Multi-station automatic burr removal machine

A deburring machine and multi-station technology, which is applied in the direction of machine tools, manufacturing tools, and grinding feed motions suitable for grinding workpiece edges, can solve the problems that cannot meet the requirements of parts deburring, limit the processing of deburring parts, Problems such as single model, to achieve the effect of saving human operation, reducing labor cost, and saving processing links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

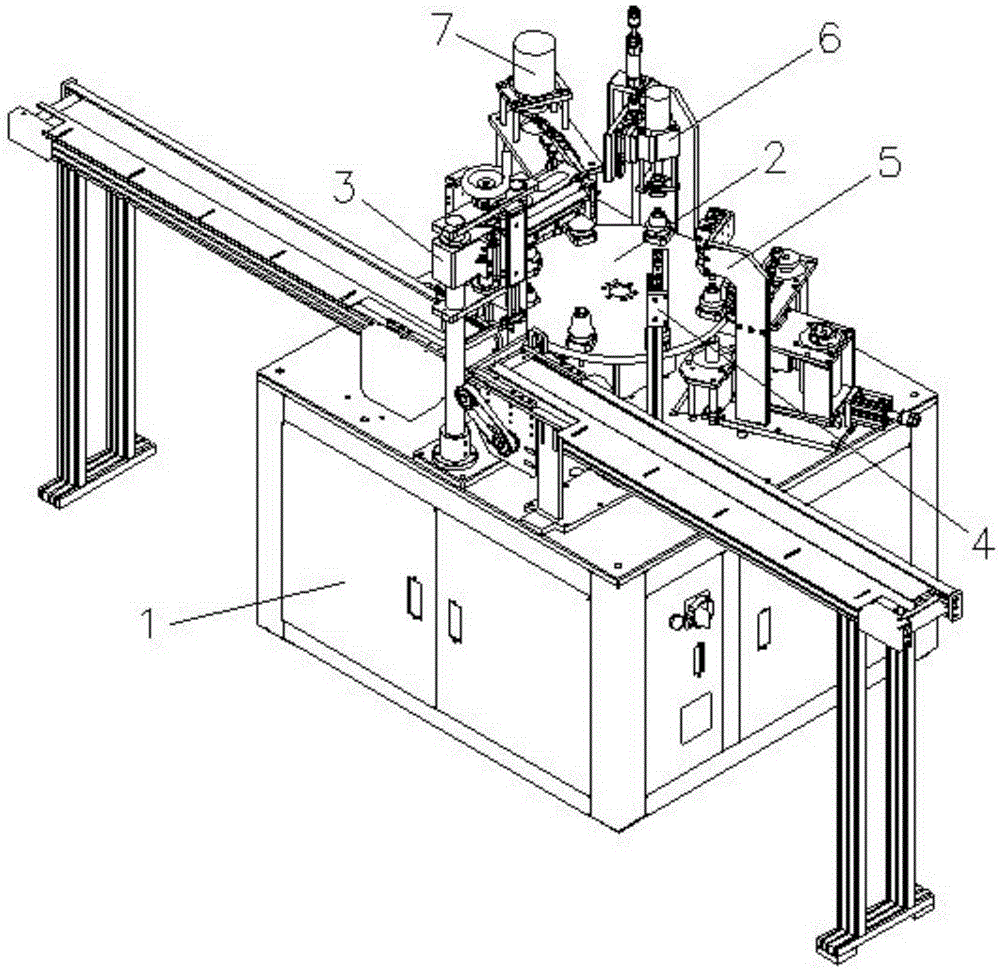

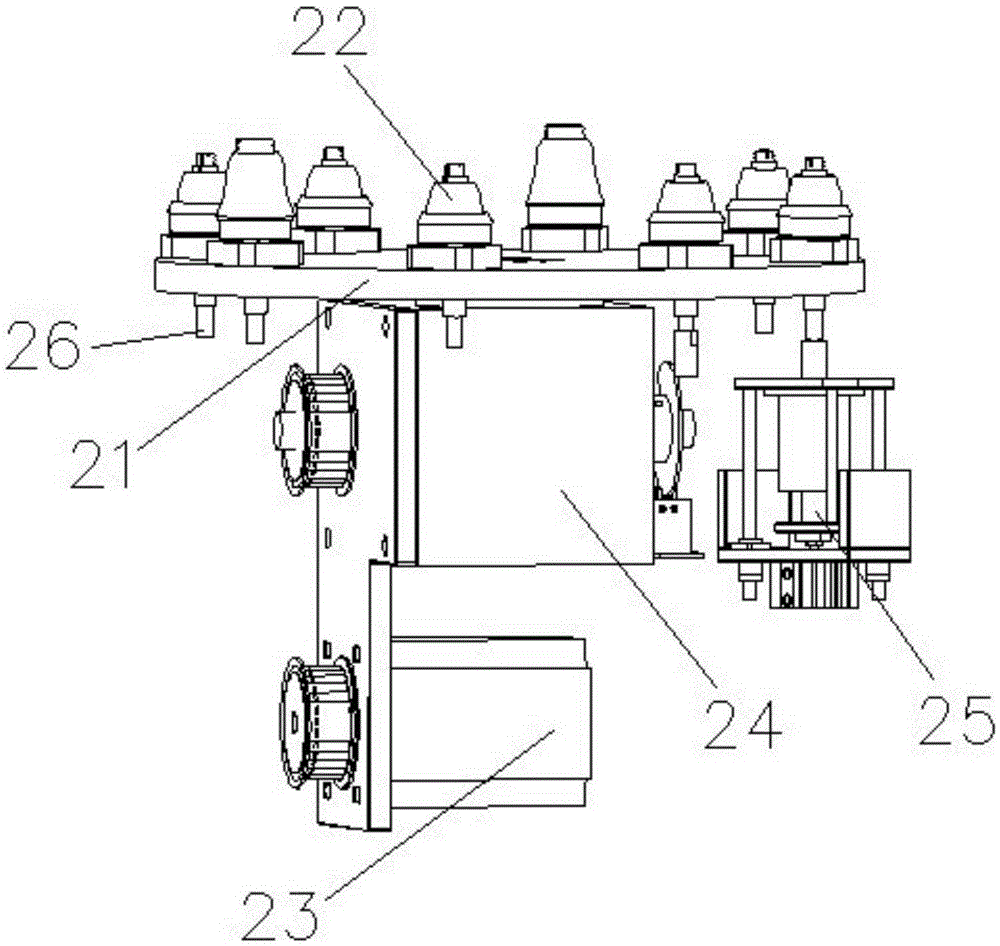

[0027] attached figure 1 It is a multi-station automatic deburring machine according to the present invention, including a cabinet 1, a lifting and rotating index plate 2, a conveying mechanism 3, a molding mechanism 4, a side deburring mechanism 5, a hole deburring mechanism 6, a top The deburring mechanism 7; the lifting and rotating index plate 2 is arranged at the center position of the cabinet 1; the periphery of the lifting and rotating indexing plate 2 is successively provided with a conveying mechanism 3, a die pressing mechanism 4, a side deburring mechanism 5, and the inside of the hole Deburring mechanism 6 and top deburring mechanism 7. When the machine starts to start, the conveying mechanism 3 first puts the parts to be processed into the lifting and rotating indexing mold 22 on the lifting and rotating indexing plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com