Water-rich sandy gravel geological pile group hole forming construction method

A construction method and technology of sand and pebbles, which are applied in sheet pile walls, earthwork drilling, and foundation structure engineering, can solve problems such as high safety risks, large construction impacts, and good hole quality, achieving low environmental pollution and high quality Guaranteed and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the embodiments and the accompanying drawings.

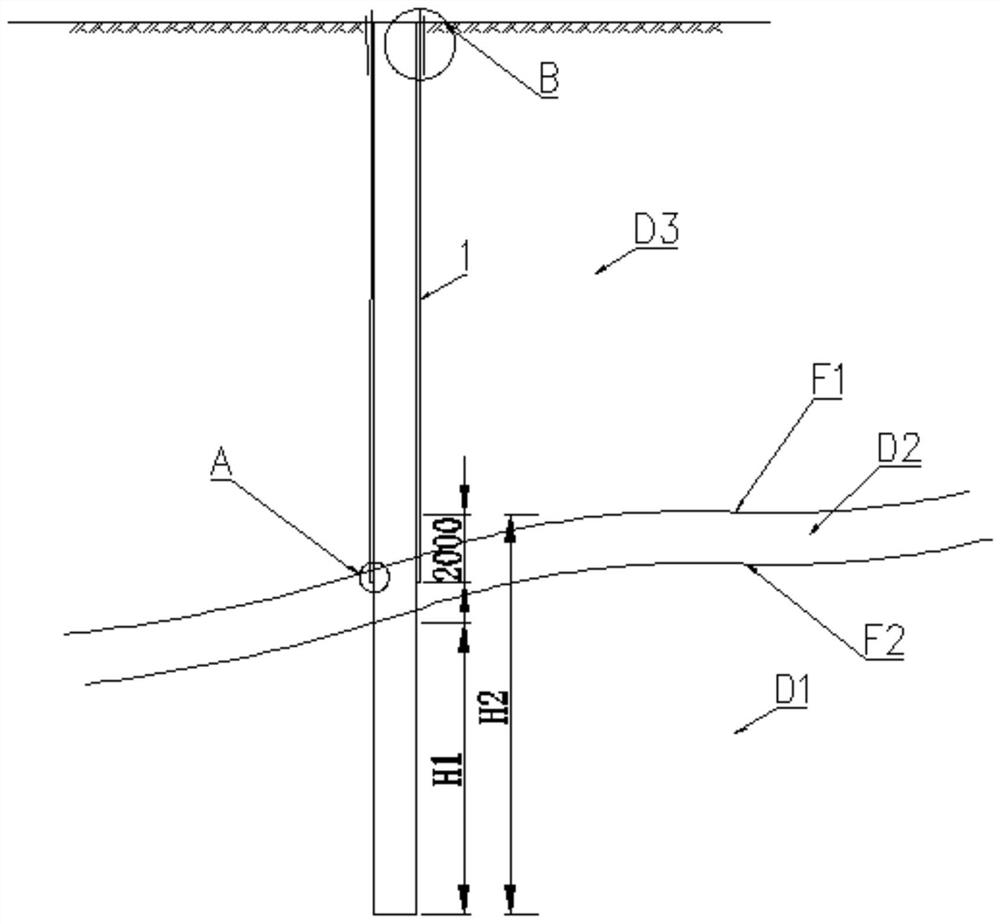

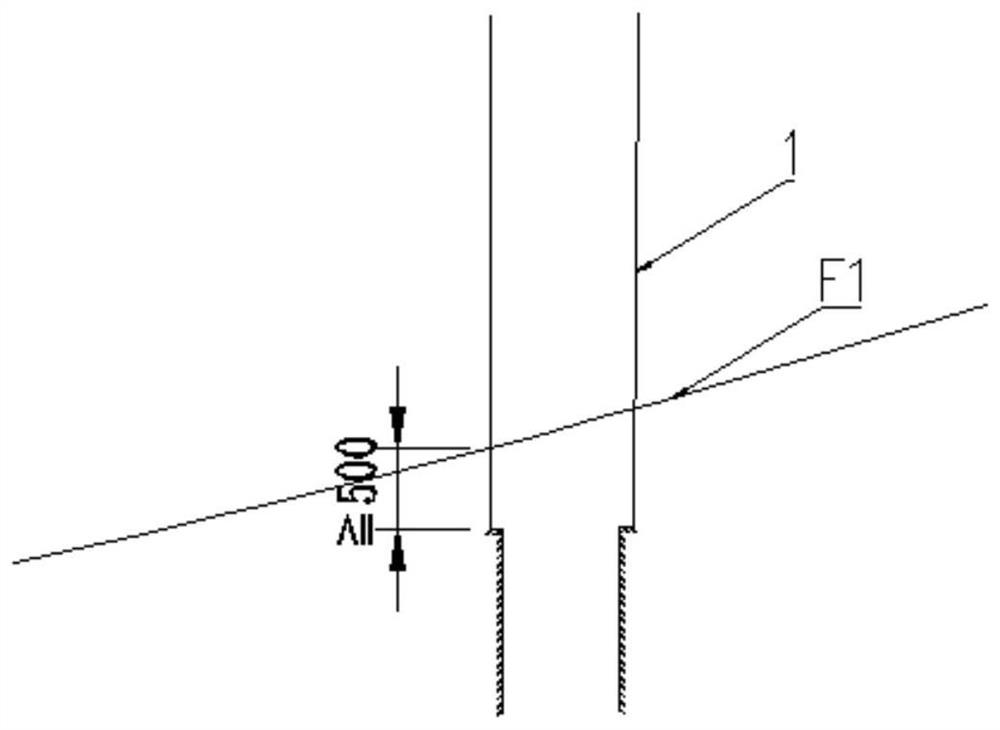

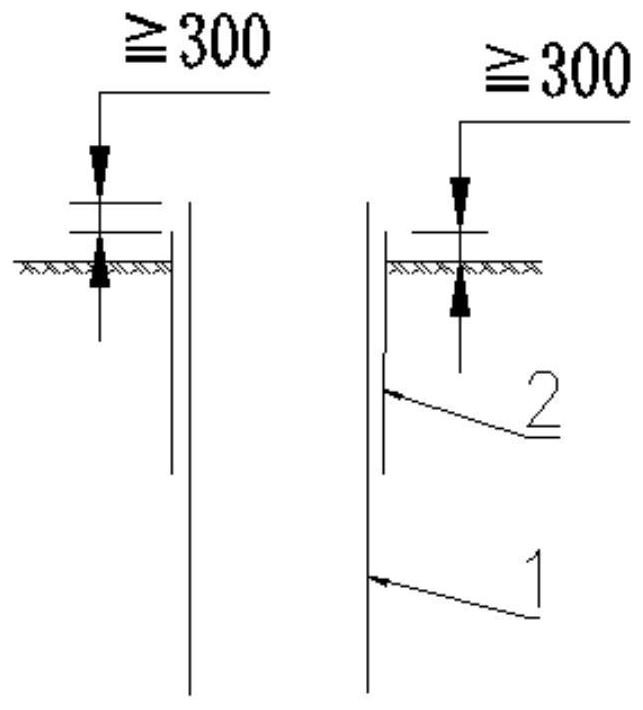

[0028] like Figure 1-3 As shown in the figure, a construction method for hole formation of water-rich sand and pebble geological group piles is specifically described on the basis of the following geology: the underlying bedrock of the geology is sandy mudstone, which is divided into strong weathering zone D2 and medium weathering zone D1, strong wind The thickness of D2 is 0.5-3.0m, the bottom boundary fluctuates with the bedrock surface, the weathering is strong, and the core is broken. The core of D1 in the middle weathering zone is relatively complete, mostly in columnar or short columnar shape, and the middle weathering zone D1 is located below the strong weathering zone D2. , the boundary line between the two is F2, the upper covering layer of the underlying bedrock is the sand and gravel backfill layer D3, the boundary line between the D3 laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com