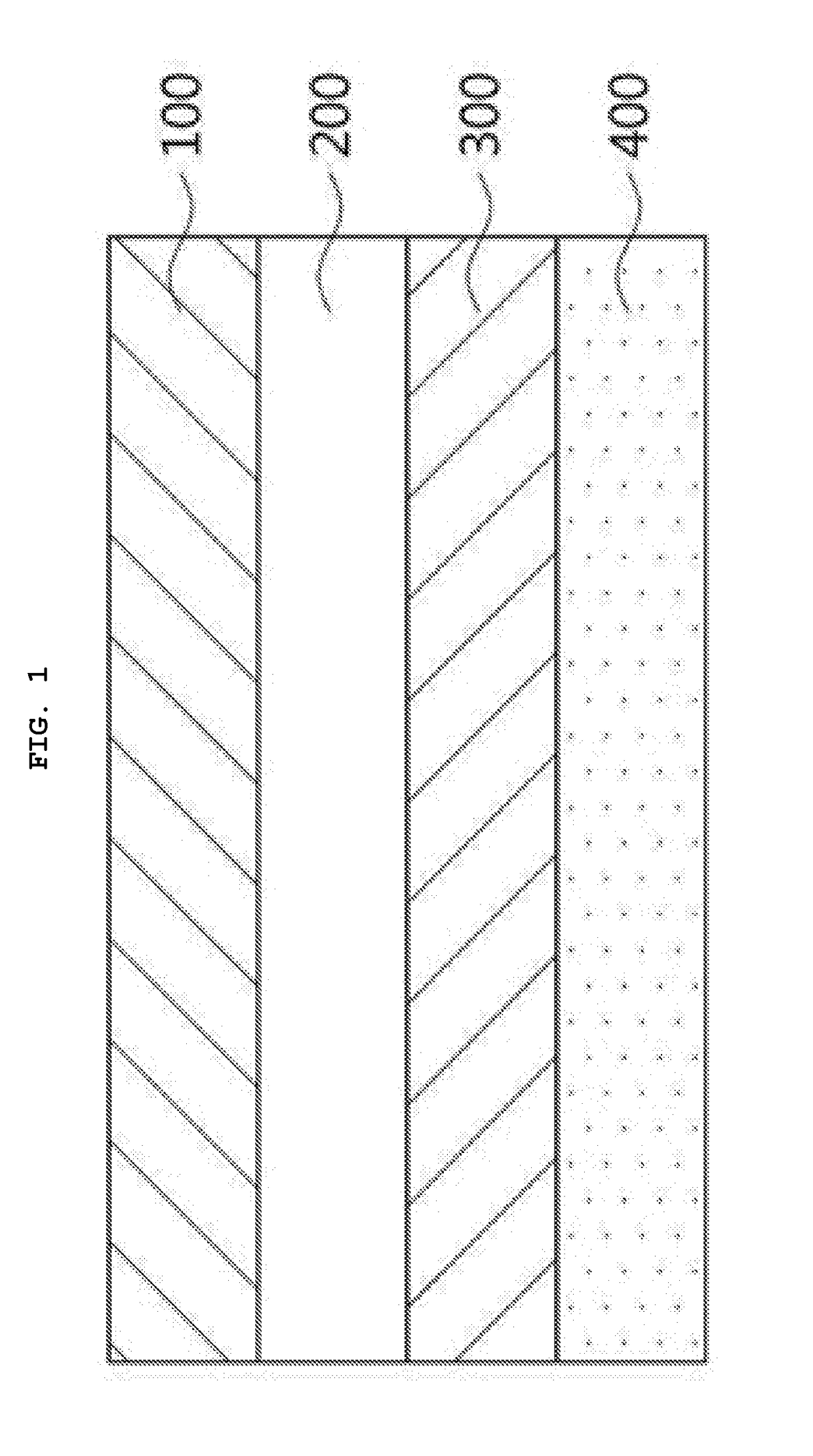

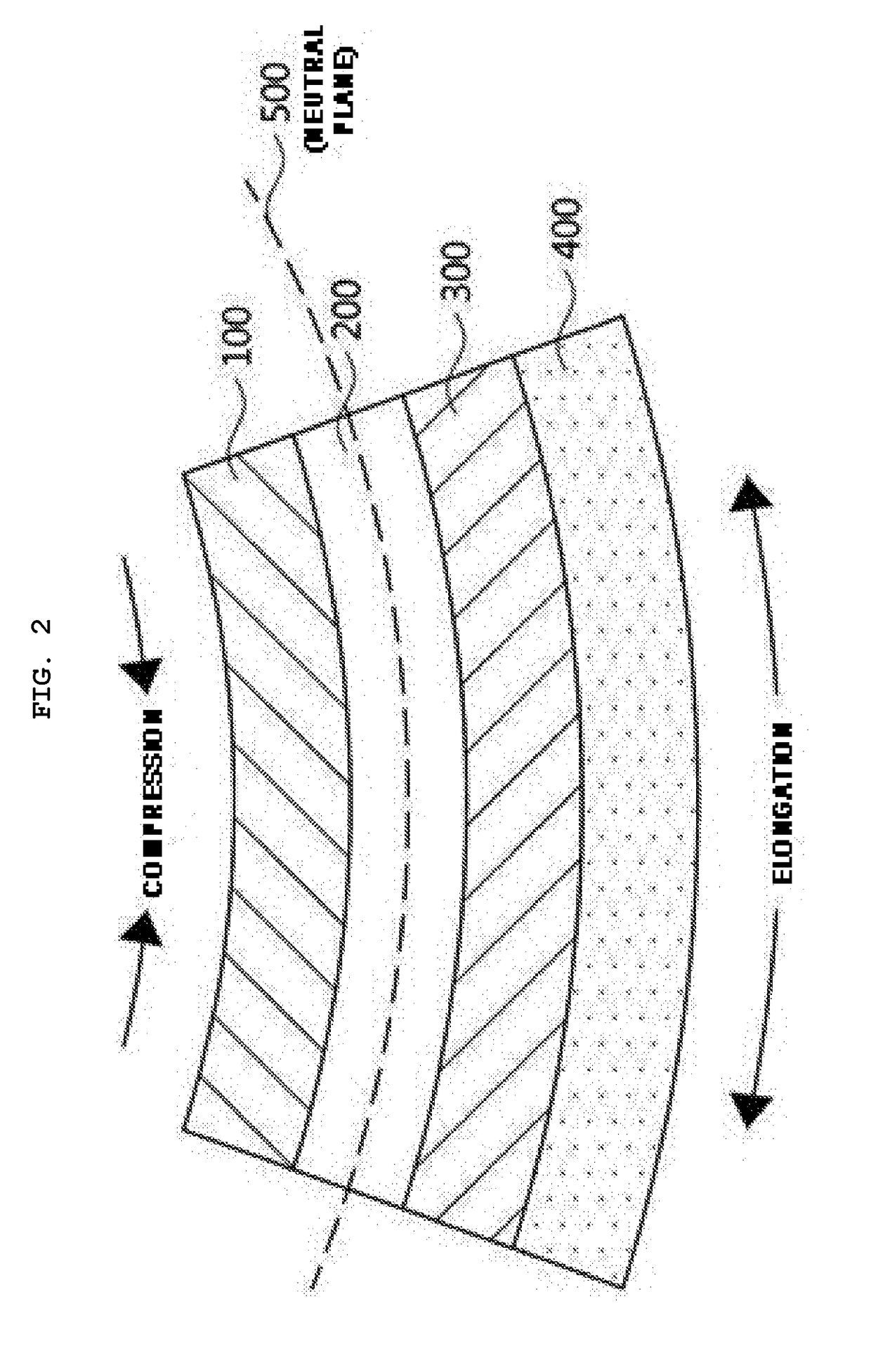

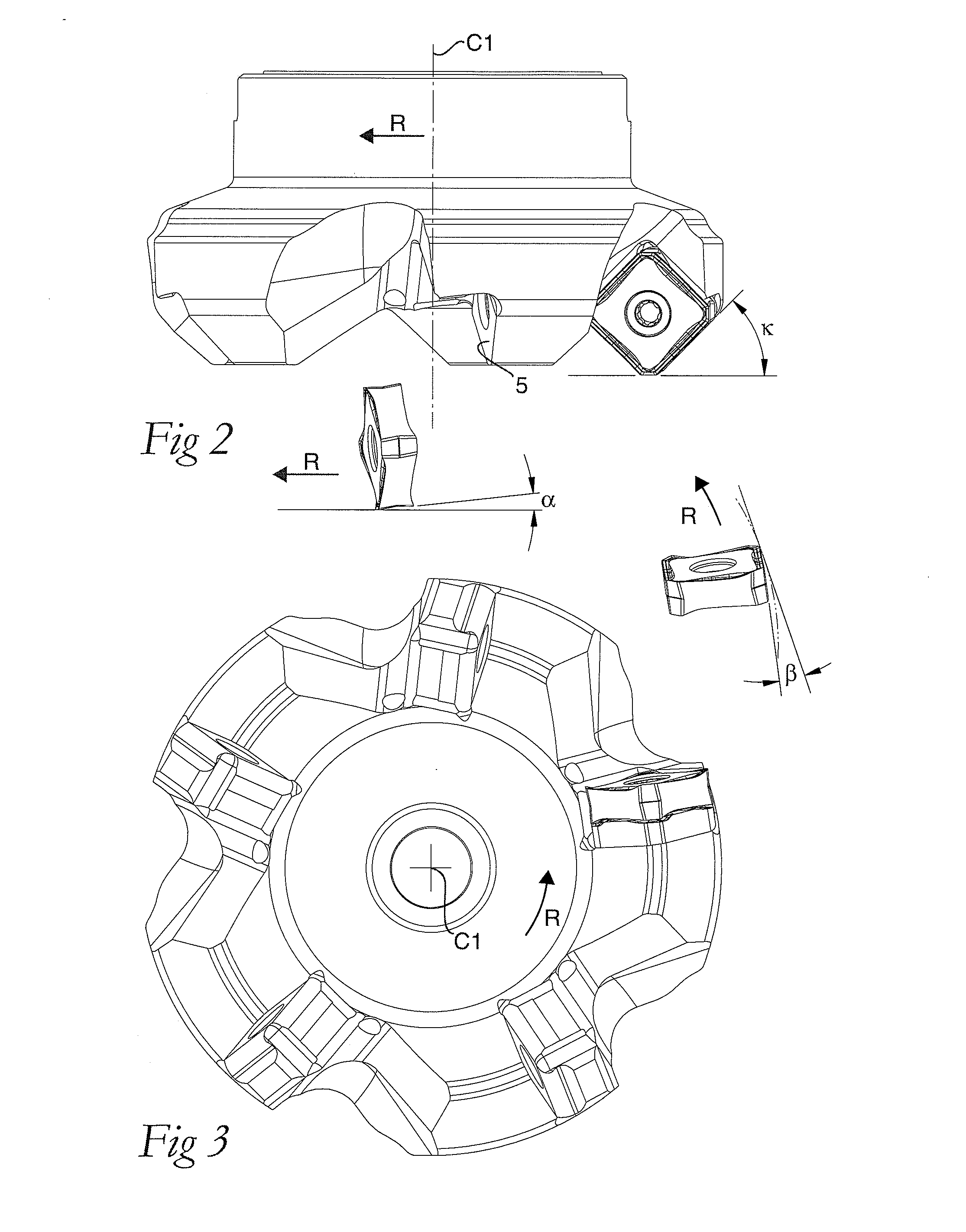

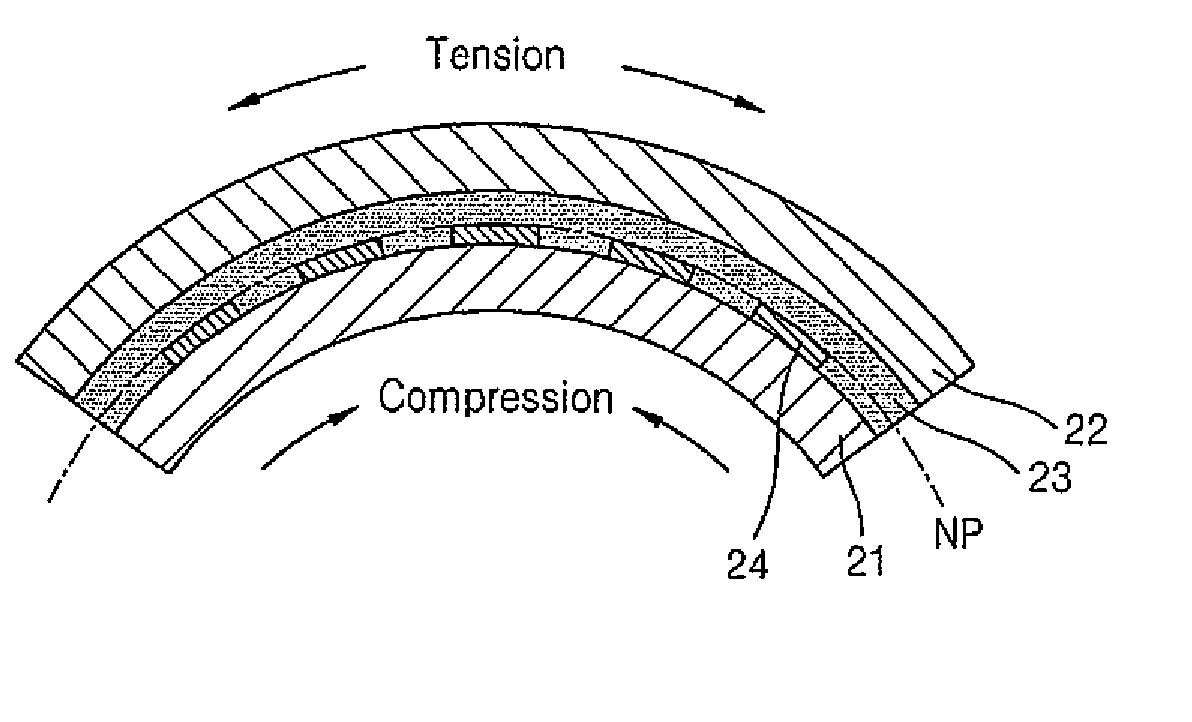

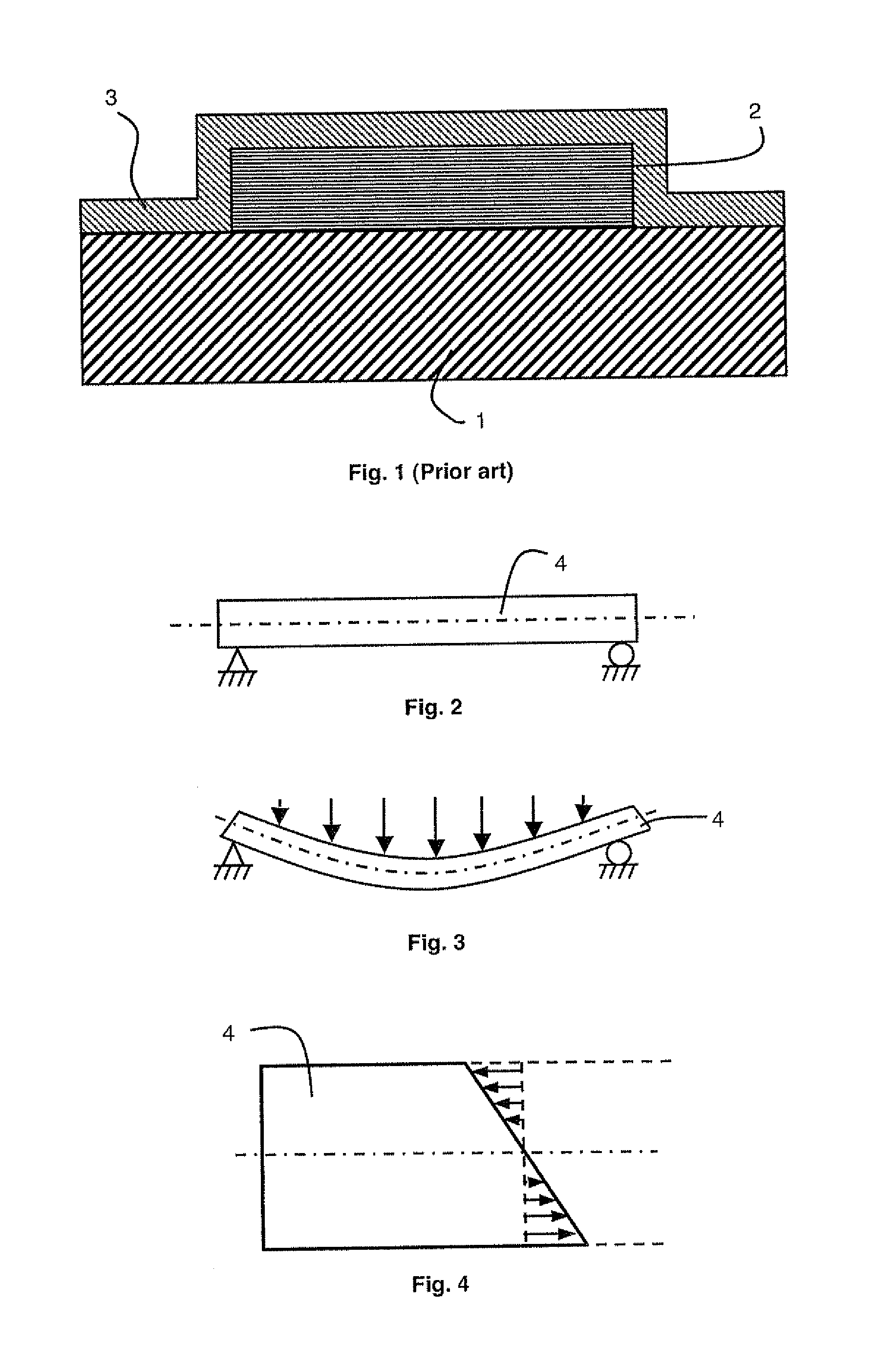

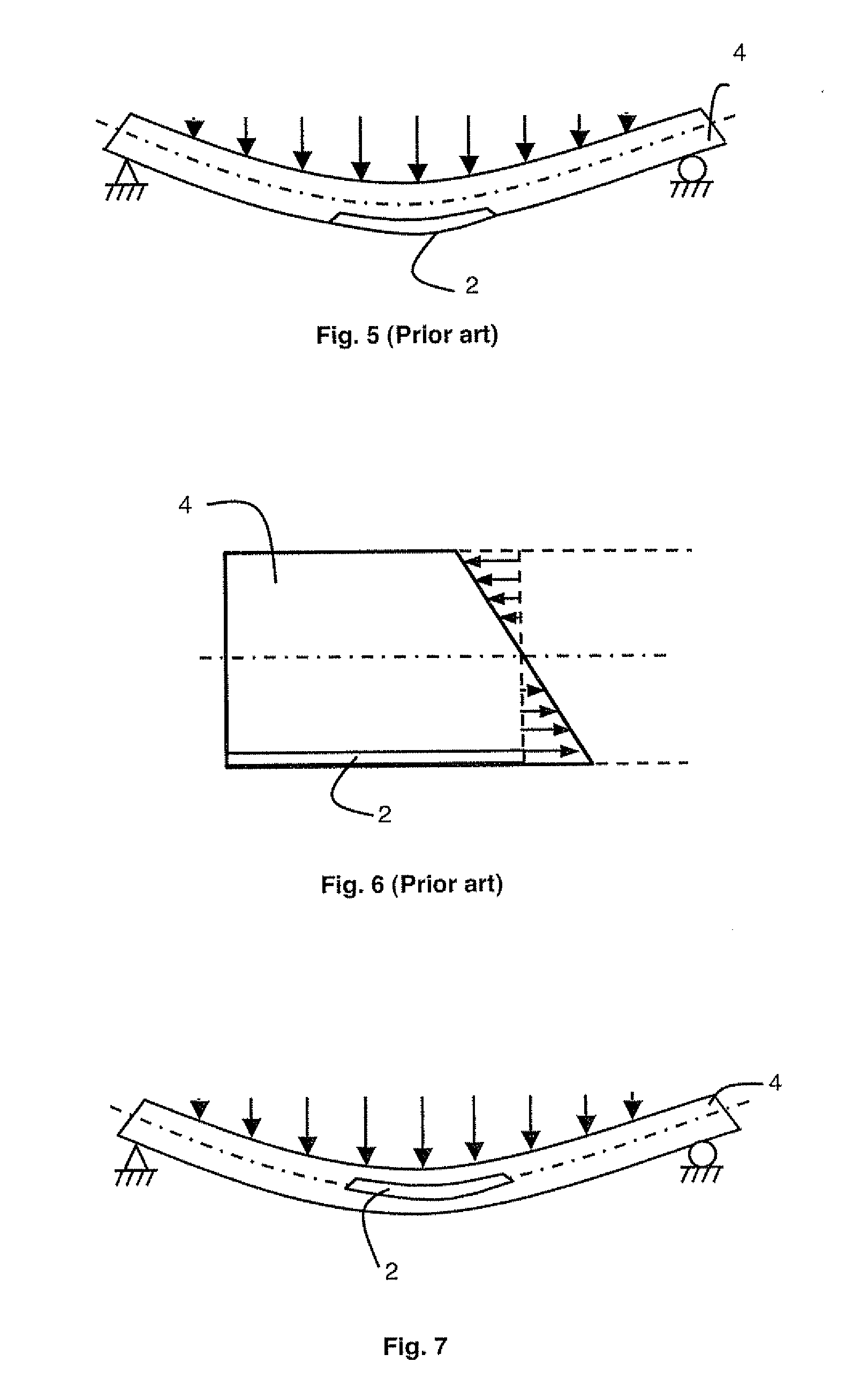

In mechanics, the neutral plane or neutral surface is a conceptual plane within a beam or cantilever. When loaded by a bending force, the beam bends so that the inner surface is in compression and the outer surface is in tension. The neutral plane is the surface within the beam between these zones, where the material of the beam is not under stress, either compression or tension.

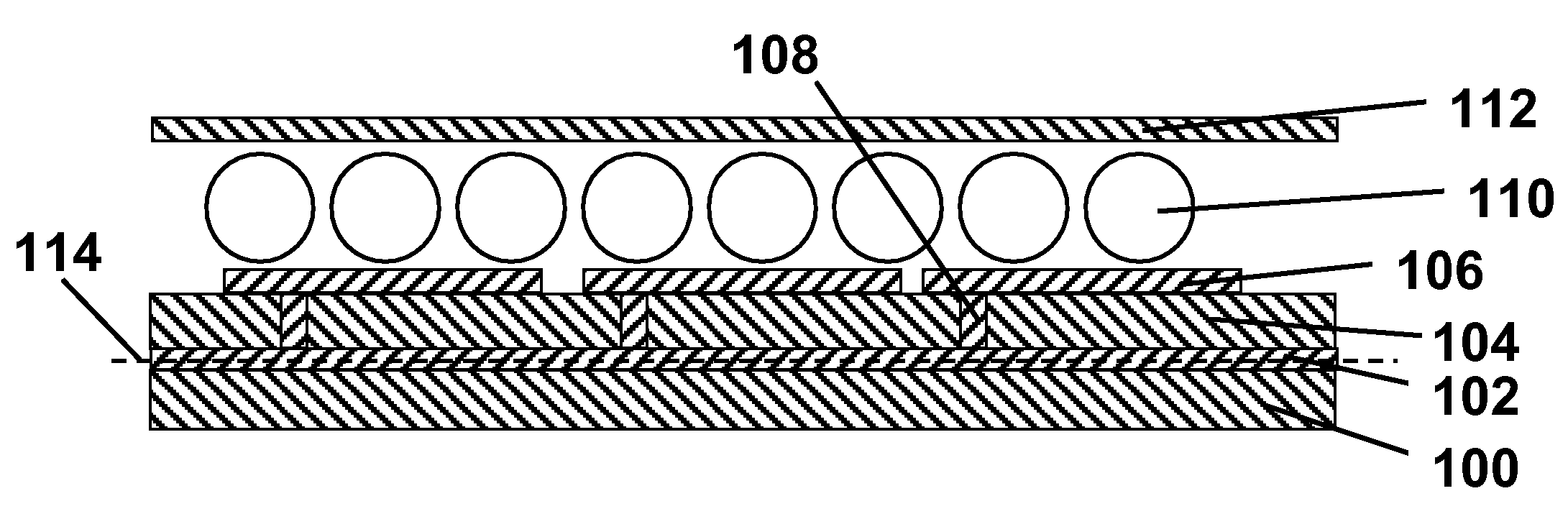

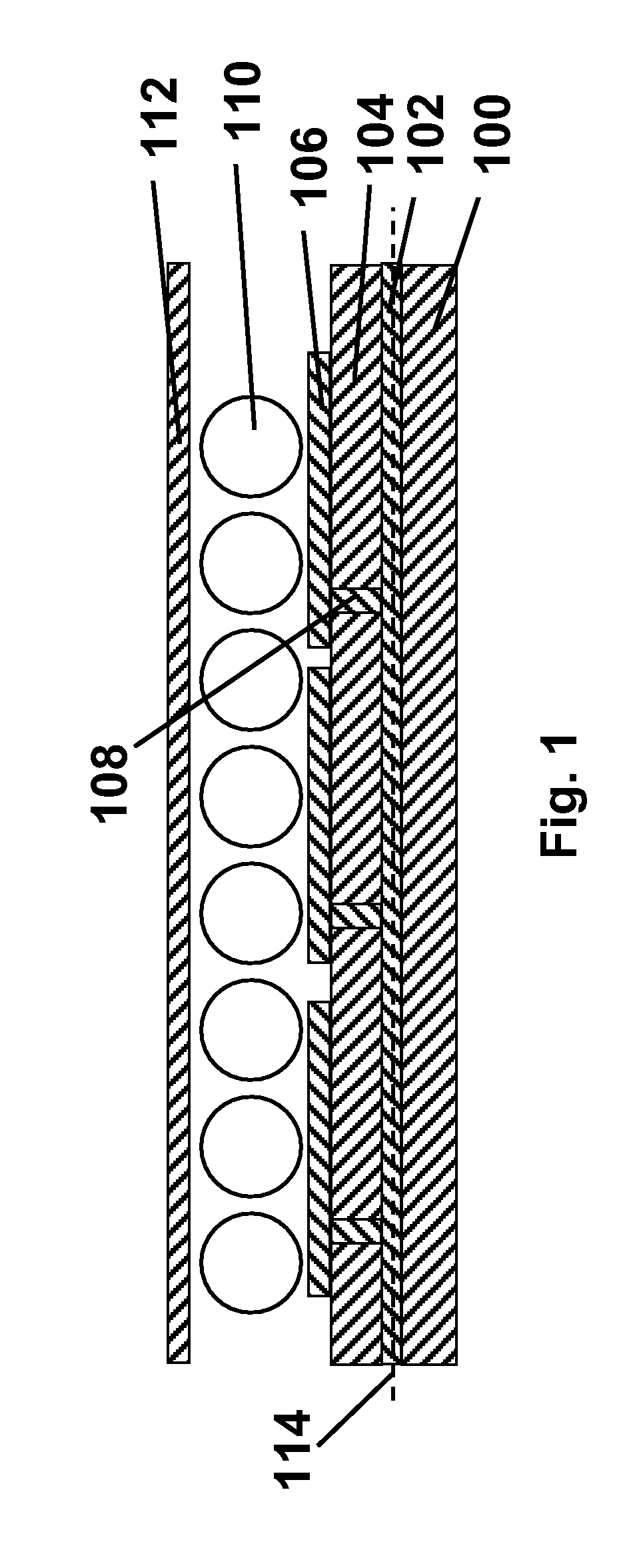

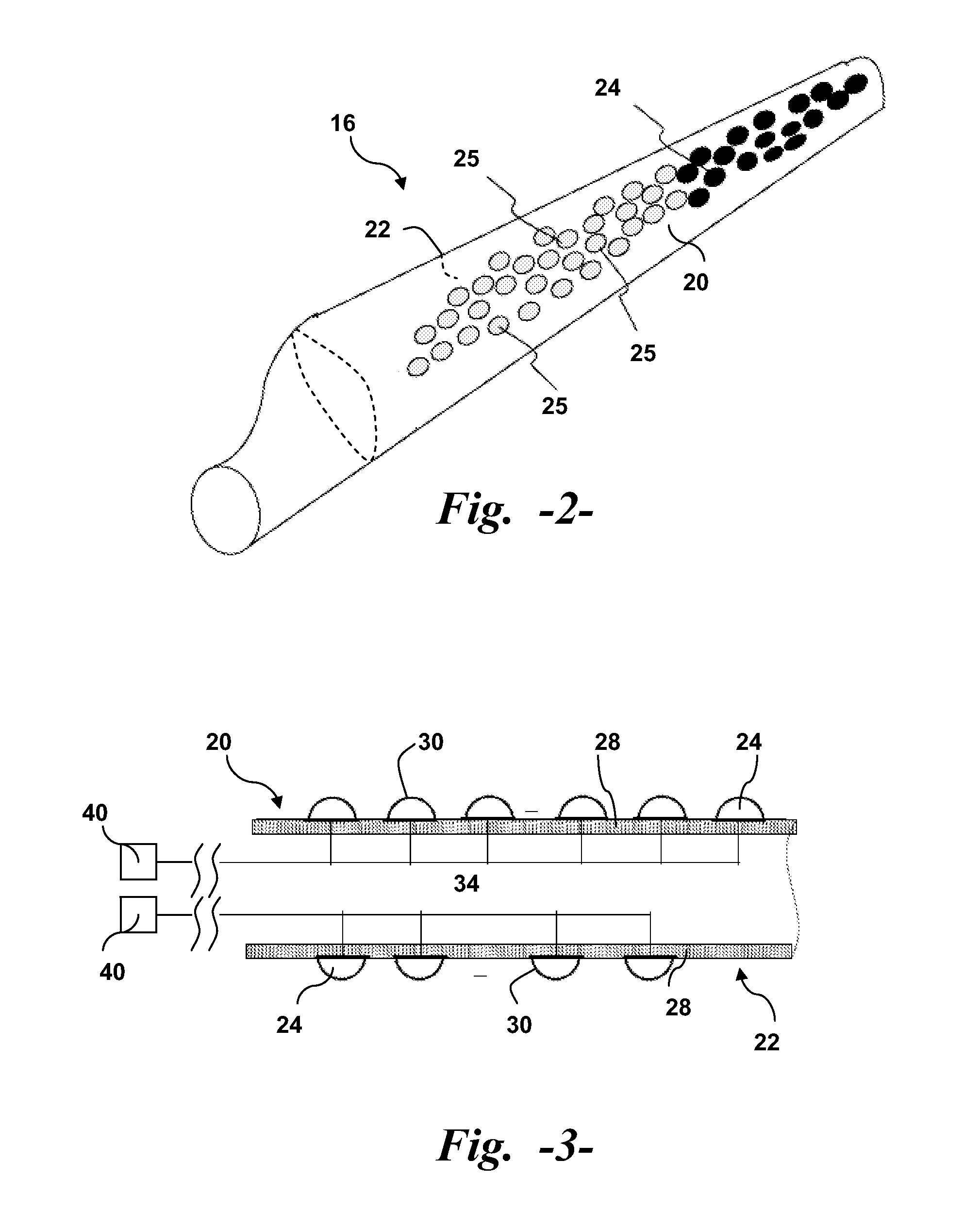

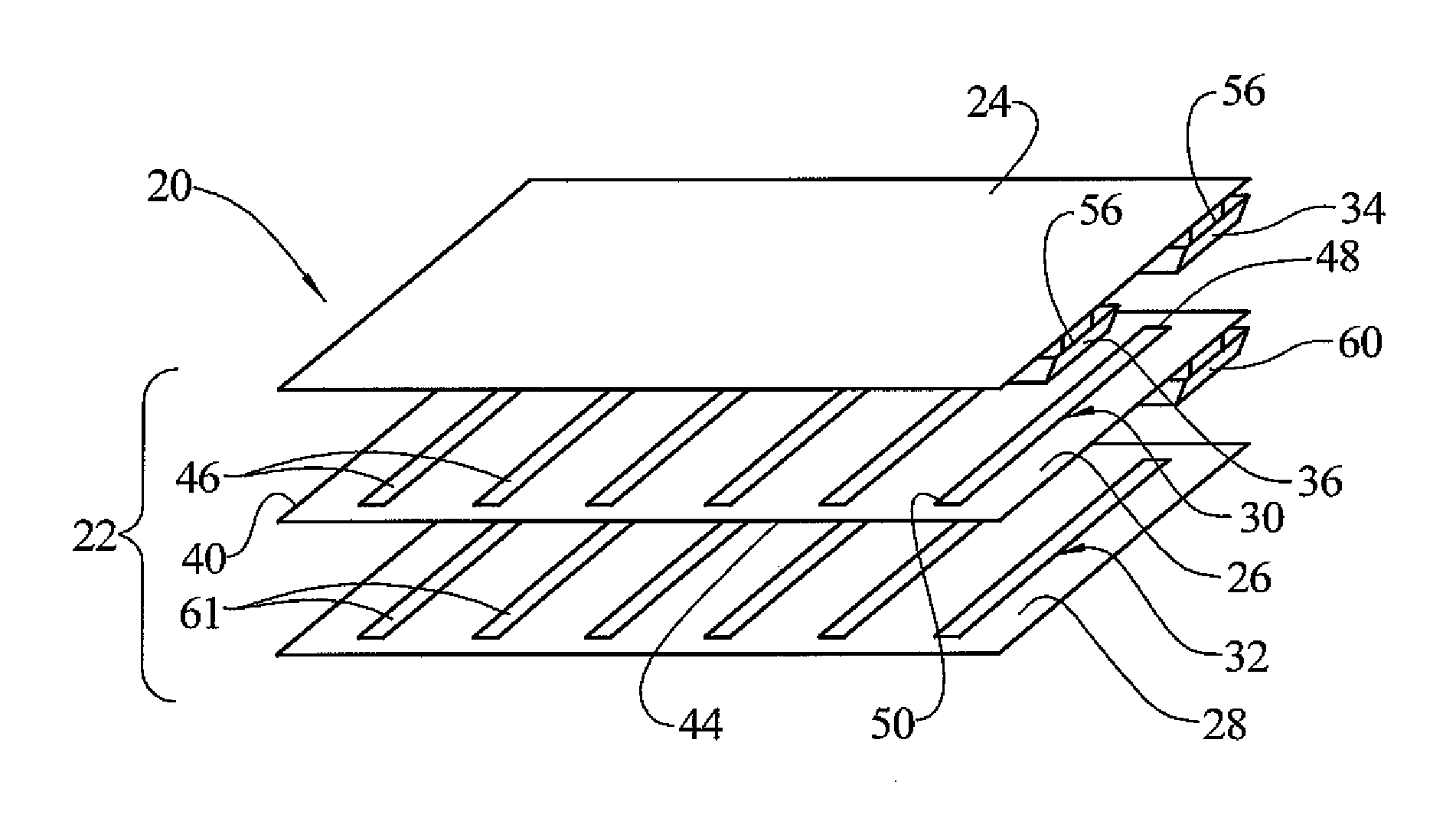

Electro-optic displays, and components for use therein

InactiveUS7190008B2Change conductivitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceNeutral plane

