Spray distillation device

A technology of distillation device and evaporation chamber, which is applied in the direction of spray evaporation, etc., can solve the problems of large energy consumption and waste liquid not meeting the national environmental protection requirements, and achieve the effect of fast contact speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: there is tower spray distillation bed system

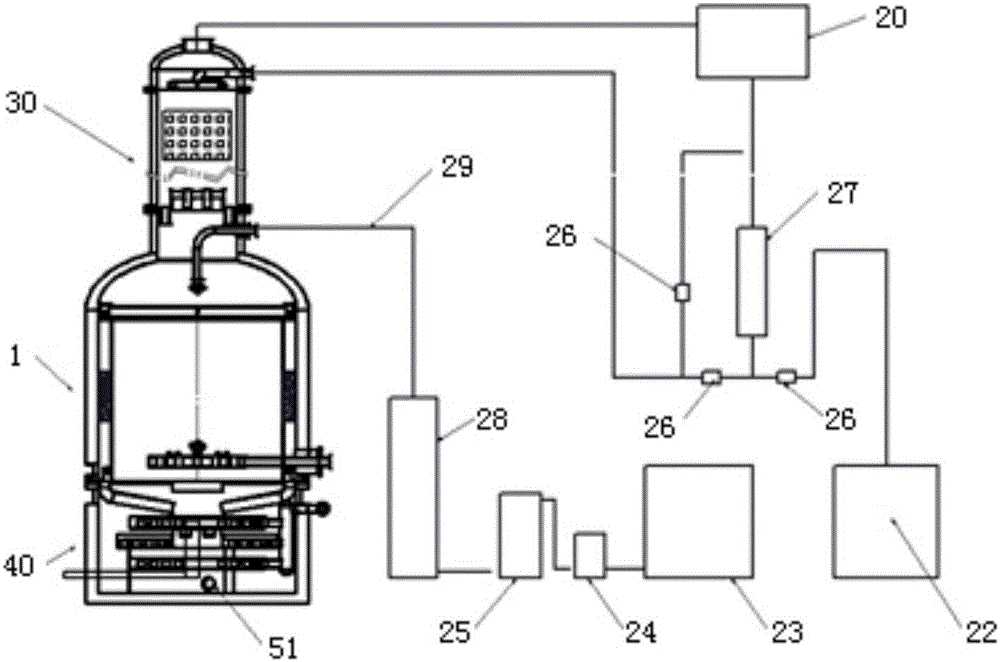

[0034] The spray distillation device of the present invention includes an evaporation chamber 1, a rectification column 30, a raffinate processor 40, a condenser 20, a raw material liquid storage tank 23, a finished product storage tank 22, a pump 24, a filter 25, and a raw material preheater 28. Finished product cooler 27, the above-mentioned equipment is composed of pipeline 29 and valve 26 as figure 2 Shown is a column spray distillation bed system.

