Patents

Literature

81results about "Testing metal constituents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

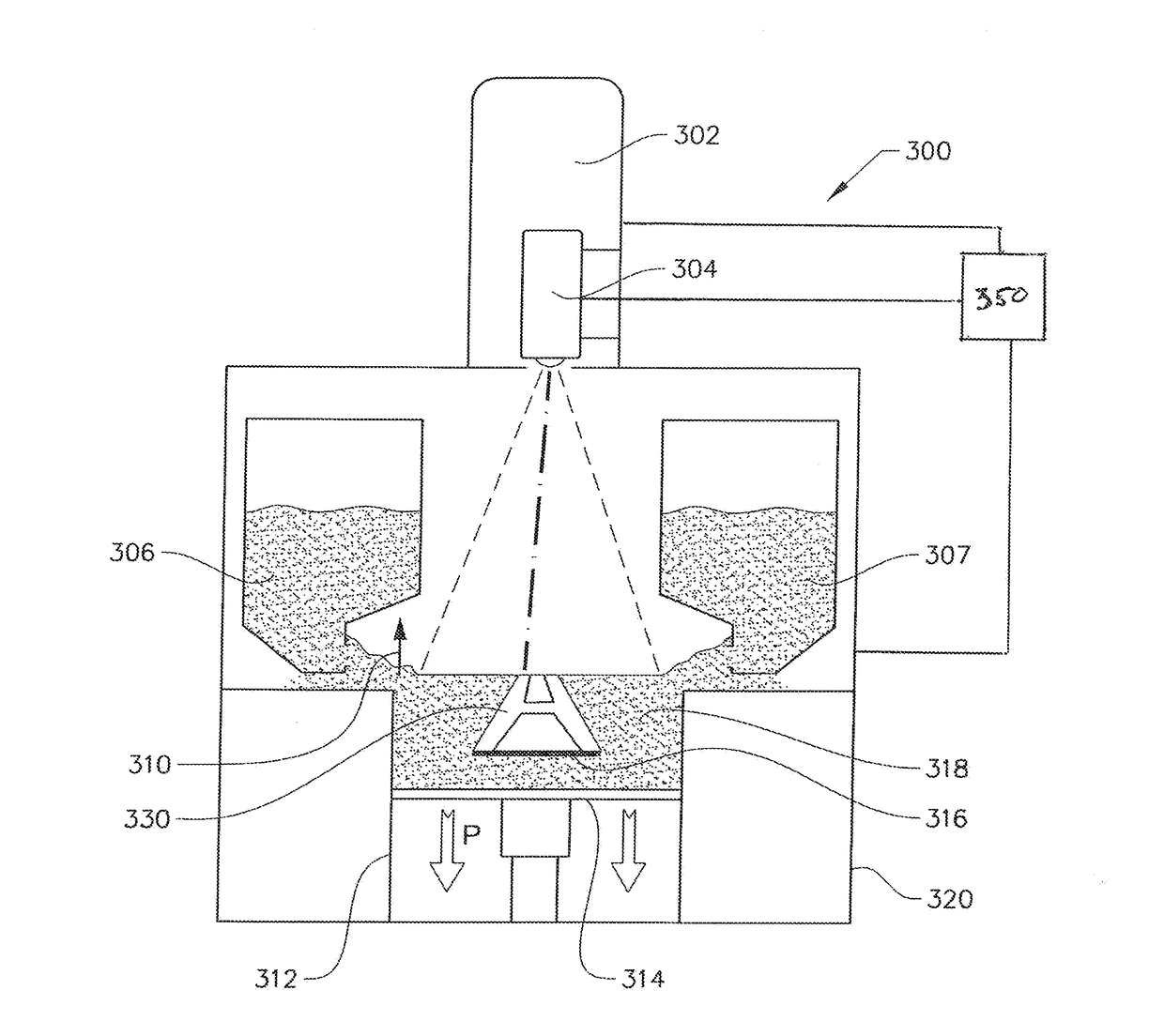

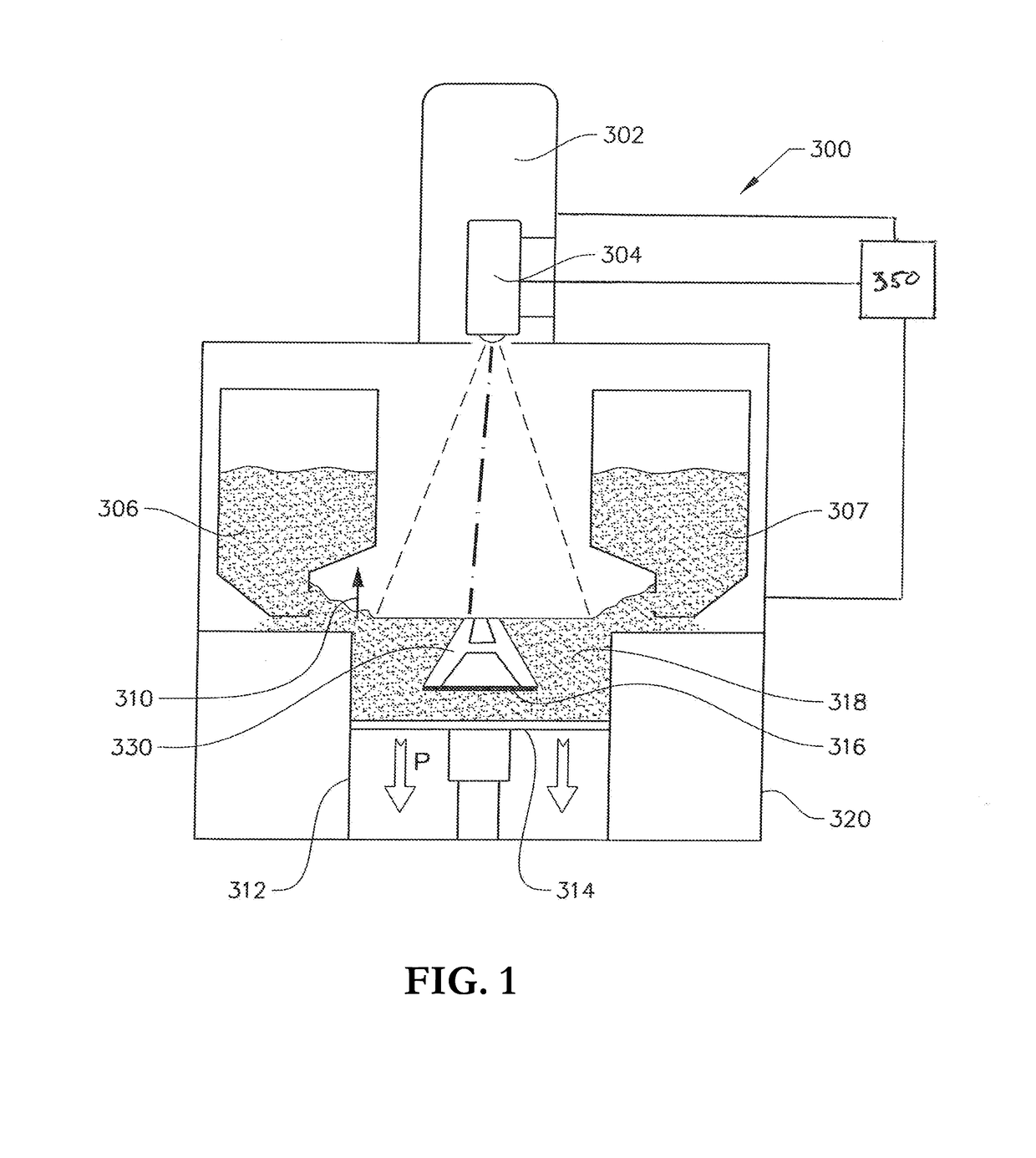

Method and apparatus for additive manufacturing

InactiveUS20170066051A1Characteristic variesEffective timeAdditive manufacturing apparatusIncreasing energy efficiencyNon destructiveMelting tank

A method for non-destructive evaluation of a manufacturing process when forming a three-dimensional article through successive fusion of parts of a metal powder bed, which parts corresponds to successive cross sections of the three-dimensional article, the method comprising the steps of collecting an X-ray signal, created by the electron beam, from at least one position of the first and / or second metal powder layer and / or a melt pool of the first and / or second metal powder layer and / or a fused first and / or second powder layer by an X-ray detector, comparing the X-ray signal with a reference signal, alarming if the generated X-ray signal compared to the reference signal is indicating contamination material of larger amount than a predetermined value and / or a deviation in Atomic % of the powder material larger than a predetermined value.