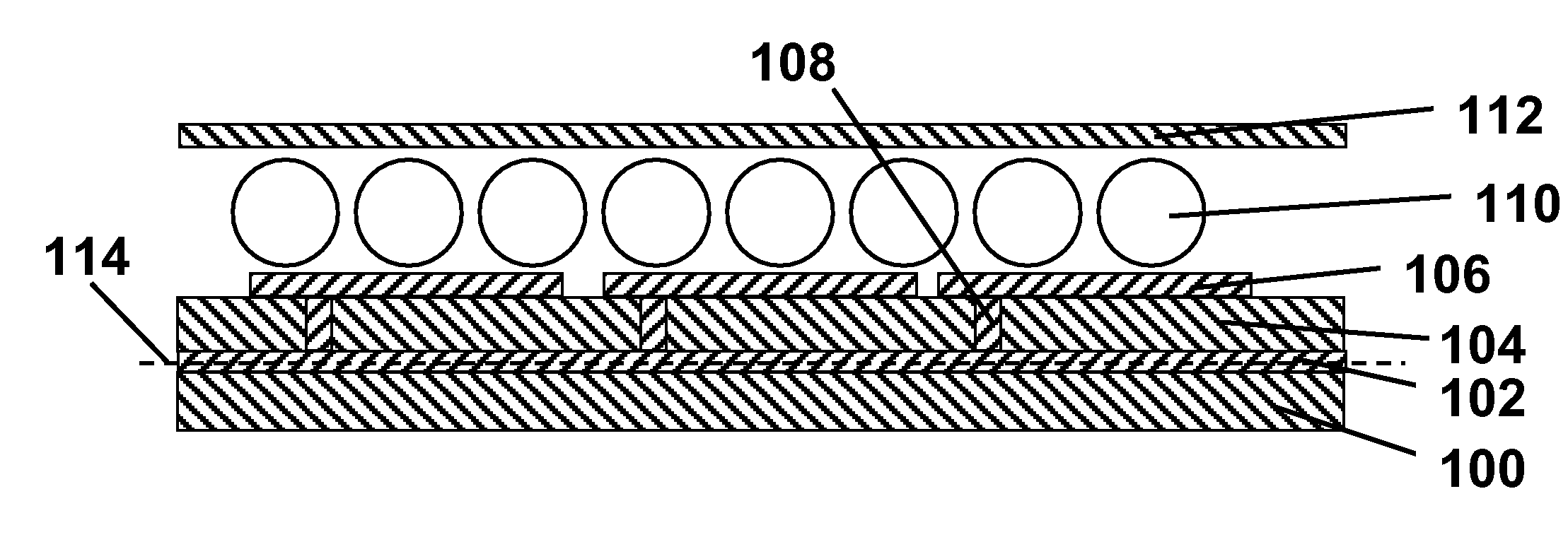

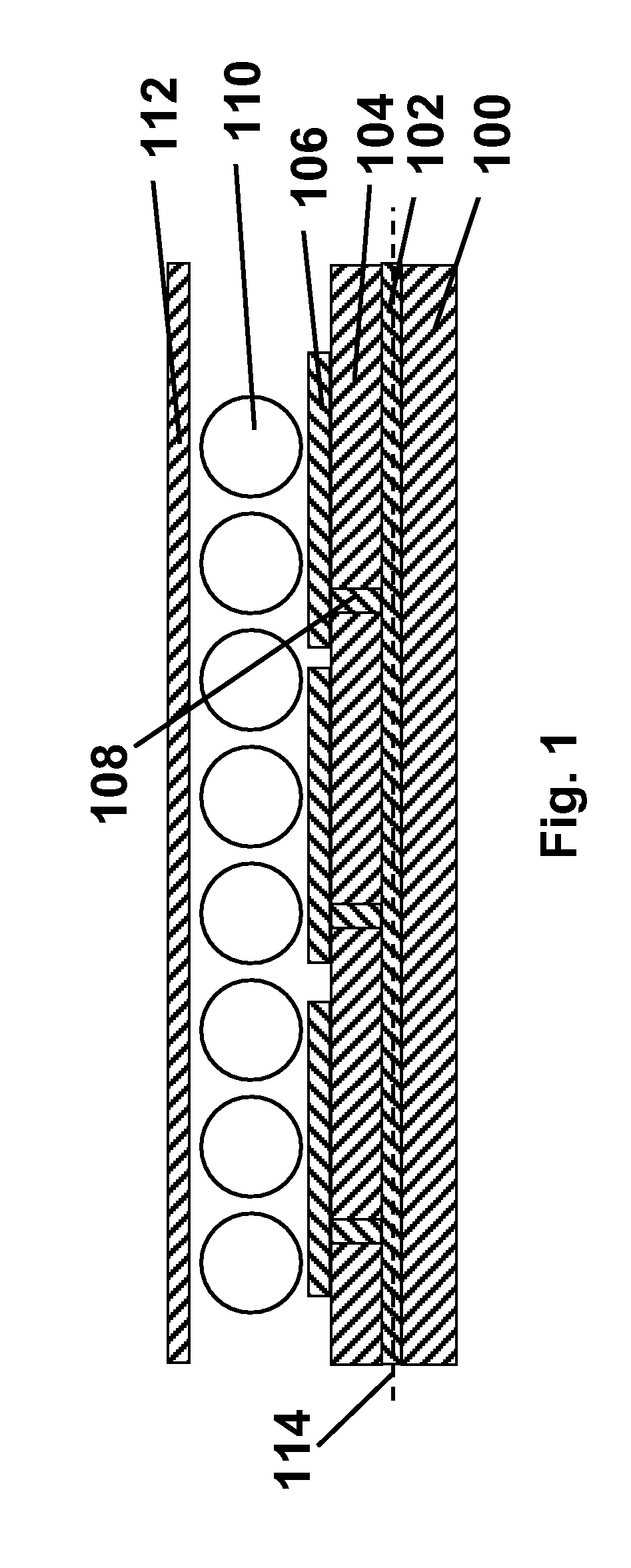

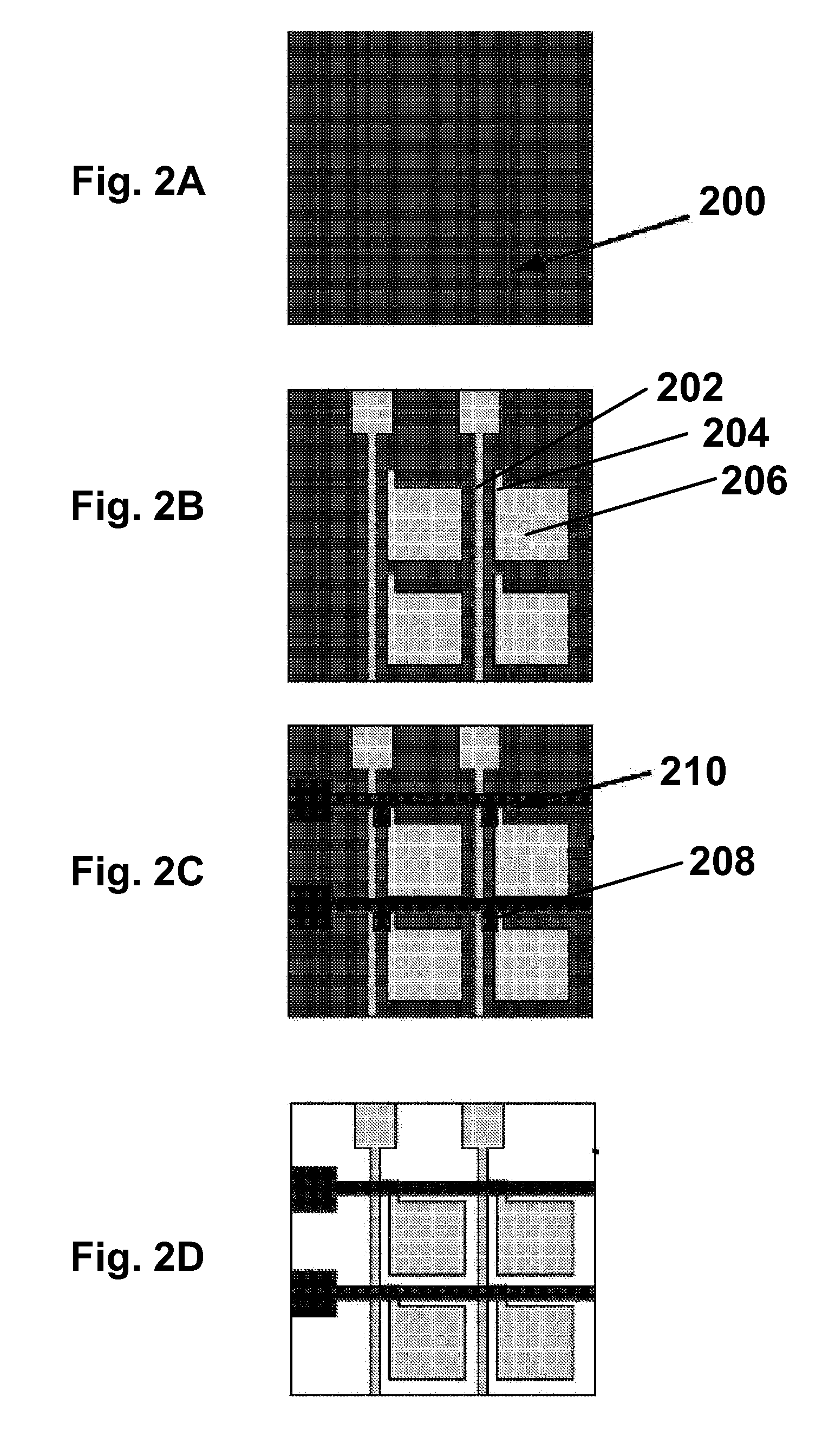

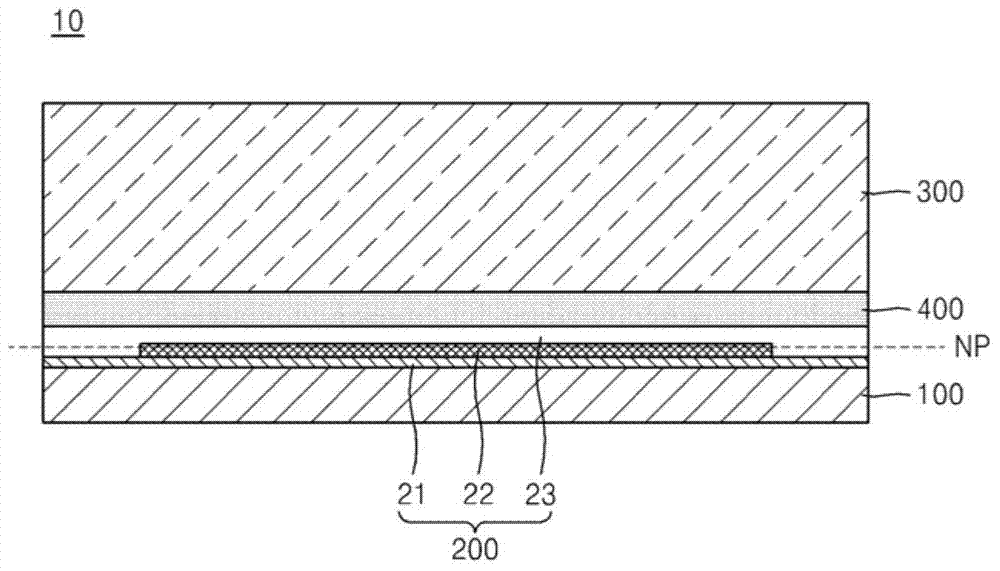

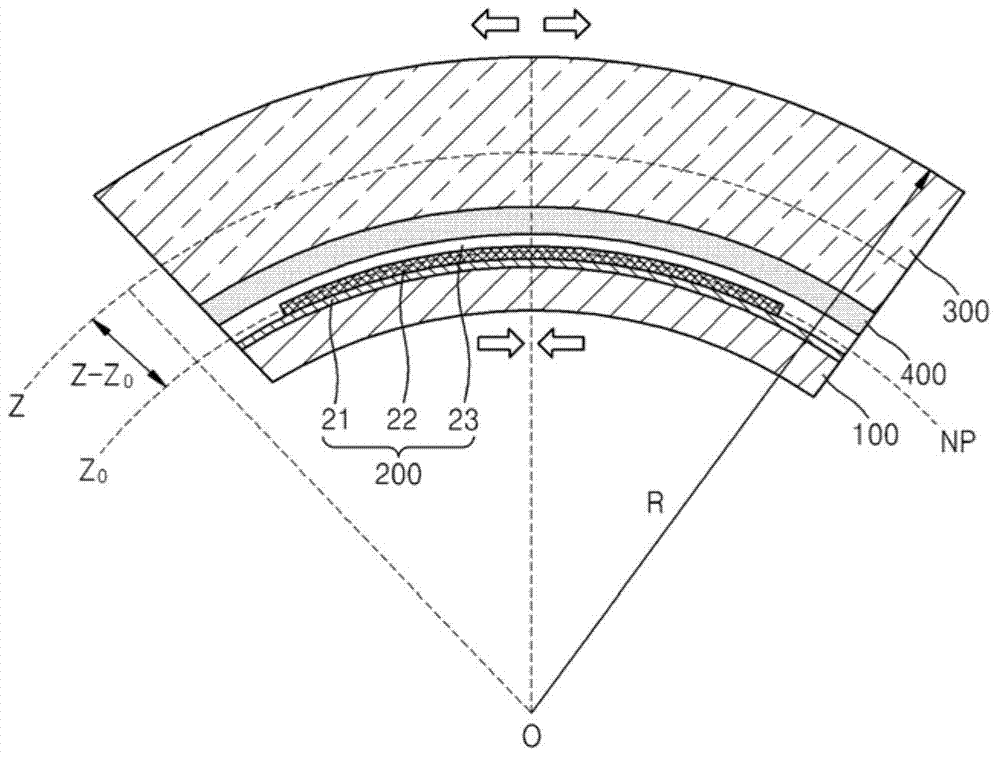

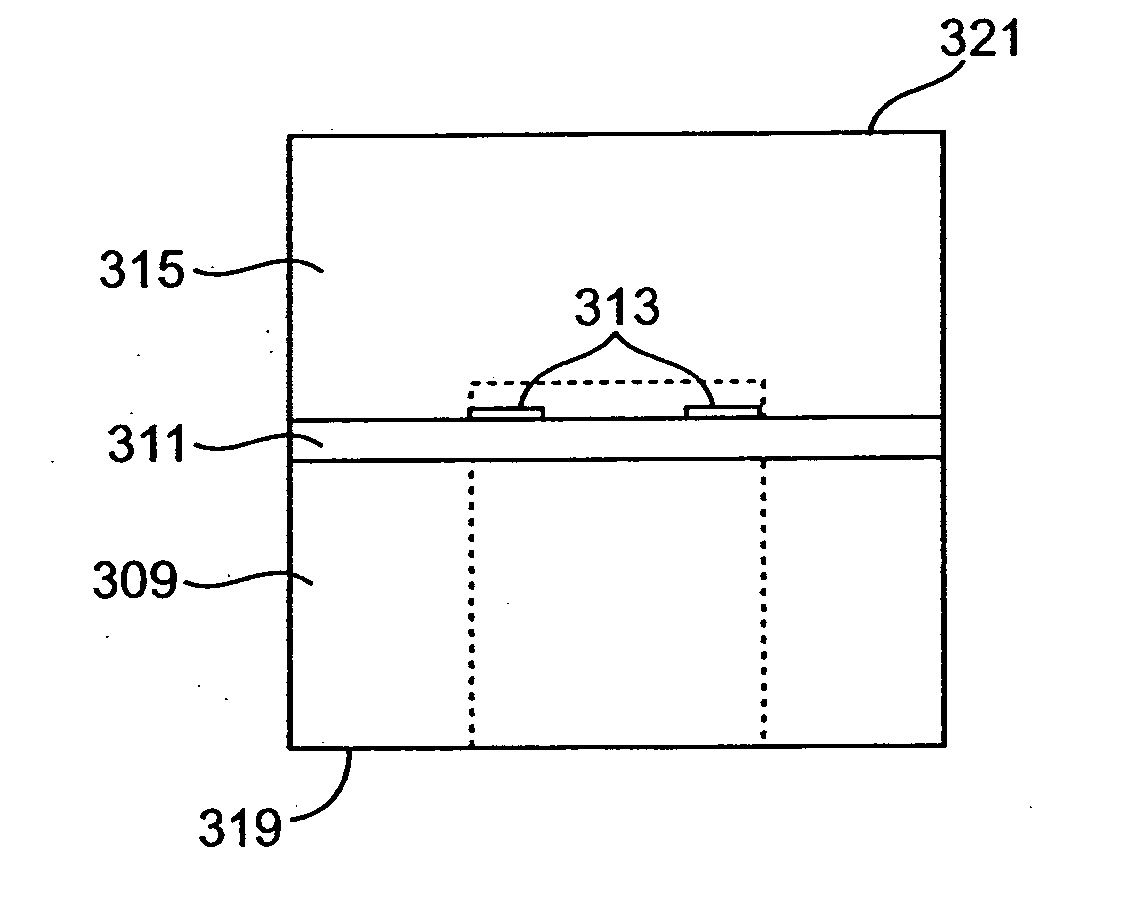

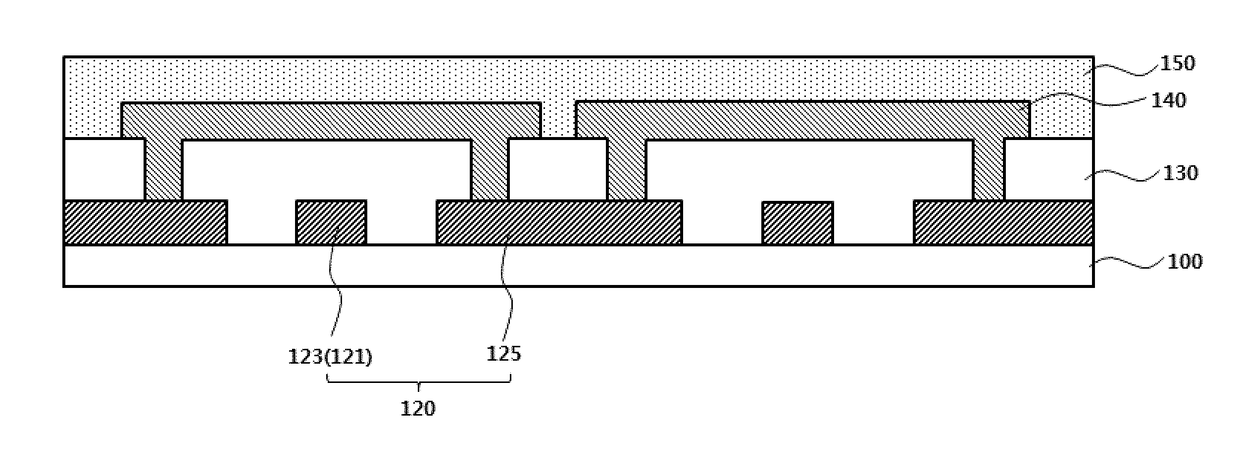

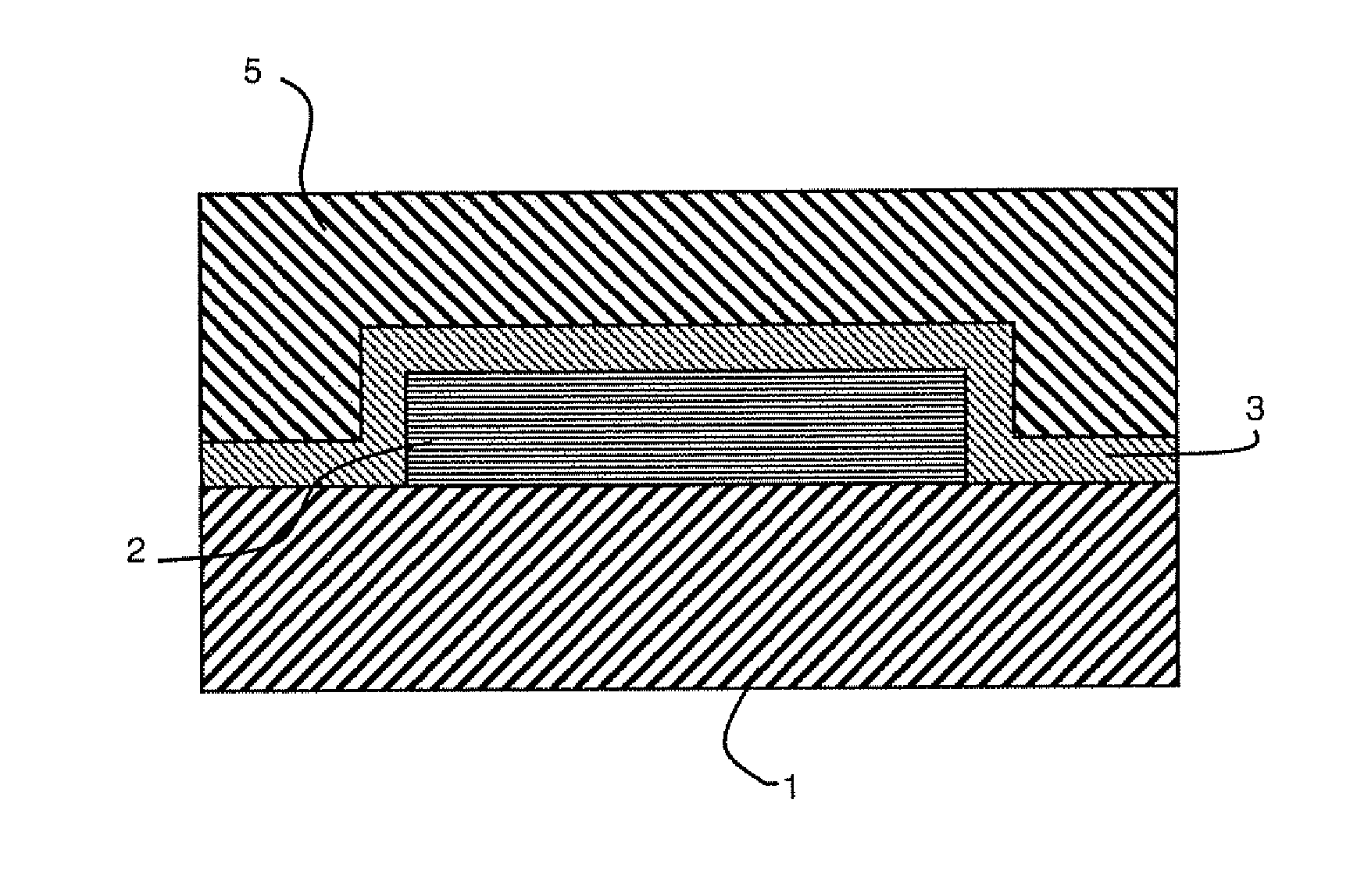

An electro-optic display comprises a substrate (100), non-linear devices (102) disposed substantially in one plane on the substrate (100), pixel electrodes (106) connected to the non-linear devices (102), an electro-optic medium (110) and a common electrode (112) on the opposed side of the electro-optic medium (110) from the pixel electrodes (106). The moduli of the various parts of the display are arranged so that, when the display is curved, the neutral axis or neutral plane lies substantially in the plane of the non-linear devices (102).

Owner:E INK CORPORATION

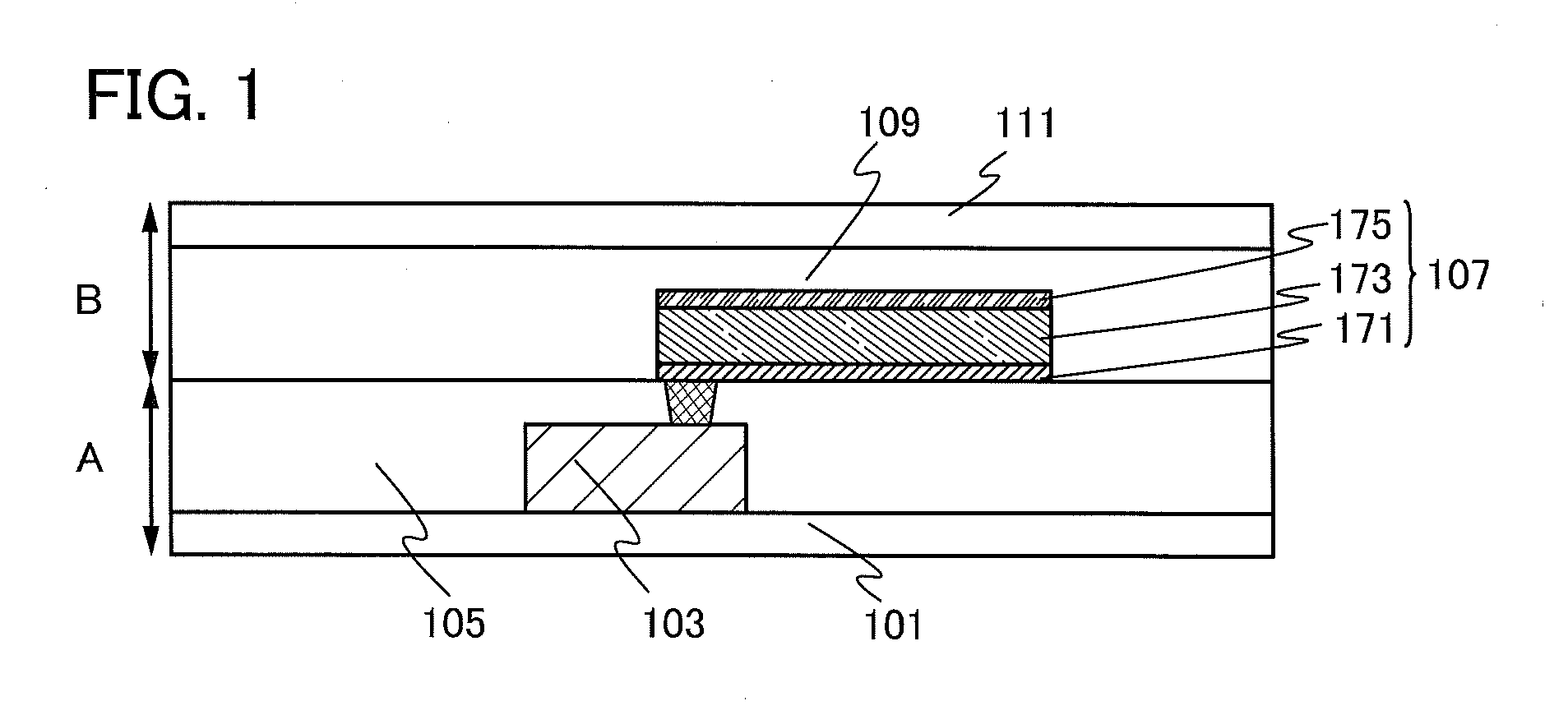

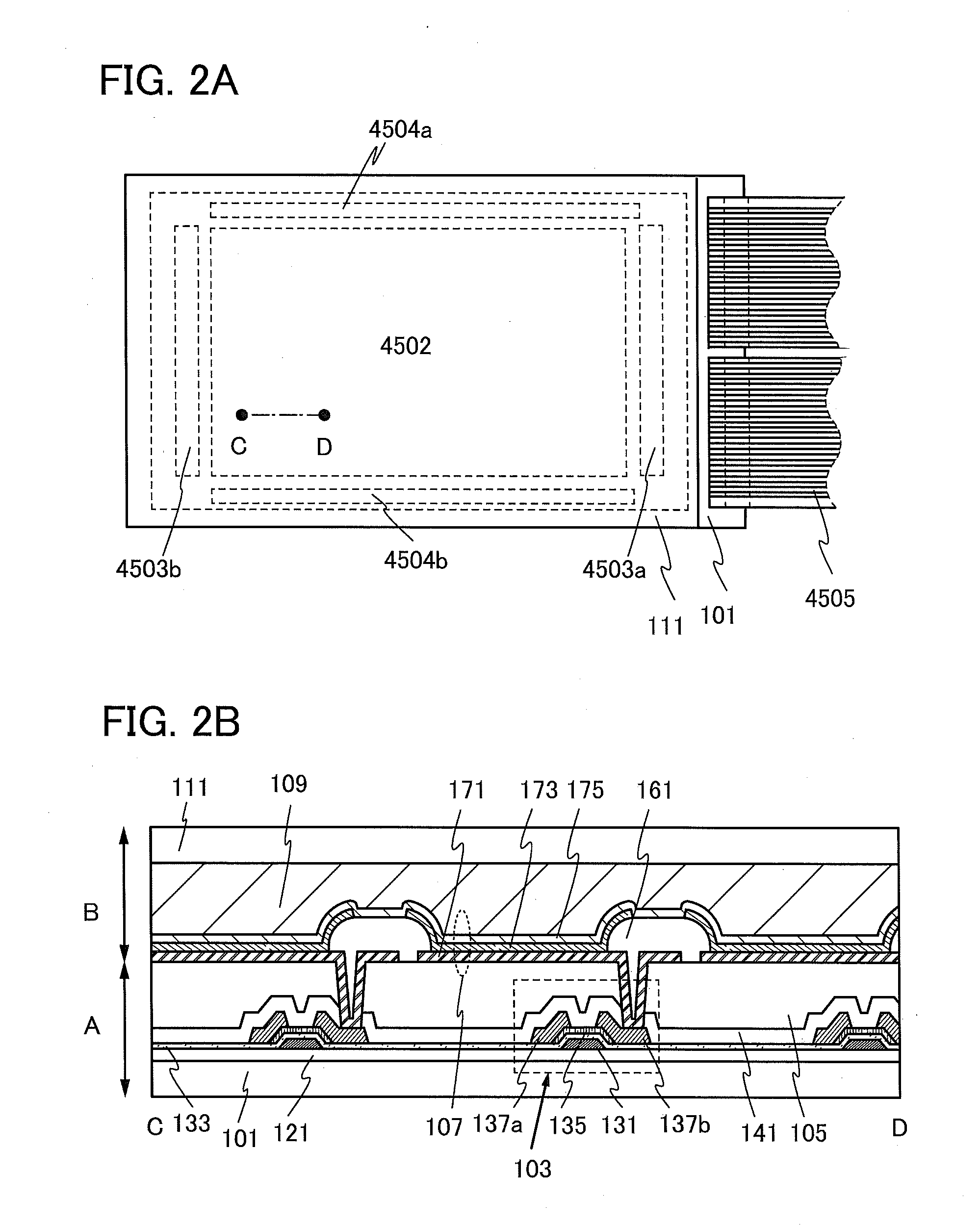

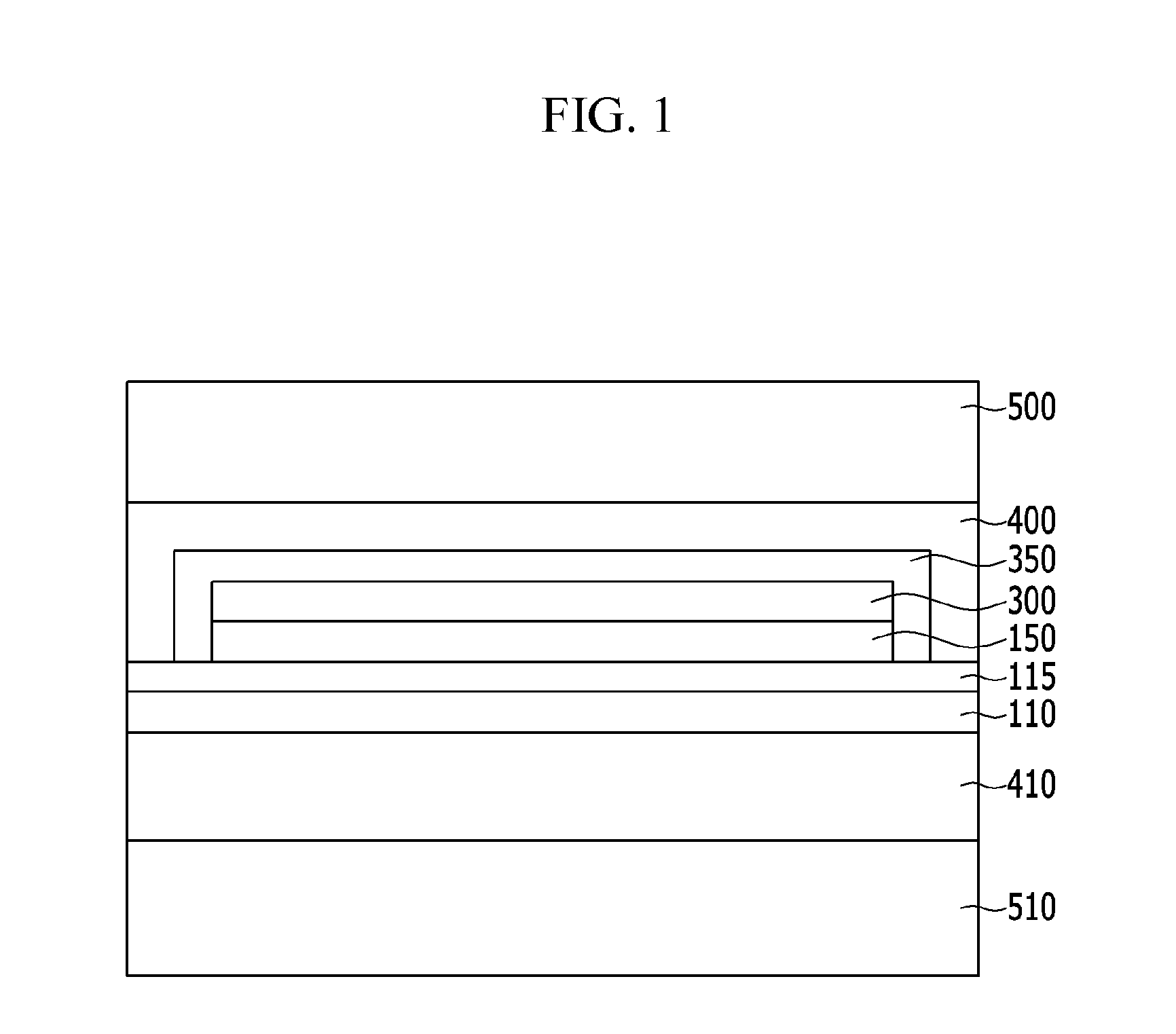

Light-Emitting Device and Electronic Device

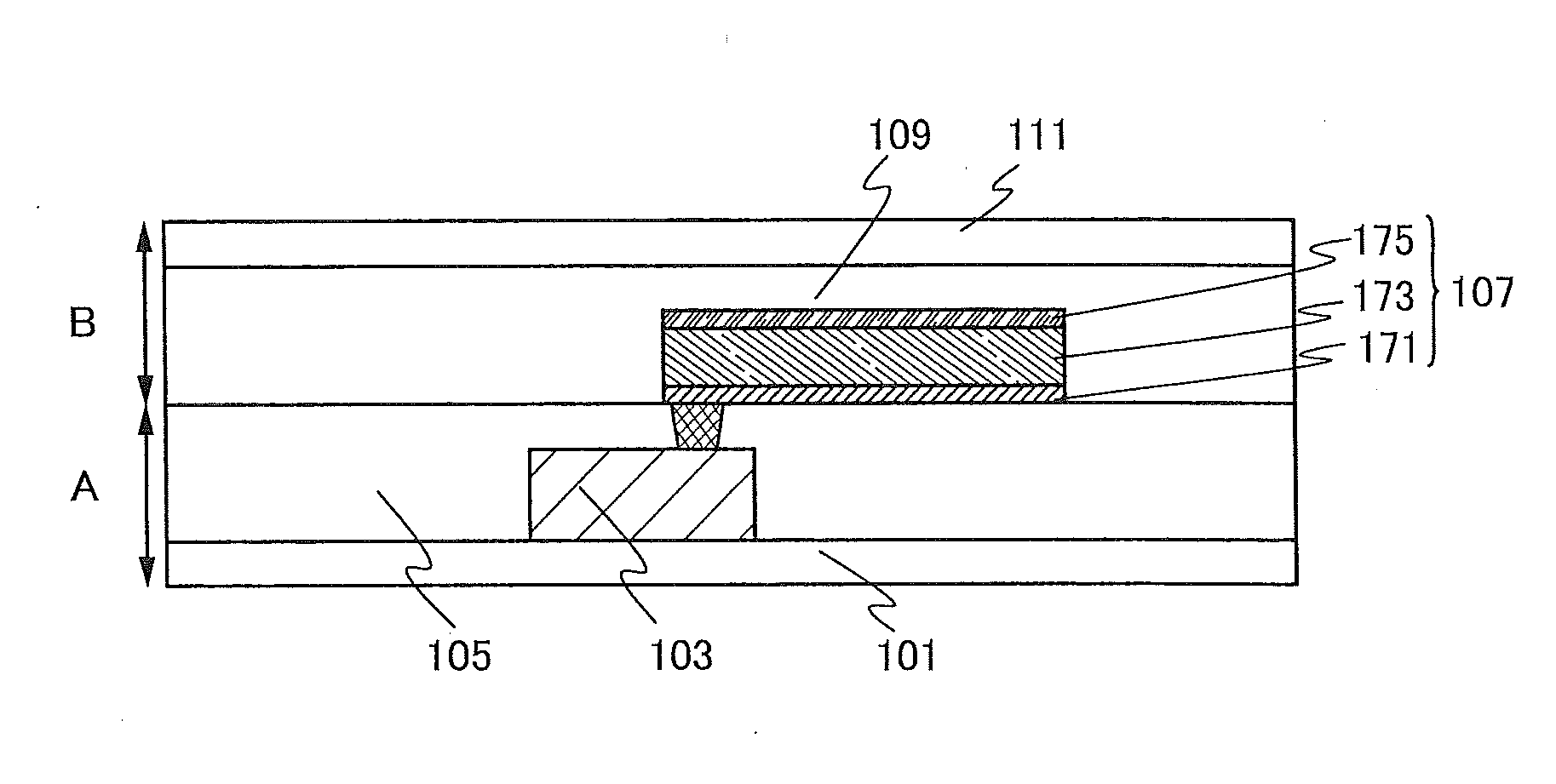

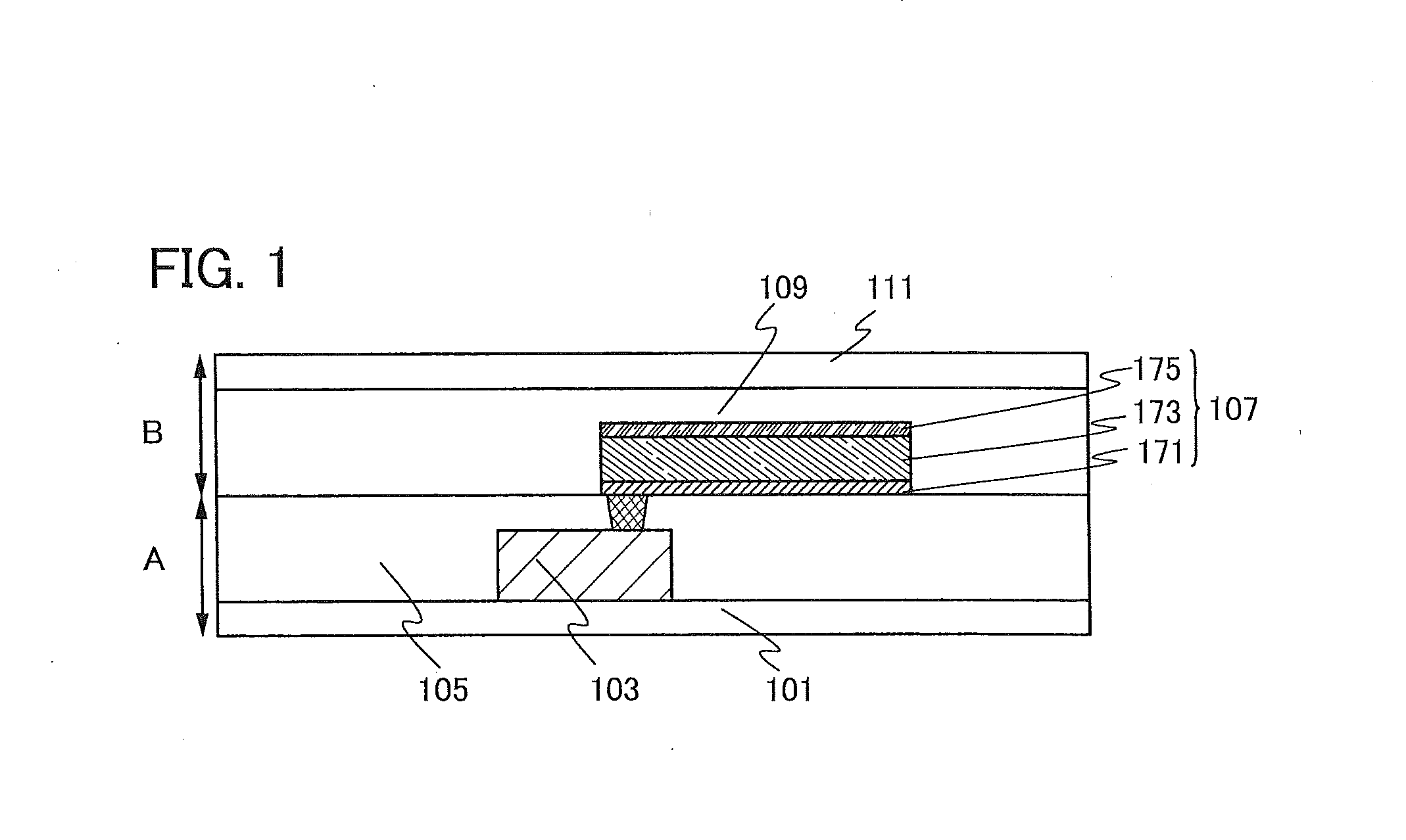

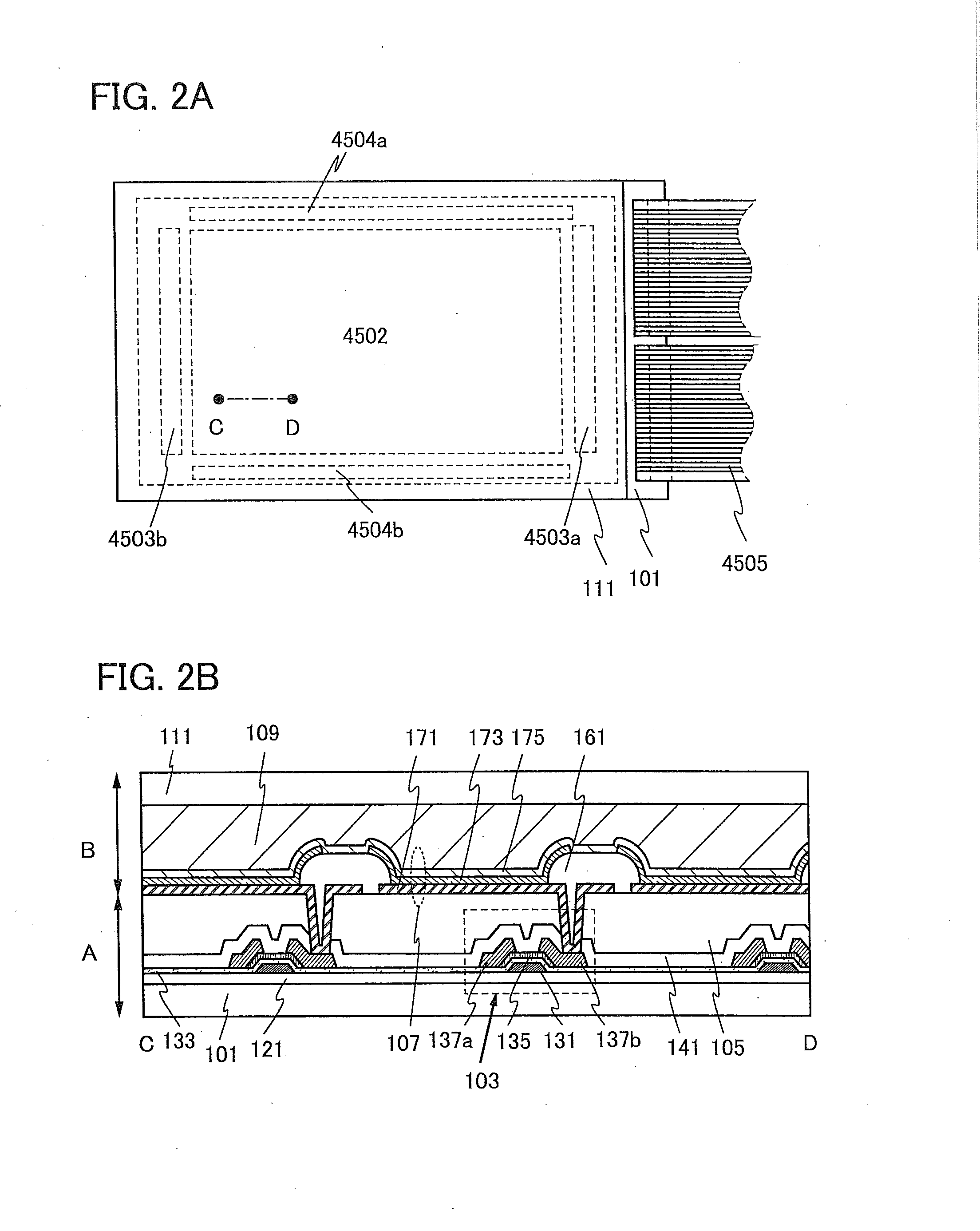

ActiveUS20130299789A1Improve reliabilitySmall valueElectroluminescent light sourcesSolid-state devicesEngineeringNeutral plane

