Flexible array substrate, display panel and preparation method

A flexible array and display panel technology, used in semiconductor/solid-state device manufacturing, photovoltaic power generation, instruments, etc., can solve the problems of abnormal display, easy fracture, high stress, etc., to reduce thickness, increase thickness, and improve bending resistance. The effect of folding performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

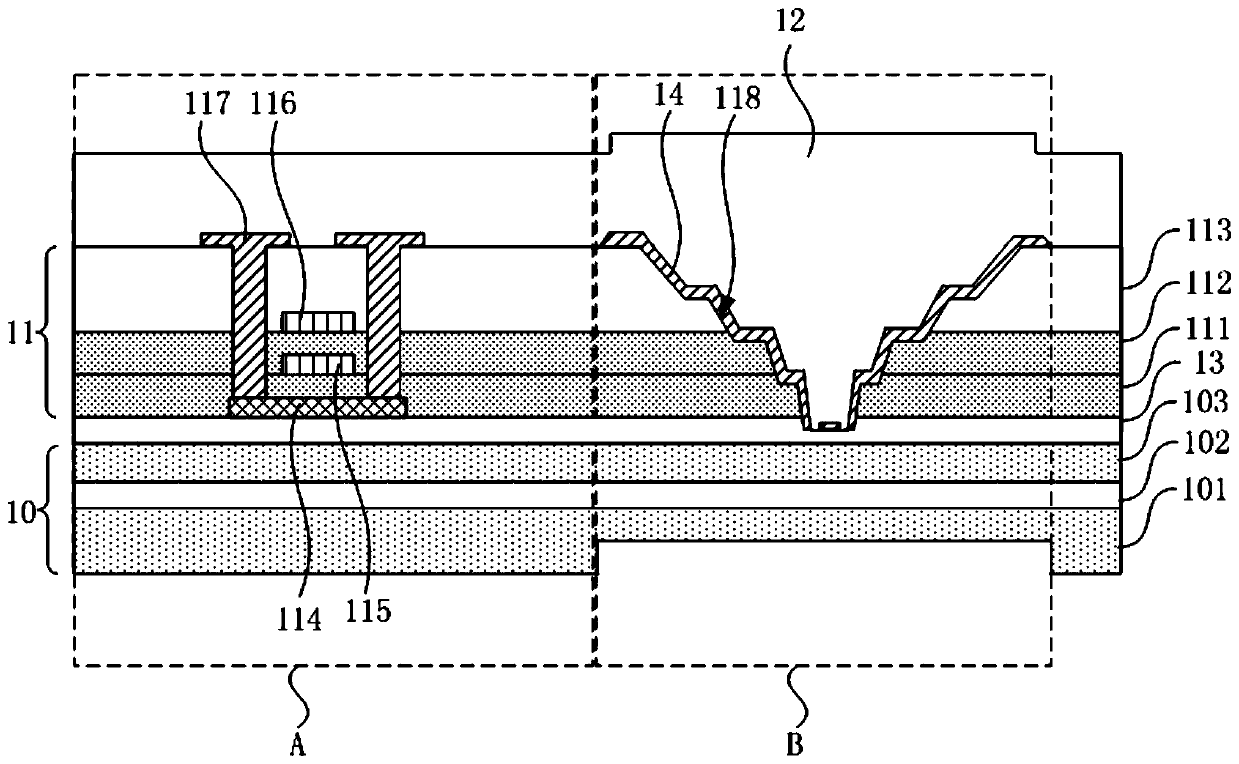

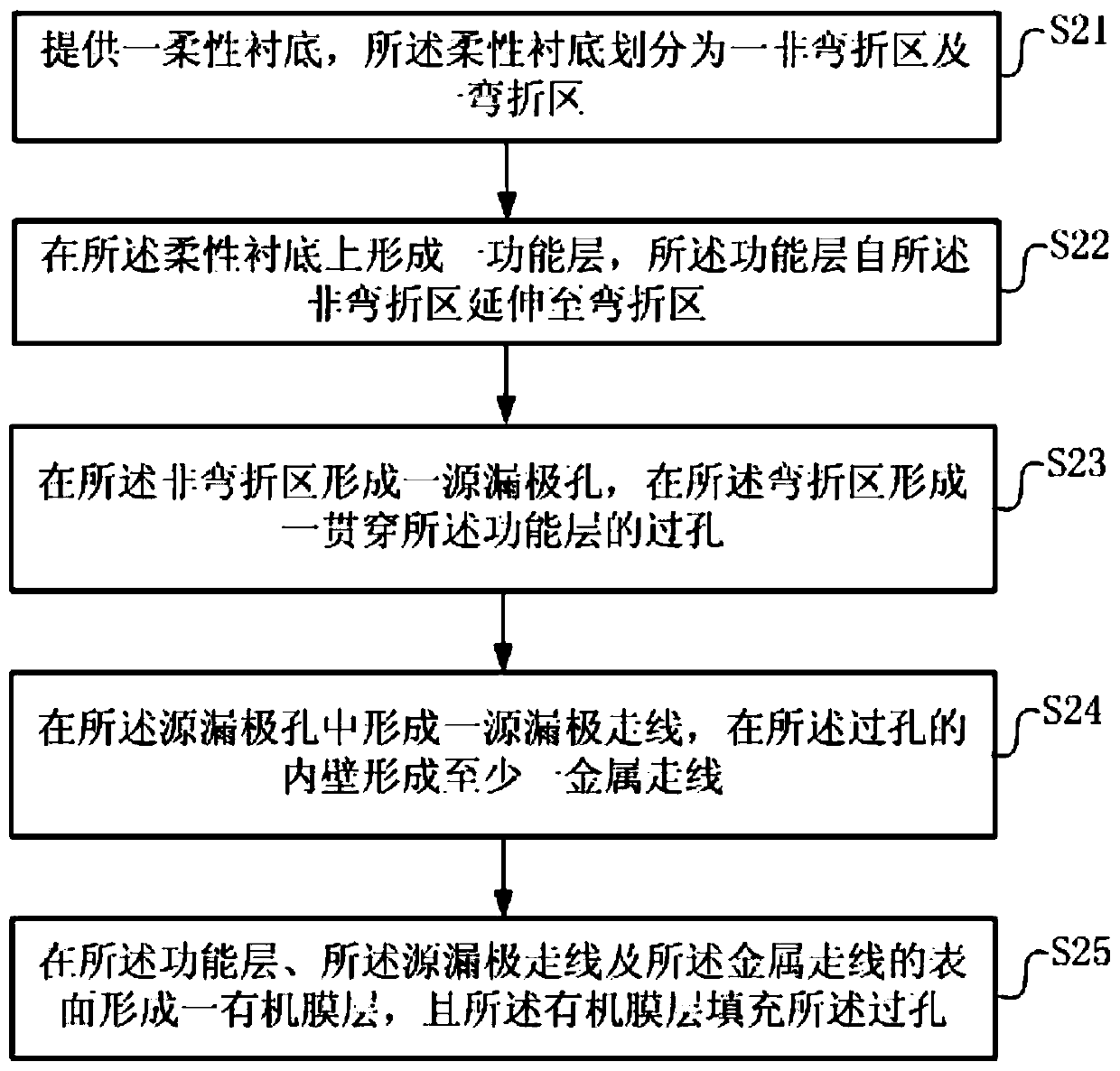

[0031] The present invention also provides a method for preparing the above-mentioned flexible array substrate. figure 2 It is a schematic diagram of the steps of an embodiment of the manufacturing method of the flexible array substrate of the present invention. see figure 2 , the preparation method of the flexible array substrate of the present invention comprises the following steps: step S21, providing a flexible substrate, the flexible substrate is divided into a non-bending area and a bending area; step S22, on the flexible substrate forming a functional layer, the functional layer extending from the non-bending region to the bending region; Step S23, forming a source and drain hole in the non-bending region, forming a hole through the bending region in the bending region A via hole in the functional layer; step S24, forming a source-drain wiring in the source-drain hole, and forming at least one metal wiring on the inner wall of the via hole; step S25, forming a wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com