Owner:ARCAM AB

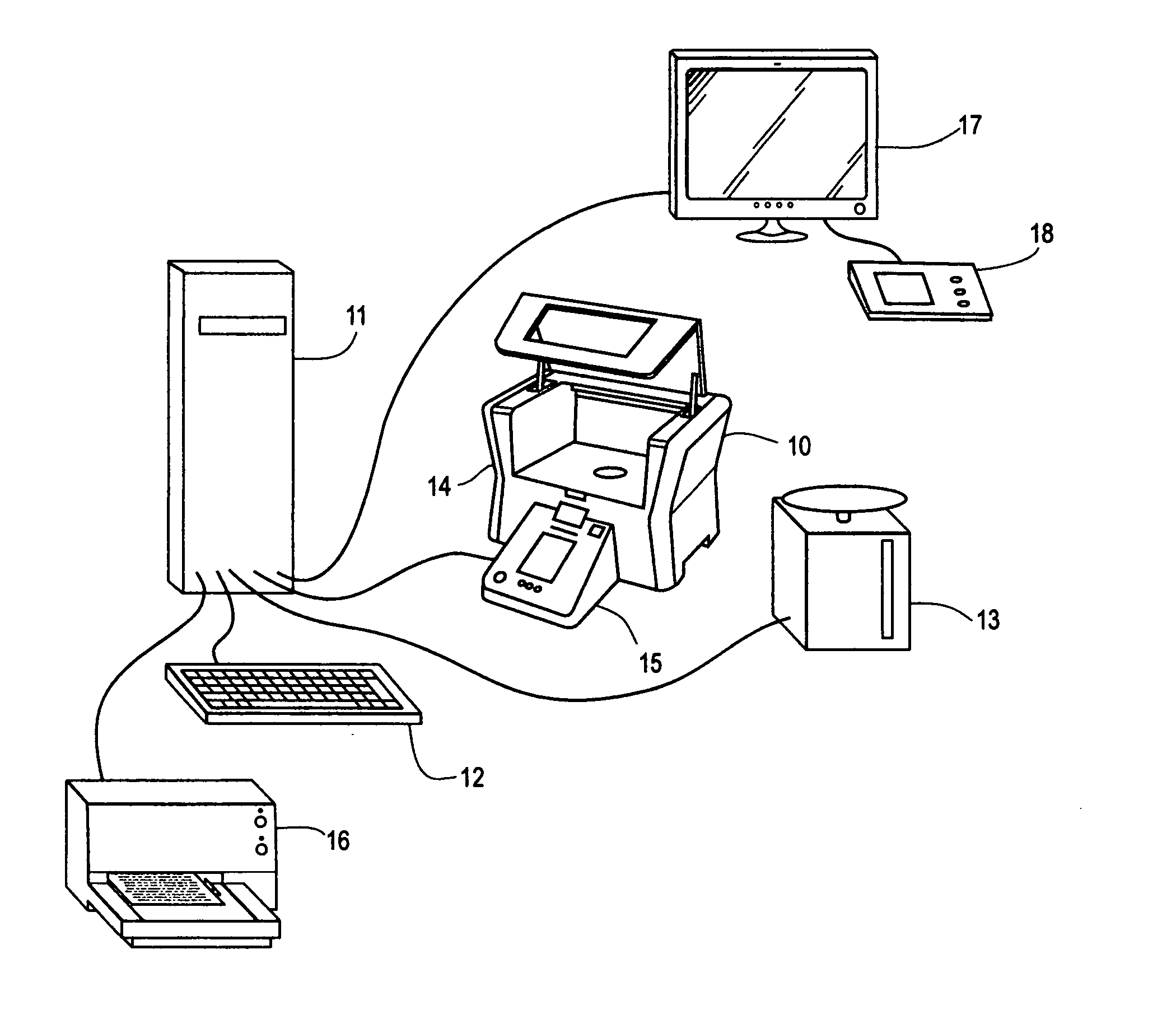

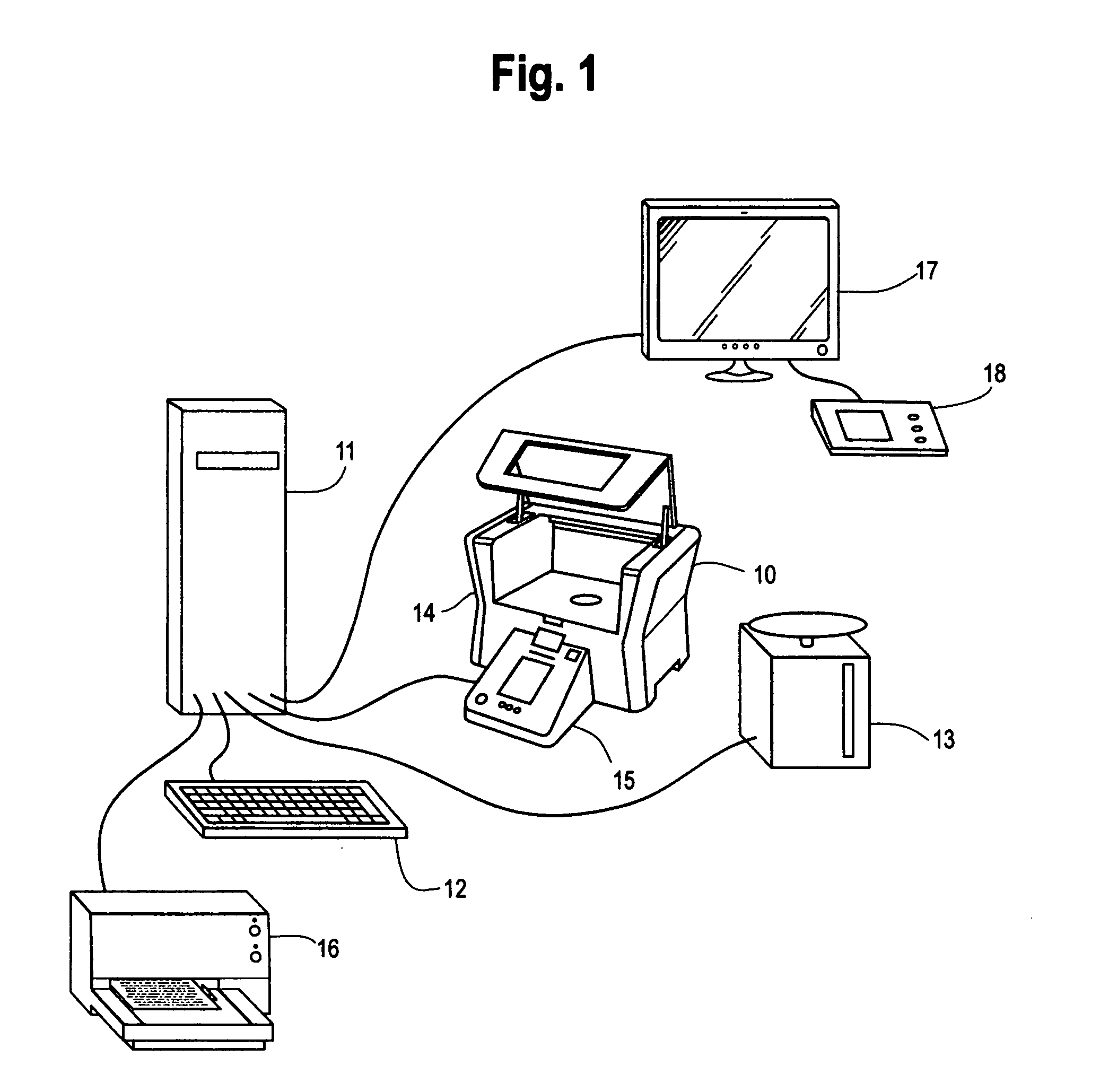

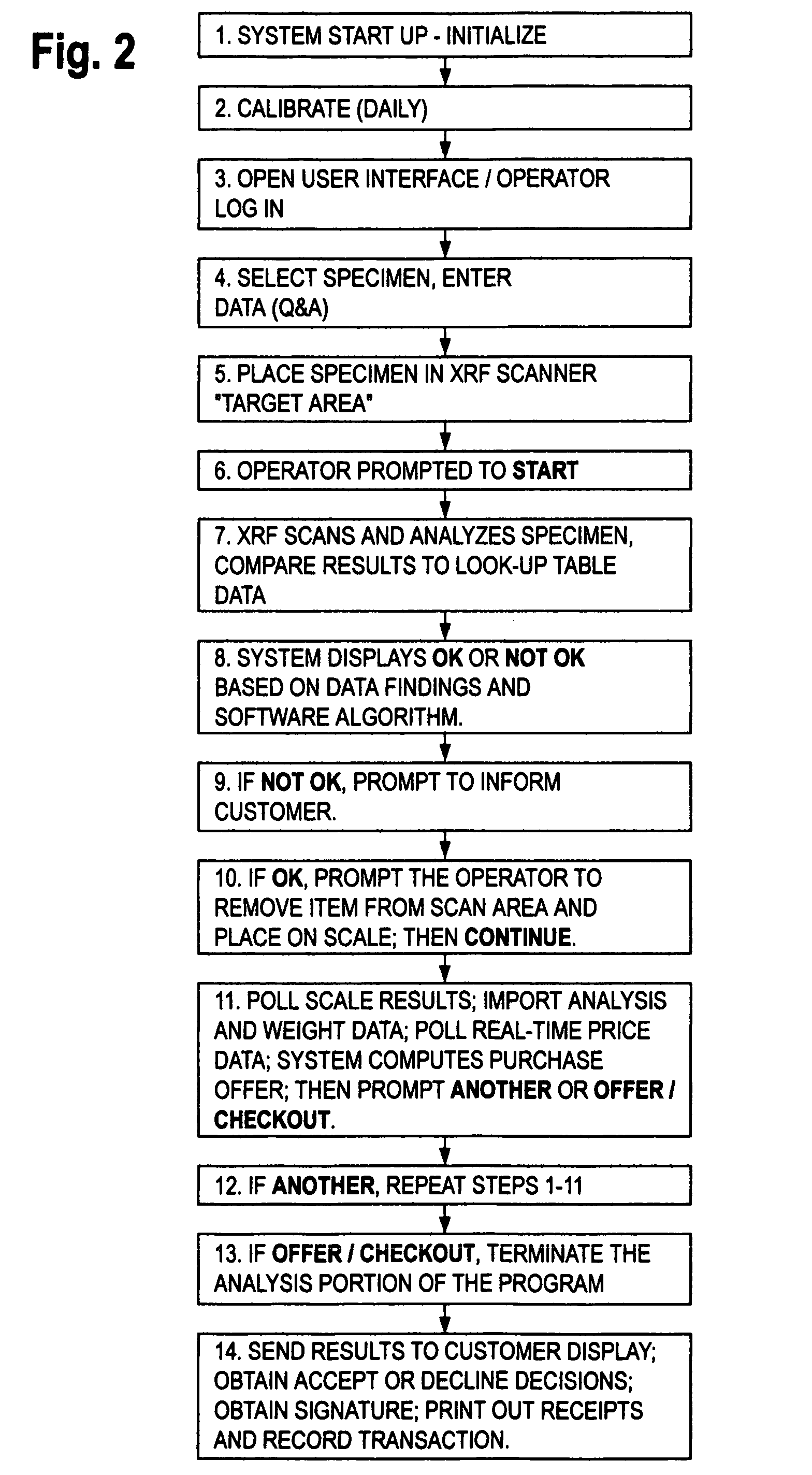

Method and apparatus for the automated assay and valuation of precious metal objects

ActiveUS20130230138A1Database may become rather largeFast and accurate resultMaterial analysis using wave/particle radiationX-ray spectral distribution measurementThe InternetTouchpad