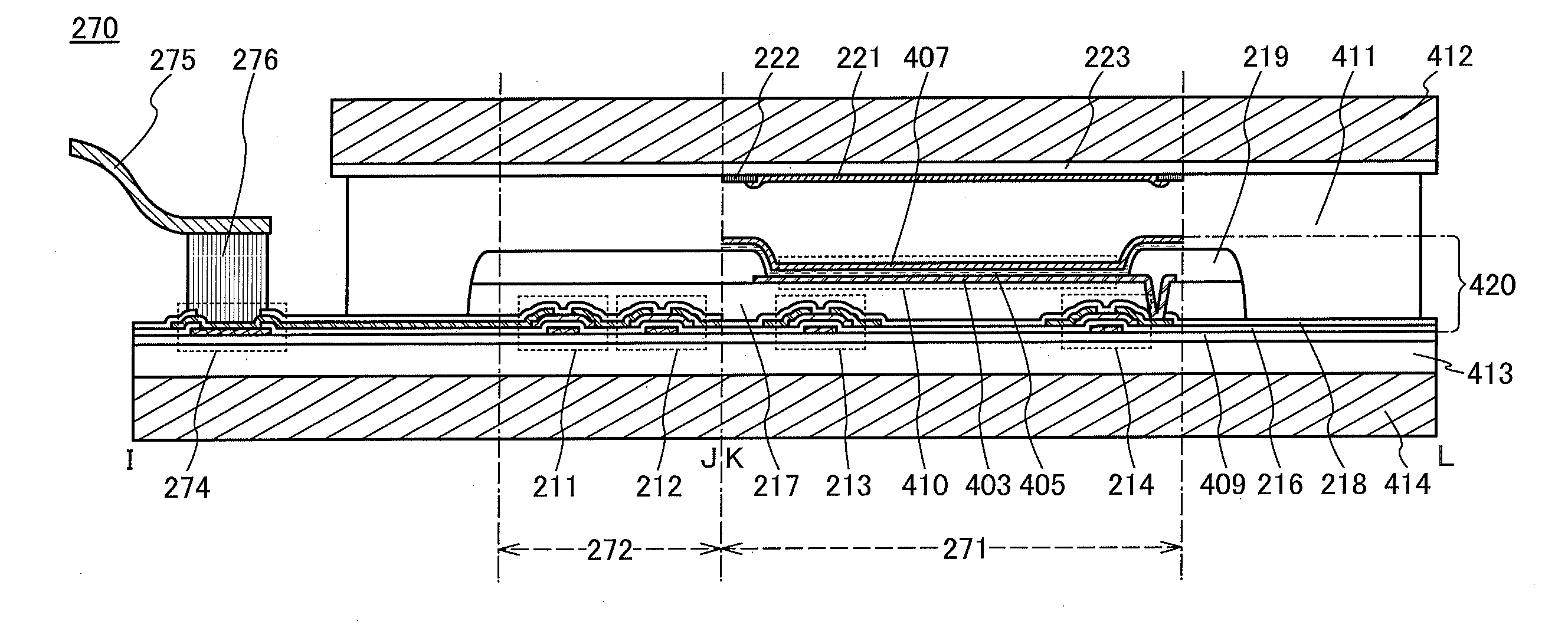

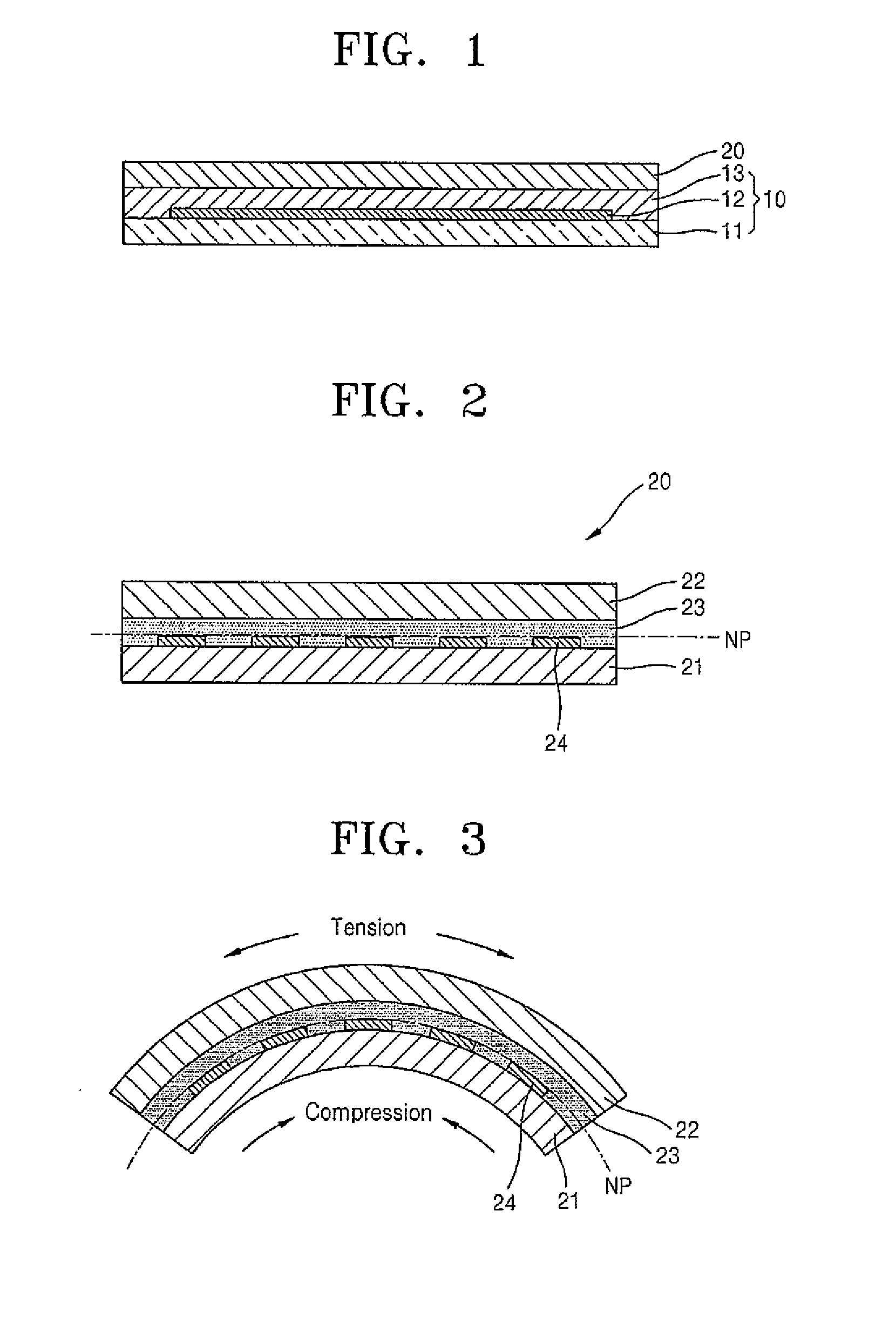

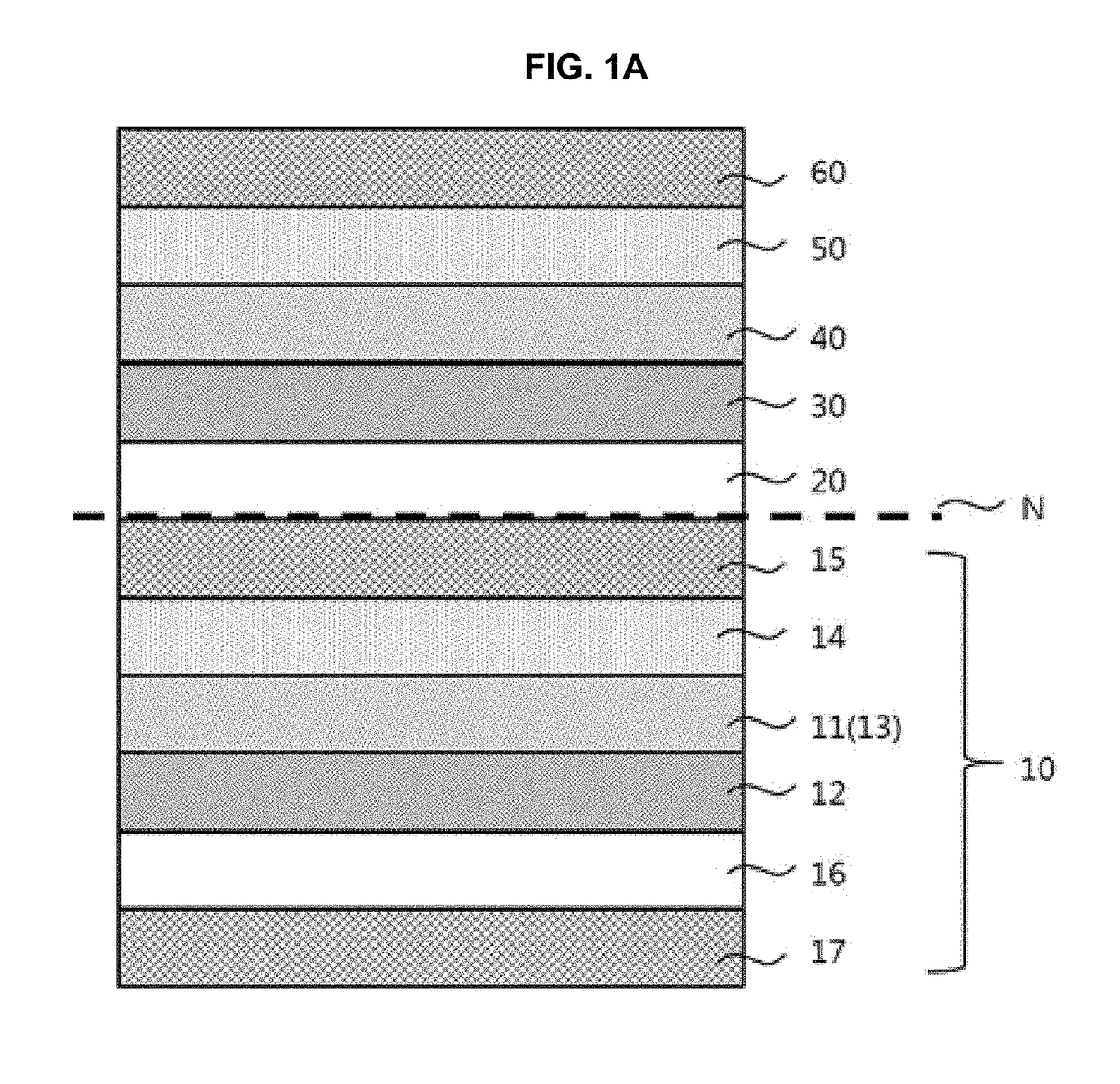

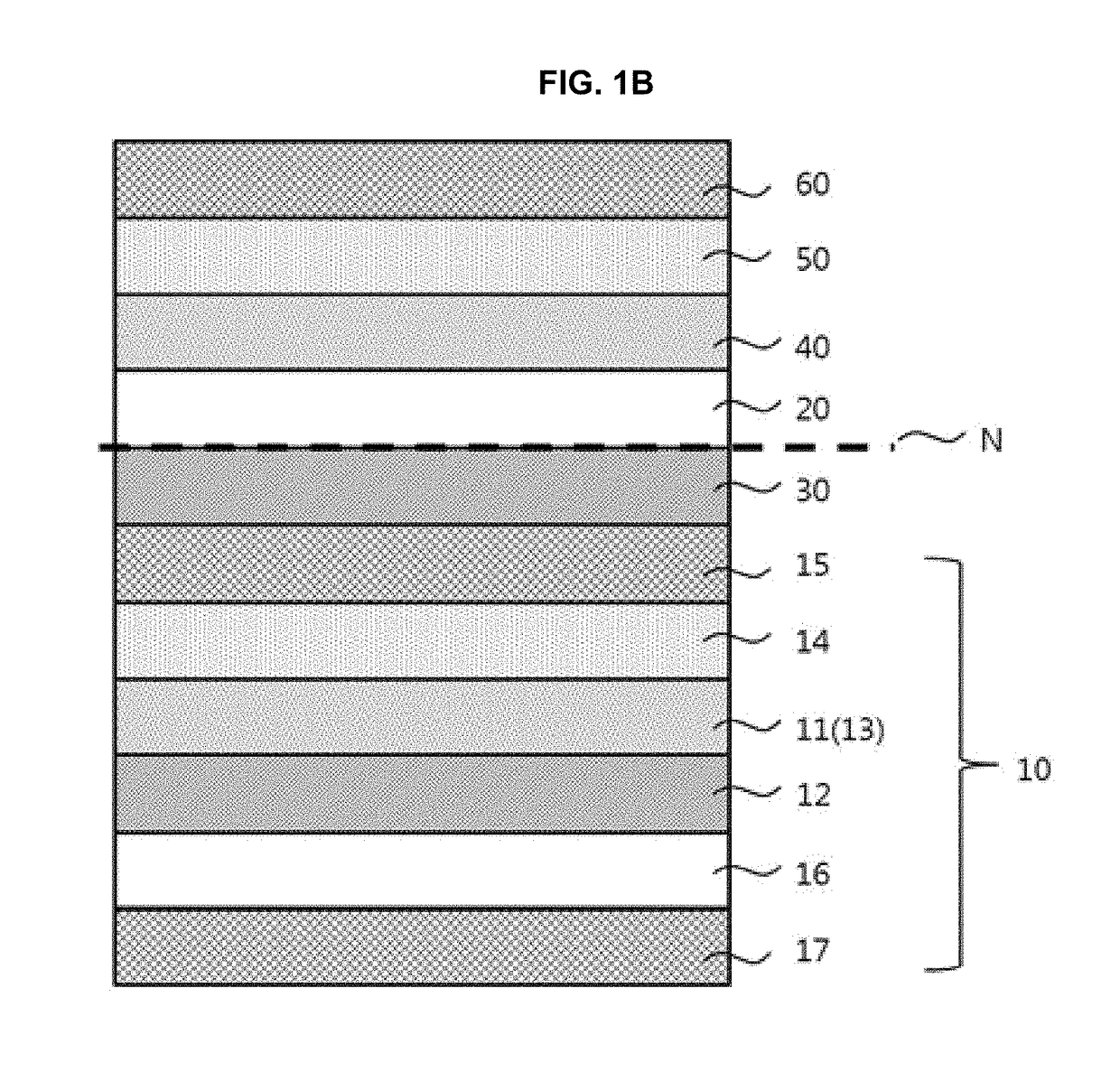

A highly reliable light-emitting device is provided. Damage to an element due to externally applied physical power is suppressed. Alternatively, in a process of pressure-bonding of an FPC, damage to a resin and a wiring which are in contact with a flexible substrate due to heat is suppressed. A neutral plane at which stress-strain is not generated when a flexible light-emitting device including an organic EL element is deformed, is positioned in the vicinity of a transistor and the organic EL element. Alternatively, the hardness of the outermost surface of a light-emitting device is high. Alternatively, a substrate having a coefficient of thermal expansion of 10 ppm / K or lower is used as a substrate that overlaps with a terminal portion connected to an FPC.

Owner:SEMICON ENERGY LAB CO LTD

Electro-optic displays, and components for use therein

InactiveUS20050078099A1Solid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceNeutral plane

An electro-optic display comprises a substrate (100), non-linear devices (102) disposed substantially in one plane on the substrate (100), pixel electrodes (106) connected to the non-linear devices (102), an electro-optic medium (110) and a common electrode (112) on the opposed side of the electro-optic medium (110) from the pixel electrodes (106). The moduli of the various parts of the display are arranged so that, when the display is curved, the neutral axis or neutral plane lies substantially in the plane of the non-linear devices (102).

Owner:E INK CORPORATION

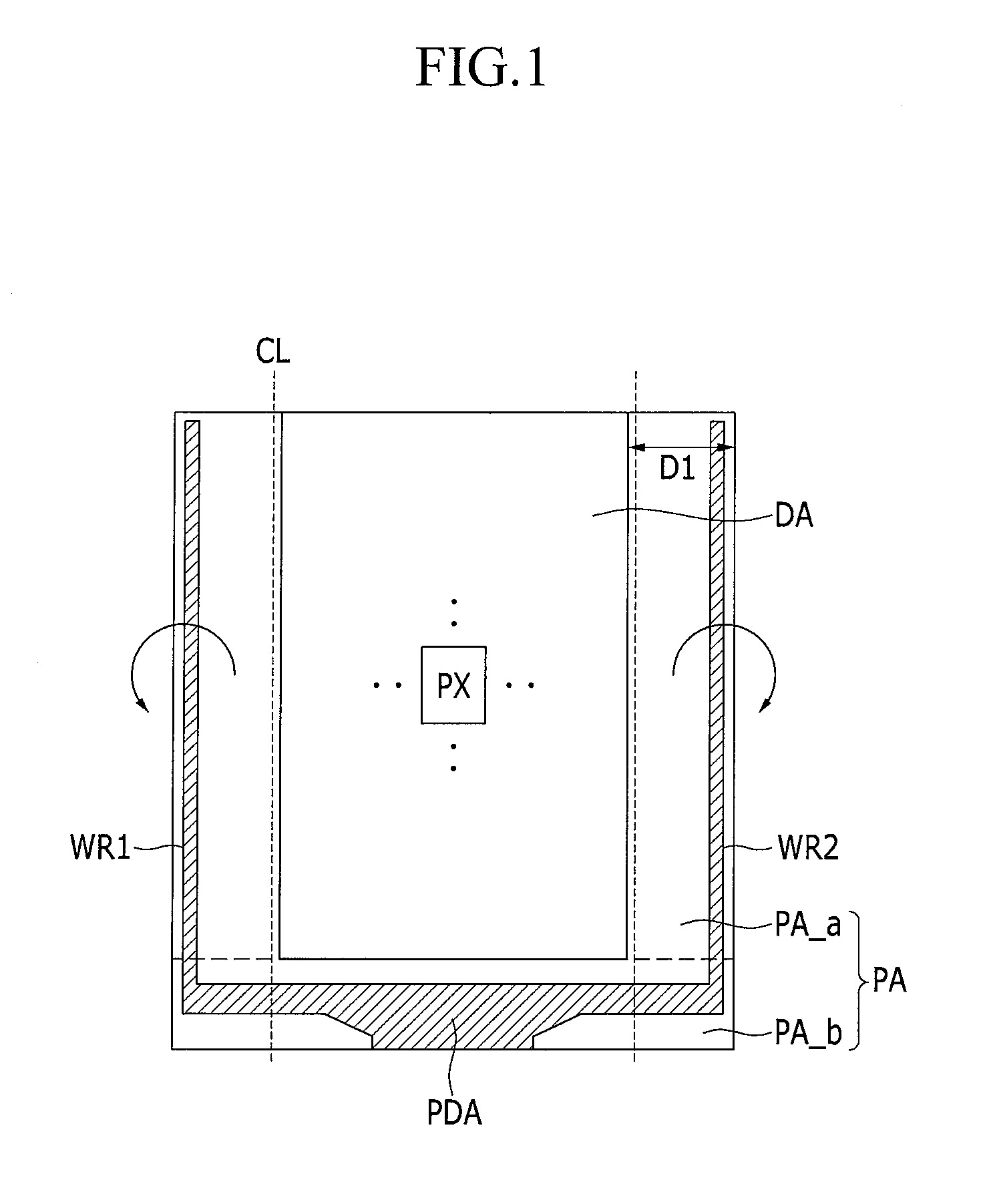

Display apparatus having improved bending properties and method of manufacturing same

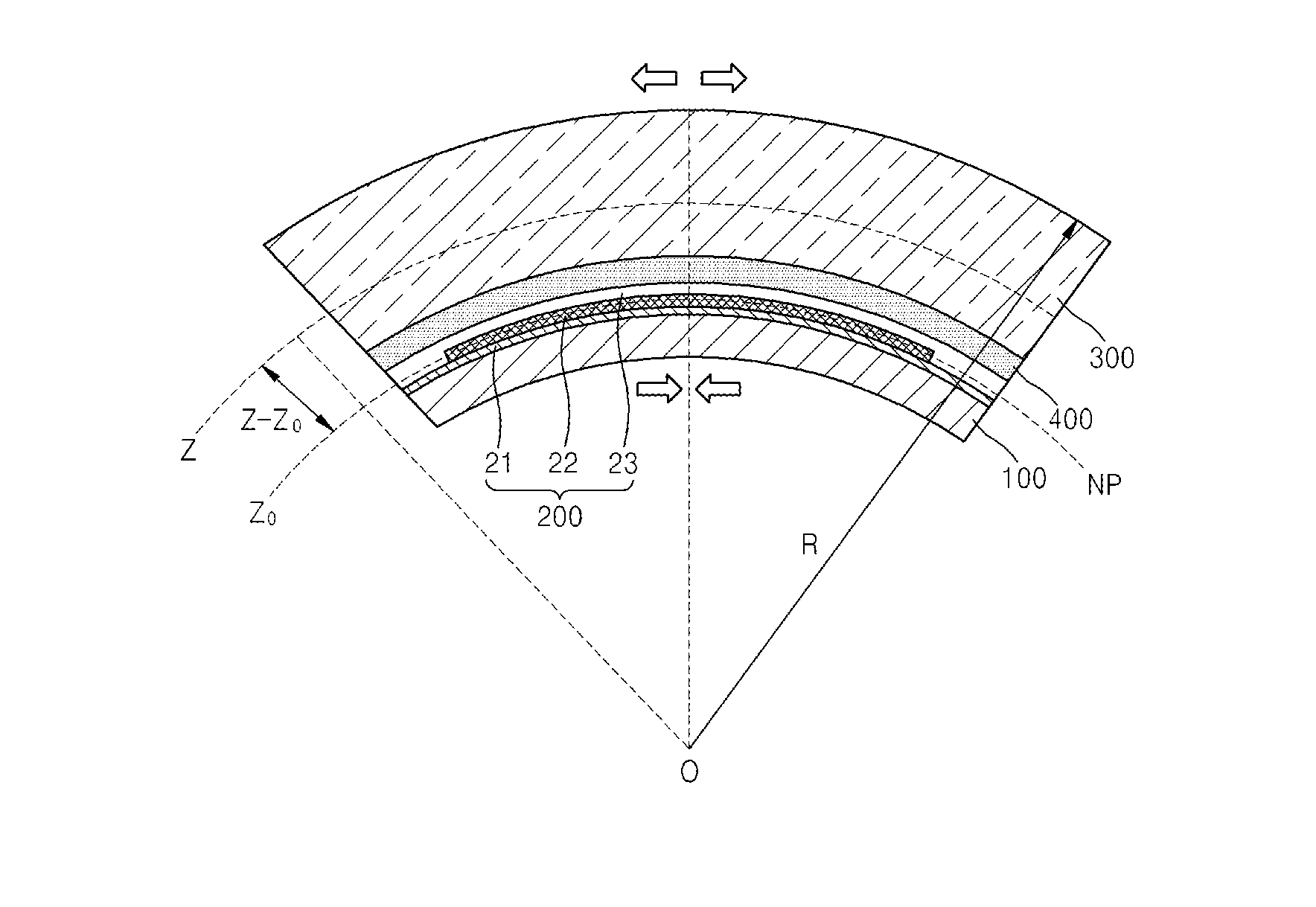

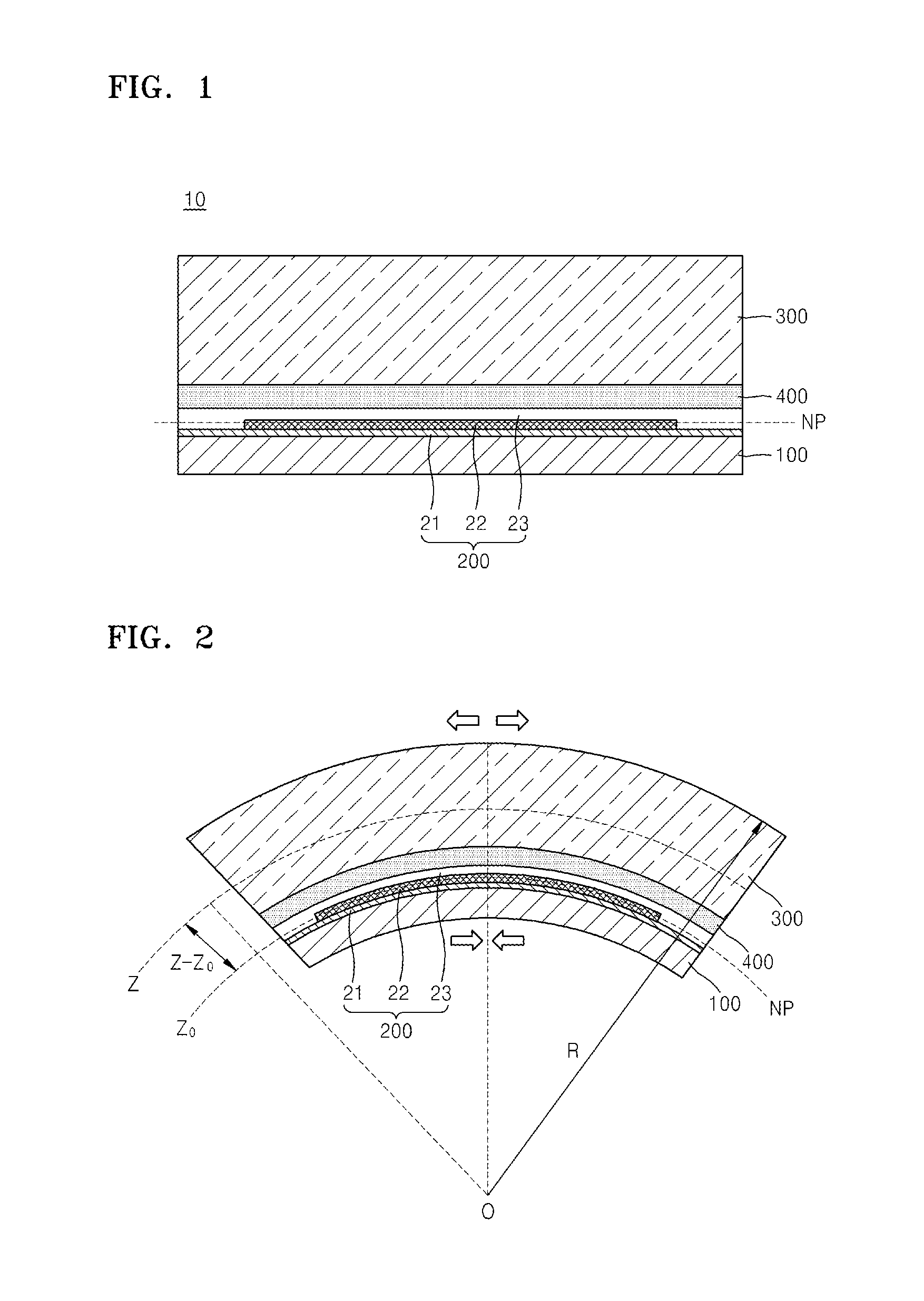

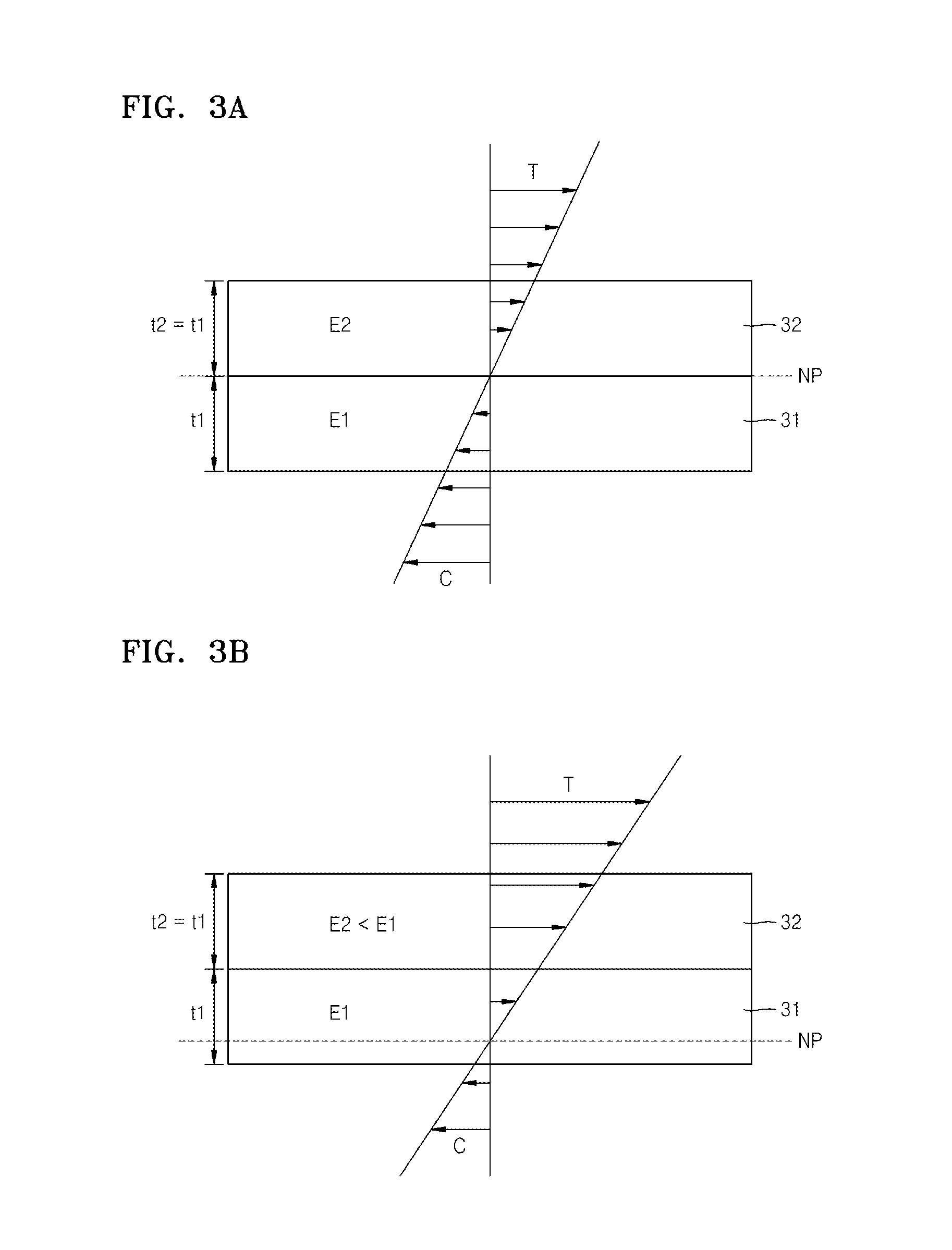

ActiveUS20140367644A1Improved durability against bendingMinimizes partOLED manufacture/treatment processesFinal product manufactureNeutral planeEngineering

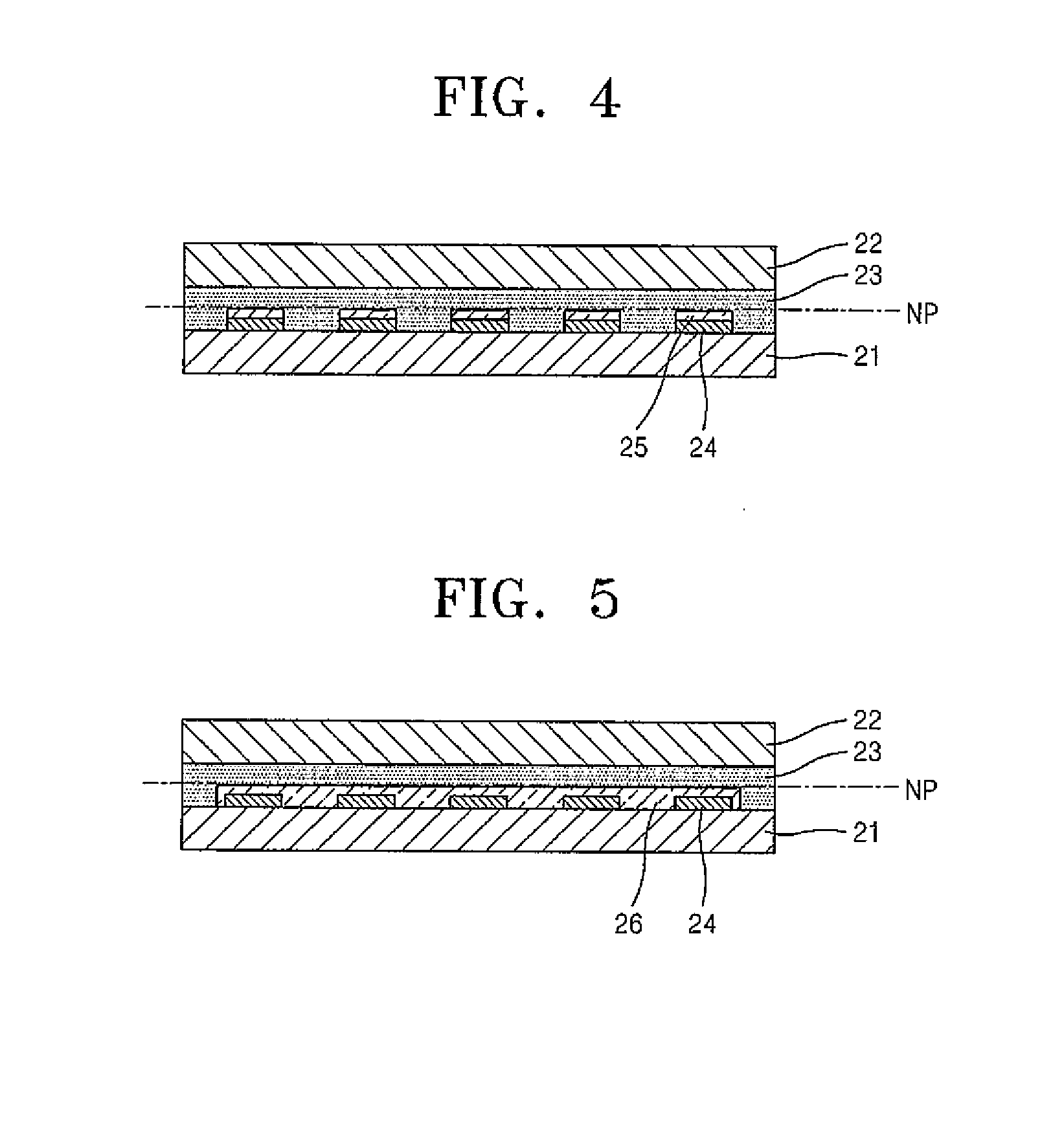

Disclosed is a display apparatus. The display apparatus includes: a display module including a flexible substrate, a display panel, and an encapsulation film; a lower module disposed below the display module; an upper module disposed on the display module; and an elasticity-adjusting layer disposed on or below the display module to adjust a position of a neutral plane in bending of the display apparatus, wherein an elastic modulus of the elasticity-adjusting layer is less than that of at least one of the display module, the lower module, or the upper module, so as to position the neutral plane within or proximate to the display module.

