Method and device for holding optical member, optical device, exposure apparatus and device manufacturing method

A technology for optical components and optical devices, which can be used in microlithography exposure equipment, optical components, semiconductor/solid-state device manufacturing, etc., and can solve the problem of high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

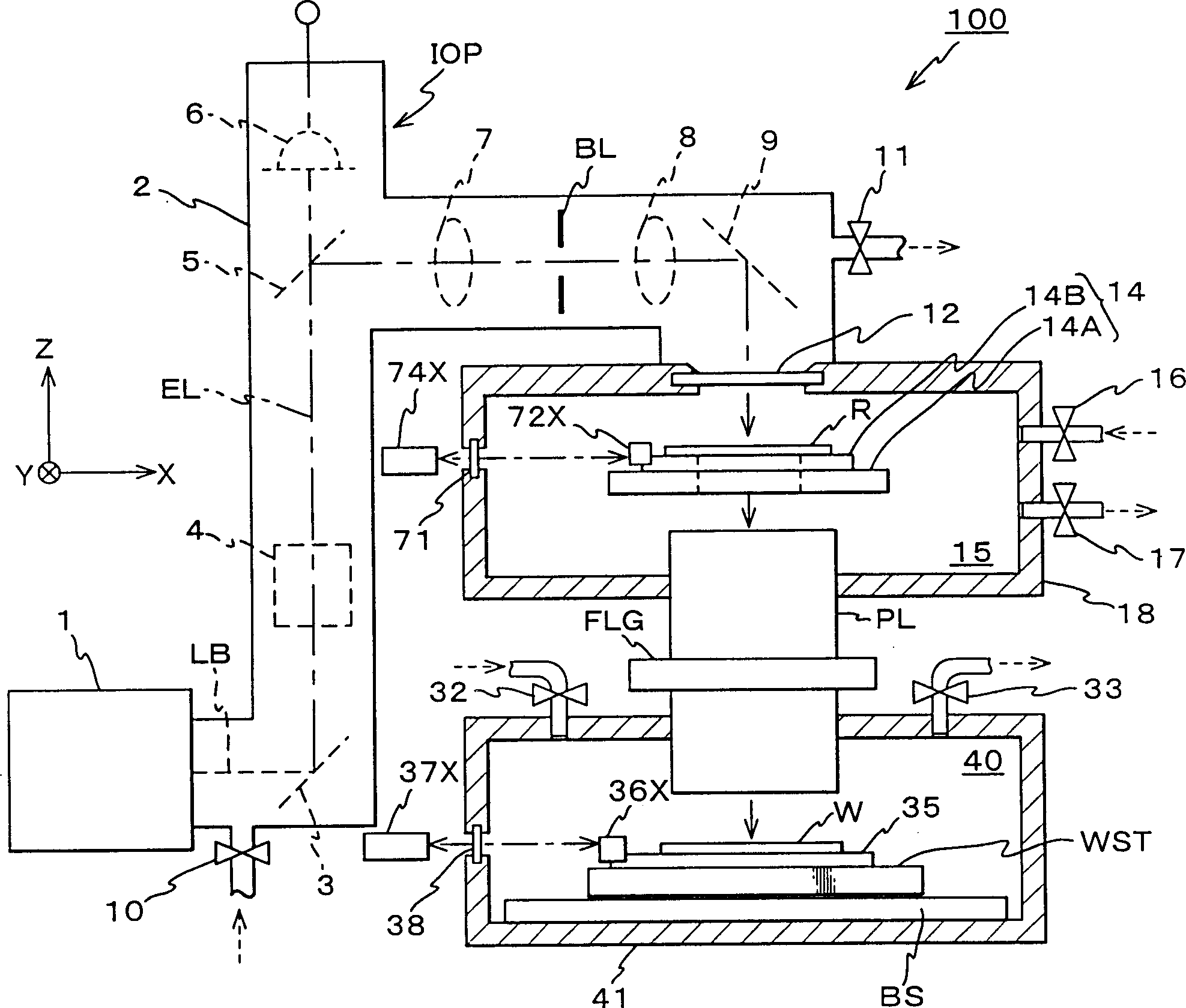

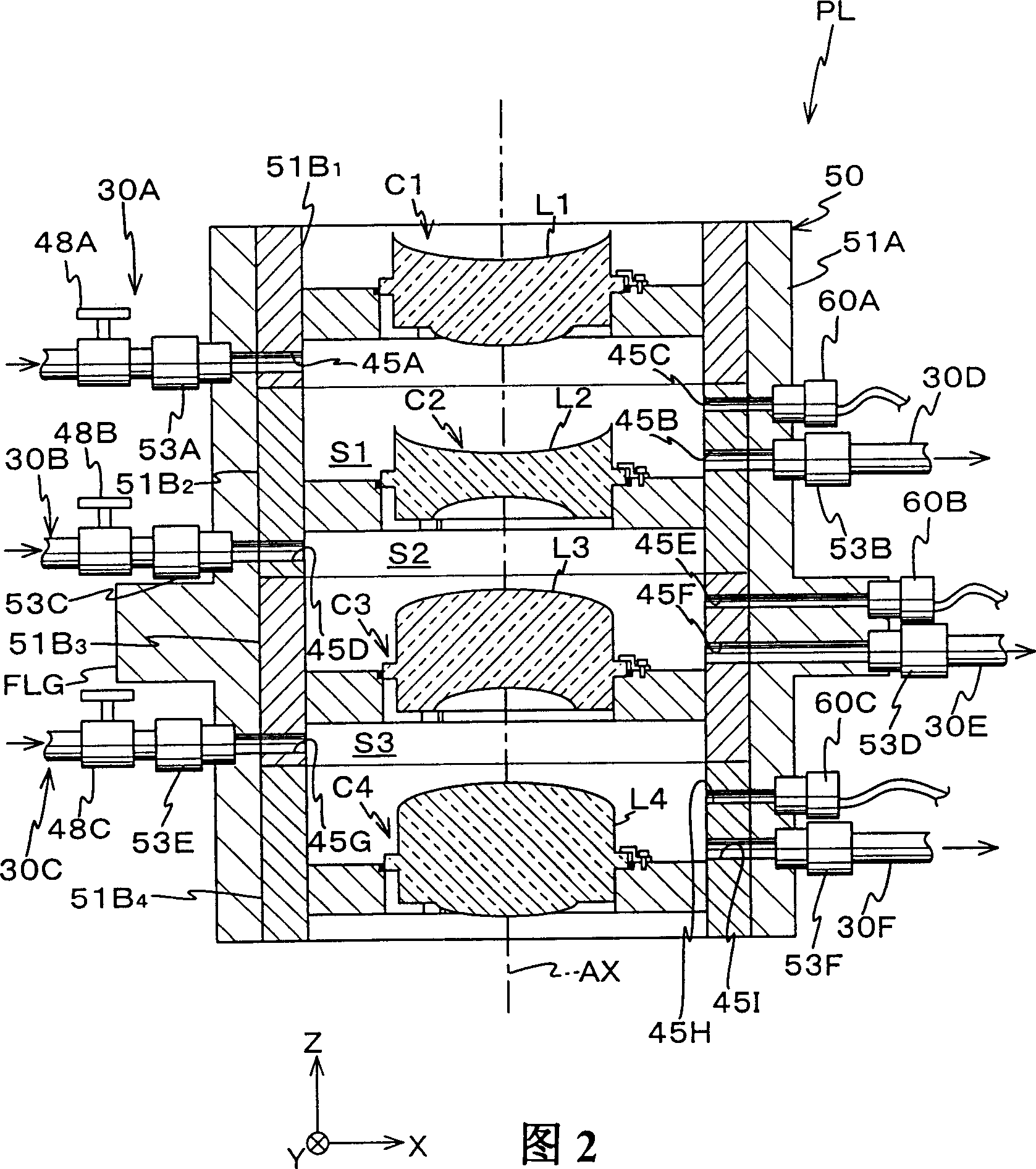

[0108] see below Figure 1~5 A first embodiment of the present invention is described. figure 1 The structure of the exposure apparatus related to the first embodiment is schematically shown. This exposure apparatus 100 is a projection exposure apparatus based on the step-and-scan method, which irradiates the reticle R with the exposure illumination light EL serving as an energy beam in the vacuum ultraviolet region, and in a predetermined scanning direction (in this case, The X-axis direction) relatively scans the reticle R and the wafer W to transfer the pattern of the reticle R as a mask to the wafer W as a substrate through the projection optical system RL.

[0109] The exposure apparatus 100 includes a light source 1 and an illumination optical system IOP. It also includes components such as an illumination system for illuminating the reticle R with exposure illumination light (hereinafter referred to as "exposure light") EL, a reticle stand 14 serving as a mask stand ...

no. 2 example

[0201] Next, referring to FIG. 6, a second embodiment of the present invention will be described. Structures and components identical or identical to those in the first embodiment are denoted by the same reference numerals and briefly described or omitted entirely.

[0202] In the second embodiment, the structure of a projection optical system serving as an optical device is different from that of the first embodiment. Other parts are the same as the first embodiment; therefore, the following description will mainly focus on this difference.

[0203] FIG. 6 shows a longitudinal cross-sectional view of projection optical system PL1 according to the second embodiment. The present projection optical system PL1 is similar to the projection optical system PL in the first embodiment, except that the pressure sensors 60A, 60B, and 60C and the airflow control valves 48A, 48B, and 48C connected to the sealed chambers S1, S2, S3, respectively, are removed, and A pair of pressure regul...

no. 4 example

[0223] A fourth embodiment of the present invention will be described below with reference to FIGS. 8 to 12 . Structures and components identical or identical to those in the first embodiment are denoted by the same reference numerals and briefly described or omitted entirely.