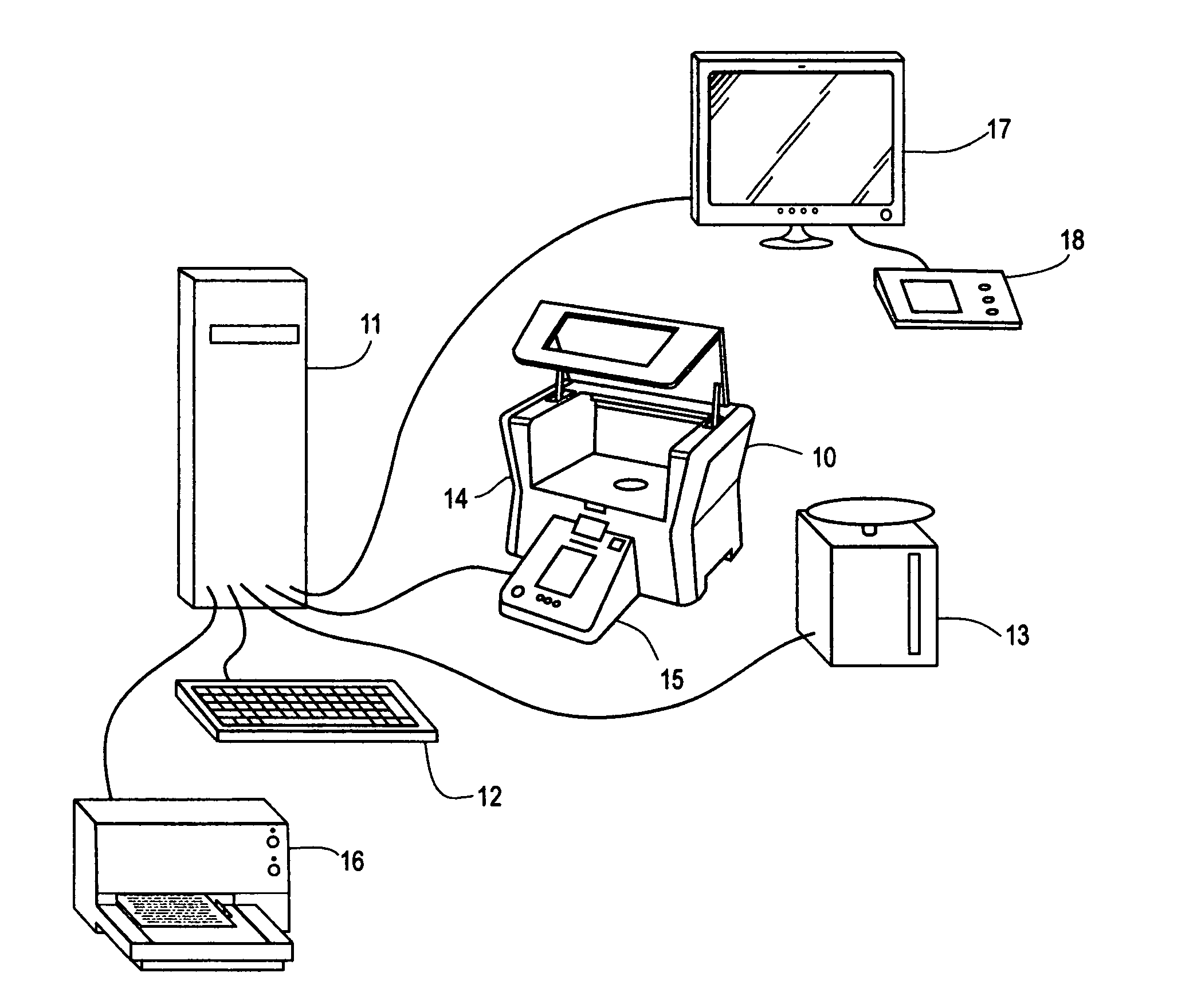

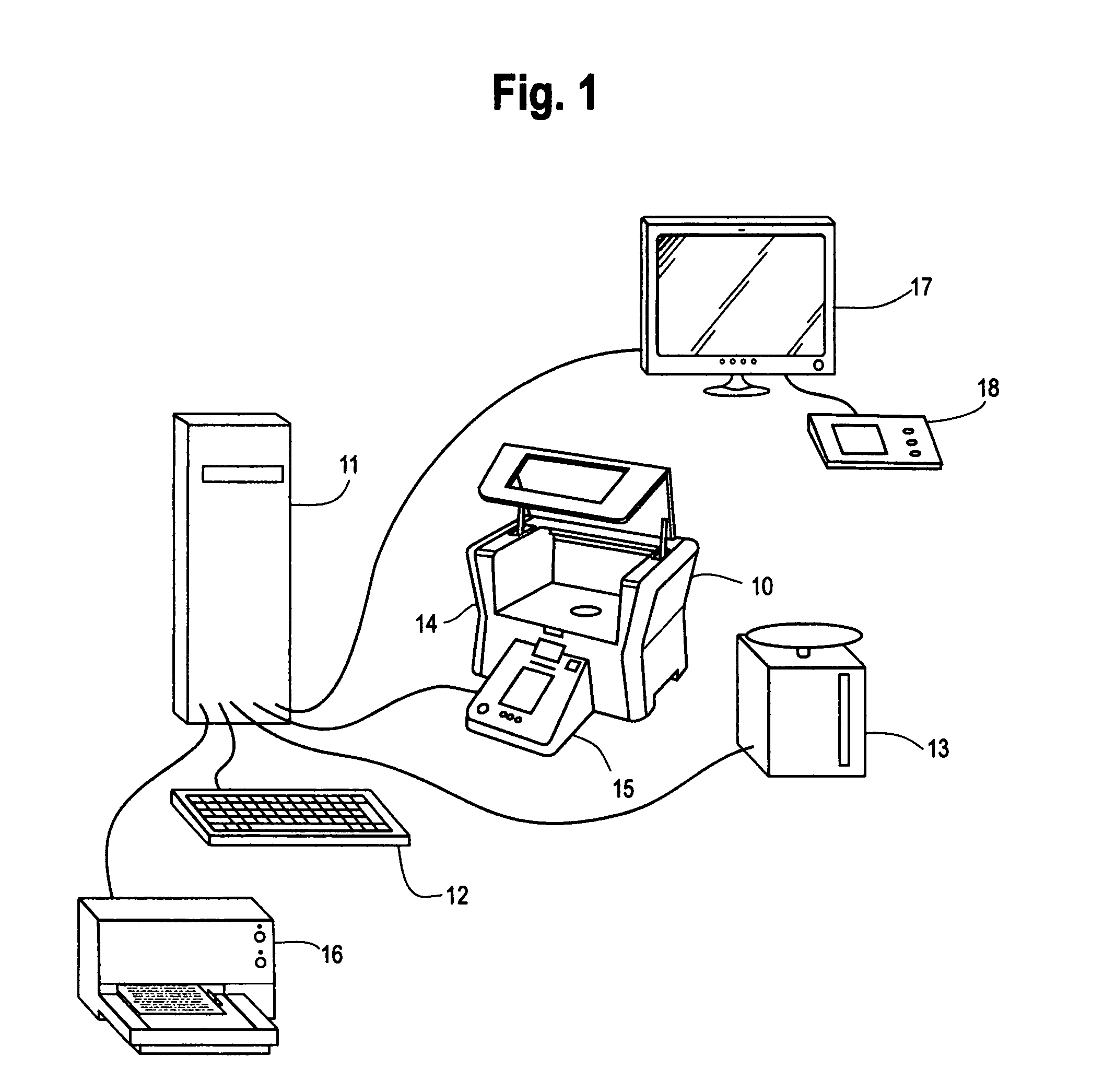

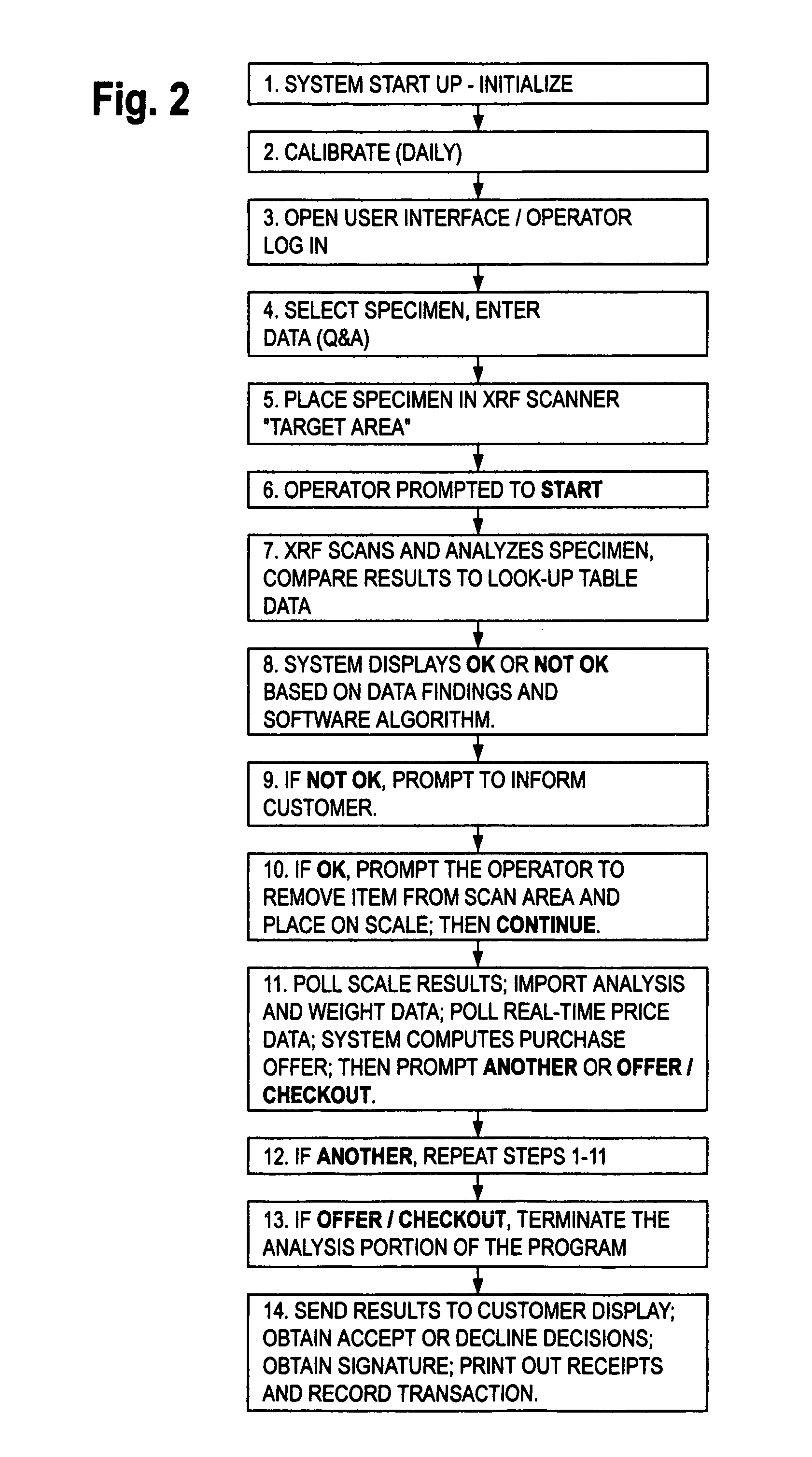

A method and apparatus for the metallurgical qualitative analysis (assay) and valuation of precious metals objects such as jewelry or coins. The system integrates a commercially available x-ray florescence (XRF) metals analyzer with associated peripheral devices including a personal computer and keyboard or touchpad computing device, a digitizing scale, a printer, an Internet link for obtaining current precious metals market price quotations, and software for processing the qualitative results with the current market price data and presenting the results to the system operator in real time. The system optionally includes a customer interface including a display screen for presenting the customer with the results of the analysis and valuation, and customer input means for accepting and recording a purchase transaction.