Owner:SAMSUNG DISPLAY CO LTD

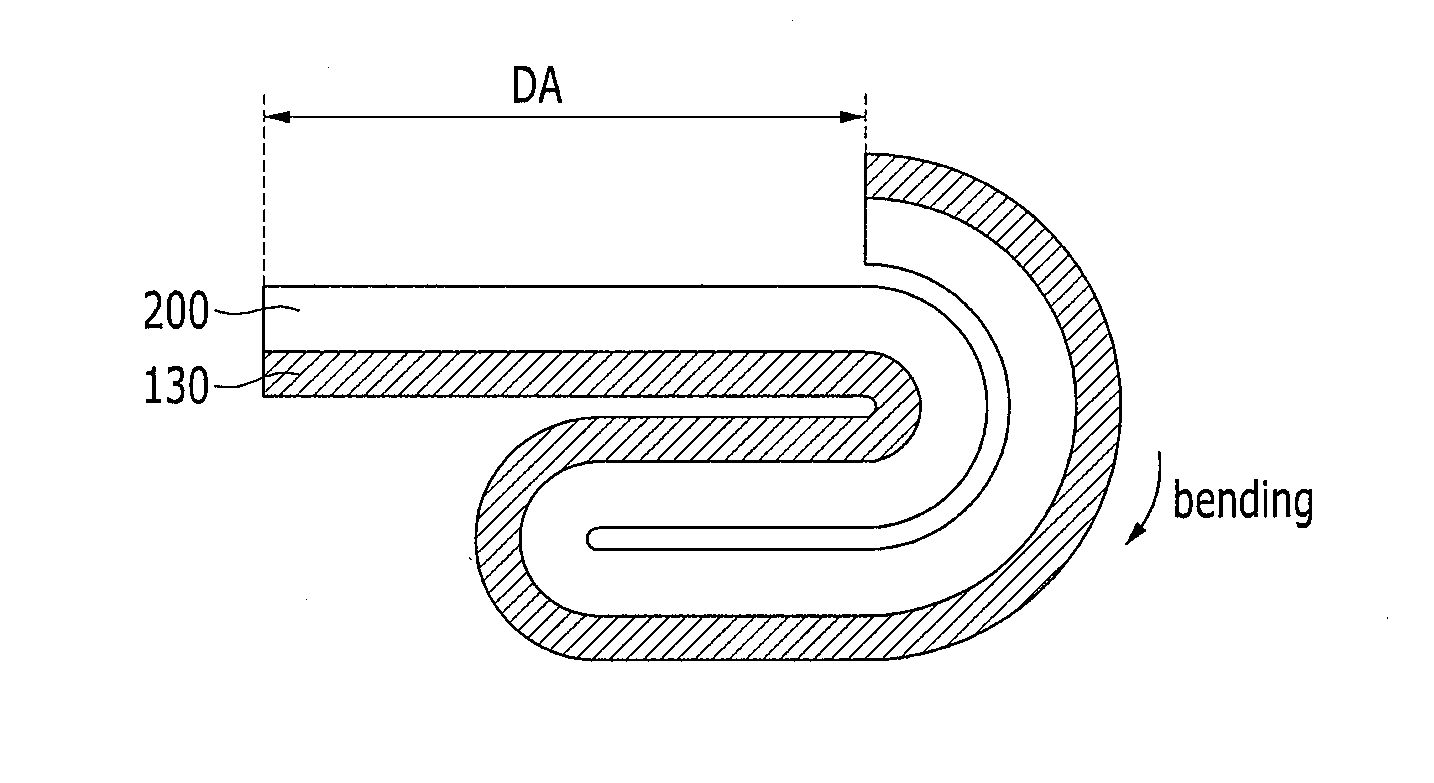

Flexible display panel and manufacturing method thereof

A flexible display panel and a manufacturing method which is capable of removing a non-display area without damaging a display element layer, the flexible display panel includes a flexible substrate which includes a display area and a peripheral area outside of the display area, a display element layer disposed on the flexible substrate, and a neutral plane balancing layer disposed on the display element layer in the peripheral area, wherein the peripheral area of the flexible substrate in which the neutral plane balancing layer is disposed is folded towards a rear side of the display area along a first bending line, and the neutral plane balancing layer overlaps the first bending line.

Owner:SAMSUNG DISPLAY CO LTD

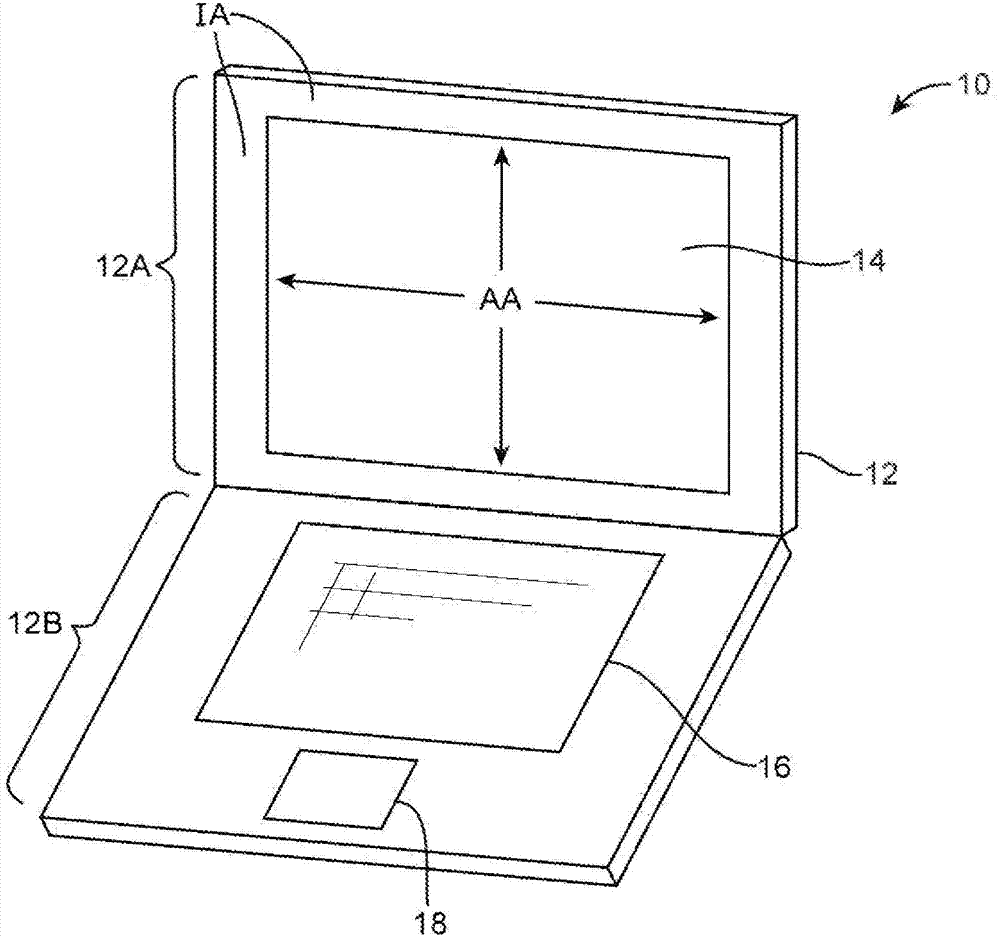

Flexible displays

An electronic device may be provided with an organic light-emitting diode display with minimized border regions. The border regions may be minimized by providing the display with bent edge portions having neutral plane adjustment features that facilitate bending of the bent edge portions while minimizing damage to the bent edge portions. The neutral plane adjustment features may include a modified backfilm layer of the display in which portions of the backfilm layer are removed in a bend region. A display device may include a substrate, a display panel on the substrate having display pixels, and peripheral circuitry proximate the display panel and configured to drive the display pixels. A portion of the periphery of the substrate may be bent substantially orthogonal to the display panel to reduce an apparent surface area of the display device. The bent portion may include an electrode for communication with the peripheral circuitry.

Owner:APPLE INC

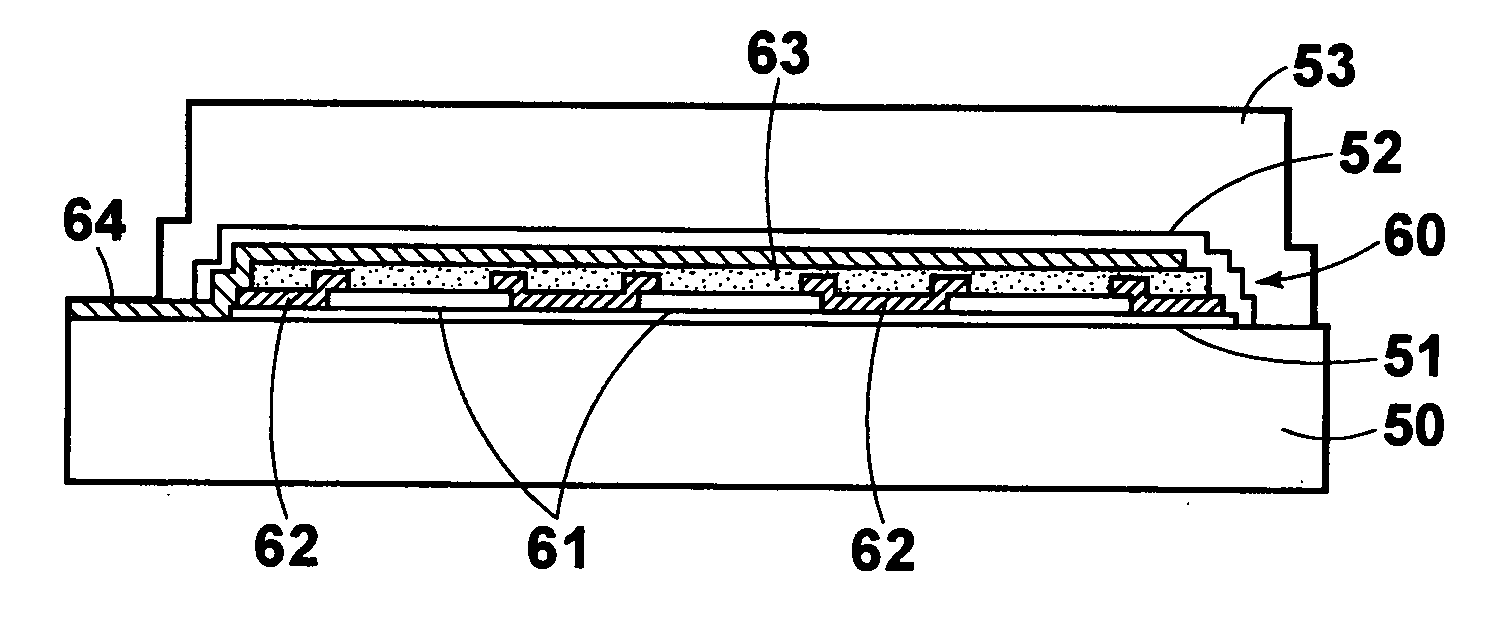

Display device

ActiveUS20060028128A1Avoid damageImprove deteriorationDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceNeutral plane

A display device includes a substrate, a display portion formed on the substrate, an upper layer which covers the display portion, and a gas barrier layer provided between at least a part of the substrate and the display portion. The gas barrier layer is positioned near to the position which forms a neutral plane when bending moment in a direction in which the substrate is warped acts on the overall display device.

Owner:FUJIFILM HLDG CORP +1

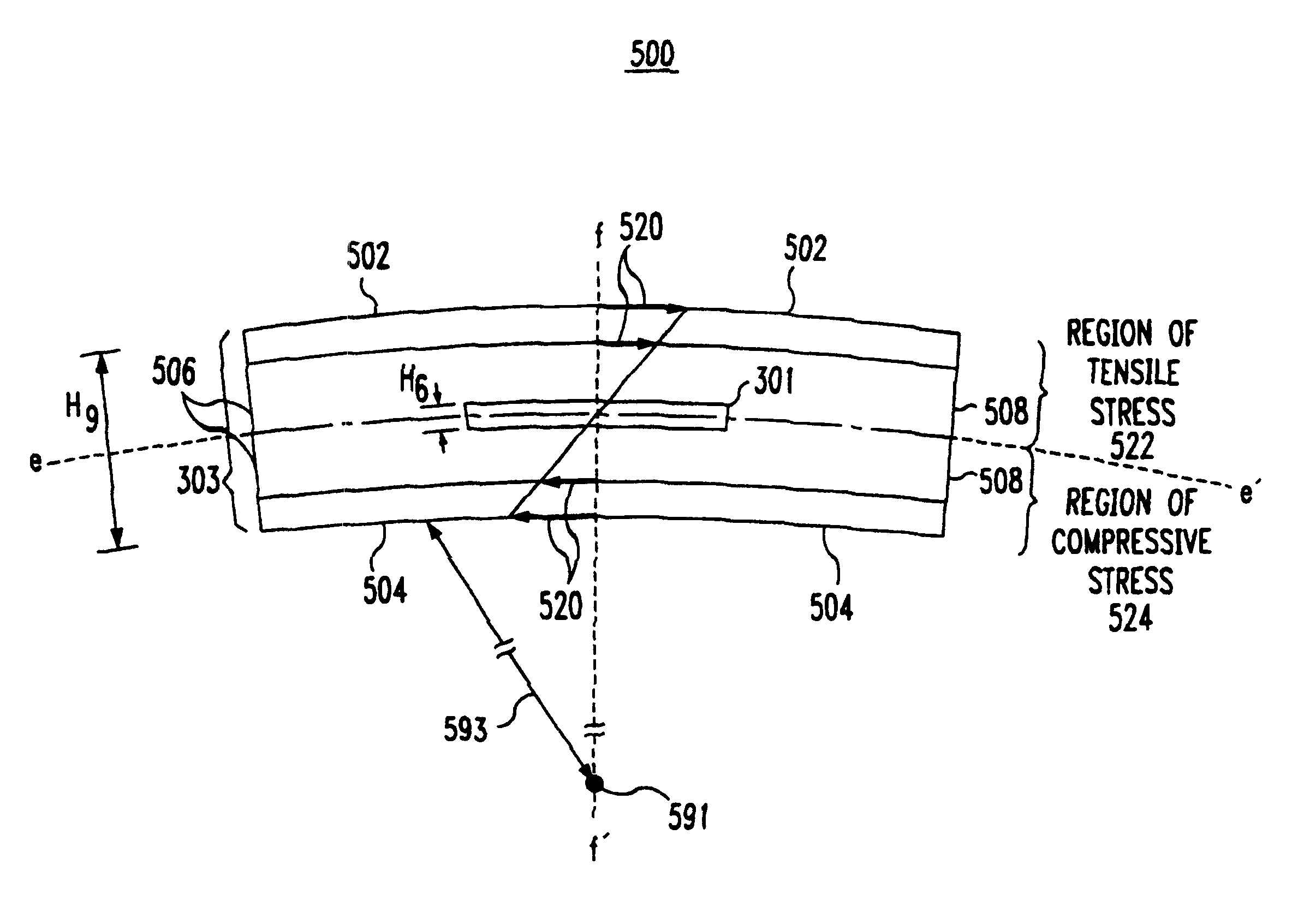

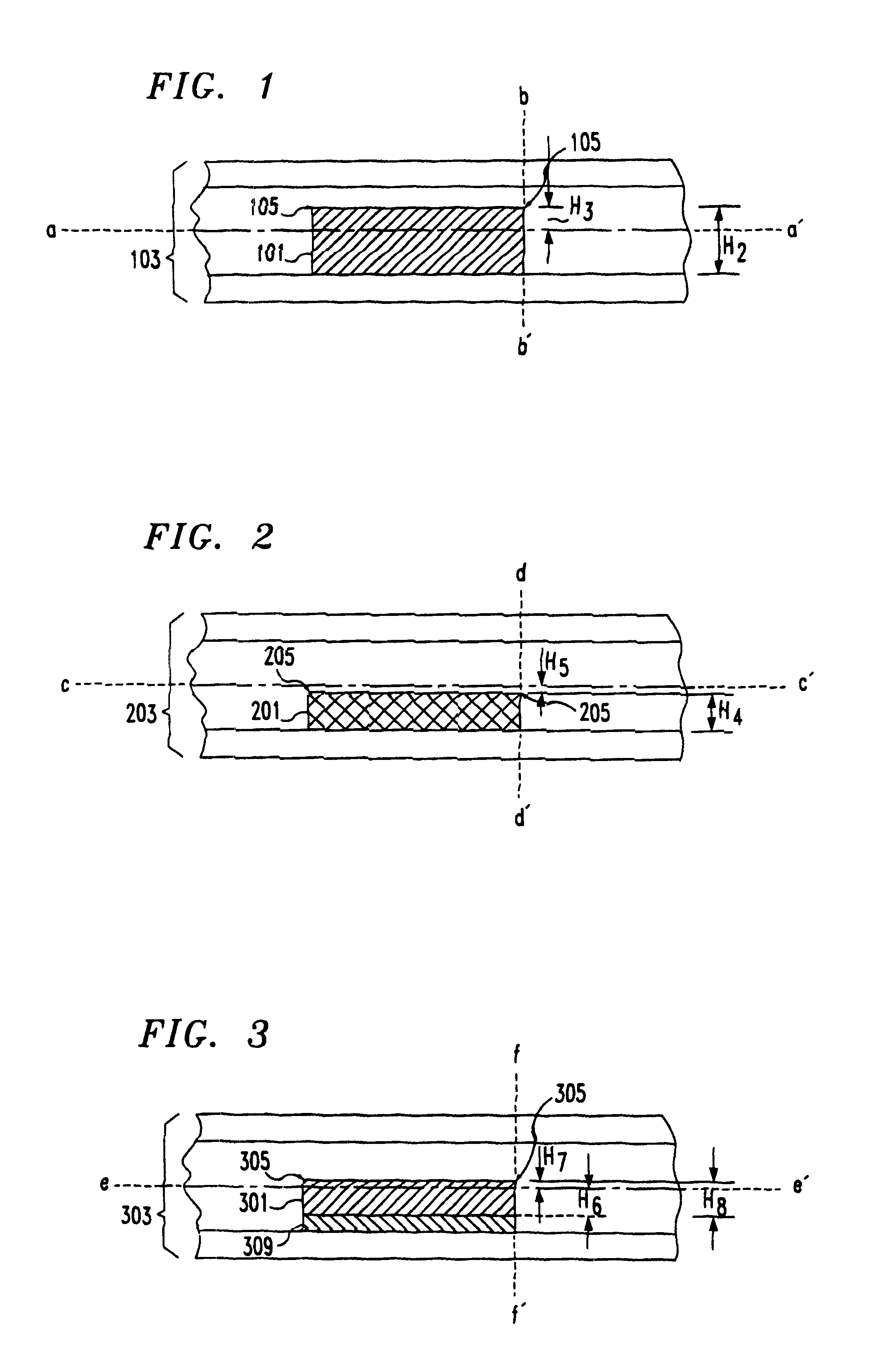

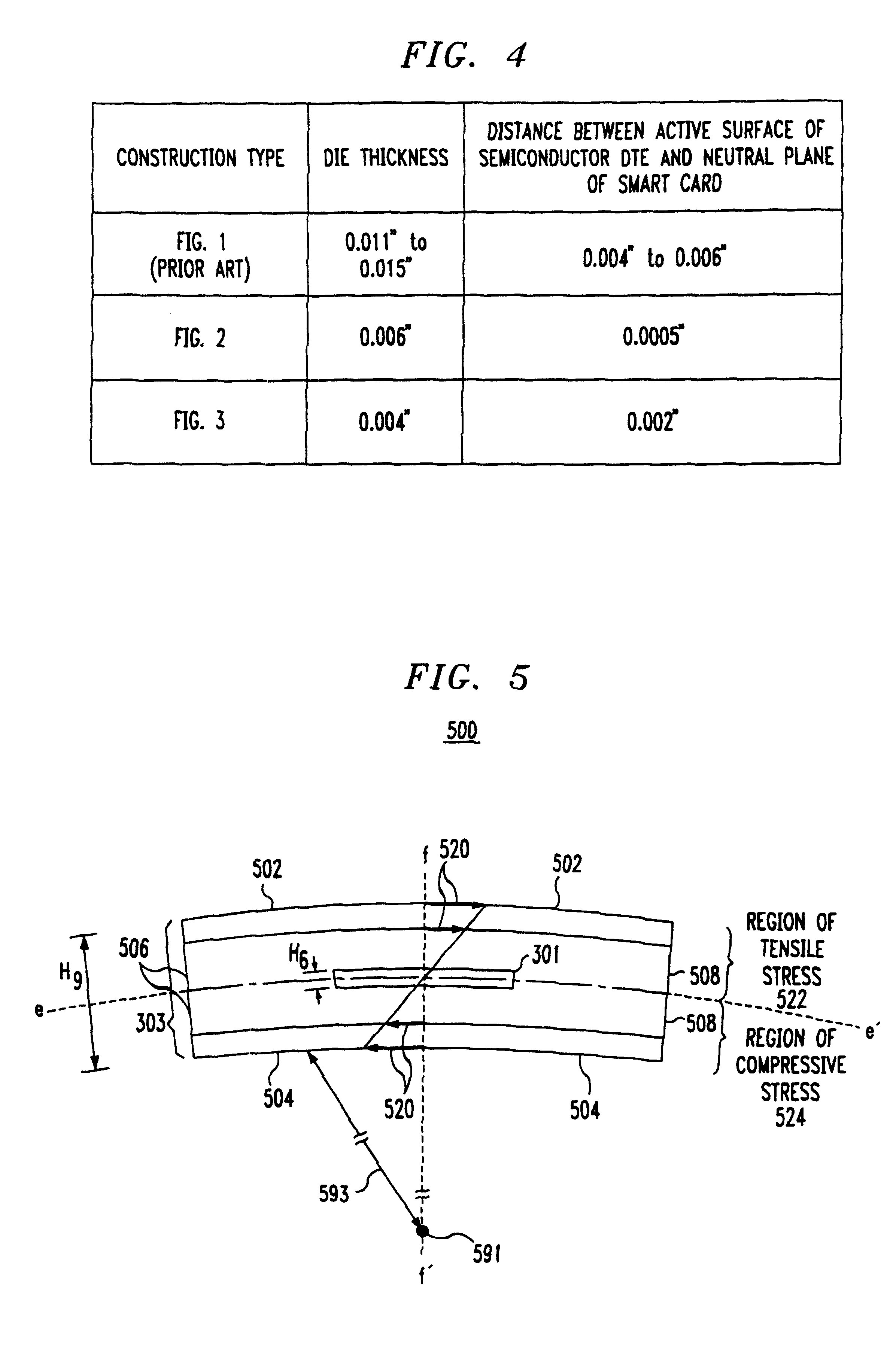

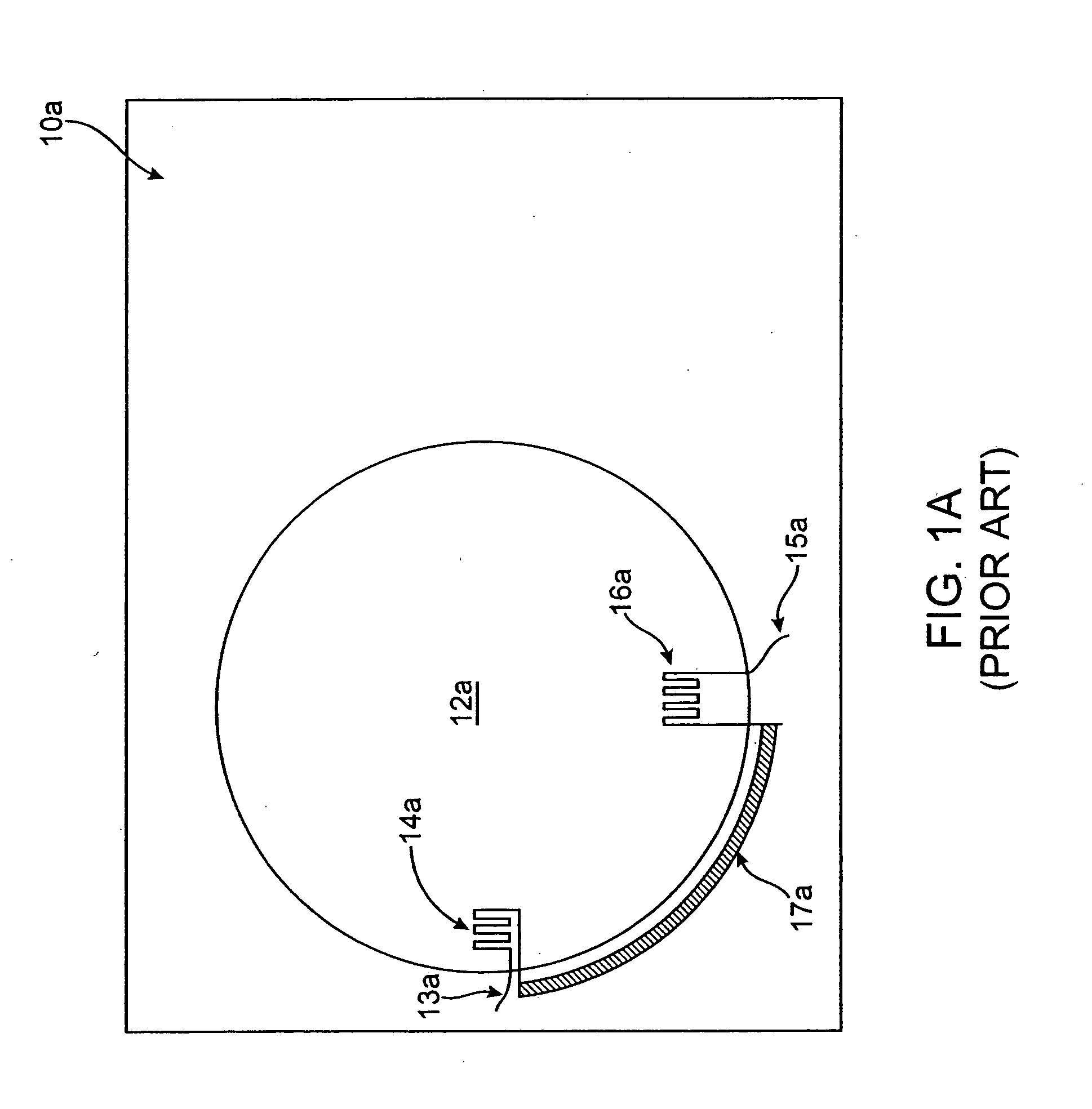

Smart cards having thin die

InactiveUSRE37637E1Improve performanceImprove the immunitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipNeutral plane

Thin semiconductor die, approximately 0.004 to 0.007 inches thick, are positioned substantially on the neutral plane of a smart card, the neutral plane defined as the plane of substantially no mechanical strain during flexure of the smart card, thereby providing smart cards having improved resistance to mechanical flexure, and / or smart cards having improved RF performance.

Owner:LUCENT TECH INC

Display apparatus having improved bending properties and method of manufacturing same

Disclosed is a display apparatus. The display apparatus includes: a display module including a flexible substrate, a display panel, and an encapsulation film; a lower module disposed below the display module; an upper module disposed on the display module; and an elasticity-adjusting layer disposed on or below the display module to adjust a position of a neutral plane in bending of the display apparatus, wherein an elastic modulus of the elasticity-adjusting layer is less than that of at least one of the display module, the lower module, or the upper module, so as to position the neutral plane within or proximate to the display module.

Owner:SAMSUNG DISPLAY CO LTD

Optical fiber sensor and method

InactiveUS20070297712A1Optical fibre with multilayer core/claddingUsing optical meansGratingNeutral plane

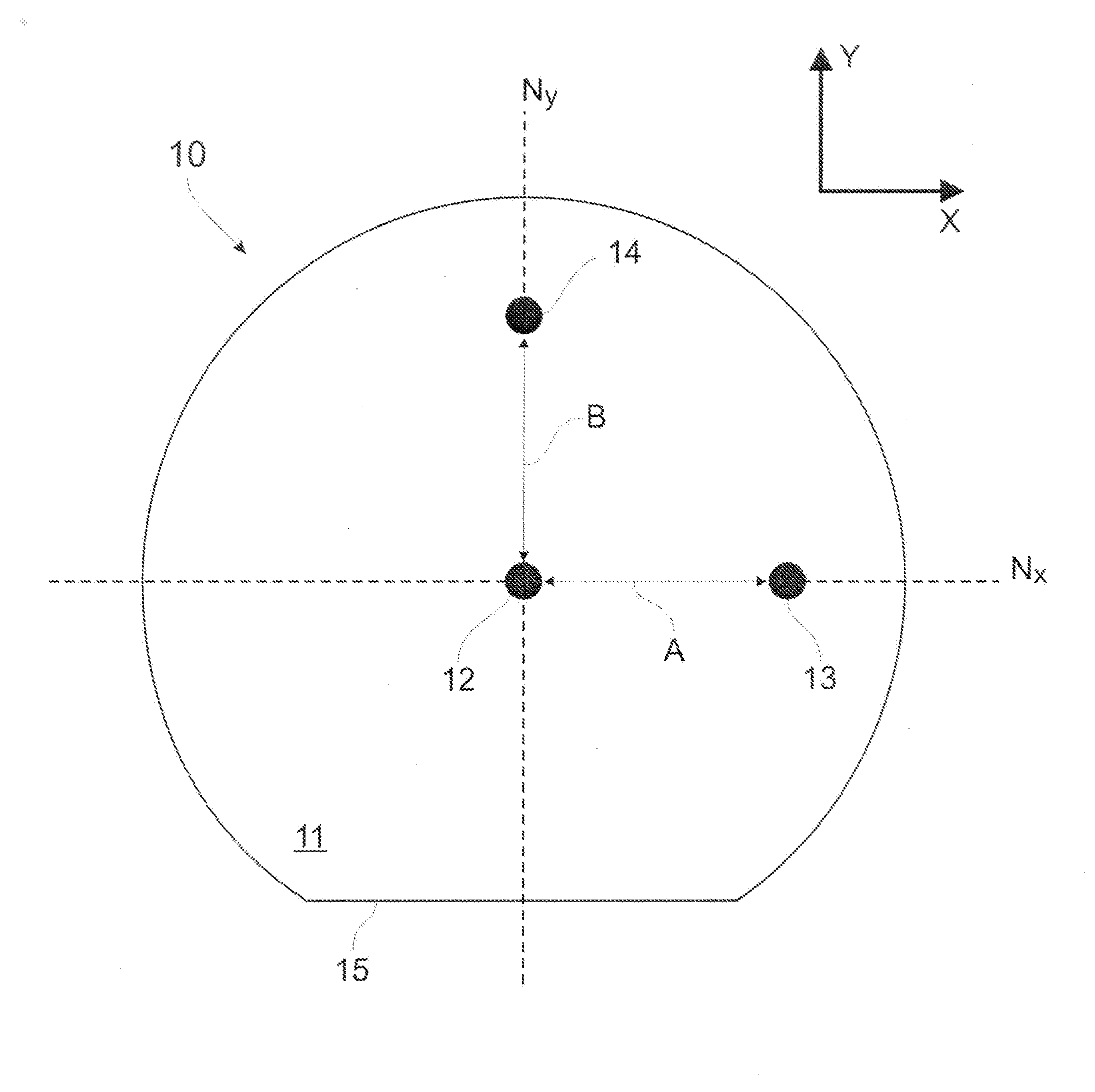

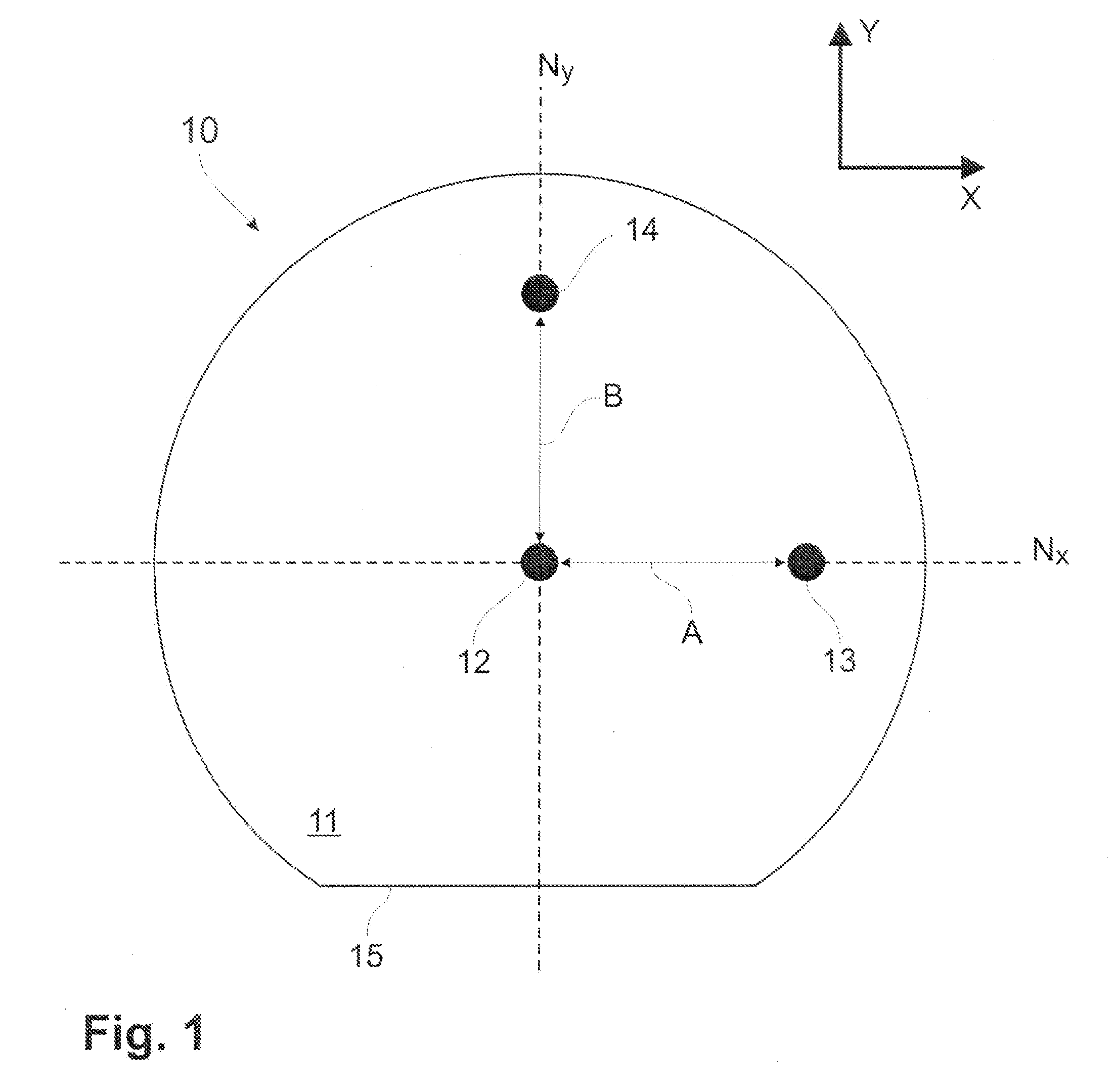

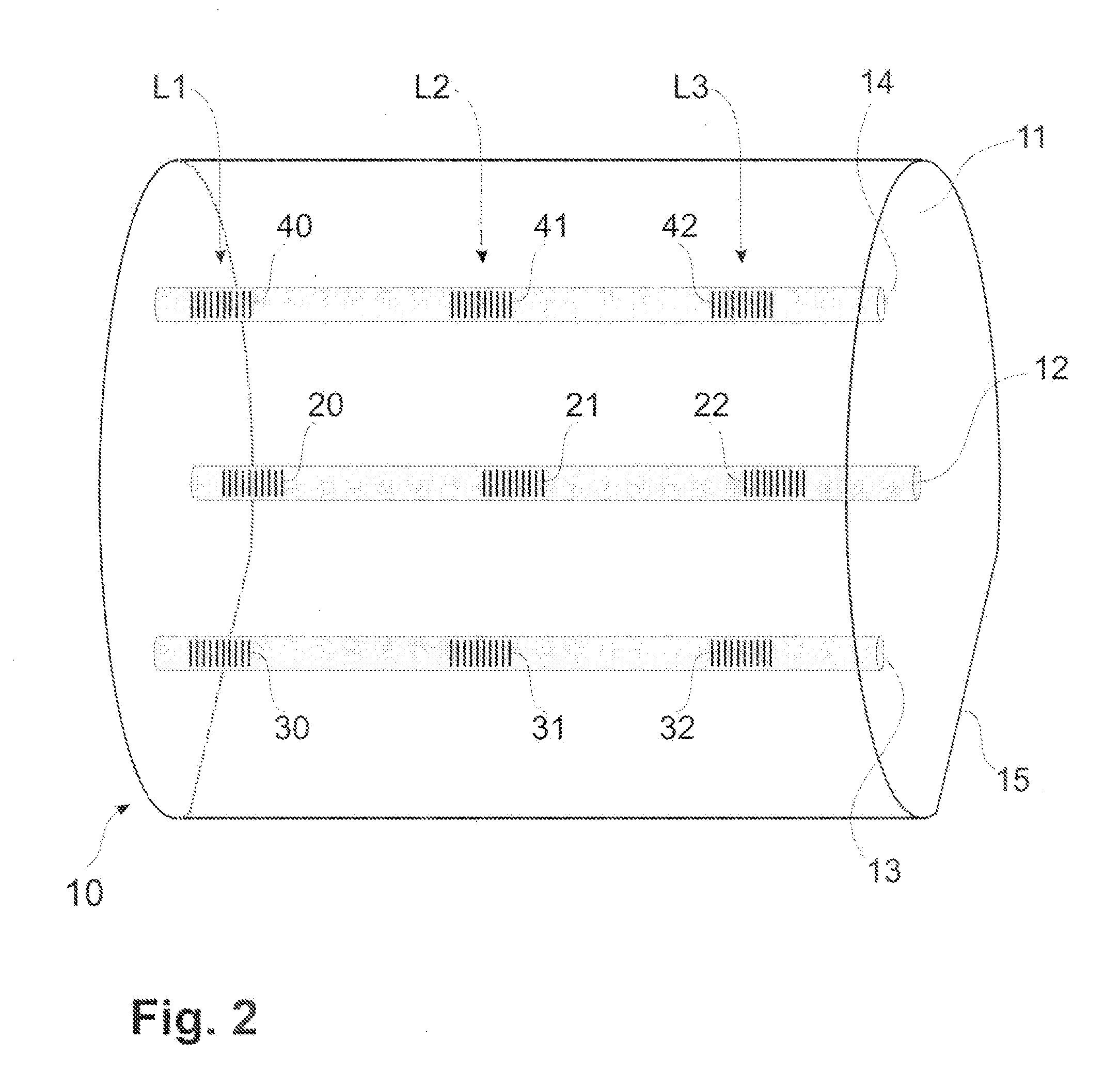

An optical fiber sensor for detecting curvature of a body / structure comprises a cladding having an outer periphery. A central core receives and transmits light. The central core has Bragg gratings and is positioned in neutral planes of the cladding. Peripheral cores receive and transmit light. The peripheral cores have Bragg gratings and are peripherally positioned in the cladding with respect to the neutral planes. A connection configuration is provided in the outer periphery of the cladding to attach the optical fiber sensor to a body / structure such that the central core and the peripheral cores are in a predetermined orientation with respect to the body / structure to measure curvature of the body / structure.