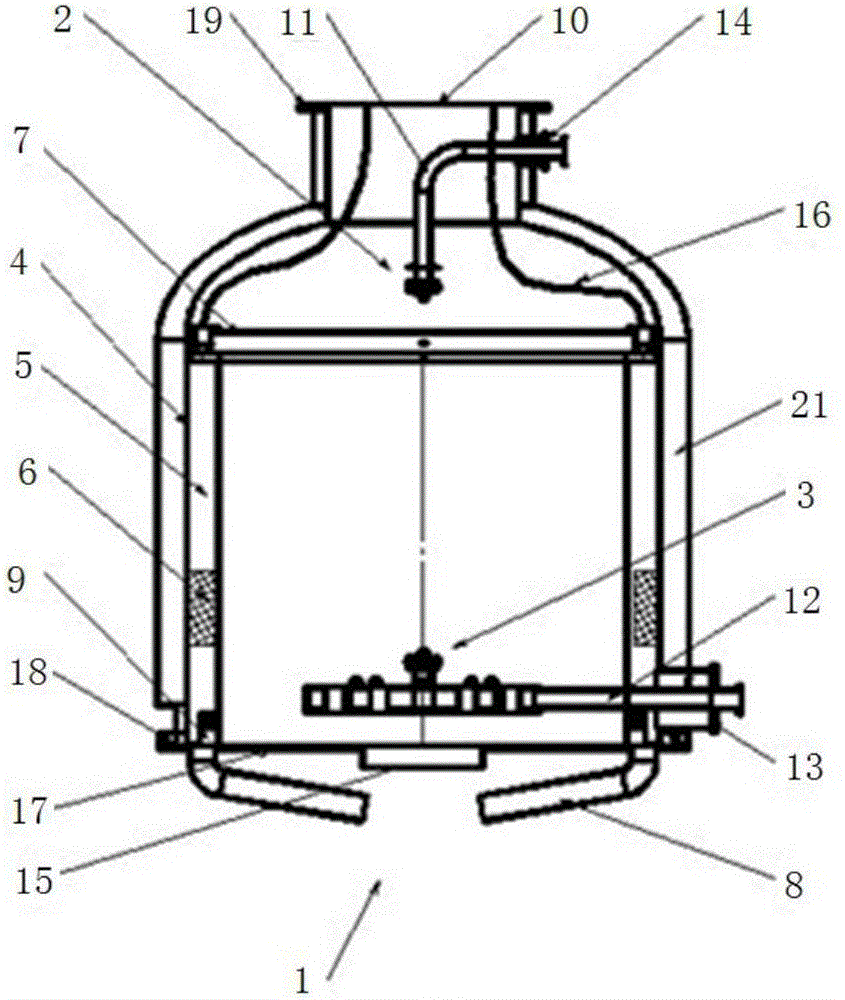

[0035] Such as figure 1 As shown, the evaporation chamber 1 includes a raw material liquid atomizer 2, a water vapor distributor 3, a housing 4 and a reflux liquid treatment device 5; the top of the housing 4 has a volatile phase outlet 10 and a tower shell bottom of a rectification column 30 Connected through a small flange 19; the reflux conduit 16 of the evaporation chamber 1 is connected to the raffinate outlet 36 of the rectification column 30; the bot...

Embodiment 2

[0045] Embodiment 2: spray distillation bed system

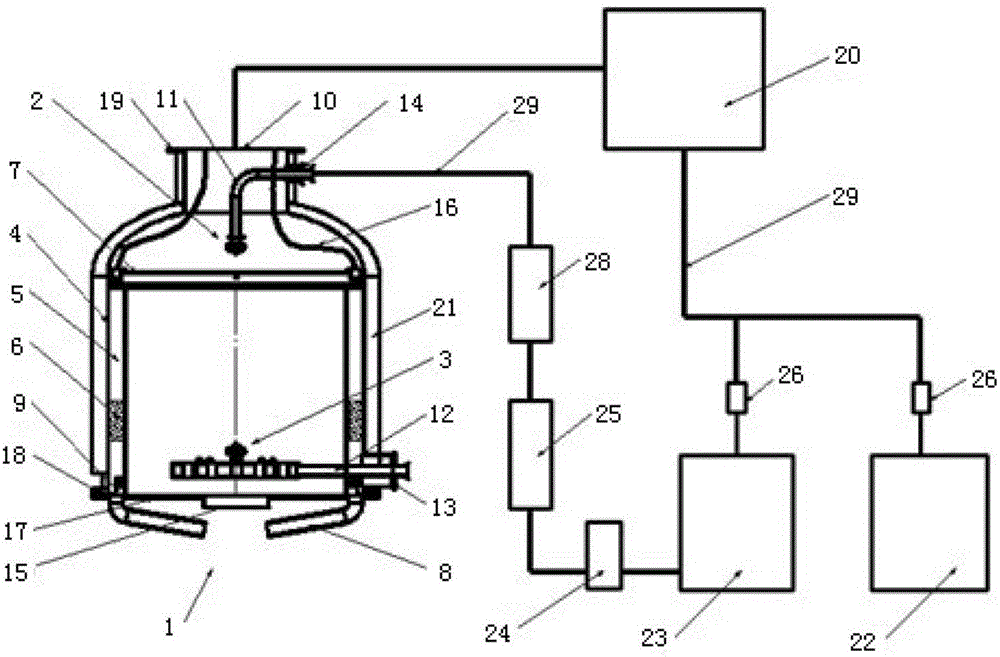

[0046] refer to figure 1 , image 3 , Figure 6-13 , the spray distillation device of the present invention, it comprises evaporation chamber 1, condenser 20, raw material liquid storage tank 23, finished product storage tank 22, pump 24, filter 25 and raw material liquid preheater 28, above-mentioned equipment passes pipeline 29 and valve 26 connected as image 3 The spray distillation bed system shown.

[0047] The structural functions of each component in this embodiment have been described in Embodiment 1. Here is a specific description of the specific working process of this simple spray distillation bed system:

[0048] The raw material mixed liquid stored in the raw material liquid storage tank 23 is driven into the raw material liquid atomizer 2 through the pump 24, the filter 25, the raw material liquid preheater 28, the pipeline 29 and the raw material liquid feeding pipe 11, and after atomization Converging ...

Embodiment 3

[0050] Embodiment 3: no tower spray distillation bed system

[0051] combine figure 1 with Figure 14 , briefly describe the use of two evaporation chambers (spray rectification beds) in series. Parts that are the same as those in the foregoing embodiments will not be described again. The descriptions are different or slightly changed as follows:

[0052] 1. The center hole of the mounting plate 17 of the previous evaporation chamber 1, that is, the outlet 15 of the difficult-to-volatile phase is raised up with a circle of cofferdams. The purpose is that the liquid that has not been evaporated does not flow down through this hole, but flows down from the residual liquid discharge pipe 8 , into the filler mesh circle 6 below.

[0053] 2. Connect a short pipe welding flange 19 under the mounting plate 17 to connect it with the evaporation chamber flange 19 below. The purpose is to ensure that the steam below enters the last evaporation chamber 1 through the less volatile ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com