Owner:JETER BOBBY D +1

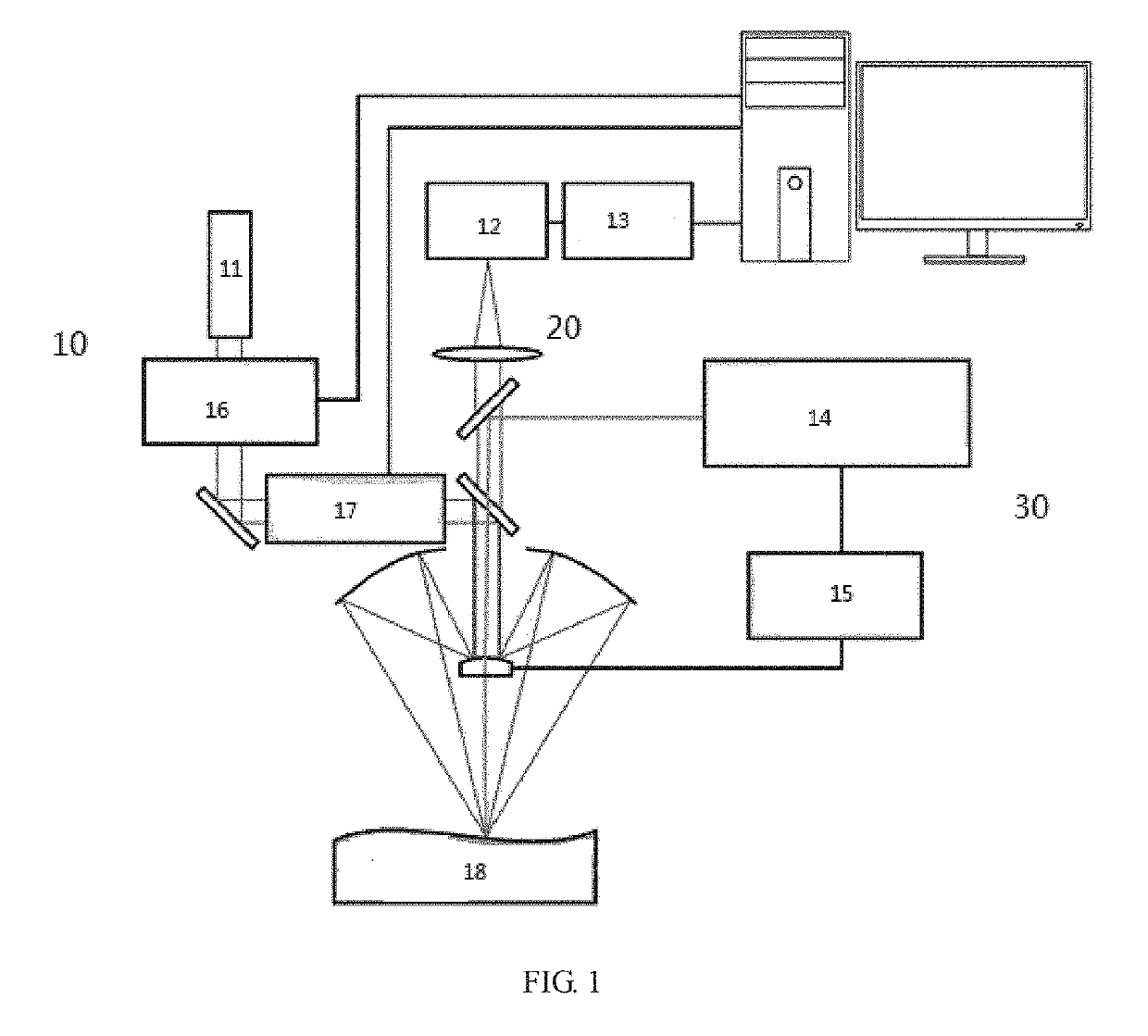

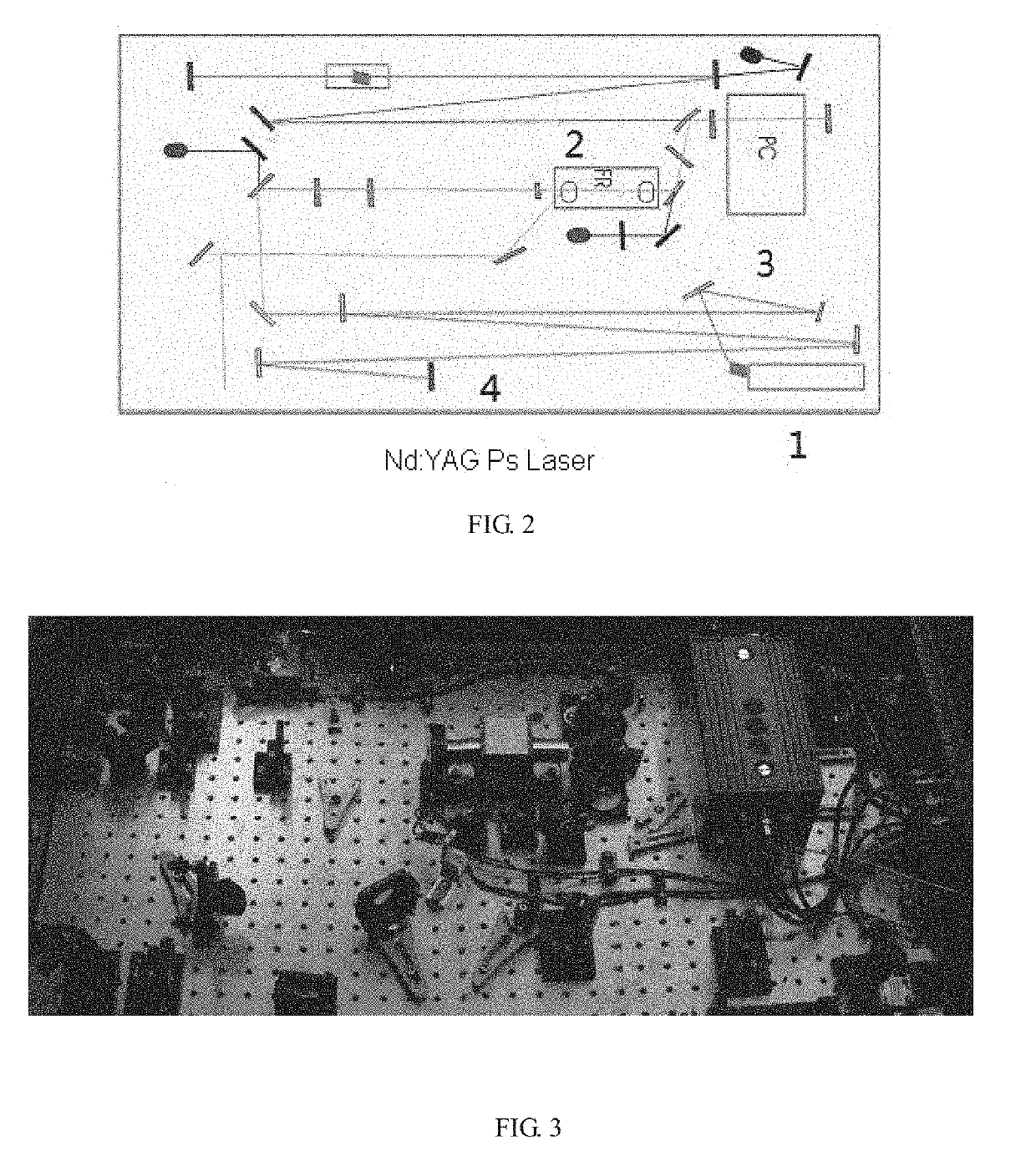

Method for Detecting Composition of Steel Sample by Using Multi-Pulse Laser-Induced Plasma Spectrometer

ActiveUS20190219511A1Enhance emission of spectralSignal-to-noise ratioAnalysis by thermal excitationFluorescence/phosphorescencePicosecond laserNanosecond laser pulse

The present invention relates to a method for detecting steel sample components by using a multi-pulse laser induced plasma spectral analysis device, and in particular, to a method for detecting steel sample components by using a multi-pulse laser induced plasma spectral analysis device that includes picosecond and nanosecond laser pulse widths. A laser induced light source is a laser light source that includes nanosecond and picosecond ultrashort pulses, and one pulse laser device can be used to generate two pulse lasers, namely, a nanosecond and a picosecond laser; the two pulse lasers pass through a same output and focusing light path, so as to ensure that the two pulse lasers are focused on a same position of a sample to be detected; a surface of the sample is irradiated by using a first beam of nanosecond laser pulse to generate plasmas; subsequently, the plasmas are irradiated by using a second beam of picosecond laser pulse to enhance spectral line emission.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