Owner:INSTITUT NATIONAL D'OPTIQUE

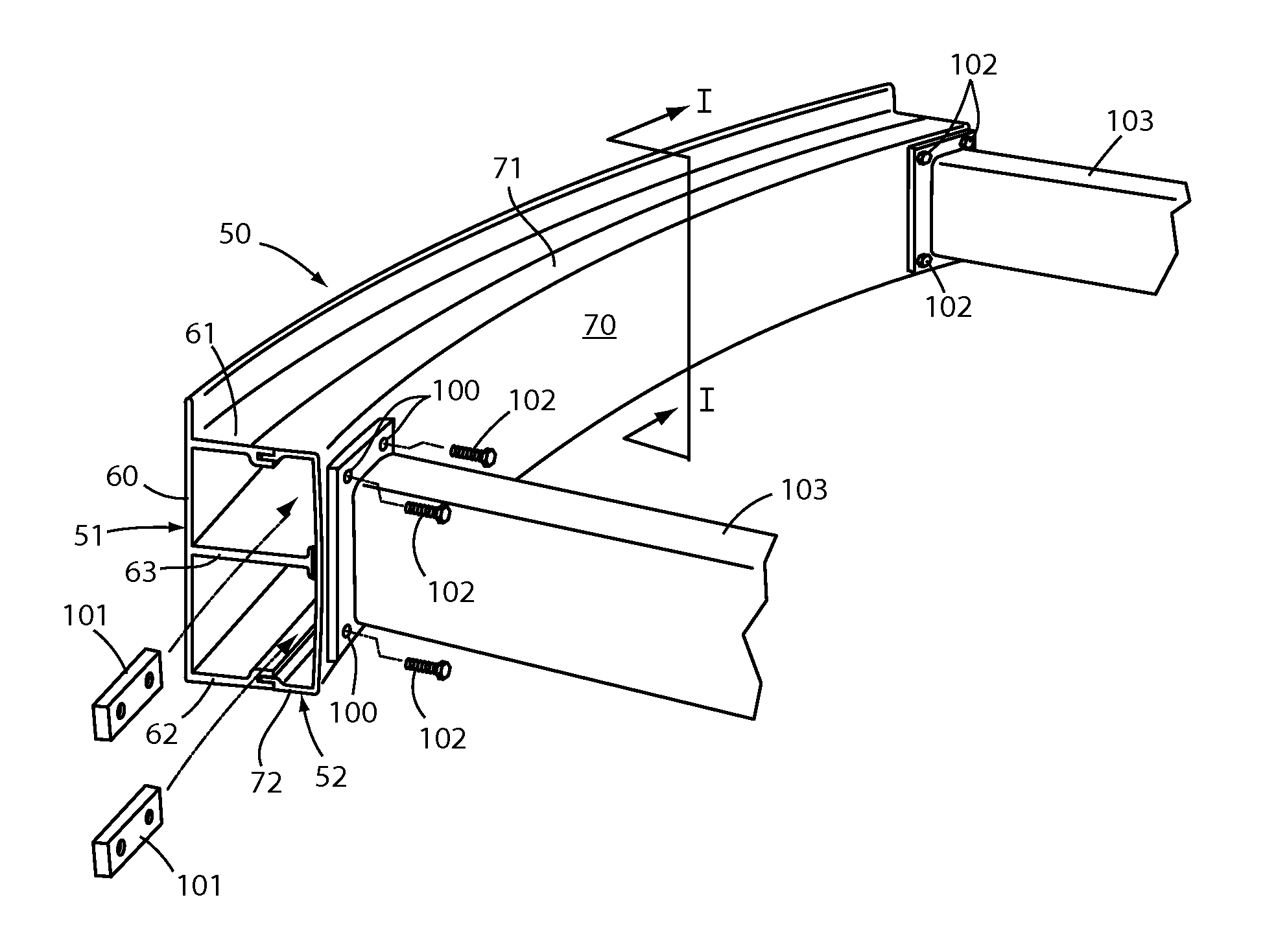

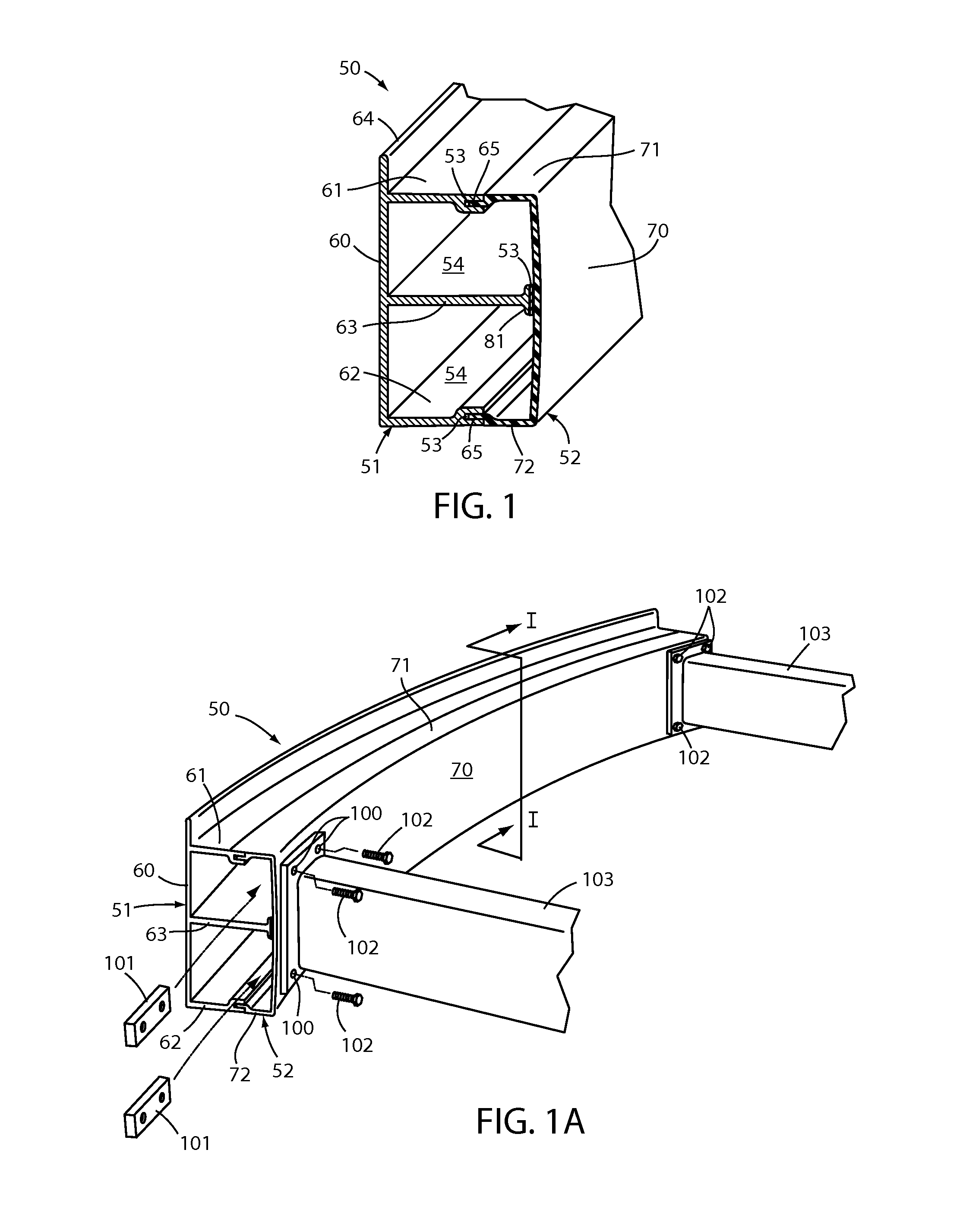

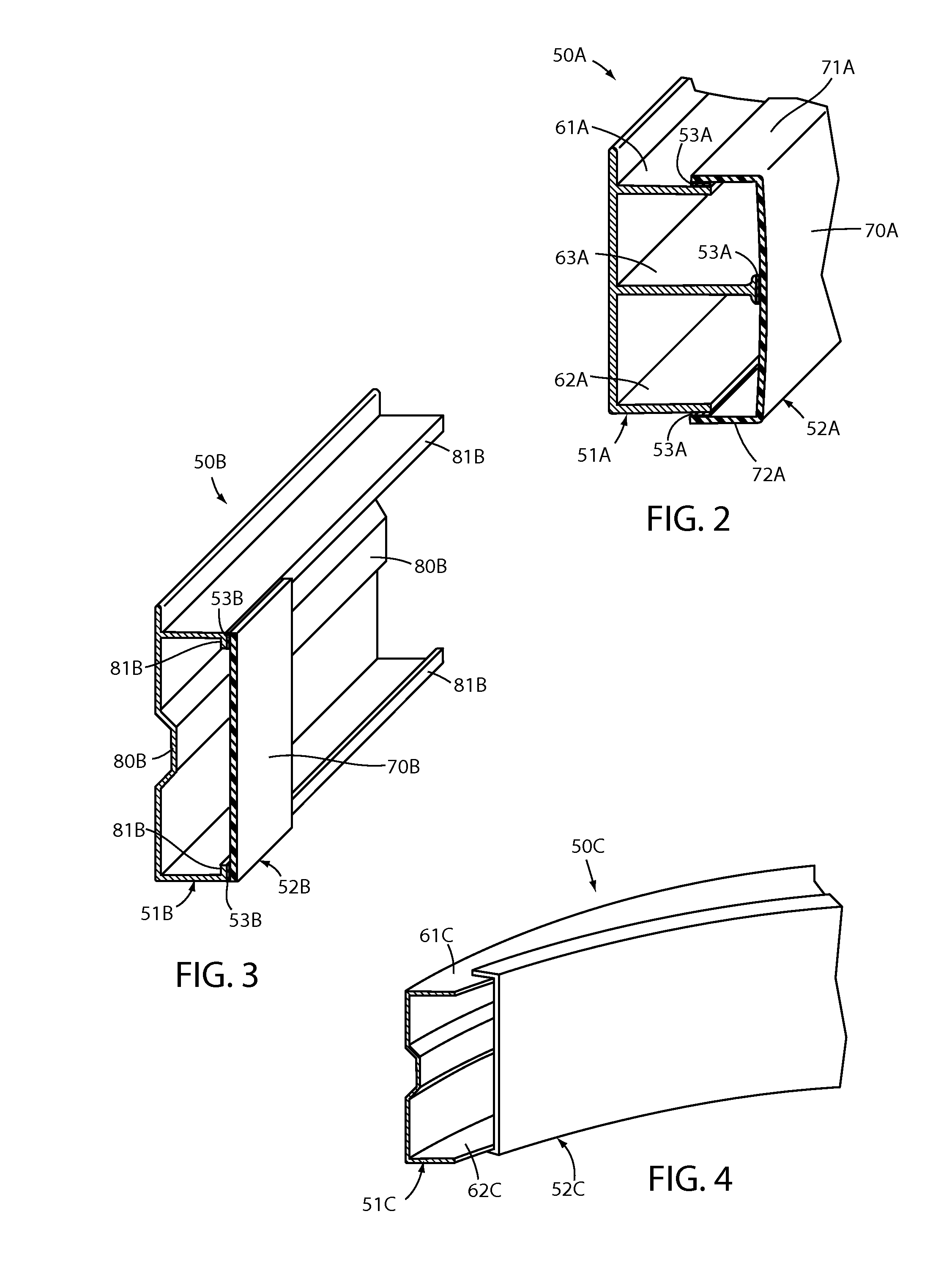

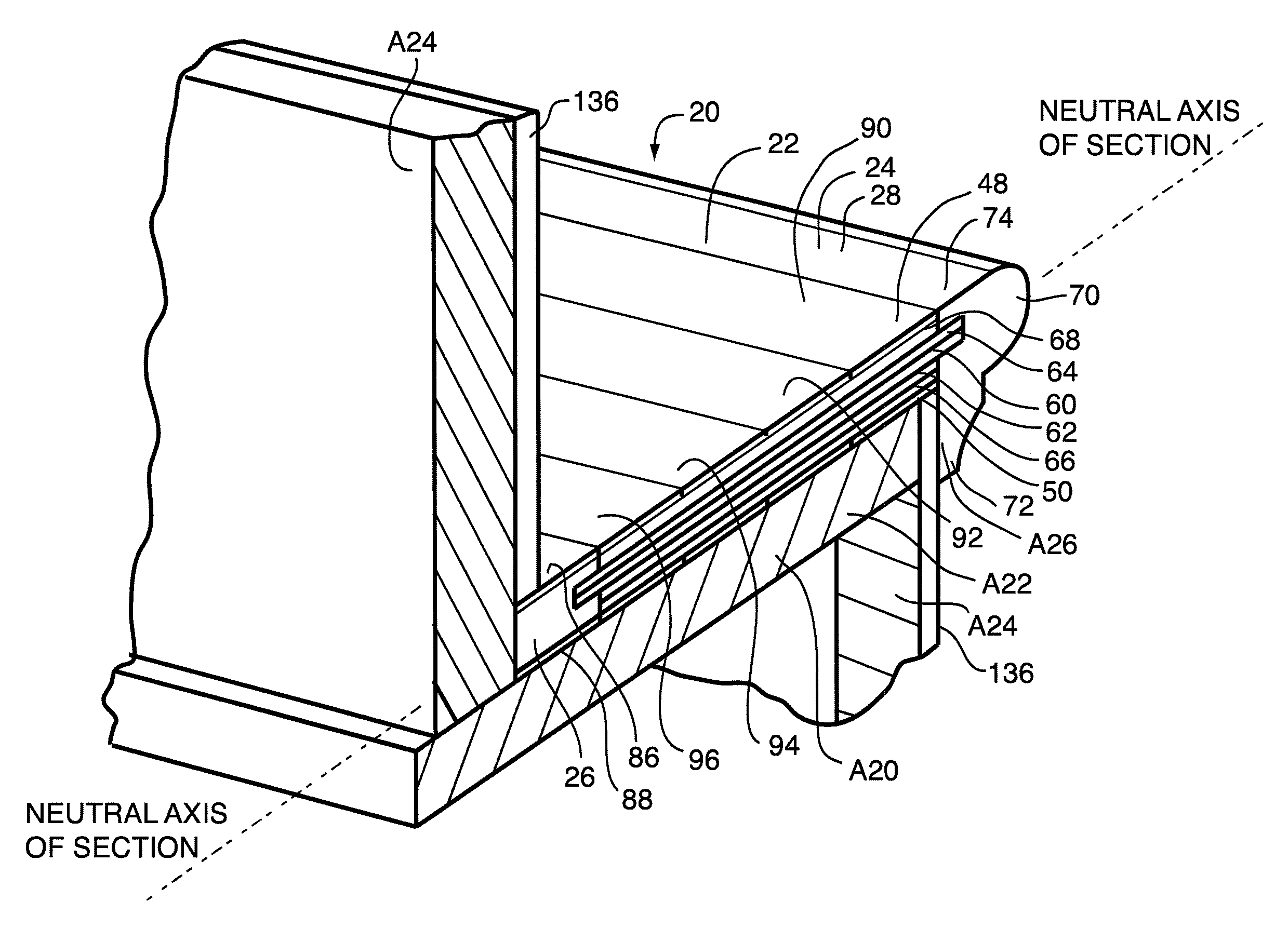

Beam incorporating aluminum extrusion and long-fiber reinforced plastic

InactiveUS20160159300A1Optimize locationReduce stressLaminationLamination apparatusCarbon fibersIn vehicle

A hybrid impact beam, suitable for use as a reinforced impact beam in vehicle bumpers, includes an extruded aluminum section, a fiber reinforced polymeric (FRP) section, and a structural adhesive bonding them together. The components are arranged so that during an impact, the aluminum section experiences compression and receives the direct impact, the FRP section experiences tension, and the adhesive experiences minimal stress by being on a neutral plane of the beam's bending moment. The extruded aluminum beam is preferably extruded as an open section, but becomes a closed section when the polymeric section is attached. The FRP section is preferably a continuous carbon fiber reinforced polymeric section, although different reinforcements can be used. A related method includes bonding an extruded aluminum and fiber-reinforced polymeric section together to form a closed bumper impact beam.

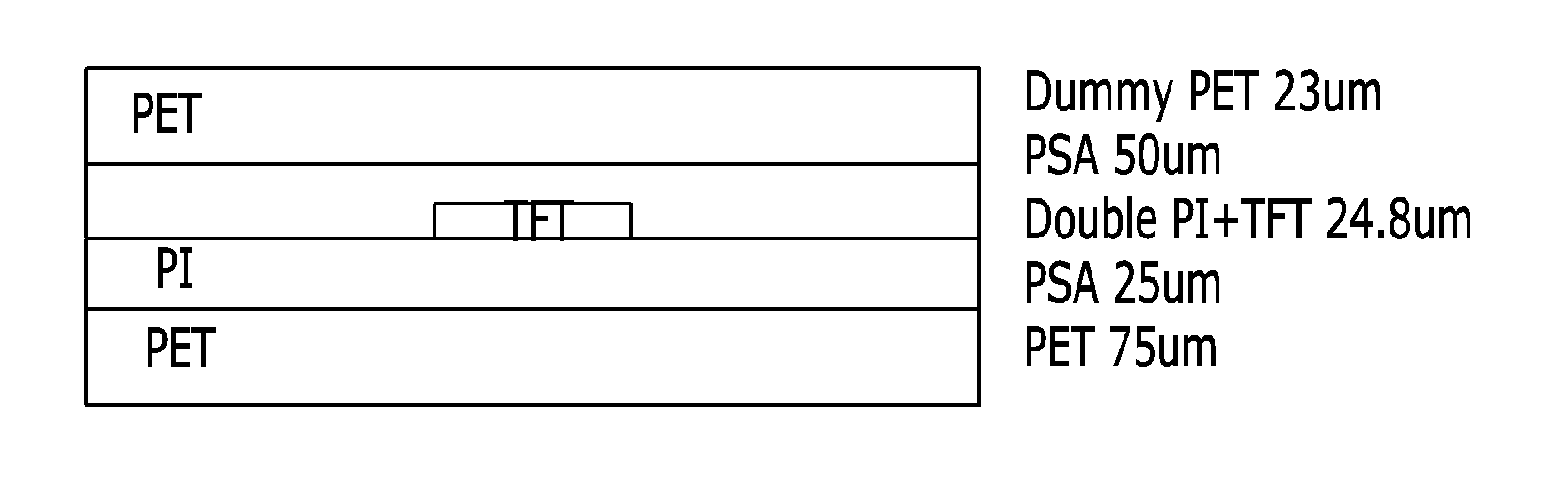

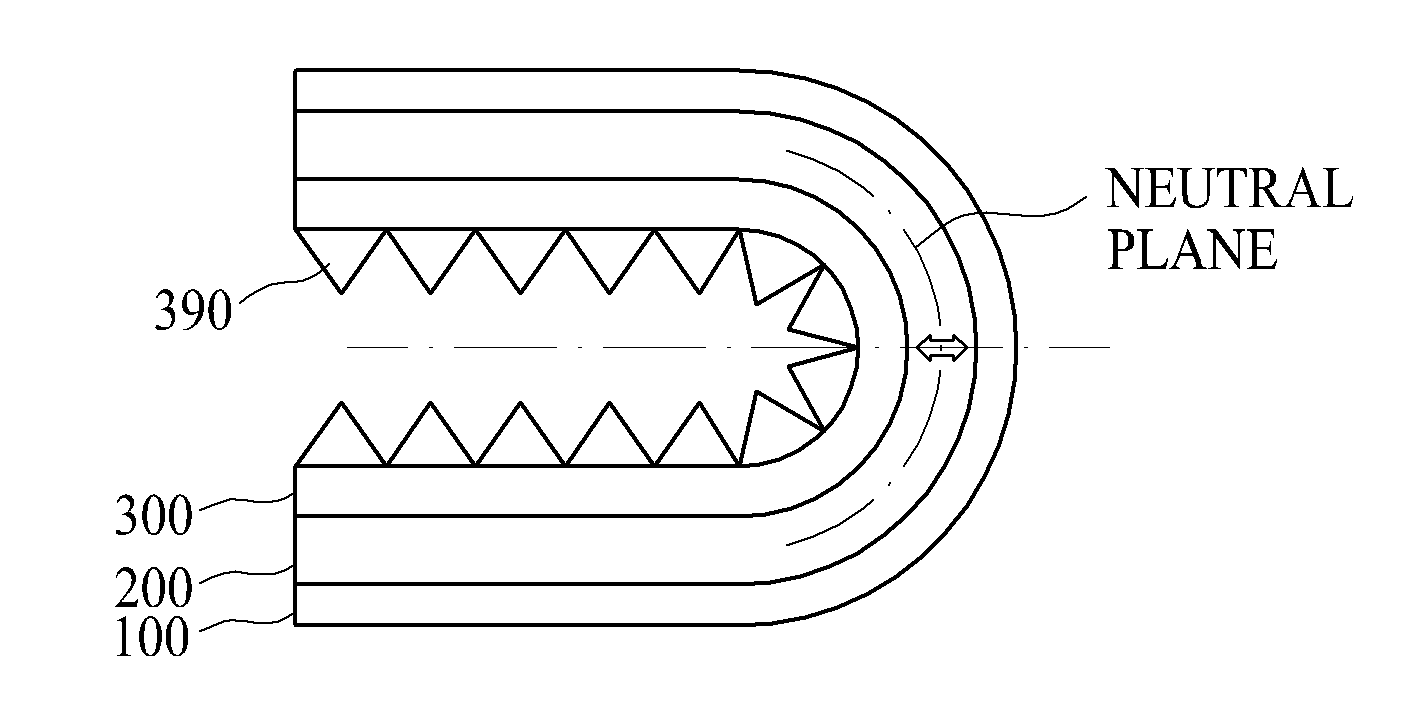

Flexible image display device

ActiveUS20170147117A1Good flexibilityMinimize damageSolid-state devicesSemiconductor/solid-state device manufacturingNeutral planeComputer science

Owner:DONGWOO FINE CHEM CO LTD

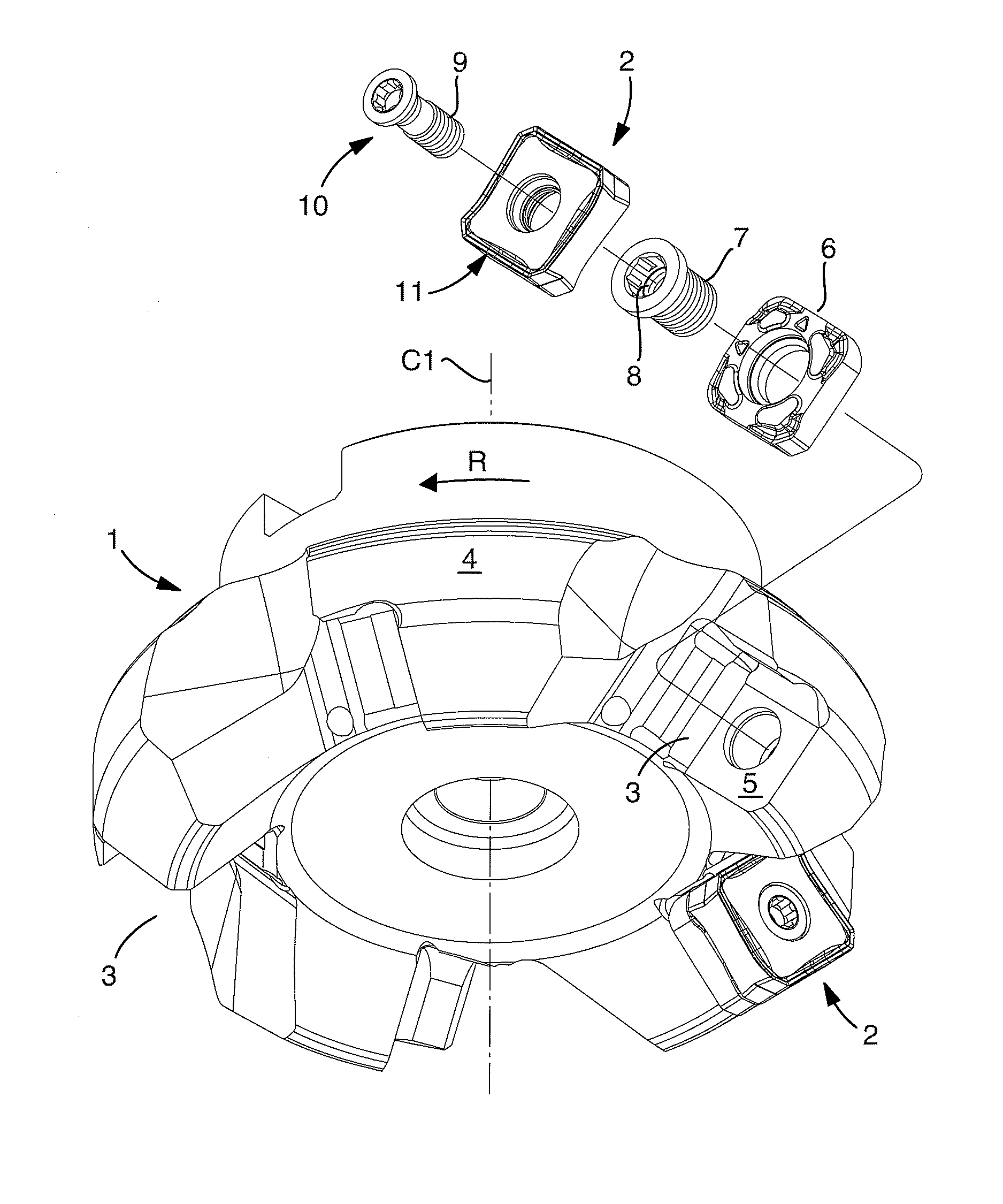

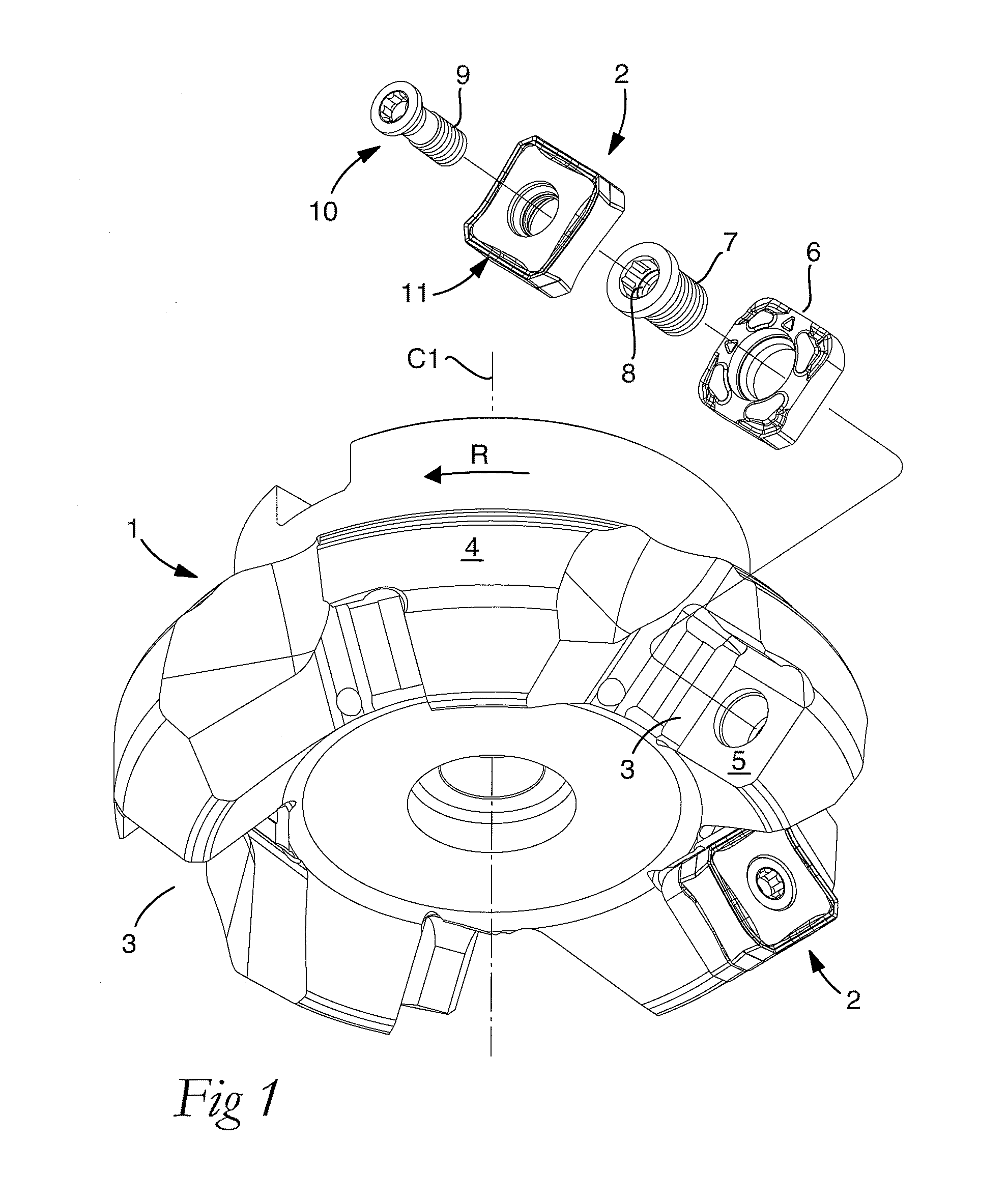

Double-sided indexable face milling insert

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Flexible touch screen panel and flexible display apparatus including the same

InactiveUS20140354558A1Effectively reducing and preventing crackFunction increaseDigital data processing detailsInput/output processes for data processingEngineeringNeutral plane

A flexible touch screen panel includes a flexible film, and a wiring layer in the flexible film, wherein the wiring layer is at a neutral plane within the flexible film, the neutral plane being a region where substantially no stress is applied when the flexible touch screen panel is bent.

Owner:SAMSUNG DISPLAY CO LTD

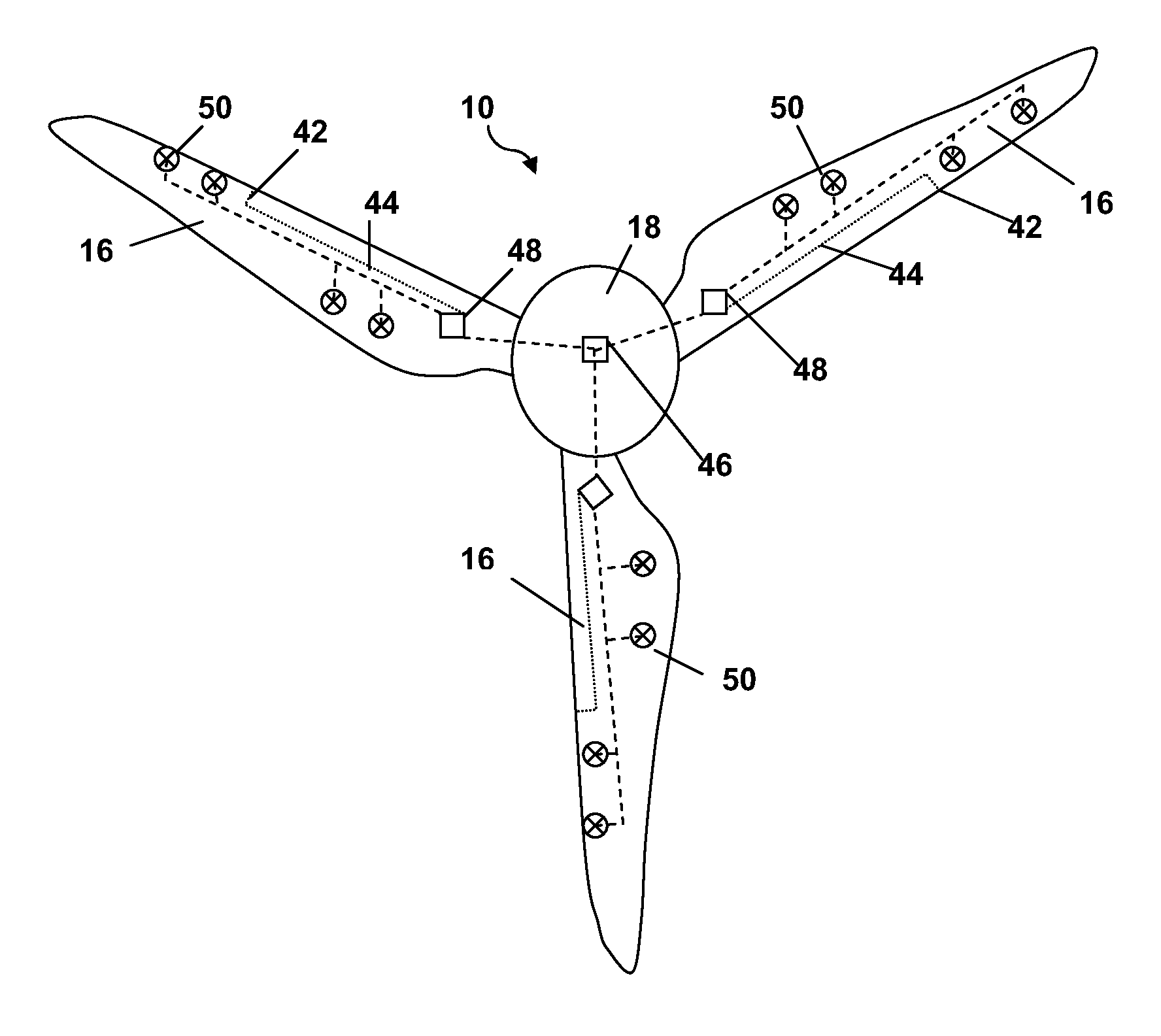

Wind turbine blades with controllable aerodynamic vortex elements

A wind turbine blade has a suction side surface and a pressure side surface. A plurality of dynamic vortex elements are formed on at least one of the suction side or the pressure side surfaces. The vortex elements are activatable between a first retracted position that is inwardly recessed relative to a neutral plane of the surface on which they are formed and a second extended position that is outwardly protruding relative to the neutral plane of the surface.