[0224] With the exposure apparatus related to the fourth embodiment, the structure of the projection optical system serving as the optical device is different from the aforementioned first embodiment. Other parts are the same as the first embodiment; therefore, the following description will mainly focus on this difference.

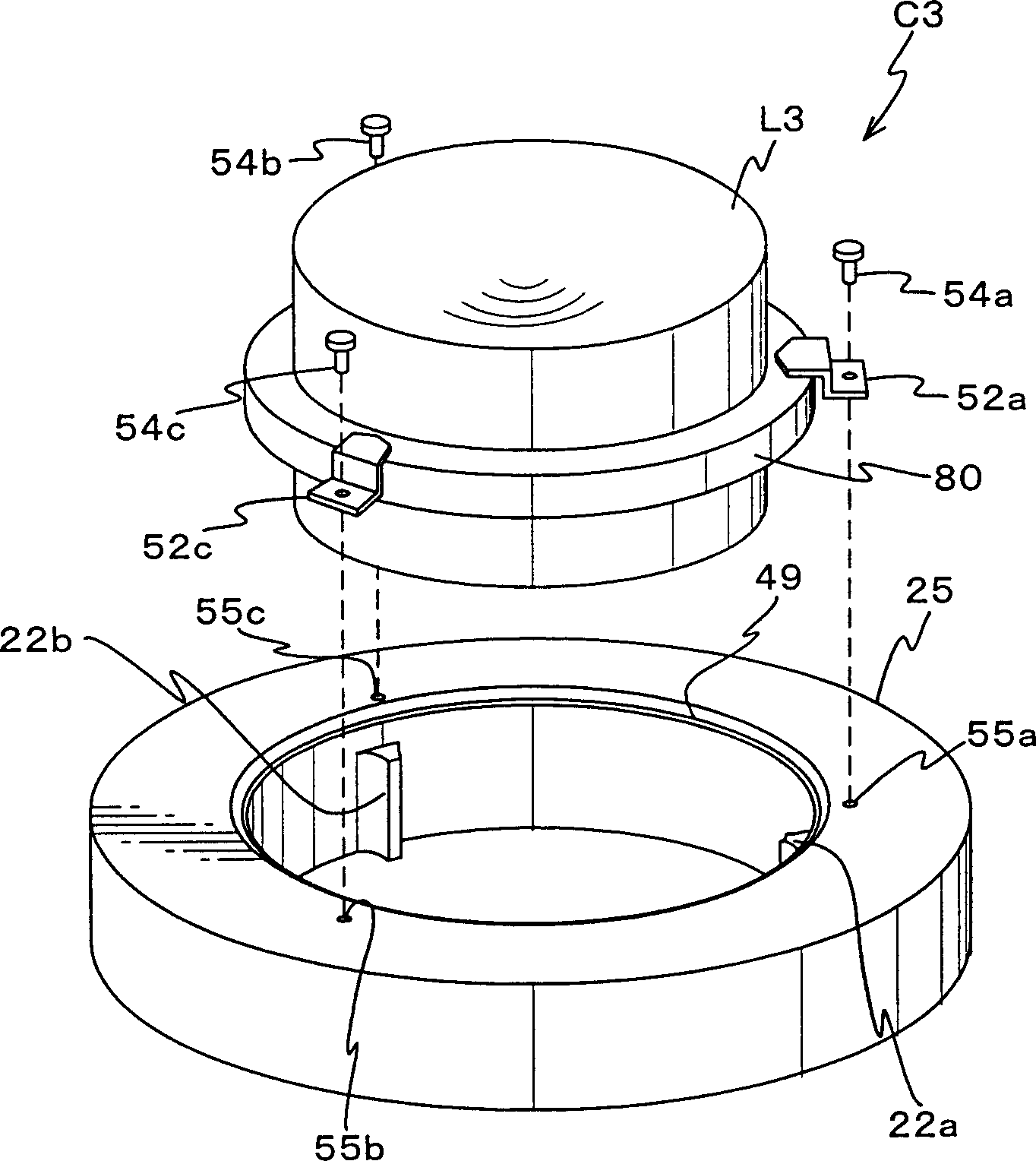

[0225] FIG. 8 shows a longitudinal sectional view of projection optical system PL3 according to the fourth embodiment, Figure 9 A cross-sectional view of projection optical system PL3 near line B-B in FIG. 8 is shown. Figure 10 also shows projection optical system PL3 along Figure 9 A cross-sectional partial end view taken along line C-C in middle, while Figure 11 Indicates...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com