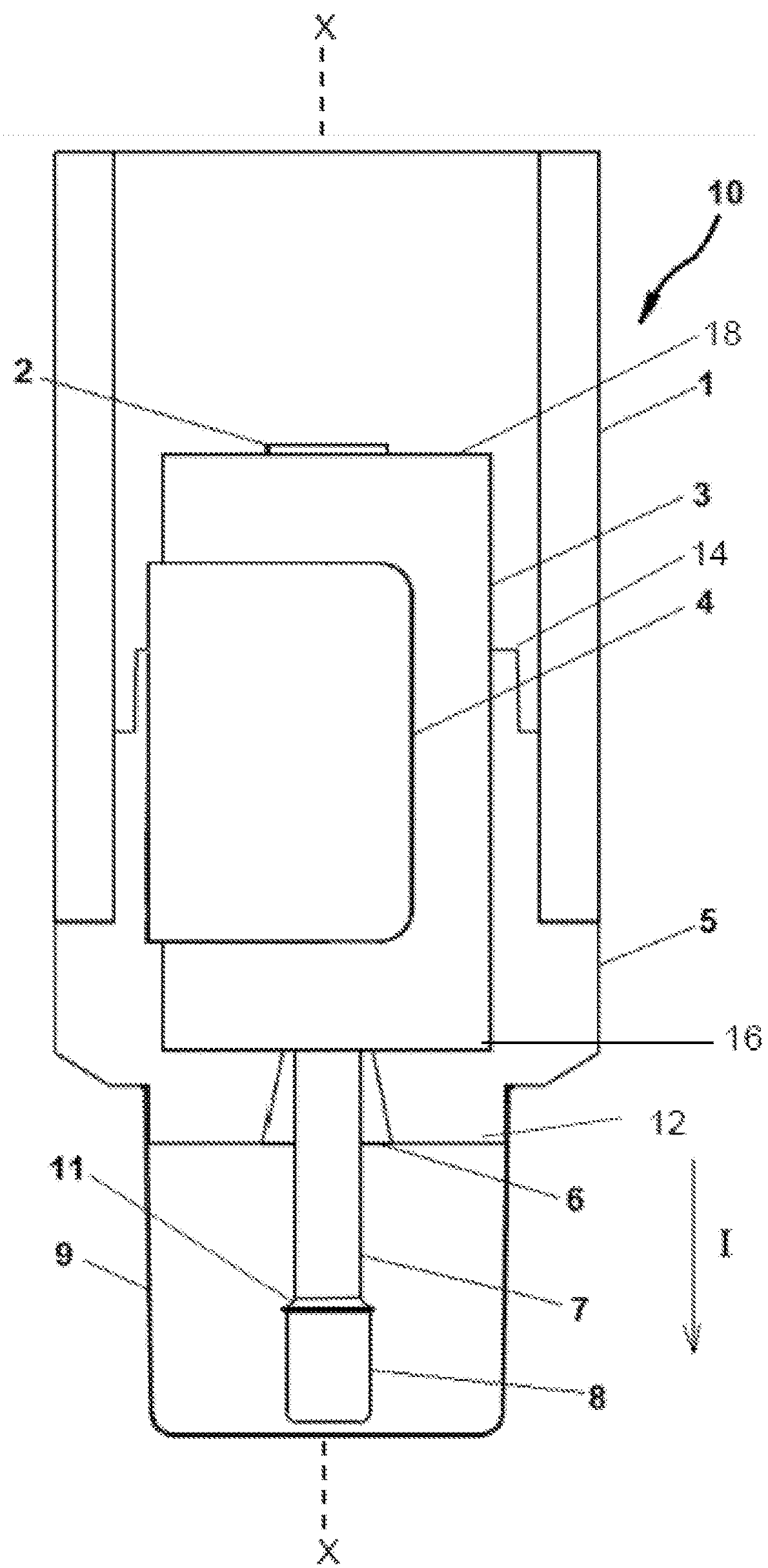

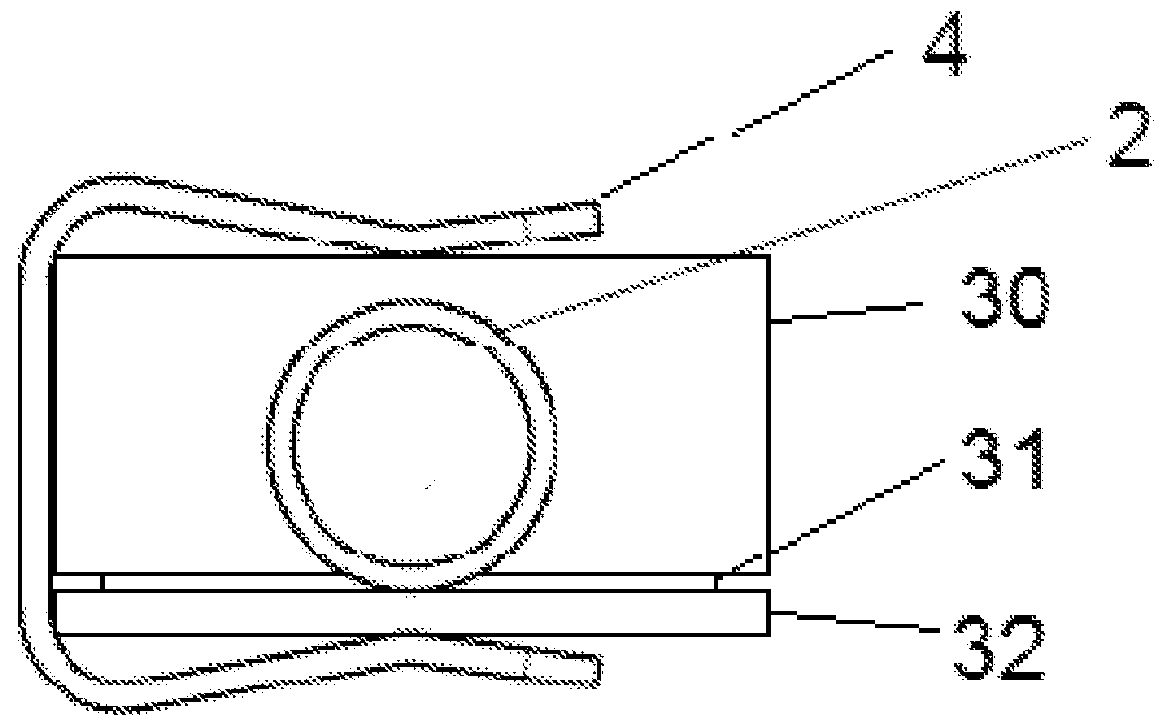

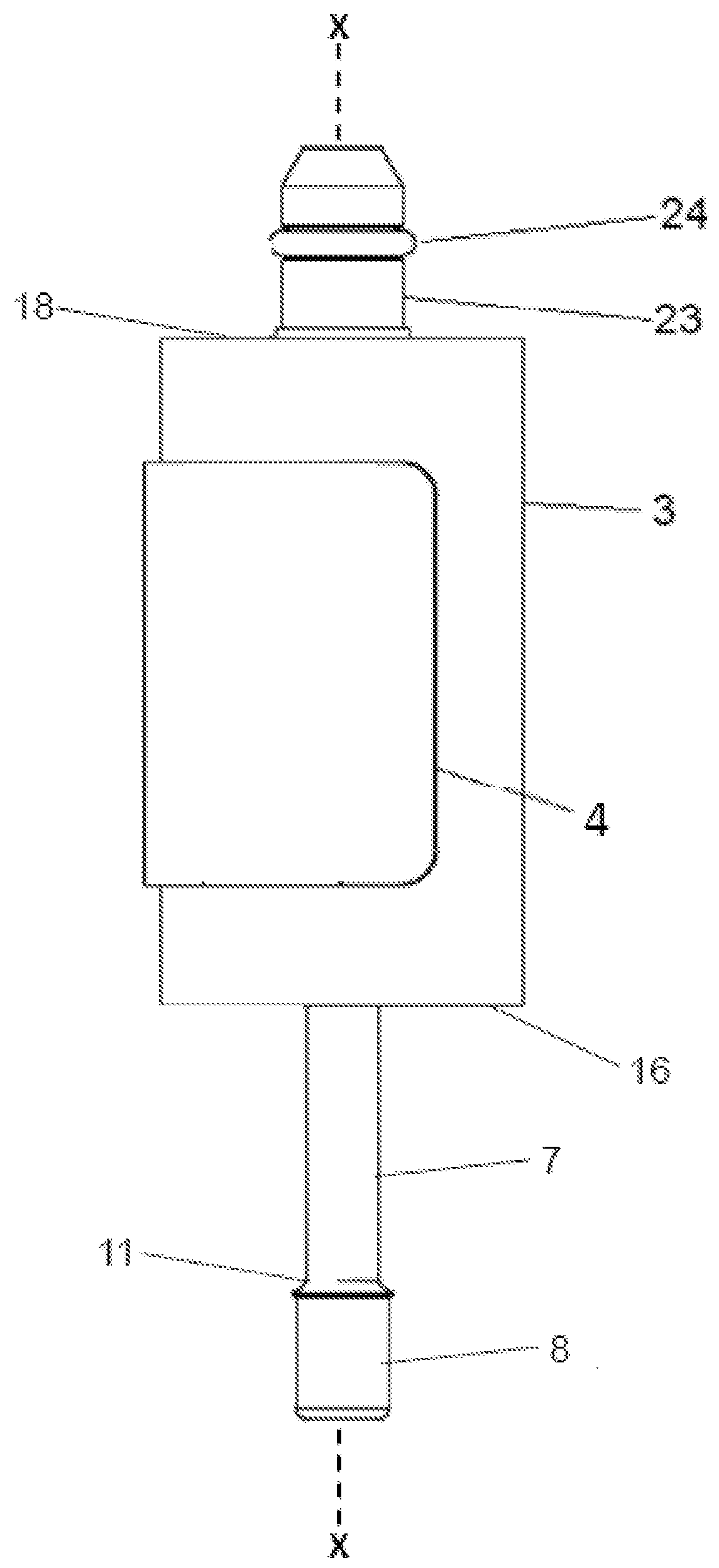

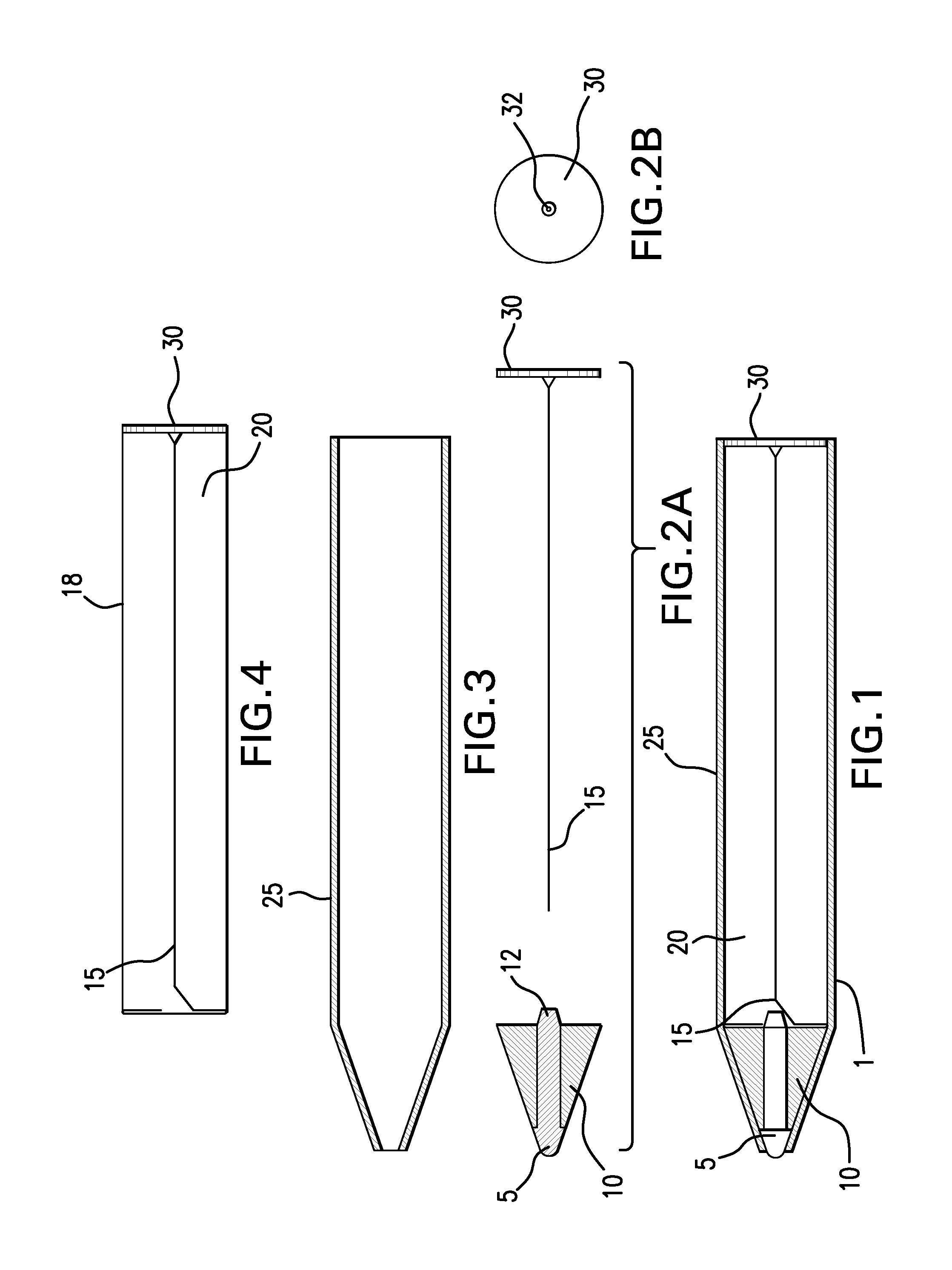

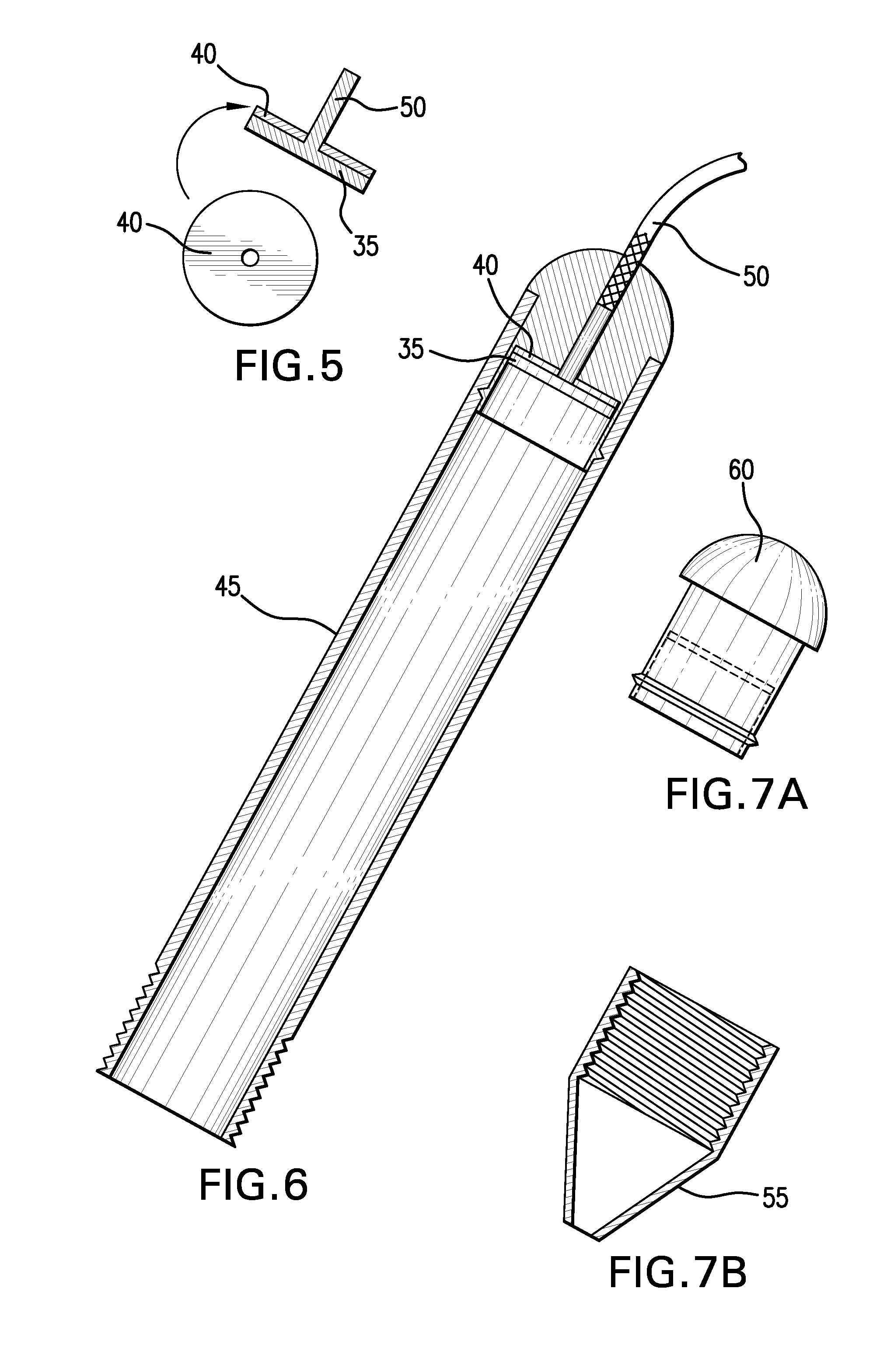

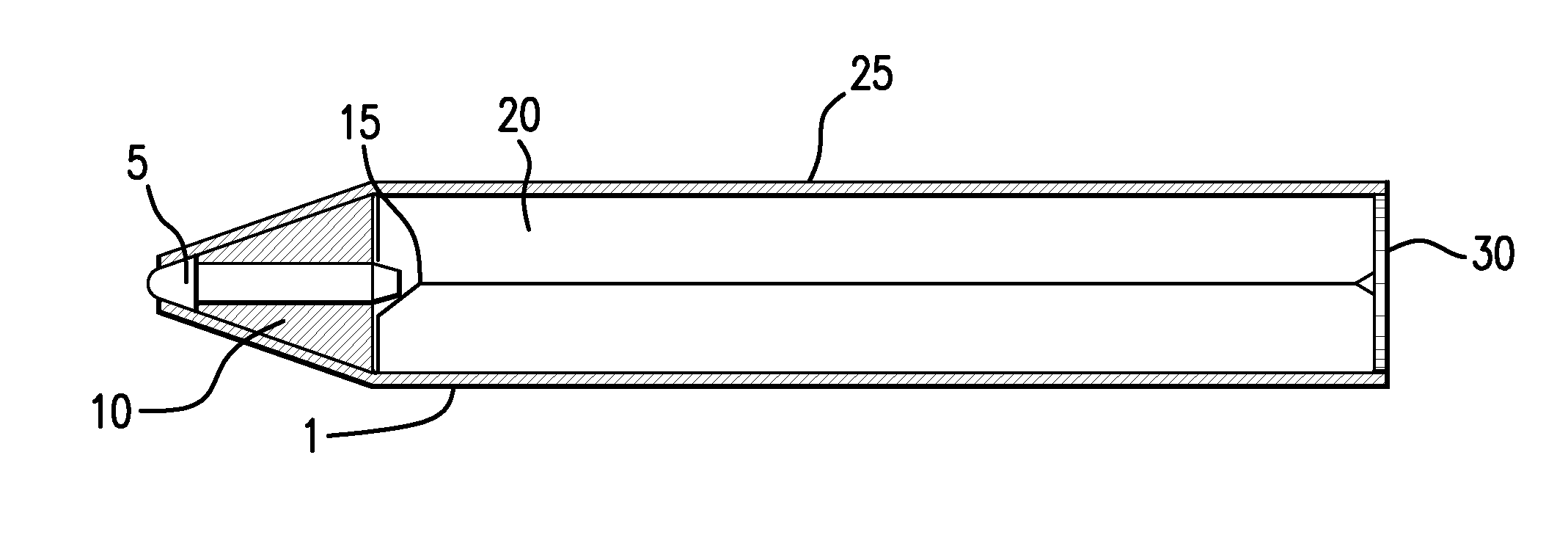

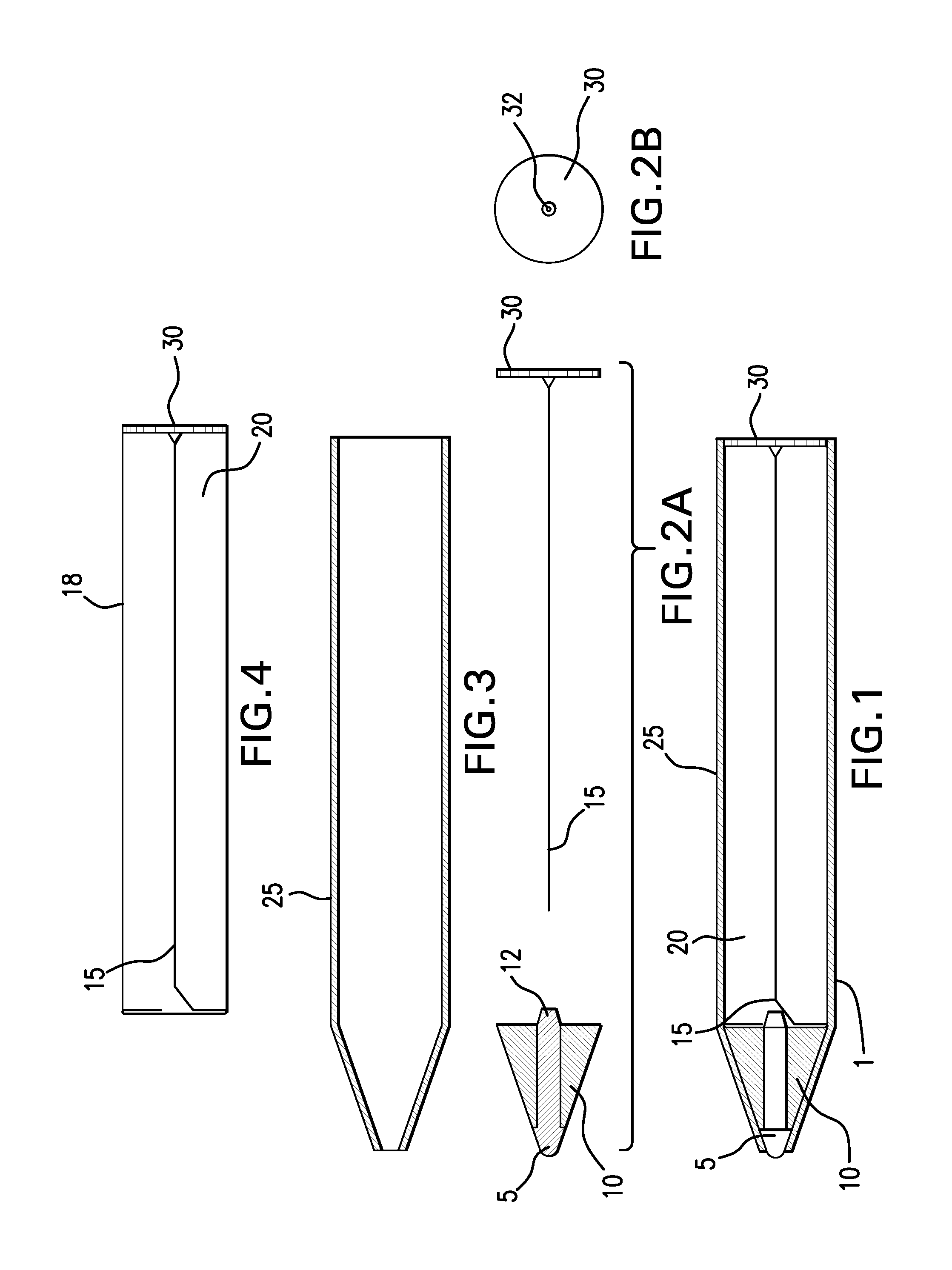

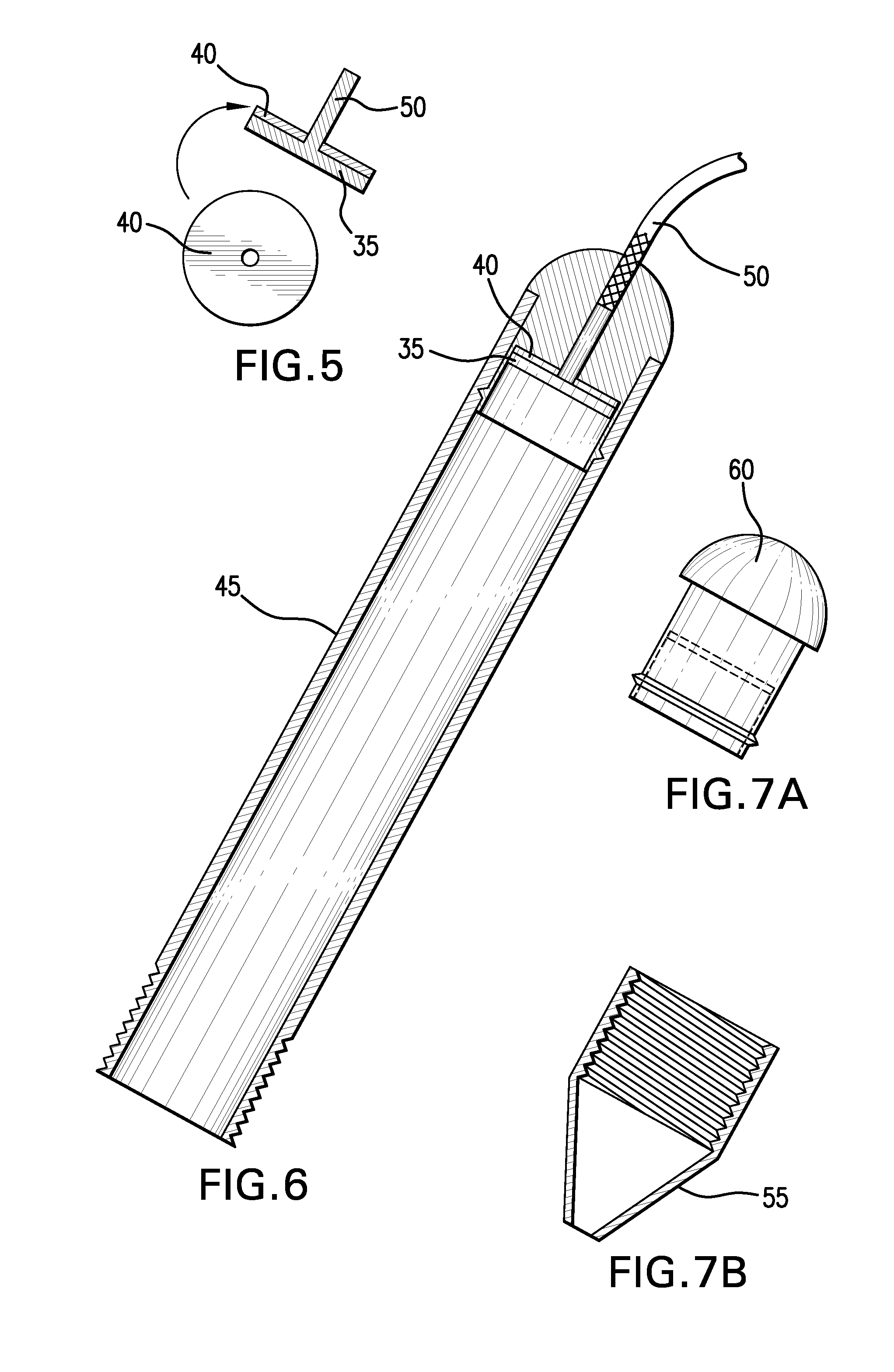

Direct analysis sampler with heat sink

ActiveUS20180164191A1Improve overall utilizationWithdrawing sample devicesAnalysis by electrical excitationThermal diffusivityEngineering