Owner:GENERAL ELECTRIC CO

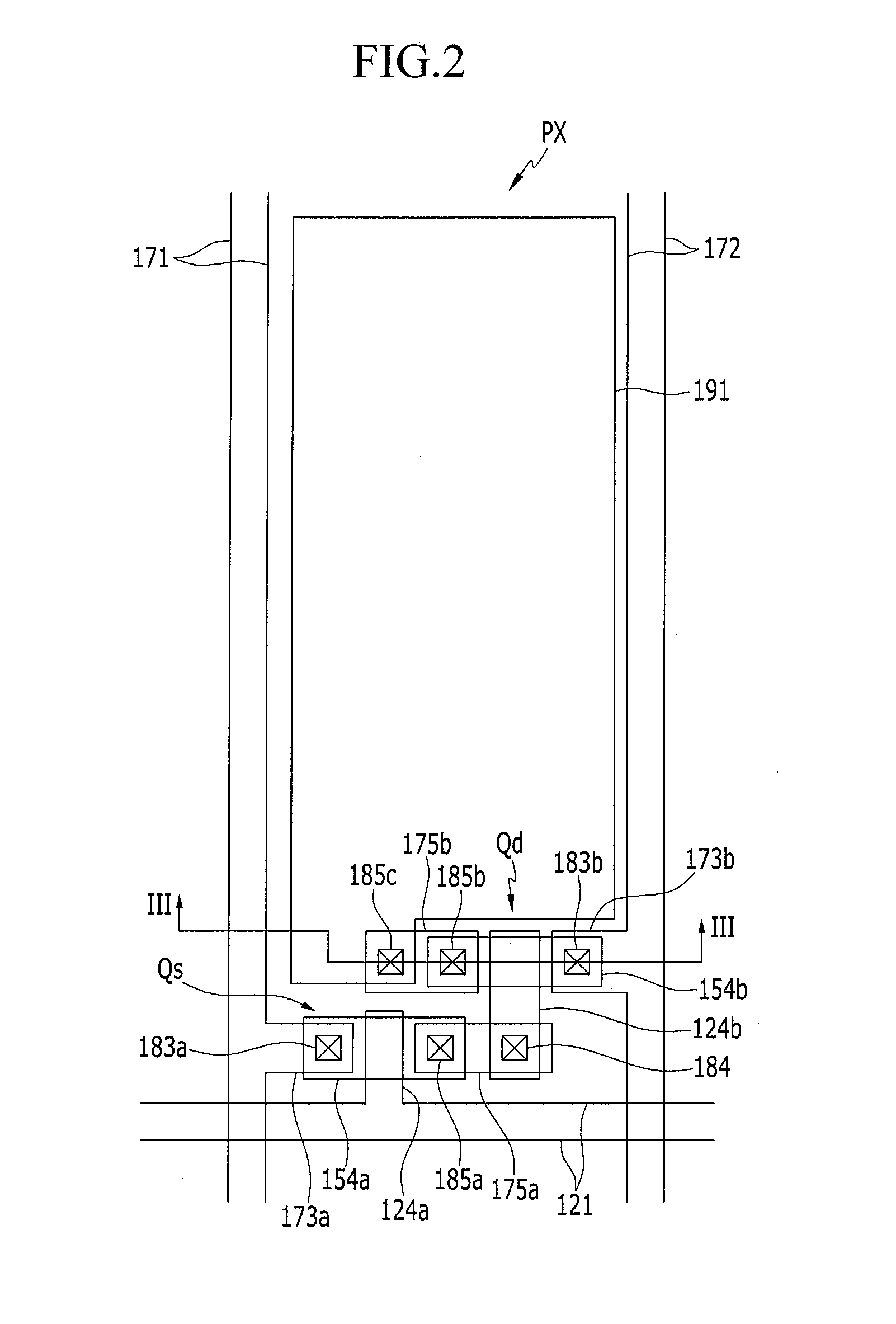

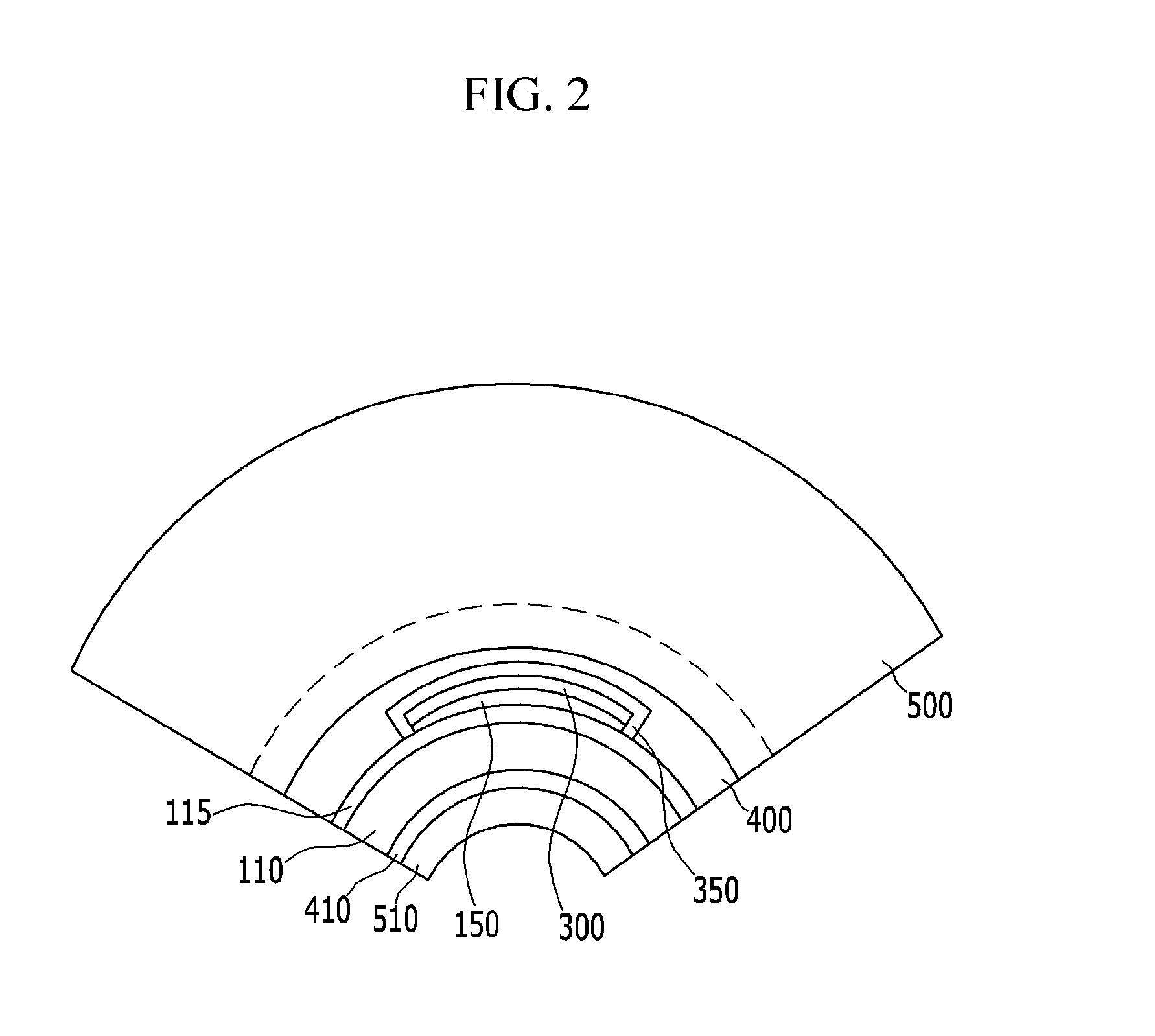

Organic light emitting display device

ActiveUS20150179722A1Operation can be causedDeterioration of display quality caused by a bending operation may be reduced or effectively preventedSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceNeutral plane

An organic light emitting display device includes: a curved organic light emitting display panel. The organic light emitting display panel includes a flexible substrate, a thin film transistor layer including a semiconductor layer, and an organic light emission layer including an organic light emitting material. In the curved organic light emitting display panel, the thin film transistor layer receives a compressive stress, or a neutral plane in which the compressive stress and a tensile stress maintain equilibrium is defined in the thin film transistor layer.

Owner:SAMSUNG DISPLAY CO LTD

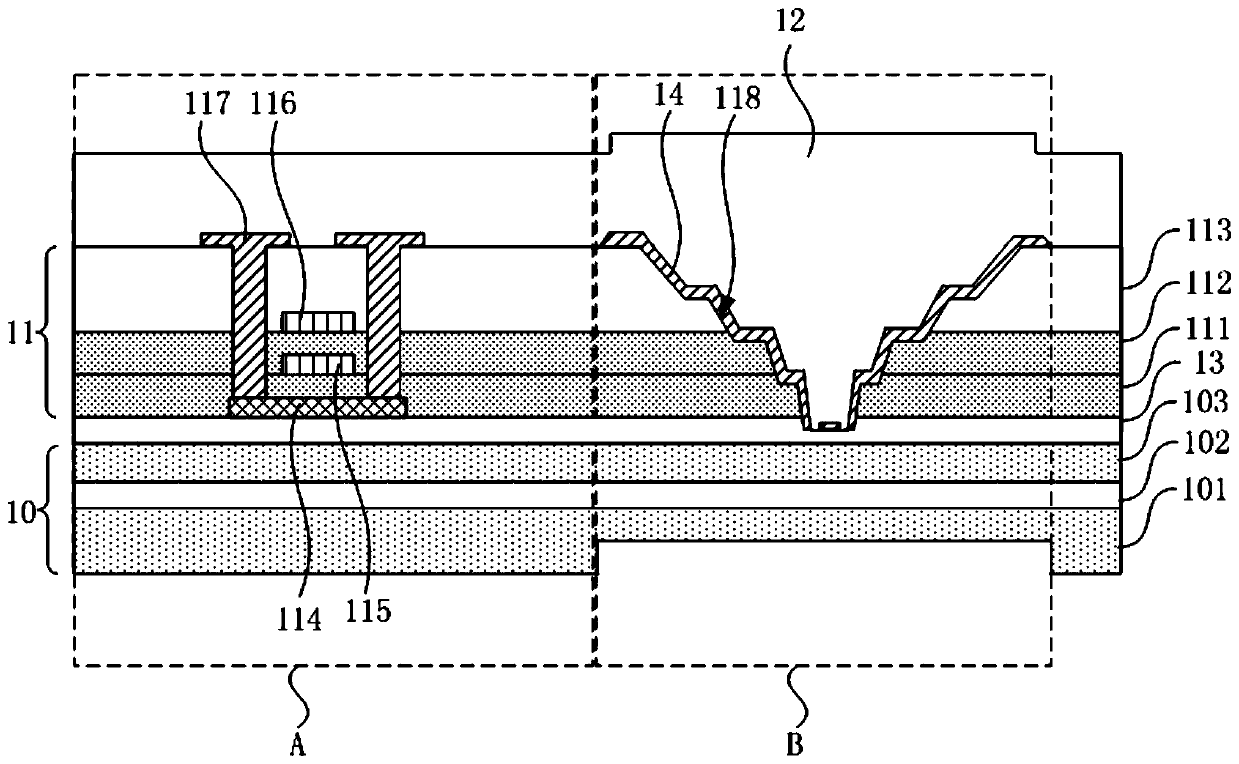

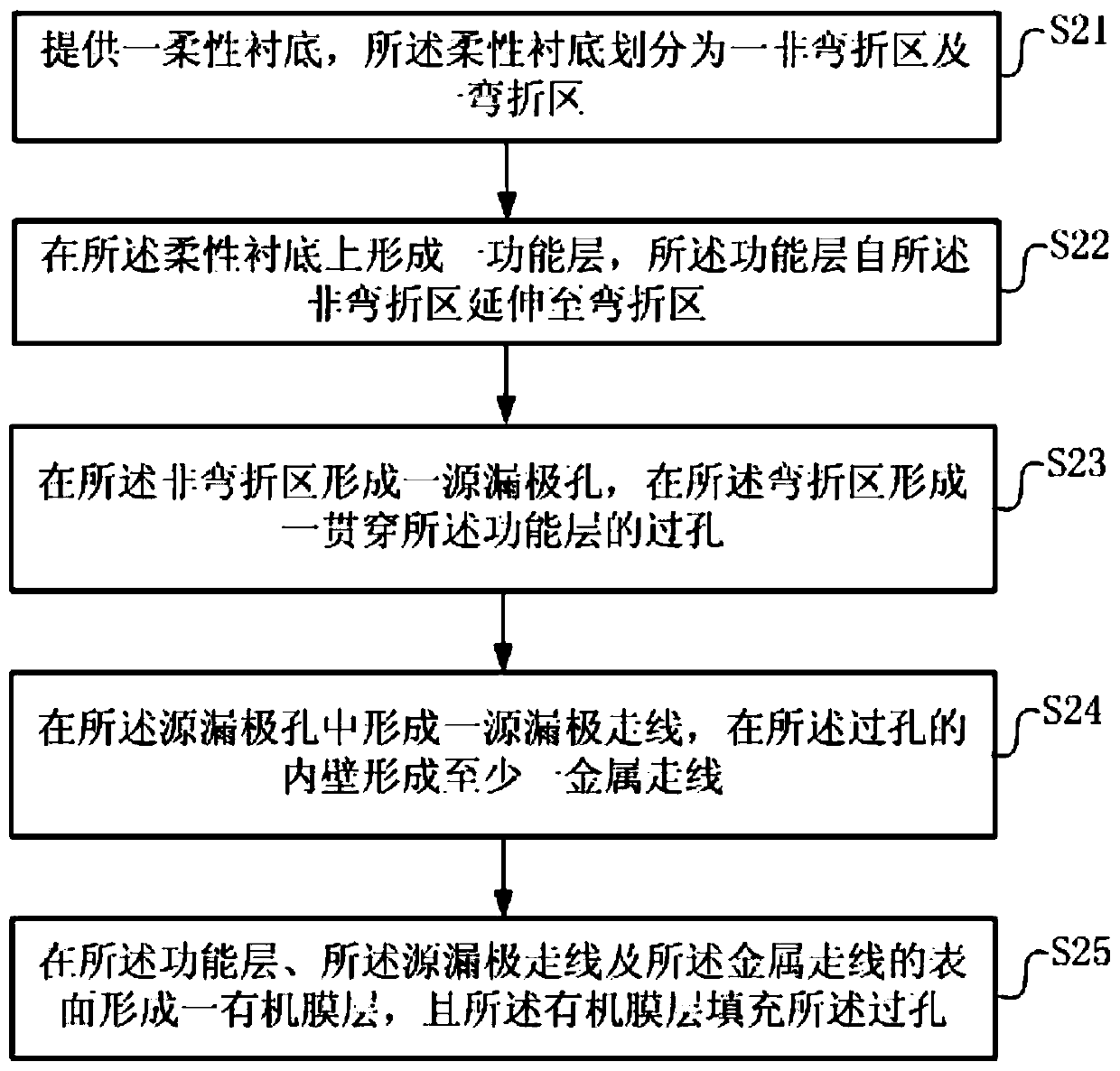

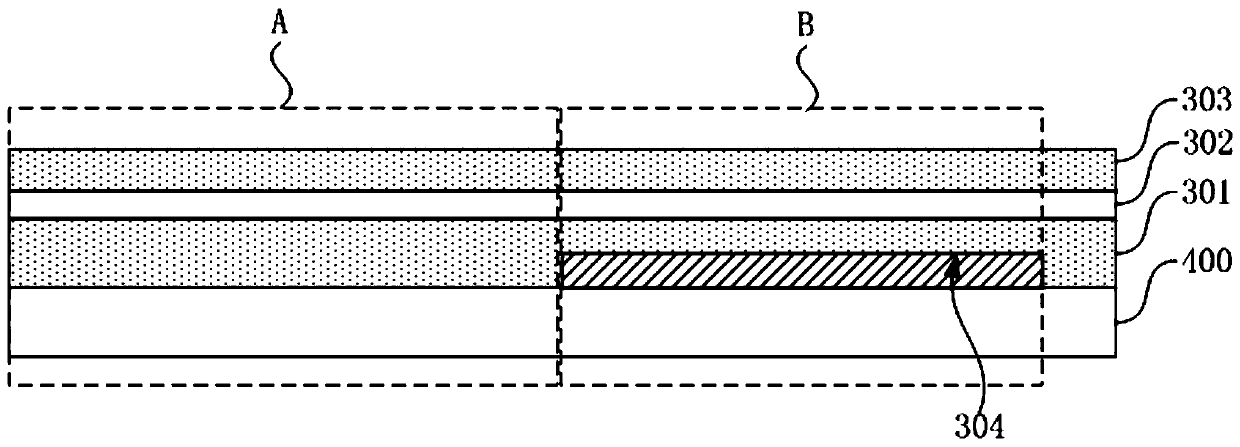

Flexible array substrate, display panel and preparation method

ActiveCN109817675AReduce thicknessEasy to adjustSolid-state devicesSemiconductor/solid-state device manufacturingNeutral planeMetal

The invention provides a flexible array substrate, a display panel and a preparation method. The method has the advantages that in a bending area, thickness of a material layer below a metal wire is reduced; meanwhile, thickness of a material layer above the metal wire is increased; the metal wire can be adjusted to a neutral plane, and then the bending resistance and stability of the metal wire are improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

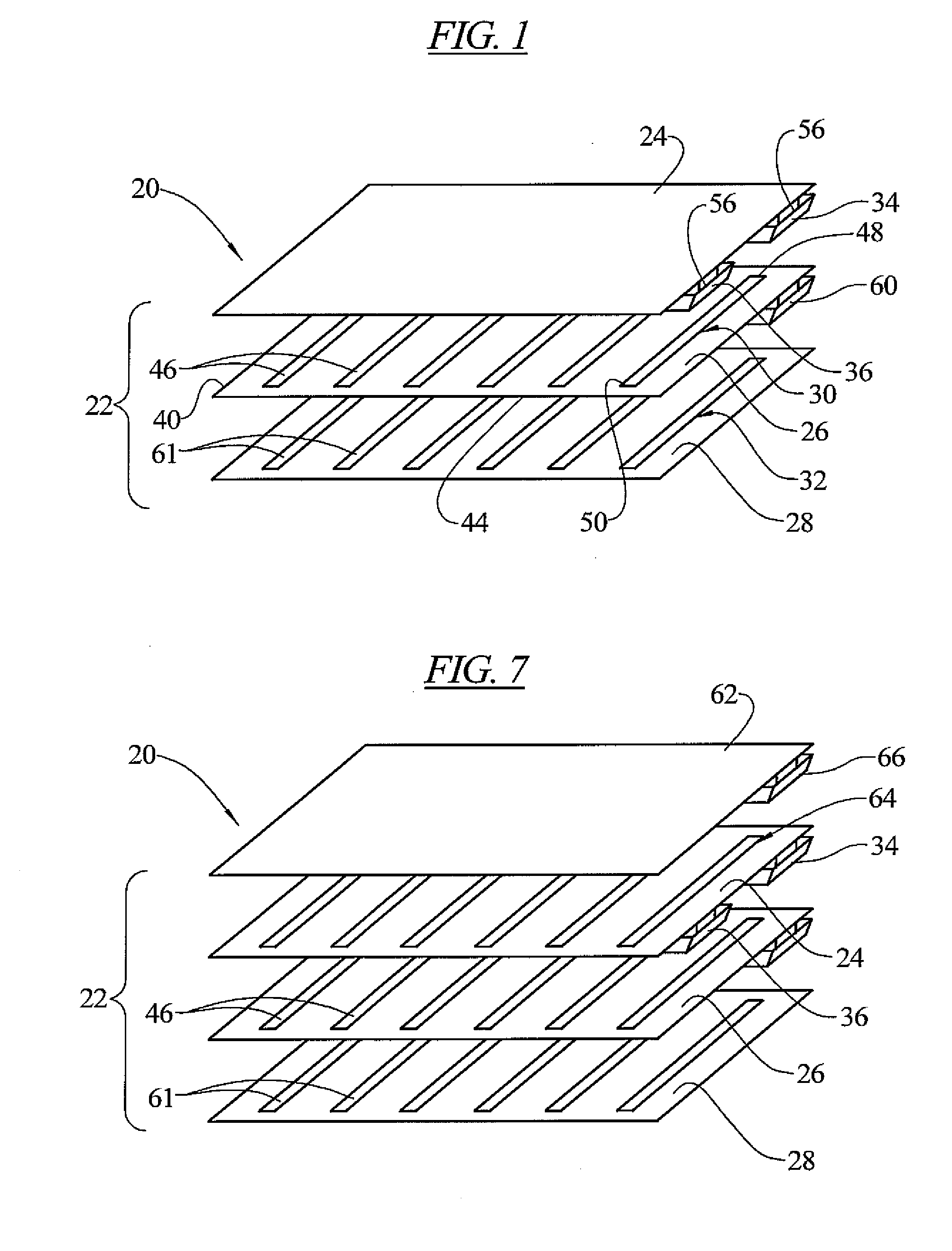

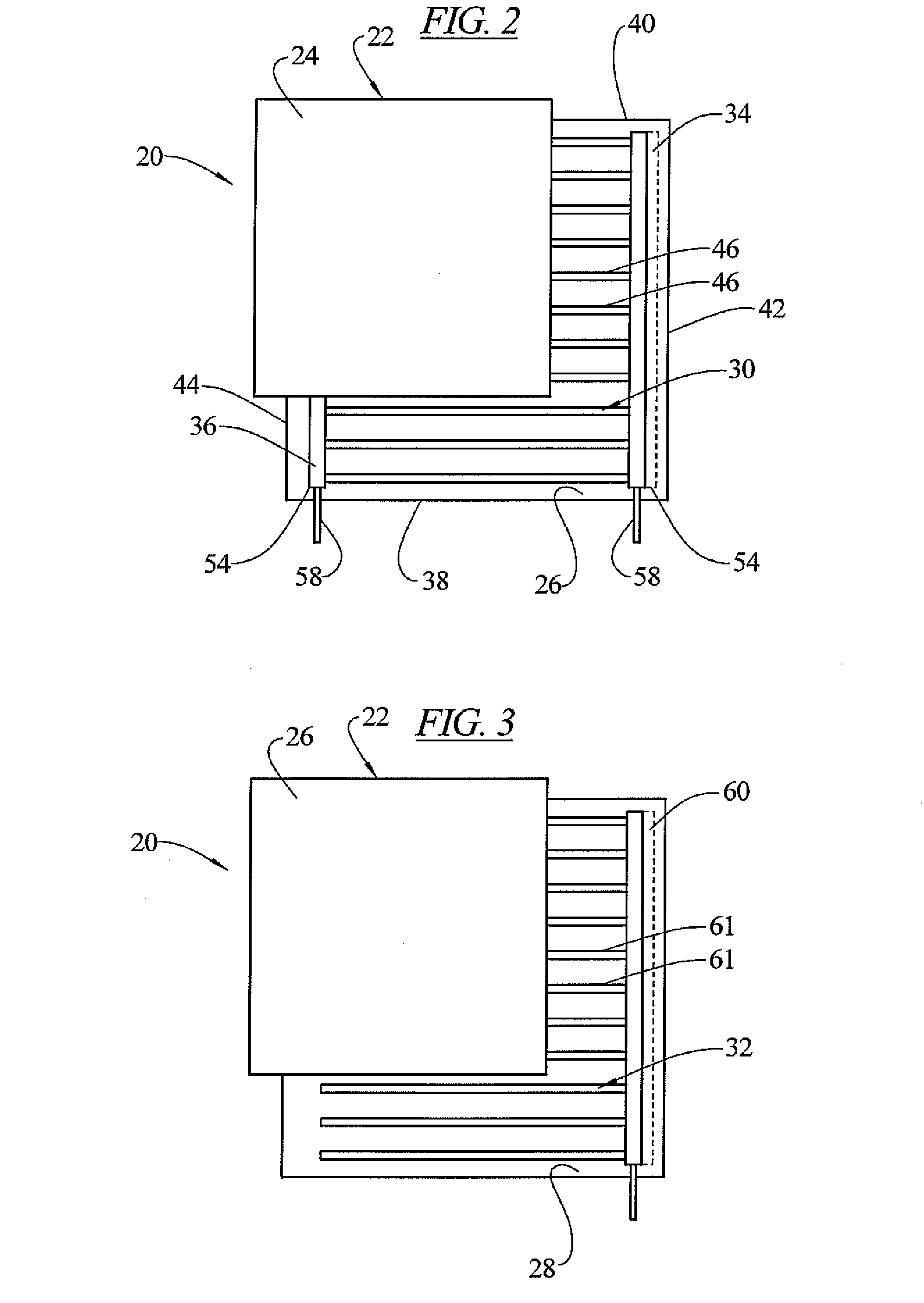

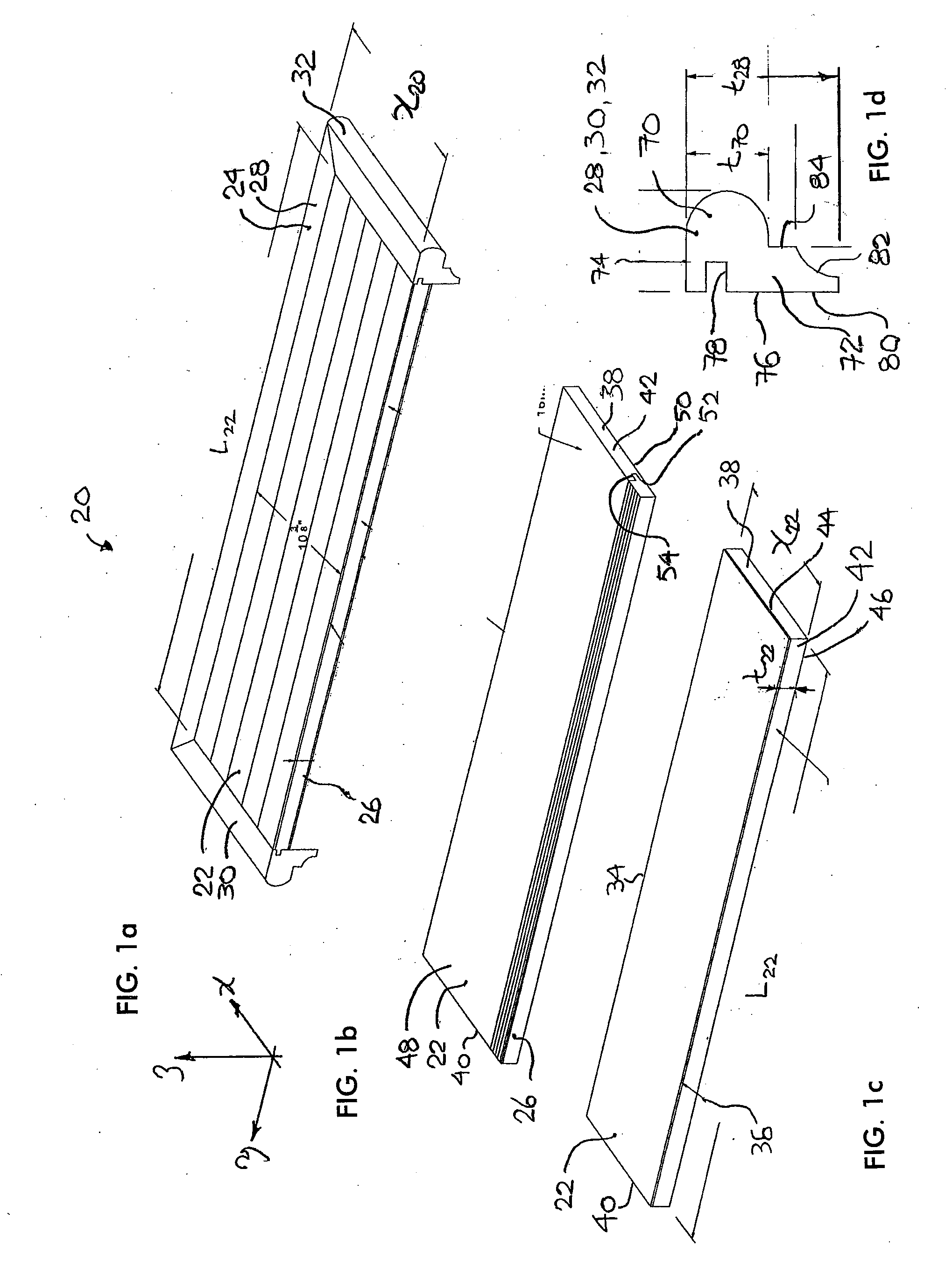

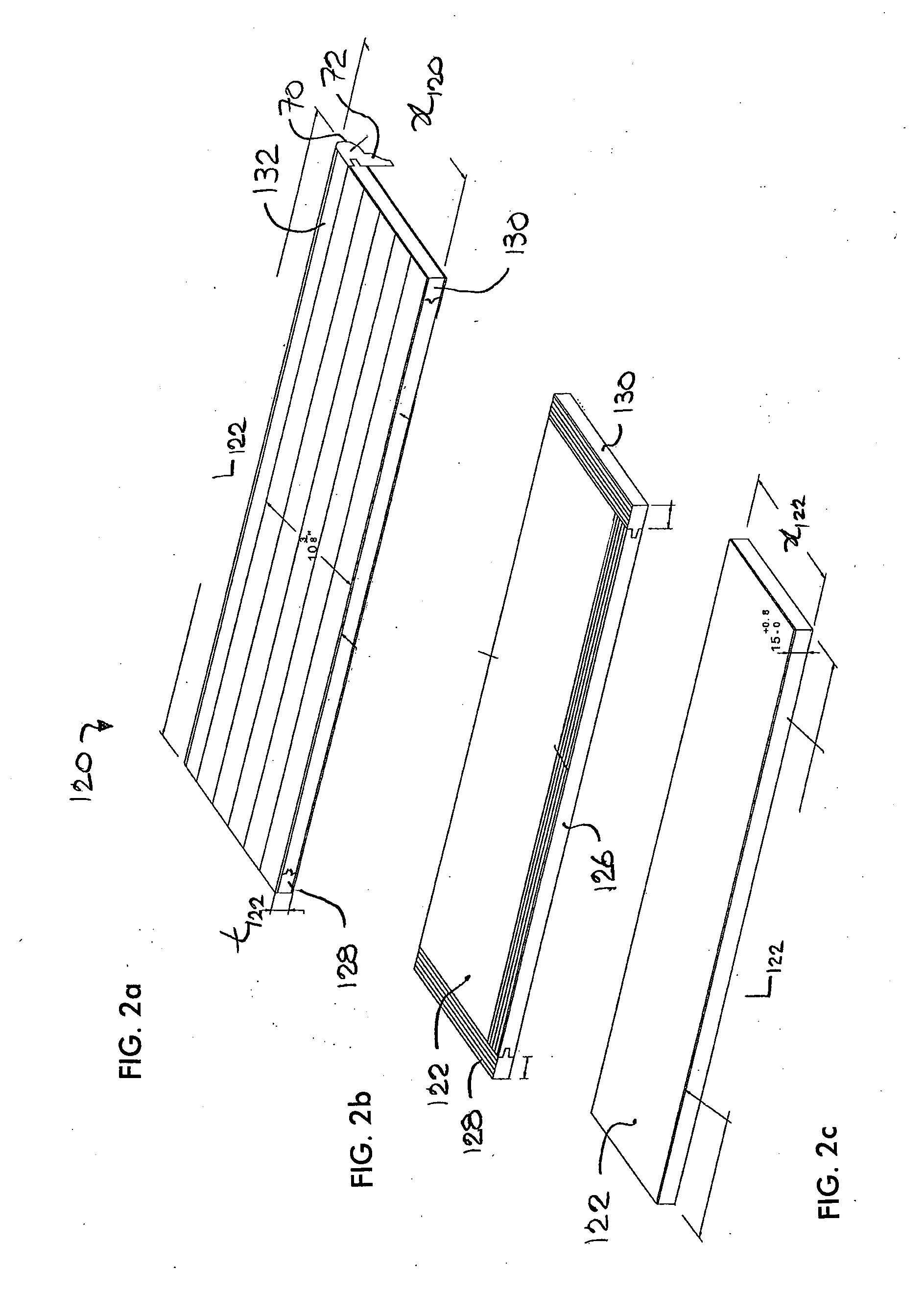

Electrical heater with a resistive neutral plane

A heating system in the form of a multi-layer, yet relatively thin and flexible panel. The panel contains a number of layers including first, second and third electrically insulating layers. A first electrically conductive resistive layer (heater layer) is sandwiched between the first and second insulating layers. A second electrically conductive resistive layer (resistive neutral plane layer) is sandwiched between the second and third insulating layers. The heater layer has a neutral electrical connection and a live electrical connection. The neutral and live electrical connections are electrically connected to each other at the panel only by electrically resistive material of the heater layer extending between the neutral and live electrical connections. The resistive neutral plane layer has a neutral electrical connection electrically connected with the neutral connection of the heater layer. The resistive neutral plane layer is electrically isolated from the live connection of the heater layer by the second insulating layer.

Owner:UNITED STATES GYPSUM CO

Pressure sensors having neutral plane positioned transducers

ActiveUS20050160825A1Fluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesTransducerSubject matter

Owner:PROTEUS DIGITAL HEALTH INC

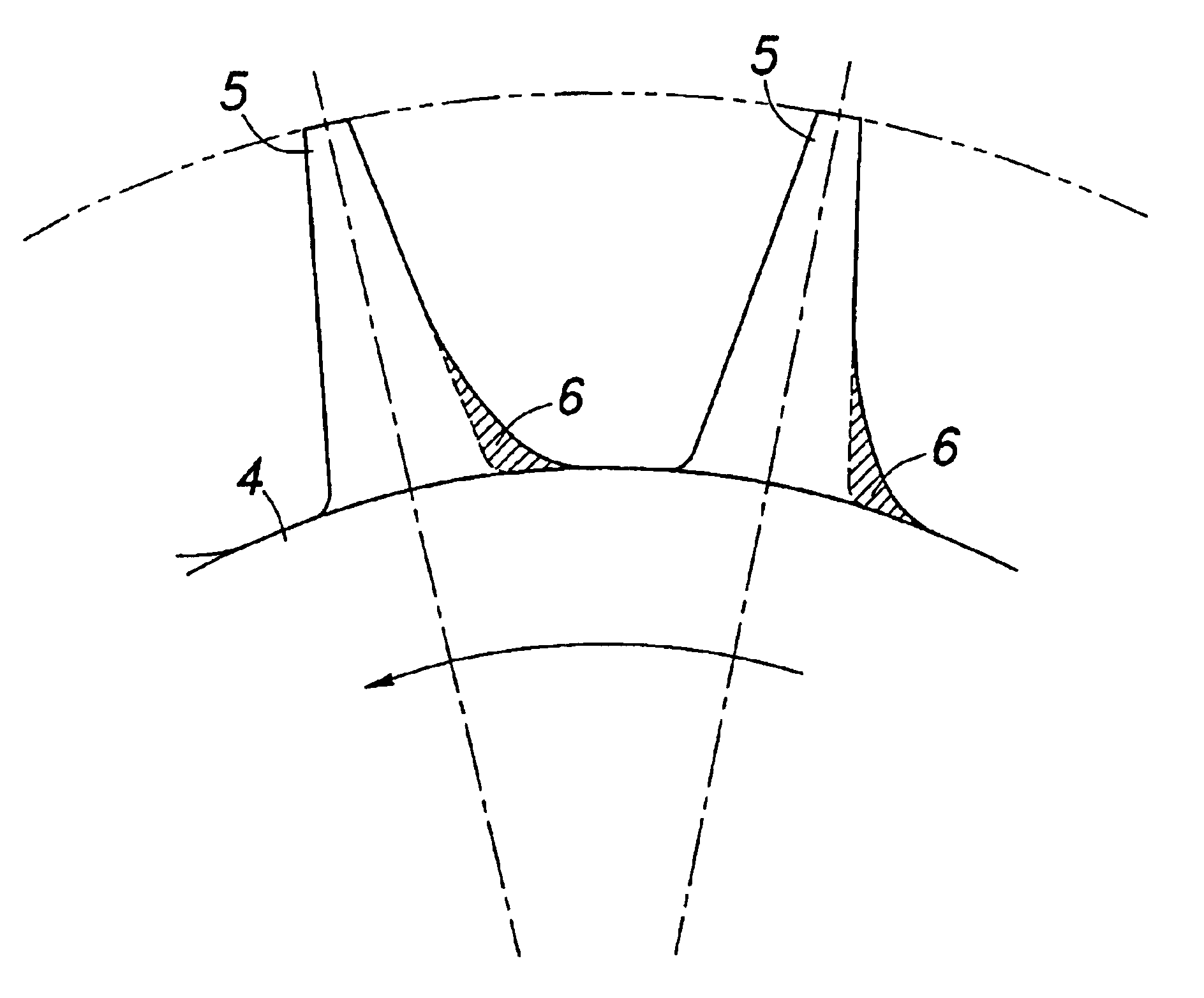

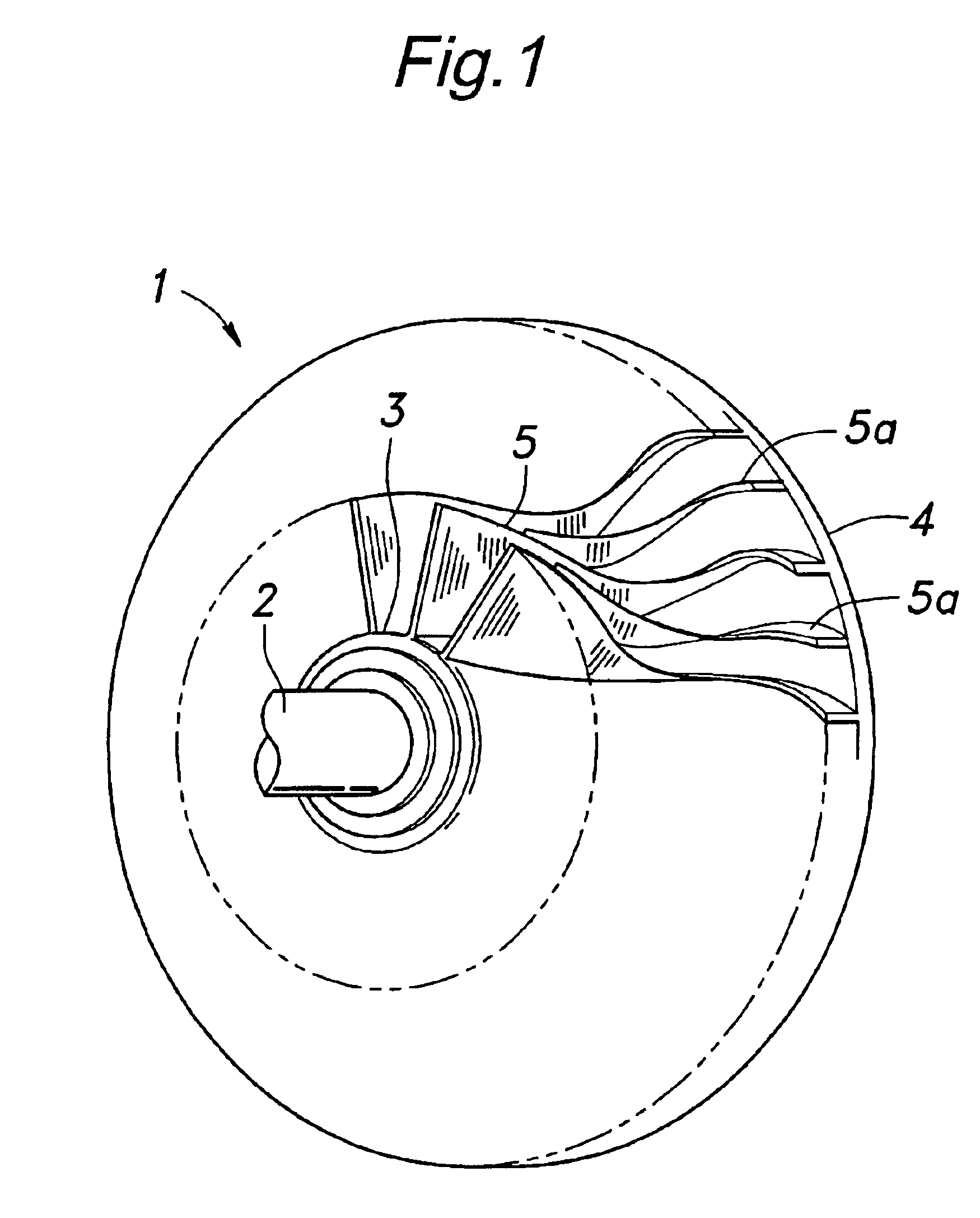

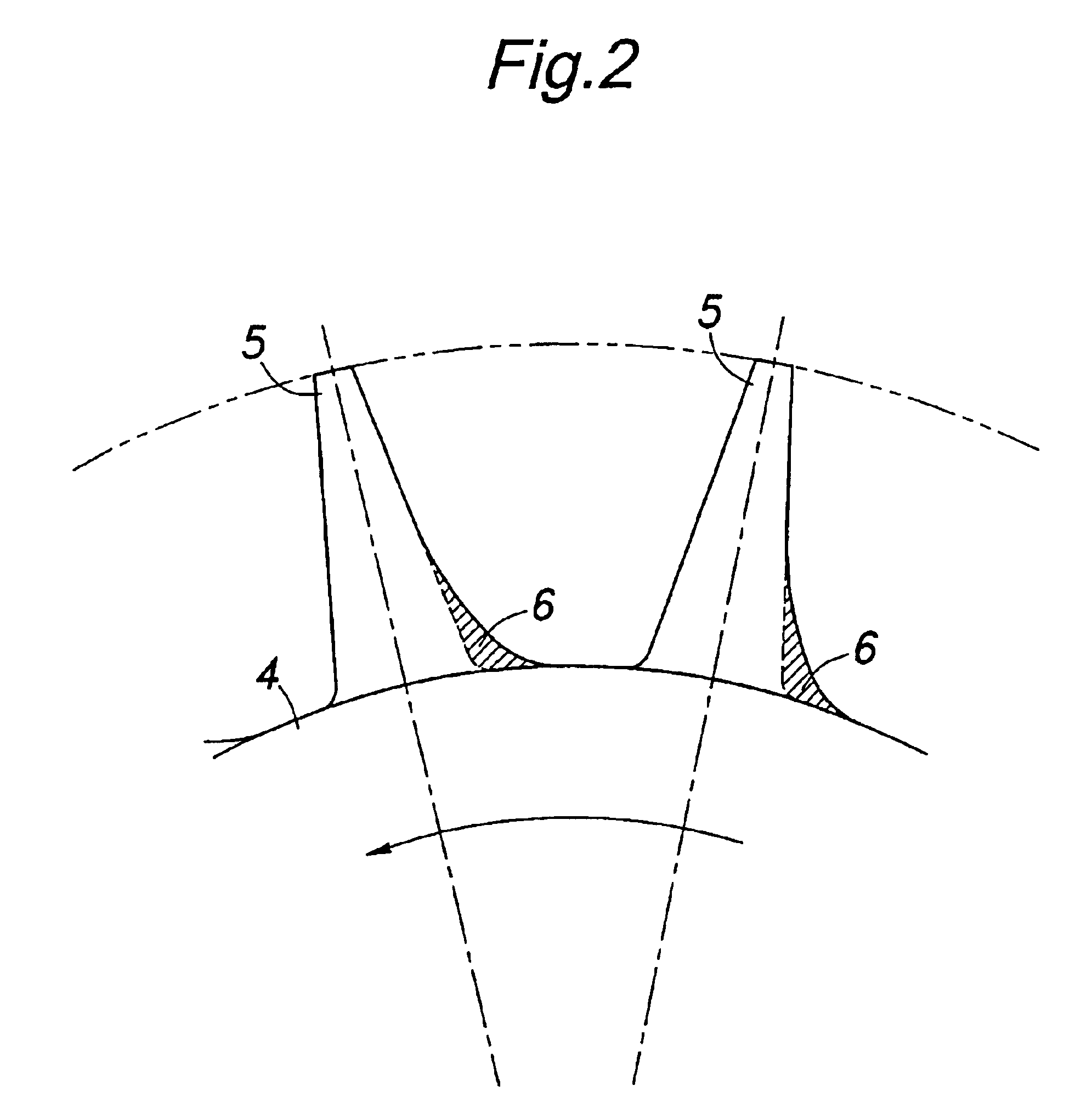

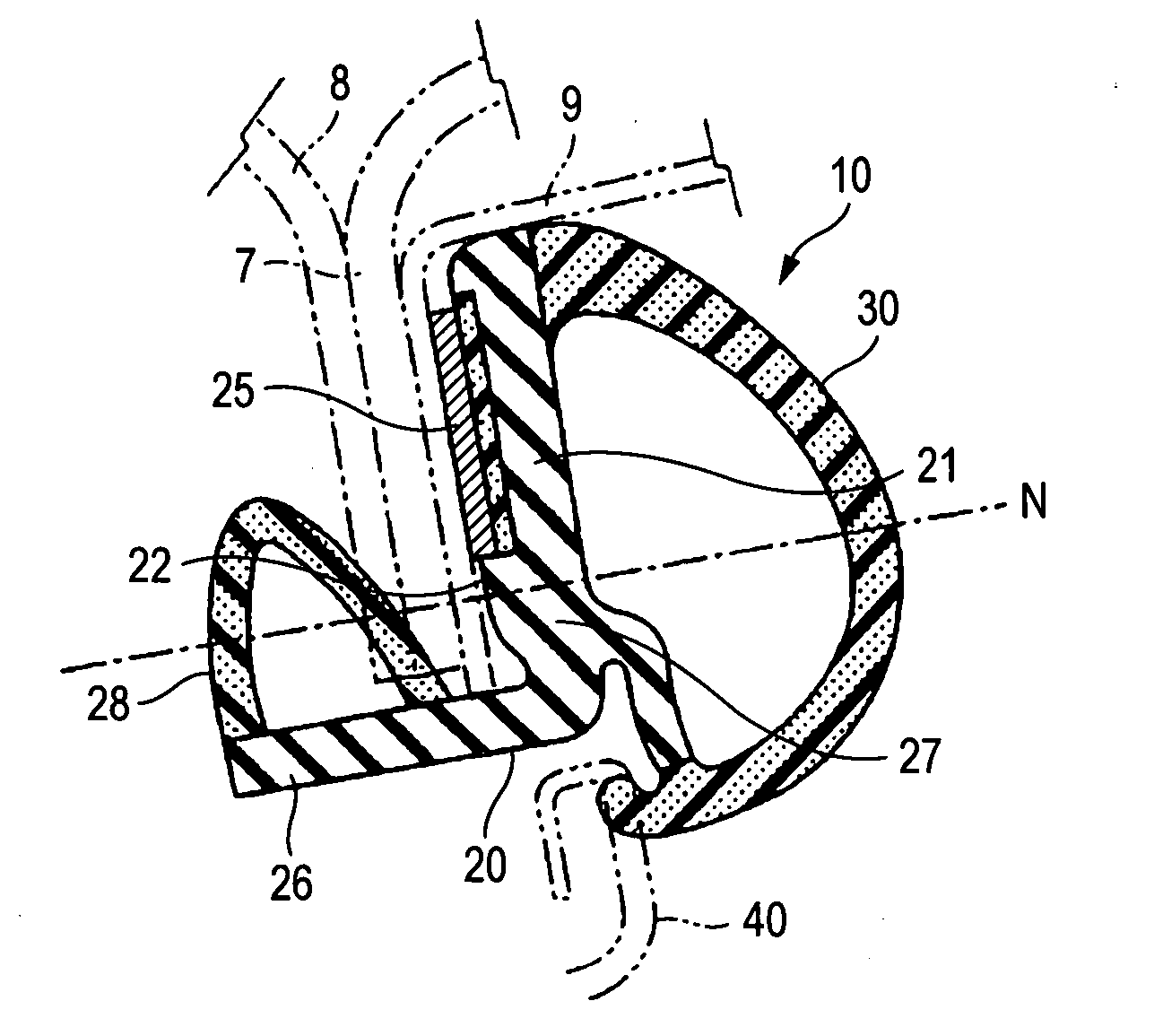

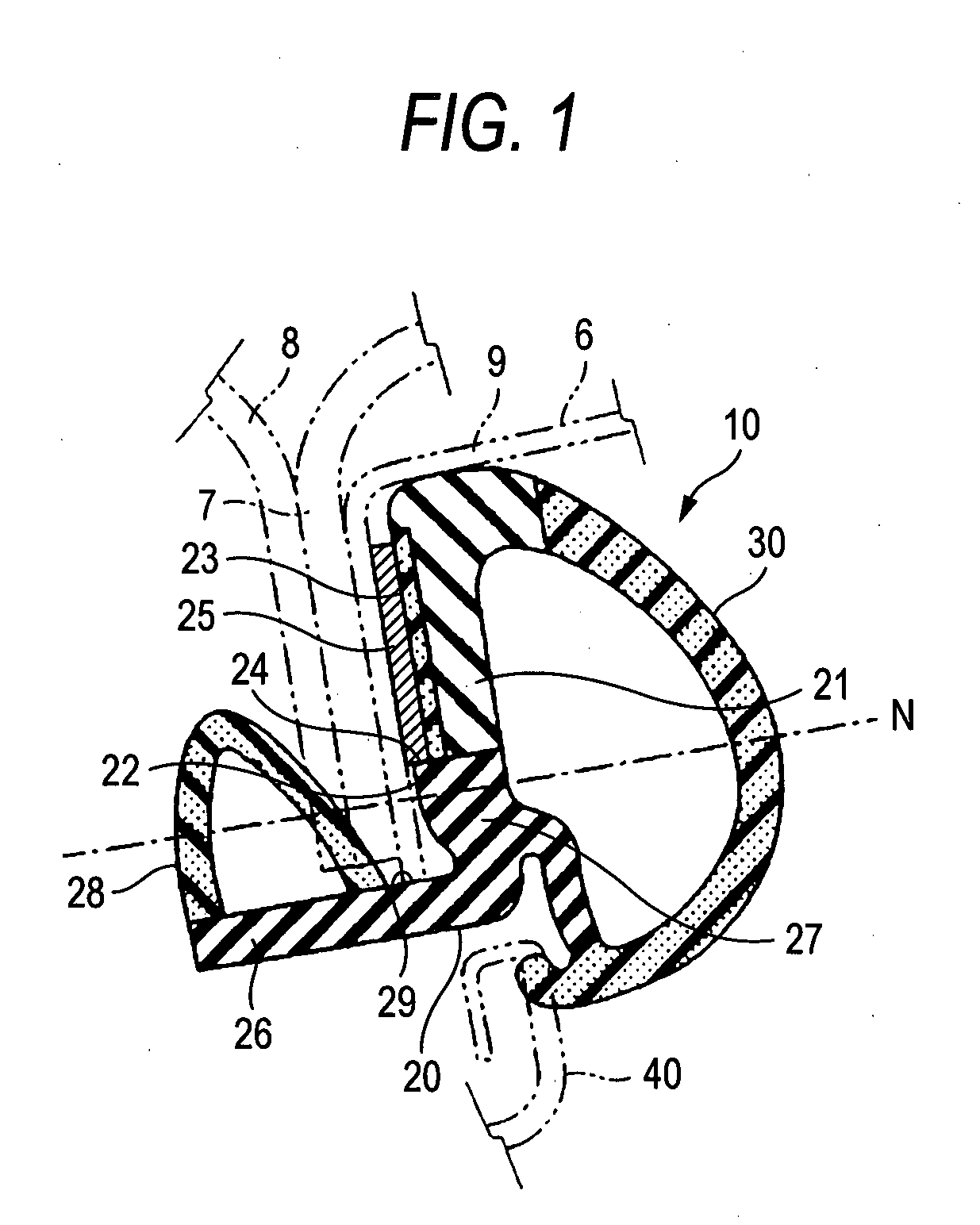

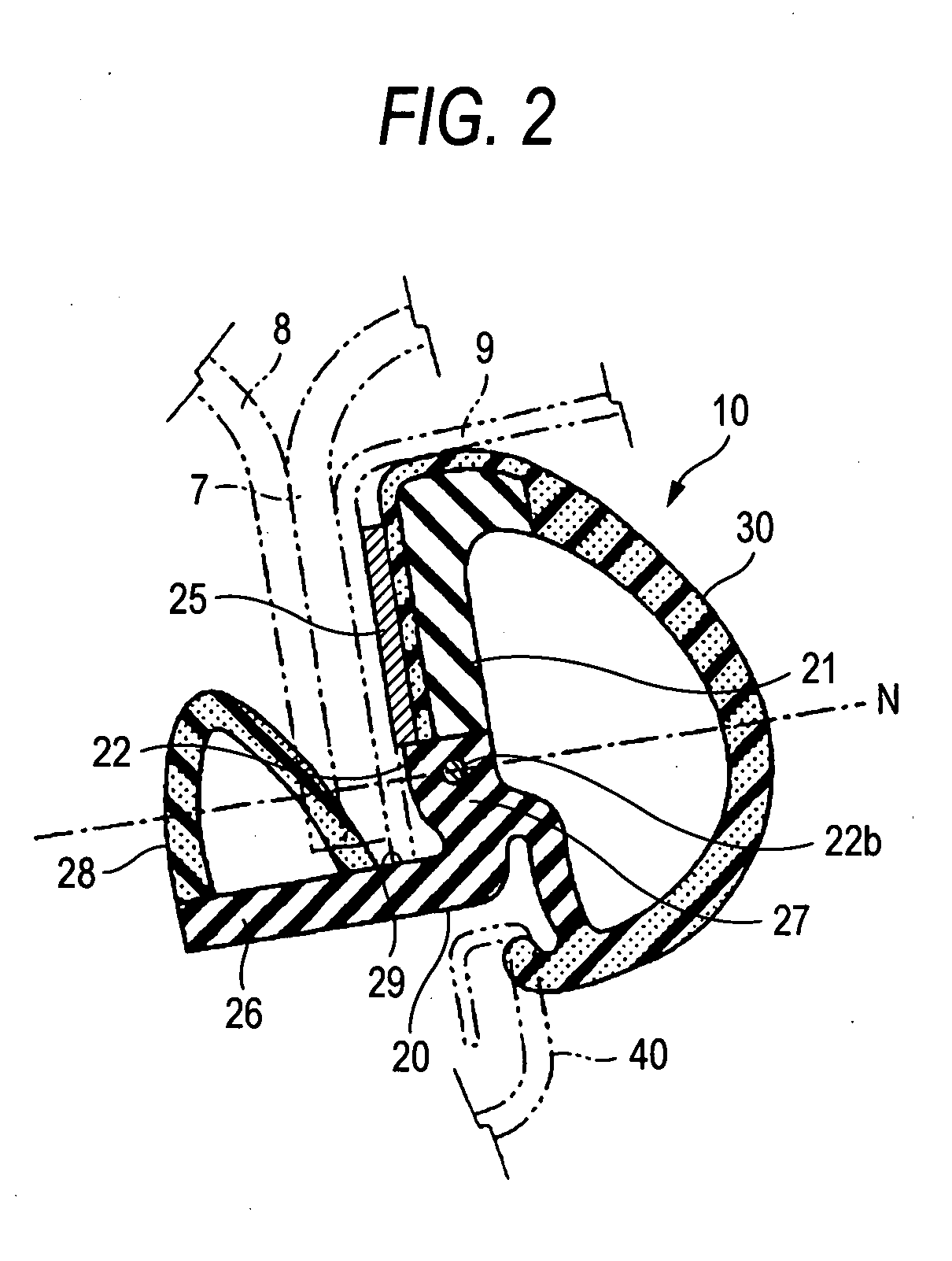

Impeller for centrifugal compressors

InactiveUS6905310B2Interference minimizationMinimizes separationPropellersRotary propellersSuction stressAerodynamic load

In an impeller for centrifugal compressors comprising a plurality of blades each having a base end attached to a central hub, each of the blades is given with a thickness which increases progressively toward a hub end thereof, and a suction surface side of the blade is given with a greater thickness increase rate with respect to a neutral plane than a pressure surface side of the blade. Thereby, the inter-blade channel is narrowed locally in the region near the hub end of the suction surface of each blade, and this locally reduces the aerodynamic loading on the blade. In particular, the surge property is improved, and the generation of radially outwardly directed secondary flows can be minimized. This allows the distribution of aerodynamic loading in the radial direction or from the tip end to the hub end of each blade to be controlled at will, and enables the optimum design of the impeller.

Owner:HONDA MOTOR CO LTD

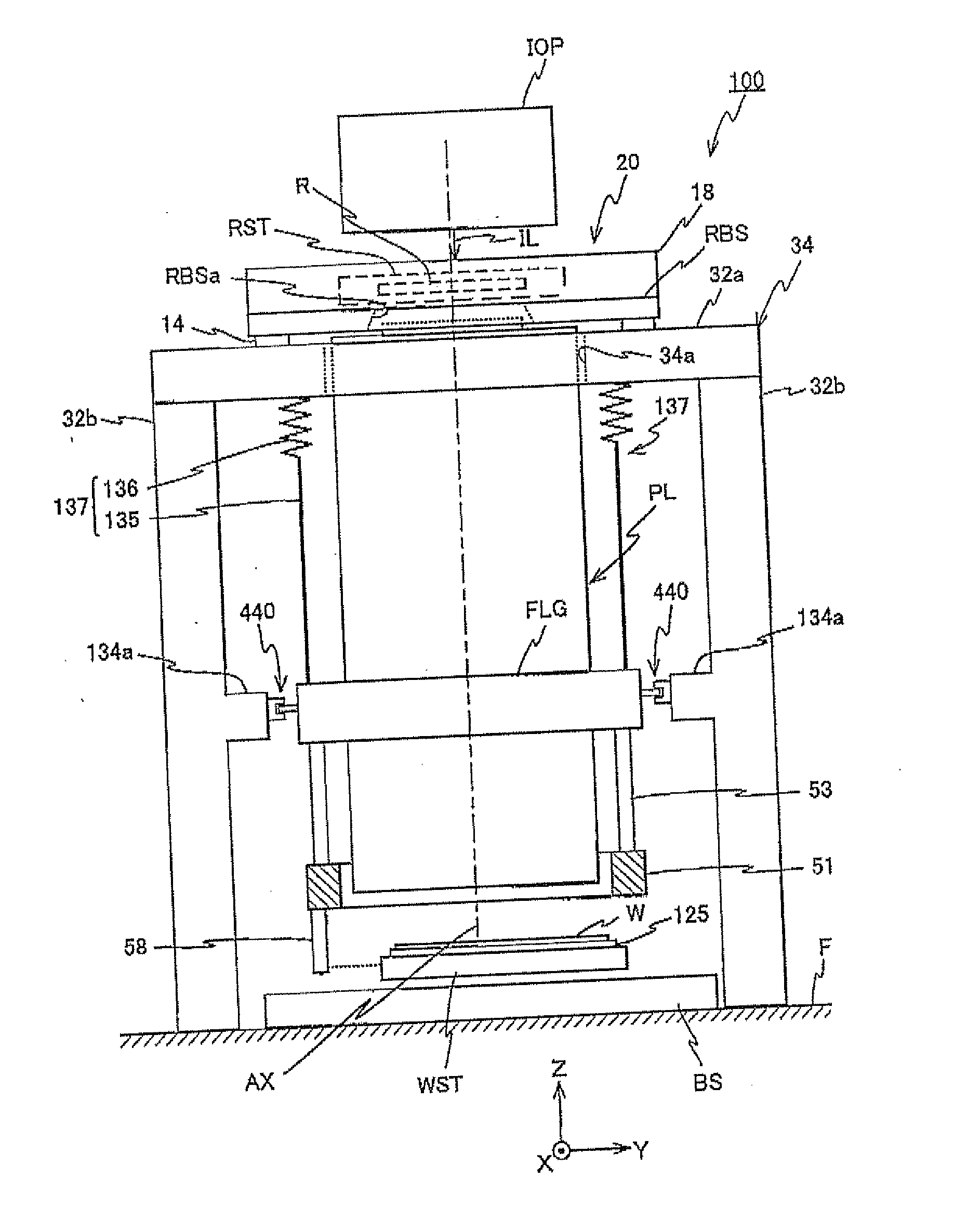

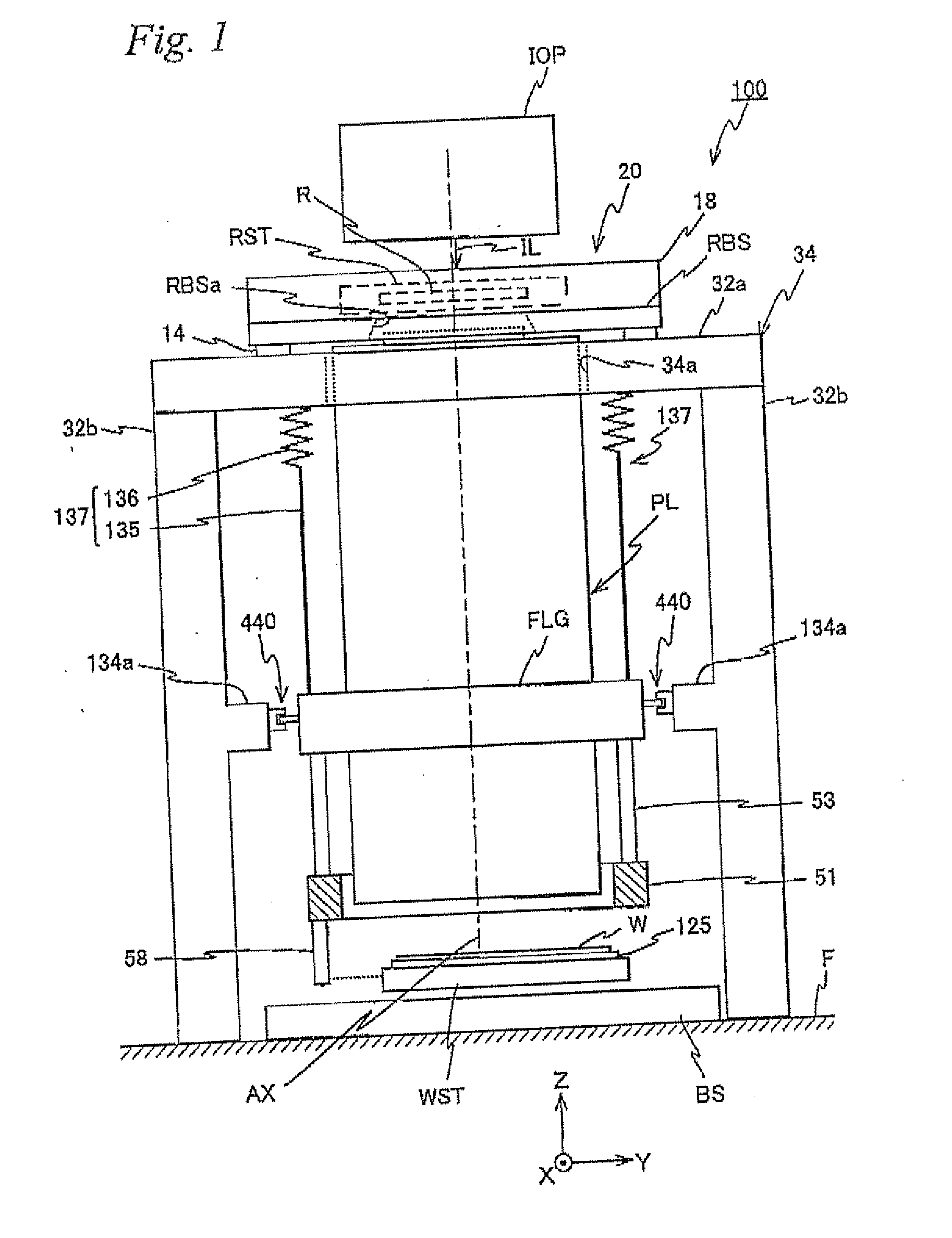

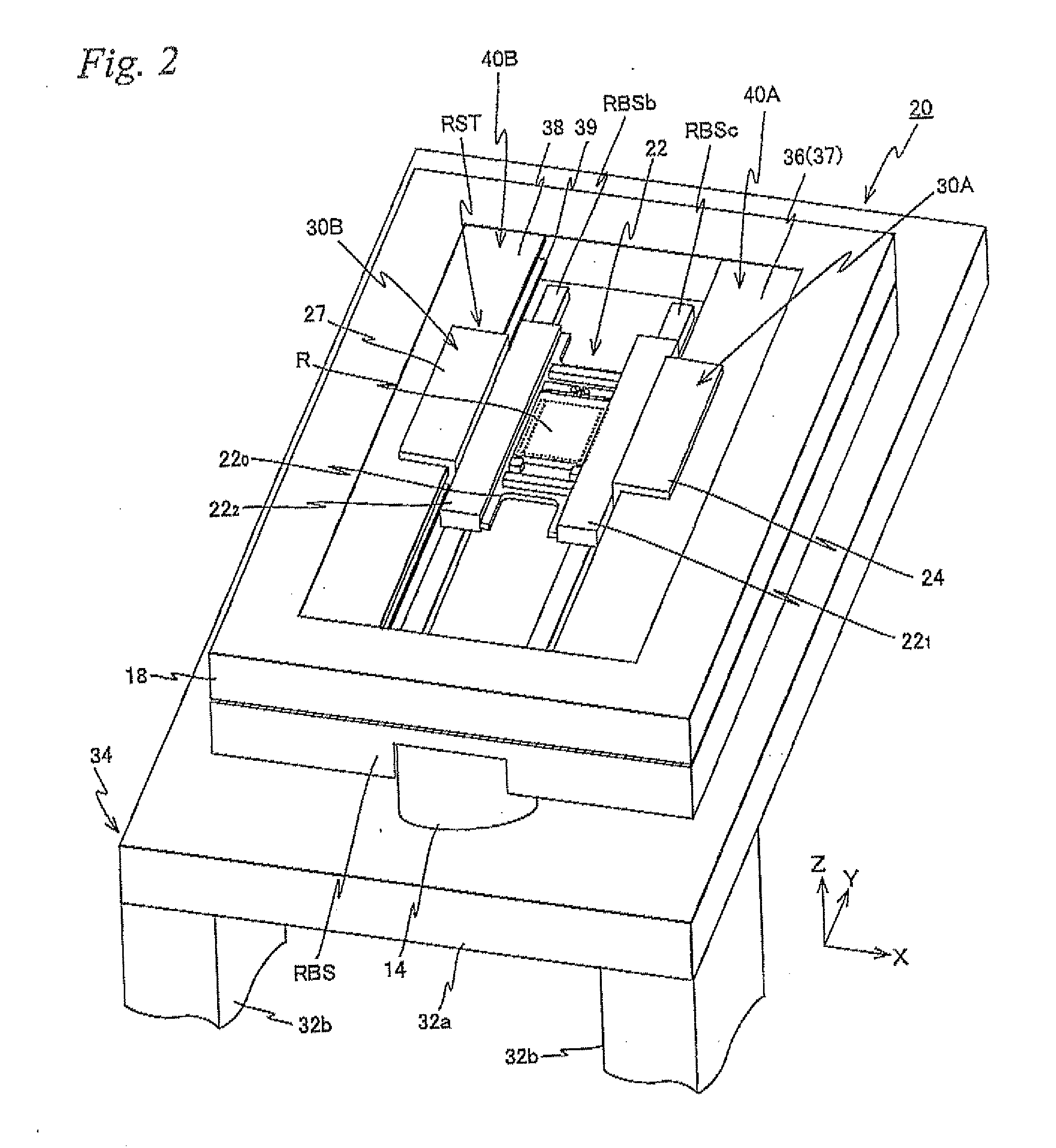

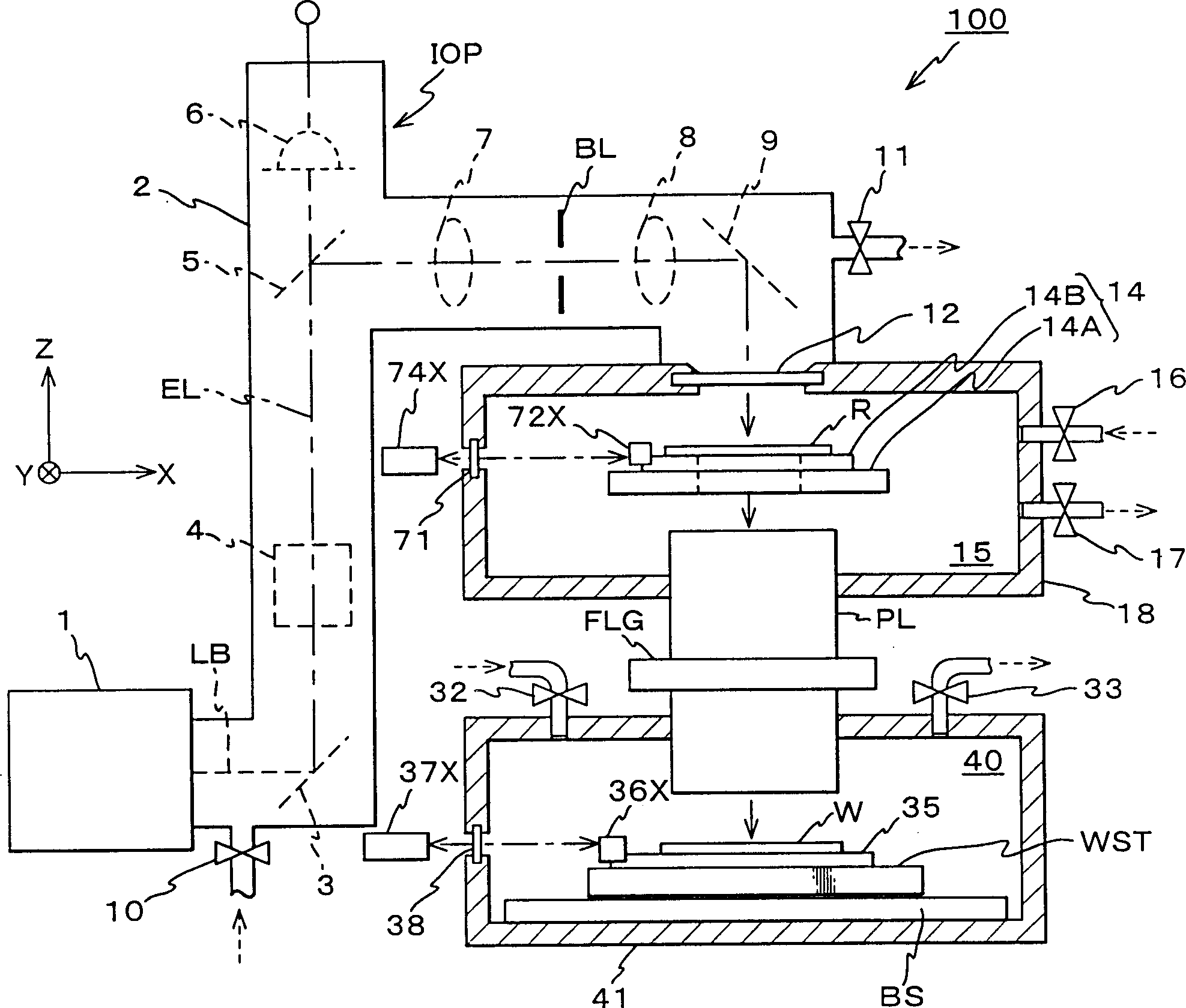

Movable body apparatus, exposure apparatus, exposure method, and device manufacturing method

ActiveUS20110032496A1Increase productionReduce weightMechanical apparatusPhotomechanical apparatusHigh accelerationEngineering

One pair each of a Y linear motor (a total of four) on the +X side and the −X side that drive a reticle stage include one pair each of a stator section (a total of four) and three each of a mover section (a total of six) on the +X side and the −X side. In this case, the three each of the mover sections on the +X side and the −X side configure one each of a mover. The mover section located in the center in the Z-axis direction of each of the movers is used in common by each pair of the Y linear motors. Therefore, the weight of the mover section (reticle stage) of the reticle stage device is reduced, which allows a higher acceleration. Further, the mover section located in the center in the Z-axis direction of each of the movers coincides with a neutral plane of the reticle stage.

Owner:NIKON CORP

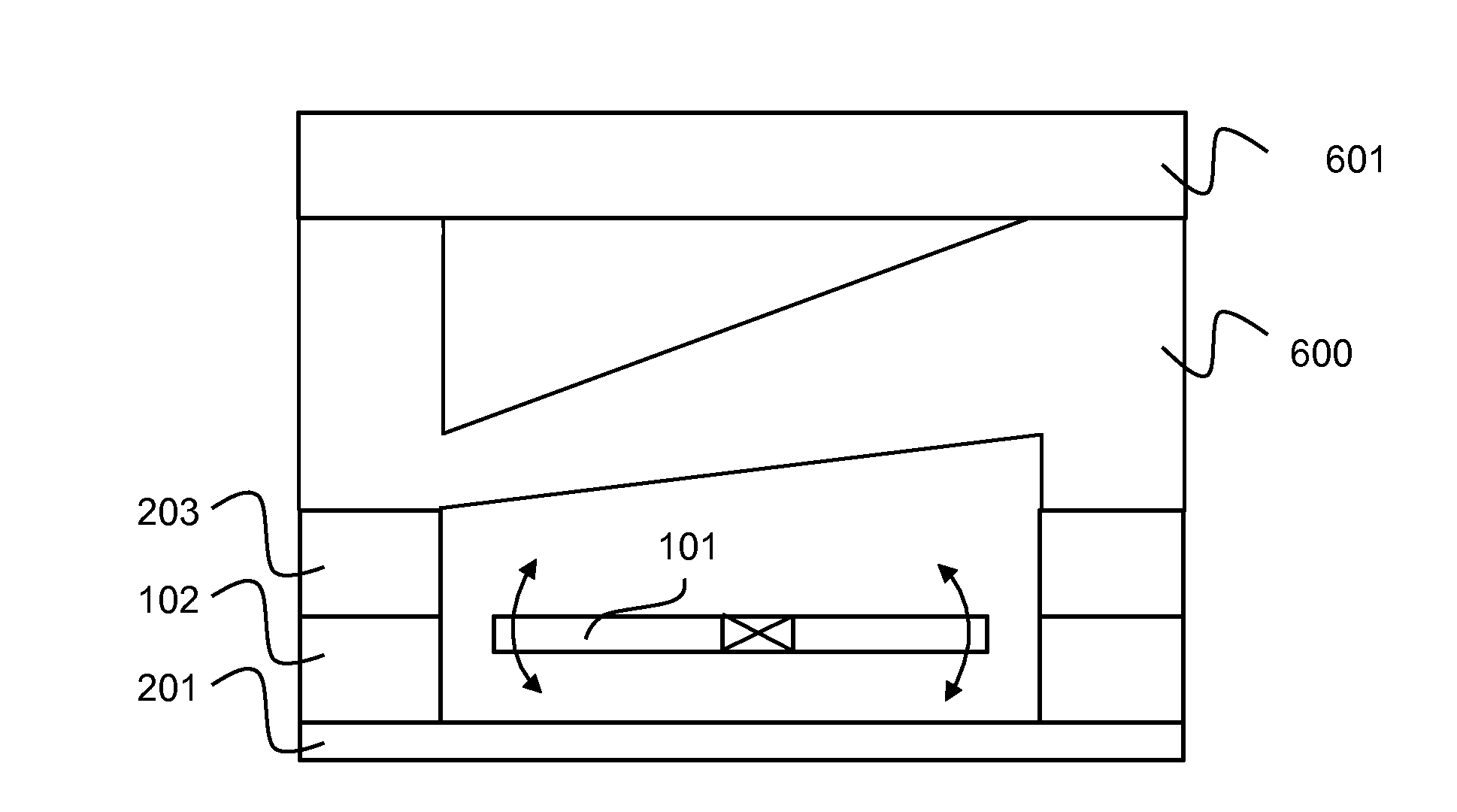

Optical MEMS scanning micro-mirror with speckle reduction

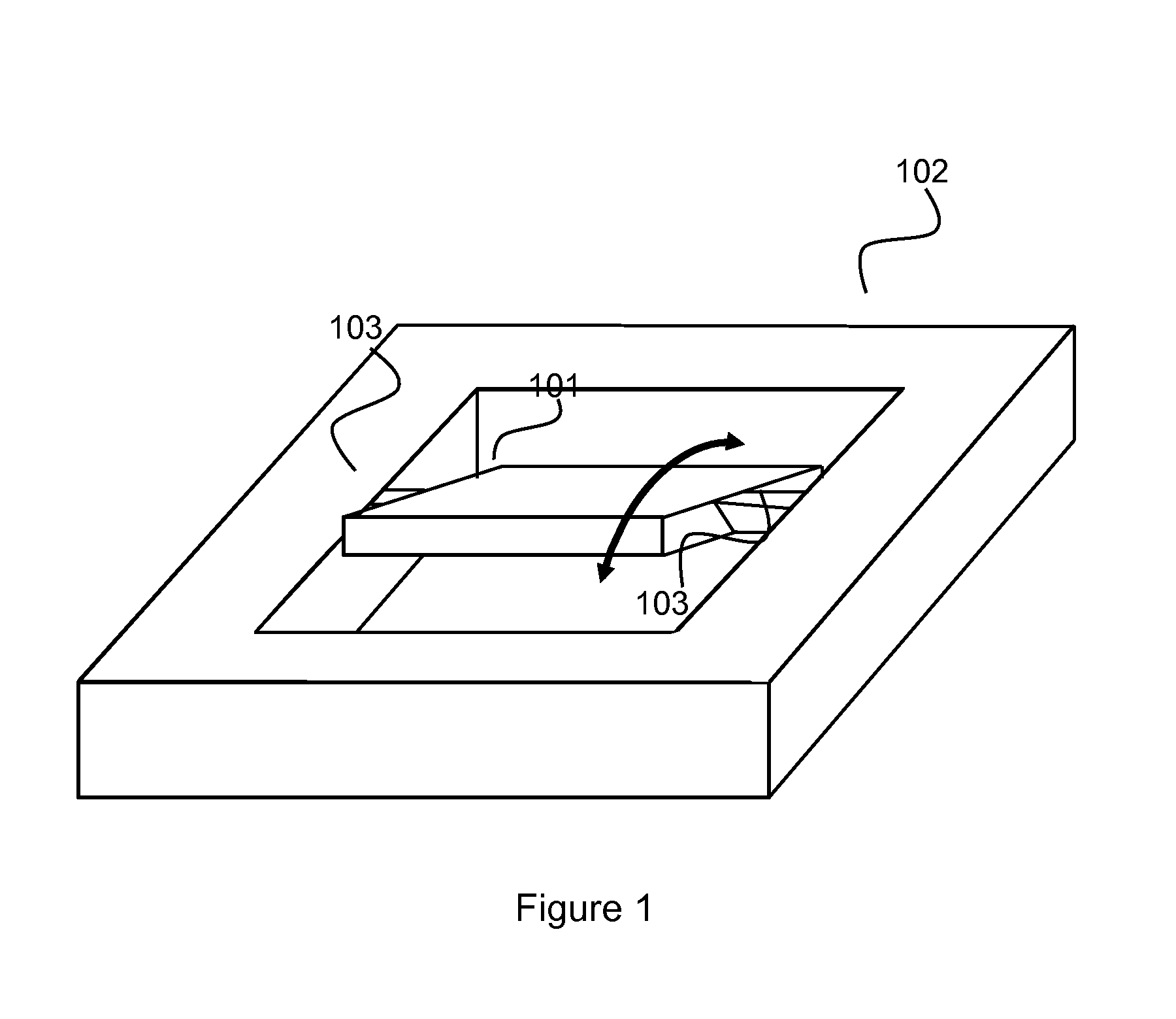

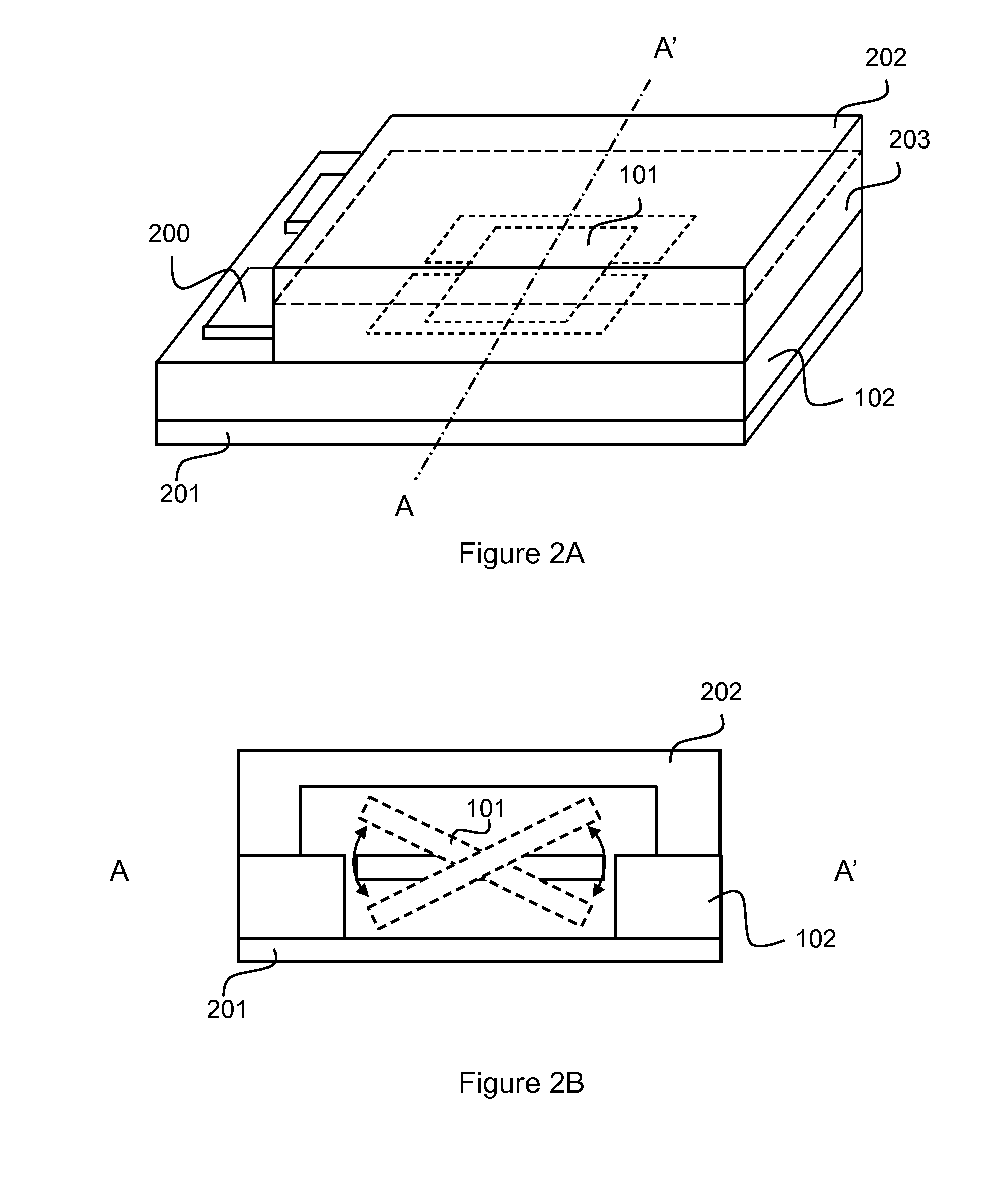

ActiveUS20130242275A1Reducing and suppressing speckleAvoid parasitic reflectionsProjectorsOptical elementsNeutral planePrism

Optical MEMS scanning micro-mirror comprising:—a movable scanning micro-mirror (101) pivotally connected to a MEMS body (102) substantially surrounding the lateral sides of the micro-mirror;—an transparent prism (500, 600) substantially covering the reflection side of the micro-mirror;—wherein said prism has its outer face non-parallel to the micro-mirror neutral plane N-N, thereby providing a dual anti-speckle and anti-reflection effect, namely against parasitic light. The invention also provides the corresponding micro-projection system and method for reducing speckle.

Owner:GOOGLE LLC

Light-Emitting Device and Electronic Device

ActiveUS20150325812A1Improve reliabilityAvoid damageElectroluminescent light sourcesSolid-state devicesHardnessThermal expansion

A highly reliable light-emitting device is provided. Damage to an element due to externally applied physical power is suppressed. Alternatively, in a process of pressure-bonding of an FPC, damage to a resin and a wiring which are in contact with a flexible substrate due to heat is suppressed. A neutral plane at which stress-strain is not generated when a flexible light-emitting device including an organic EL element is deformed, is positioned in the vicinity of a transistor and the organic EL element. Alternatively, the hardness of the outermost surface of a light-emitting device is high. Alternatively, a substrate having a coefficient of thermal expansion of 10 ppm / K or lower is used as a substrate that overlaps with a terminal portion connected to an FPC.

Owner:SEMICON ENERGY LAB CO LTD

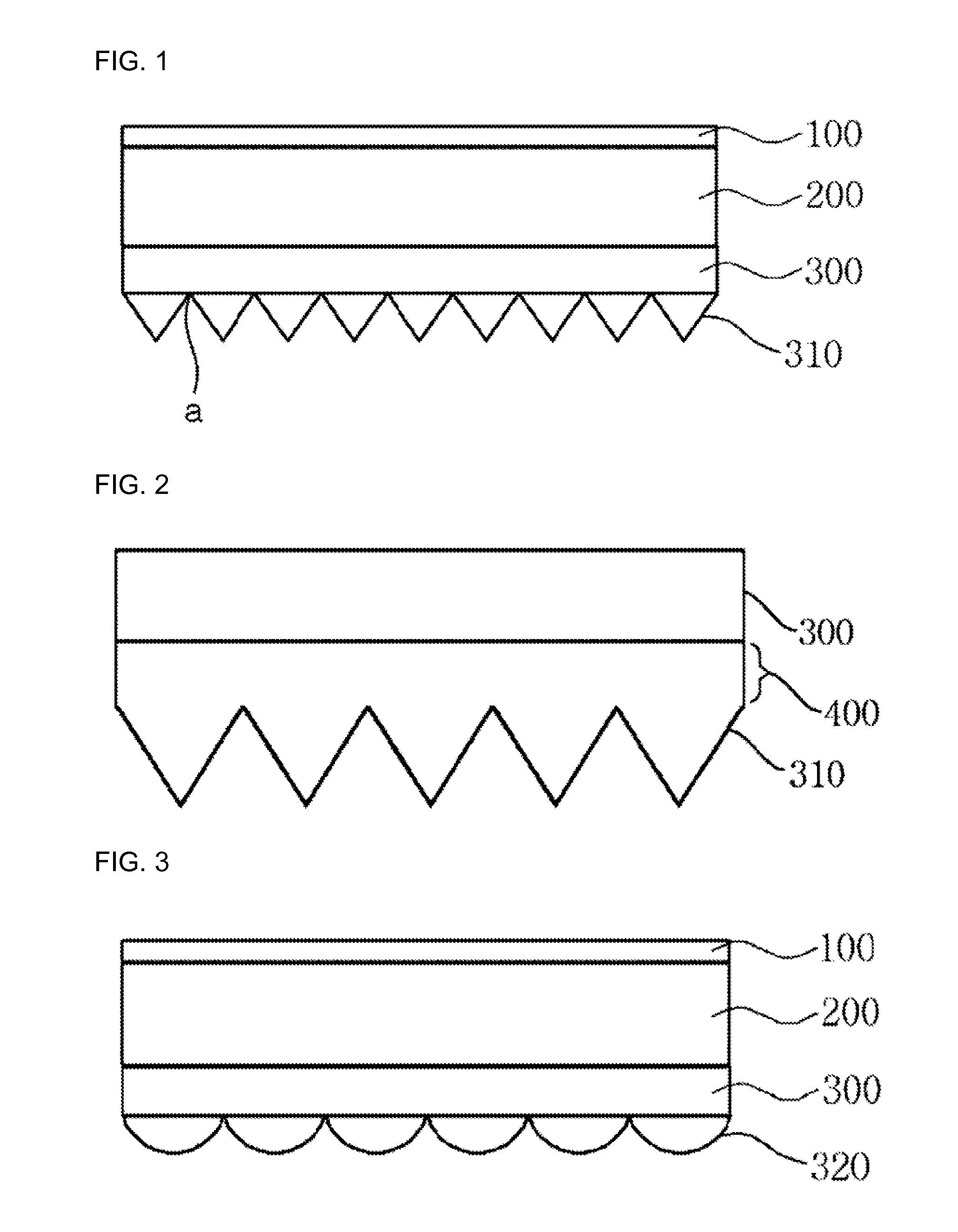

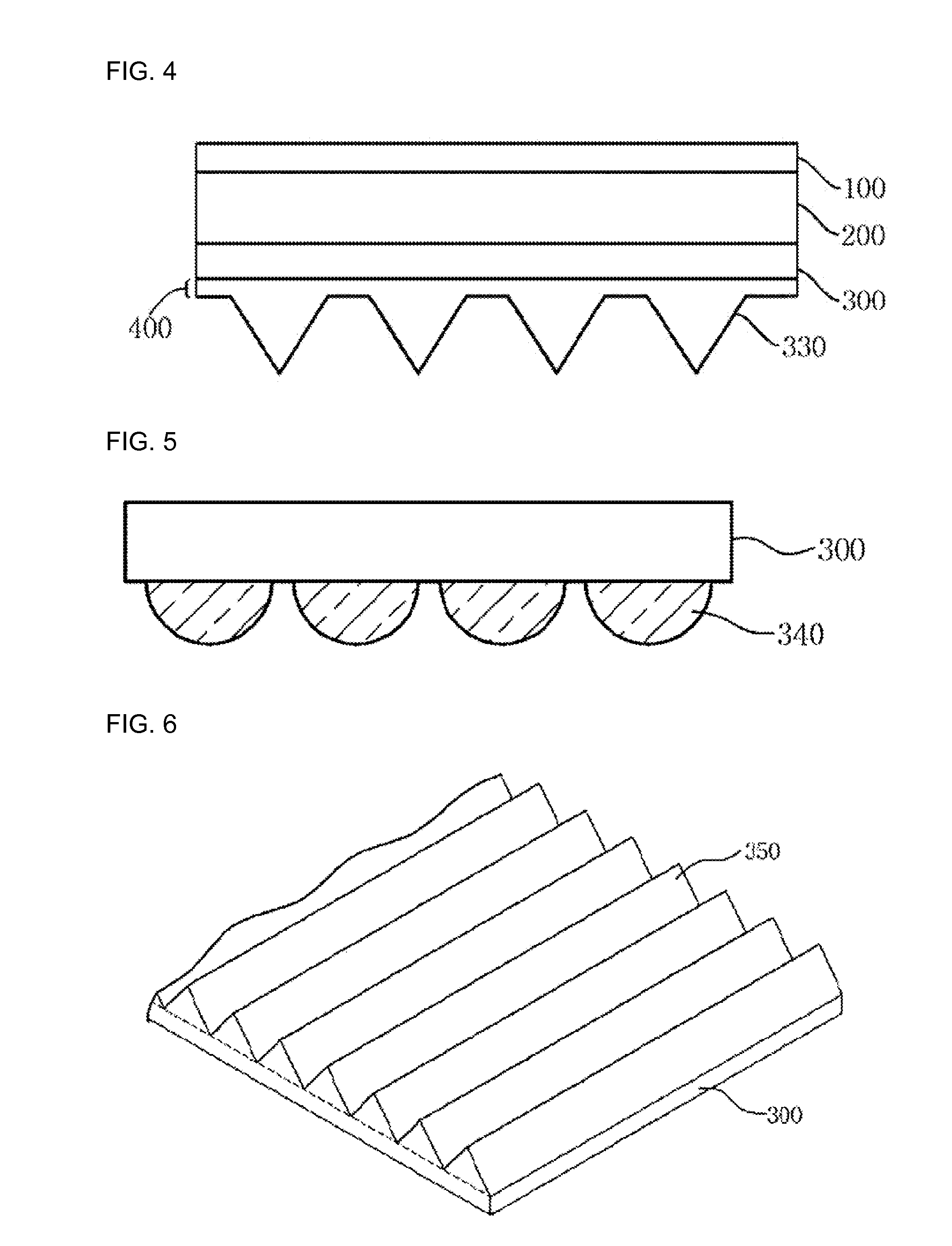

Flexible display device

ActiveUS20160014883A1Avoid crackingIncreased durabilityPrinted circuit detailsDigital data processing detailsDisplay boardEngineering

A flexible display device including; a base film; a display sheet formed over the base film; and a structural pattern formed below the base film for moving a neutral plane with respect to a bending stress applied to the display sheet to a layer having relatively low rupture point among the layers consisting of the display sheet. The neutral plane is moved to a layer having a relative low rupture point in a flexible display device by forming the structural patterns so that the bending stress applying to the layer having a relative low rupture point can be minimized.

Owner:LMS

OLED panel and image display device including the same

ActiveUS20180287092A1Enhanced visible propertySemiconductor/solid-state device detailsSolid-state devicesDisplay deviceComputer module

An organic light emitting diode (OLED) panel includes an OLED module layer, and a first adhesive layer formed on a surface of the OLED module layer. A neutral plane is formed at an interface between the first adhesive layer and the OLED module layer. A bending deformation and a stress of the OLED module layer may be avoided, and damages of the OLED module layer may be reduced.

Owner:DONGWOO FINE CHEM CO LTD

Stair tread assembly and method

A replacement or repair stair tread assembly for covering over an existing worn stair tread includes a core that is surrounded by hardwood edge members, of which at least on edge has a bullnose. The edge members and core are mated at tongue and groove joints. The bullnose has a greater depth of section than the core. The core is a multi-ply matrix with veneer surface skins of the same grain orientation and type of wood. The multiple plies are arranged such that successive layers have cross-wise grain orientation. The plies of the core have symmetrically balanced properties relative to the neutral axis or neutral plane of the core in bending, both cross-wise and length-wise. The balanced properties may pertain to water absorption and to resistance to bending.

Owner:MOULURE ALEXANDRIA MOLDING

Flexible packaging device of a microbattery

InactiveUS20100310932A1Flexible and easy to fabricateAvoid it happening againFinal product manufactureSynthetic resin layered productsThin layerYoung's modulus

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

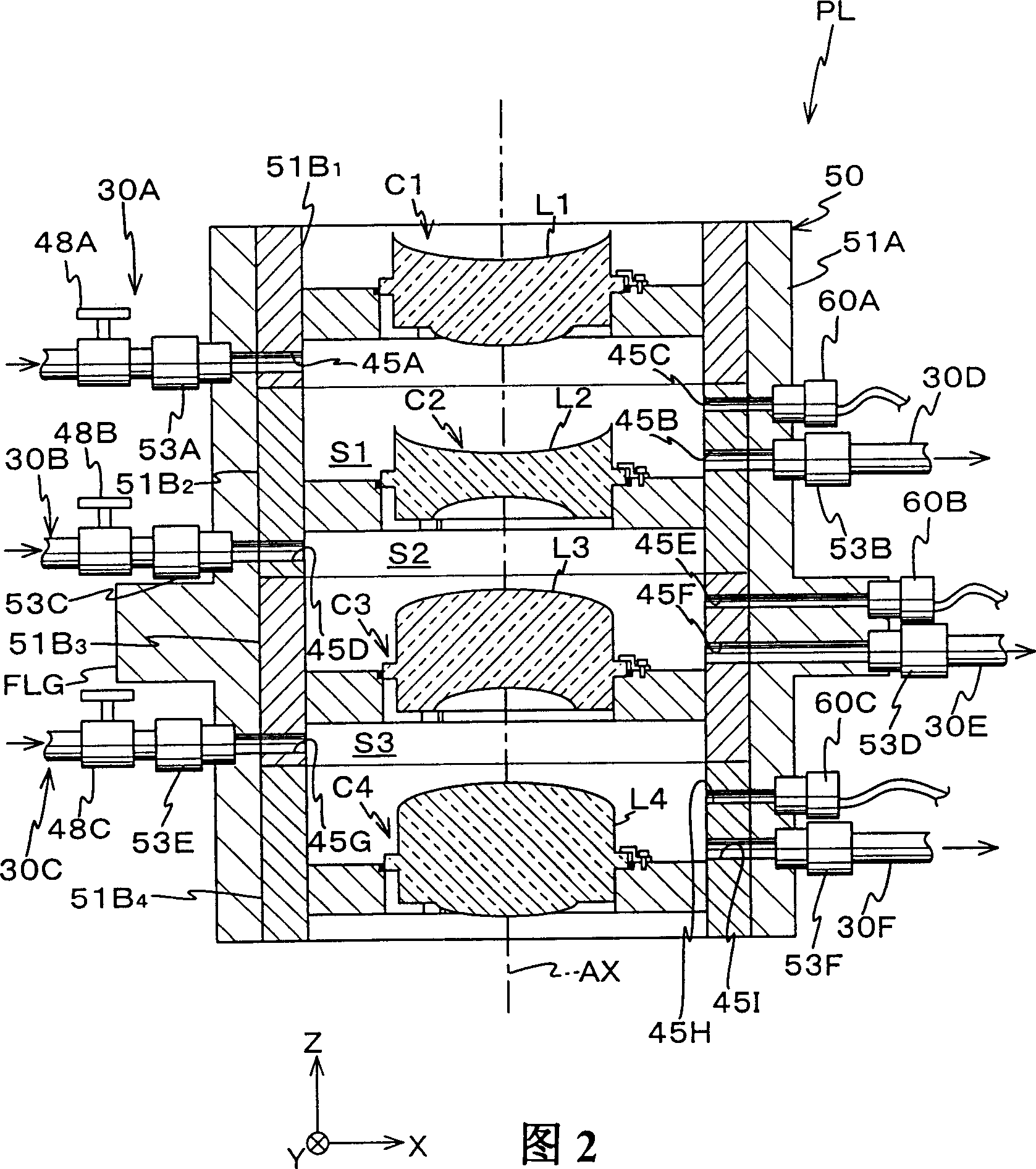

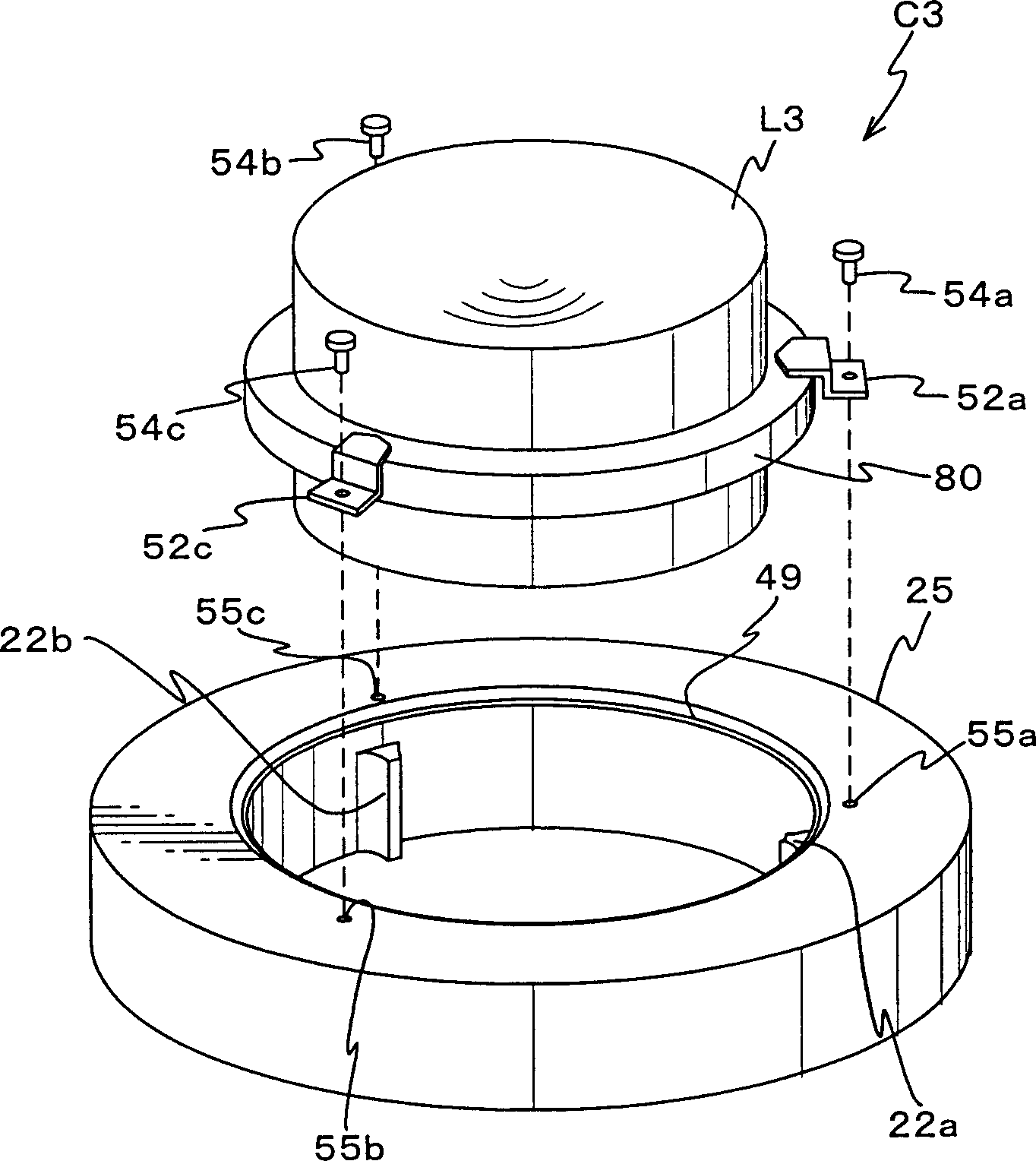

Method and device for holding optical member, optical device, exposure apparatus and device manufacturing method

InactiveCN1440512AIncrease productionHighly integratedSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusNeutral planeTensile strain

A flange portion is provided to at least a part of the periphery at the center position in the direction of the optical axis of a lens. The lens is held with clamping members and a lens holding metallic part, with the flange portion pressed by the clamping members. The portion where the flange portion is provided, suffers no compressive strain and tensile strain due to the bending of the lens, and is a part of the periphery of a neutral plane, which is the farthest plane from the optical surface of the lens. Therefore, the influence of the clamping force on the flange portion acting on other portions of the lens is reduced to the utmost, and the deformation of the optical surface due to the force acting on the flange portion is reduced to a minimum. As a result, the deterioration of the optical properties of the lens can be suppressed to the utmost.

Owner:NIKON CORP

Weather strip

InactiveUS20070245634A1Prevent intrusionGood flexibilityVehicle sealing arrangementsSealing arrangementsNeutral planeMechanical engineering

There is provided a weather strip in which a mounting base portion of the weather strip includes a portion formed into a substantially L-shape in cross section which has at least a bottom wall and an exterior side wall. A pressure sensitive adhesive double coated tape is securely affixed to an internal surface of the exterior side wall. A stretch and contraction prevention portion is formed on the exterior side wall in a position which lies more centrally in a width direction of the exterior side wall than a connecting portion where the exterior side wall and the bottom wall are connected together. When the mounting base portion is curved in the width direction, a neutral plane of the curve is made to reside within the stretch and contraction prevention portion.

Owner:TOYODA GOSEI CO LTD

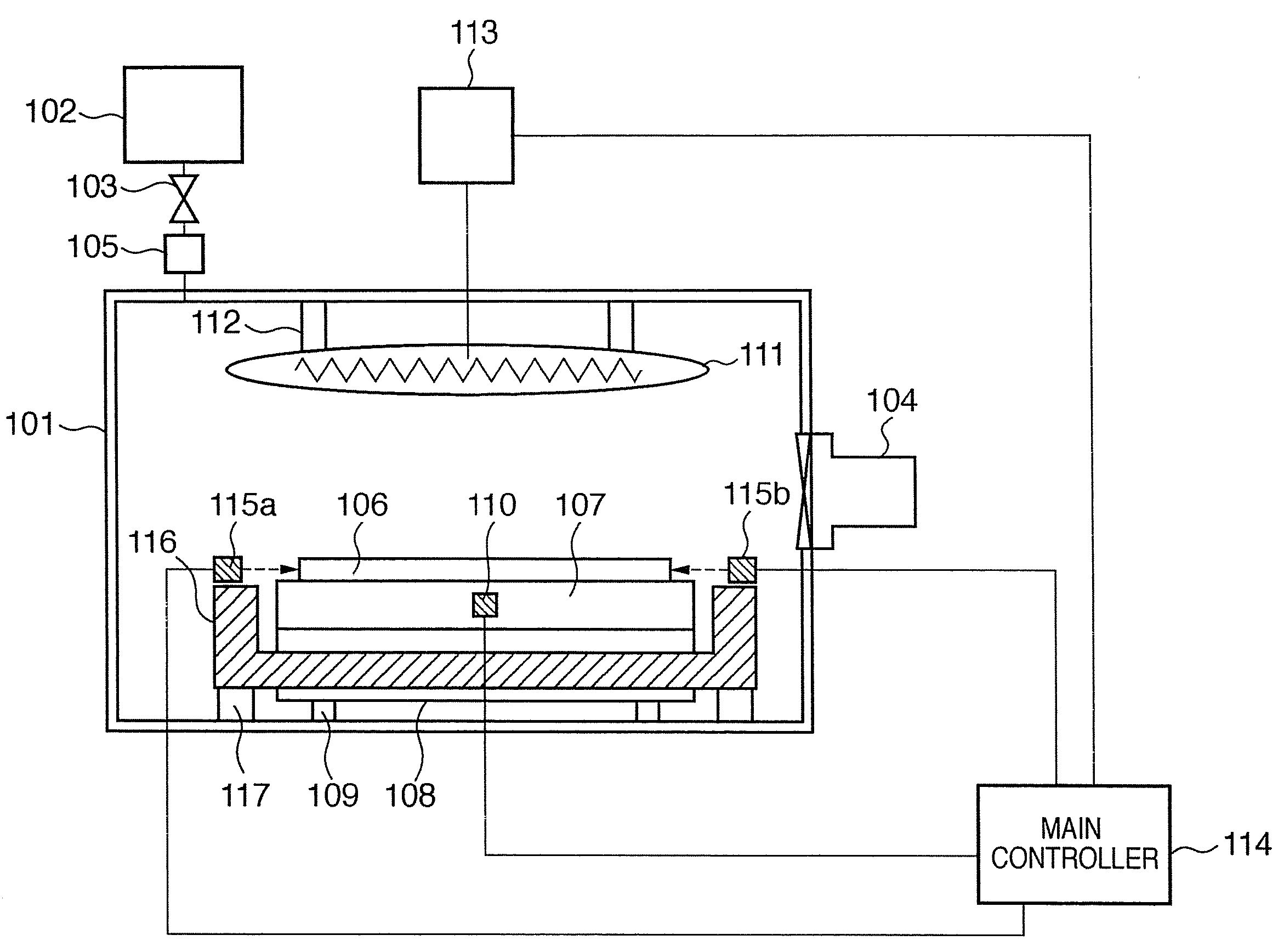

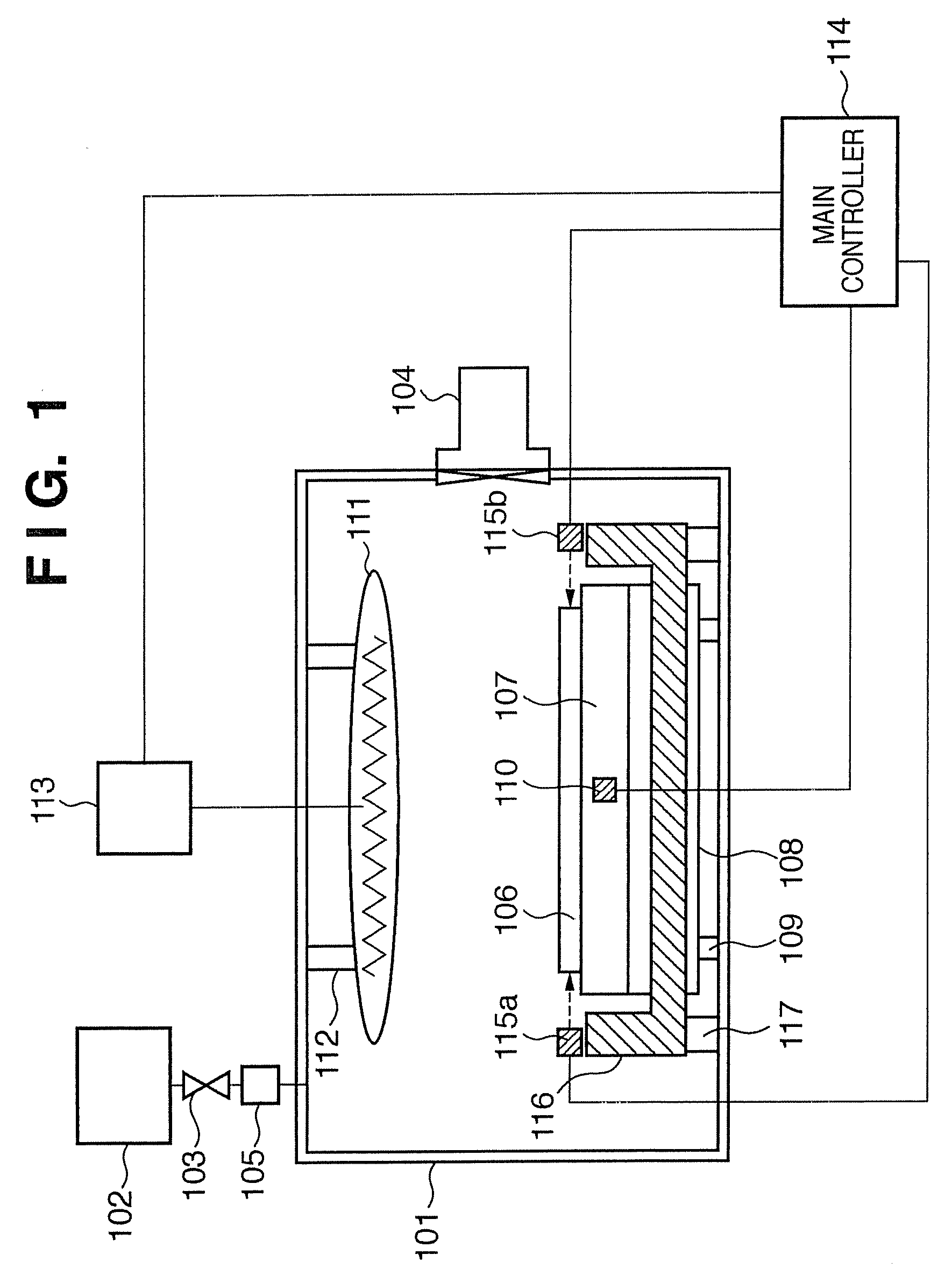

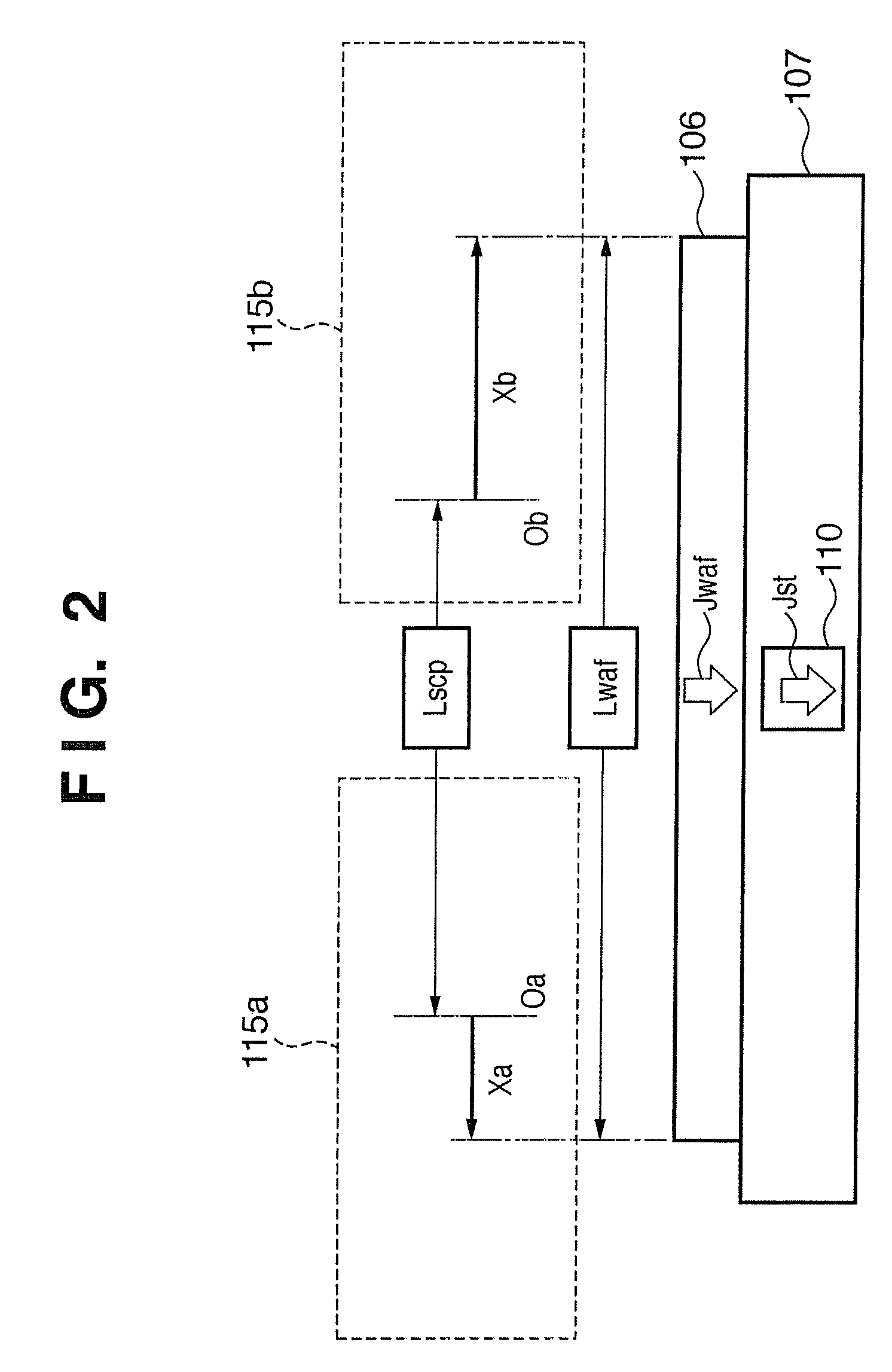

Substrate surface temperature measurement method, substrate processing apparatus using the same, and semiconductor device manufacturing method

InactiveUS20090219969A1High measurement accuracySemiconductor/solid-state device testing/measurementThermometers using material expansion/contactionEdge surfaceDevice material

The expansion amount of a substrate (106) is measured using a scope (115a, 115b) which observes the edge surface of the substrate (106). The temperature of the neutral plane of the substrate (106) is calculated using the expansion amount of the substrate (106). A heat flux in the substrate (106) is measured using a heat flux sensor (110). The temperature difference between the neutral surface and upper surface of the substrate (106) is calculated from the measured heat flux and the heat resistance of the substrate (106). The temperature of the surface of the substrate (106) is obtained using the temperature difference and the temperature of the neutral plane of the substrate.

Owner:CANON ANELVA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com