A sample chamber assembly for molten metal comprises a cover plate and a housing. A first face of the housing has a depression in direct flow communication with a first opening formed at the immersion end of the housing. The cover plate and the housing are assembled together along a first plane to form a sample cavity including the depression. An analysis surface of a solidified metal sample lies in the first plane. The sample cavity and the first opening are aligned along a common longitudinal axis. The first opening is spaced apart from the first plane. A ratio of the thermal diffusivities of the solidified metal sample and the housing material is between 0.1 and 0.5. The housing is inseparable from the solidified metal sample. A portion of the housing is directly adjacent to the solidified metal sample and lies in the first plane.

Owner:HERAEUS ELECTRO NITE INT NV

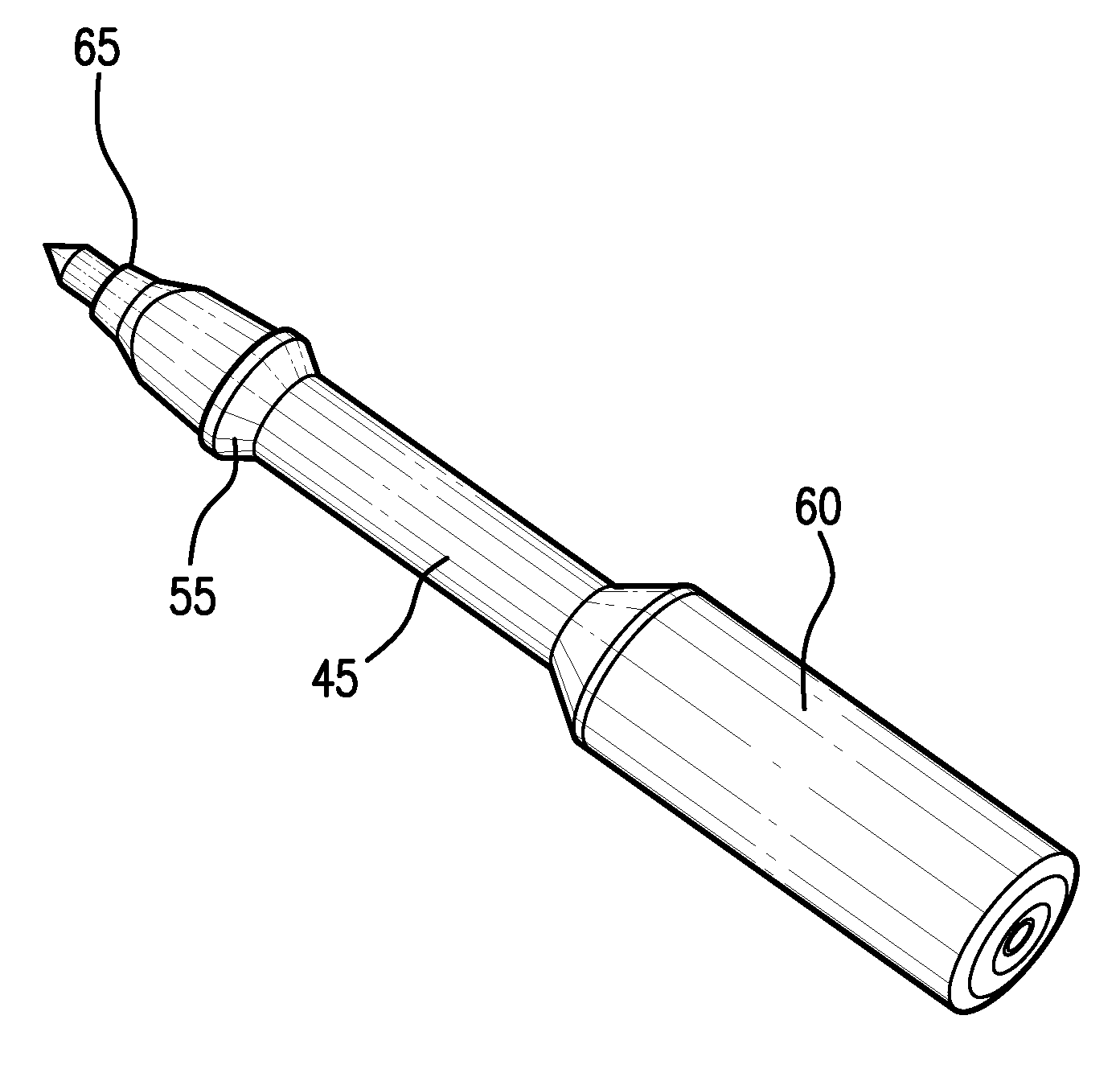

Apparatus and methods for testing impurity content in a precious metal

InactiveUS20110042240A1Reduce lossesAvoid lostWeather/light/corrosion resistanceResistance/reactance/impedenceFiberElectrical resistance and conductance

A precious metal testing apparatus and methods adapted to analyze impurities in a precious metal test sample is described. The testing apparatus contains a test probe that has a replaceable portion and that is connected to a meter to measure resistance. The replaceable portion contains or forms a reservoir that includes at least one electrolyte component, a conductive member, and a fibrous tip. The electrolyte component is fluidly associated with a fiber tip and the conductive member contacts an electrical contact located outside the reservoir. Methods of testing and instructions regarding such methods are also included.

Owner:FMS TECH

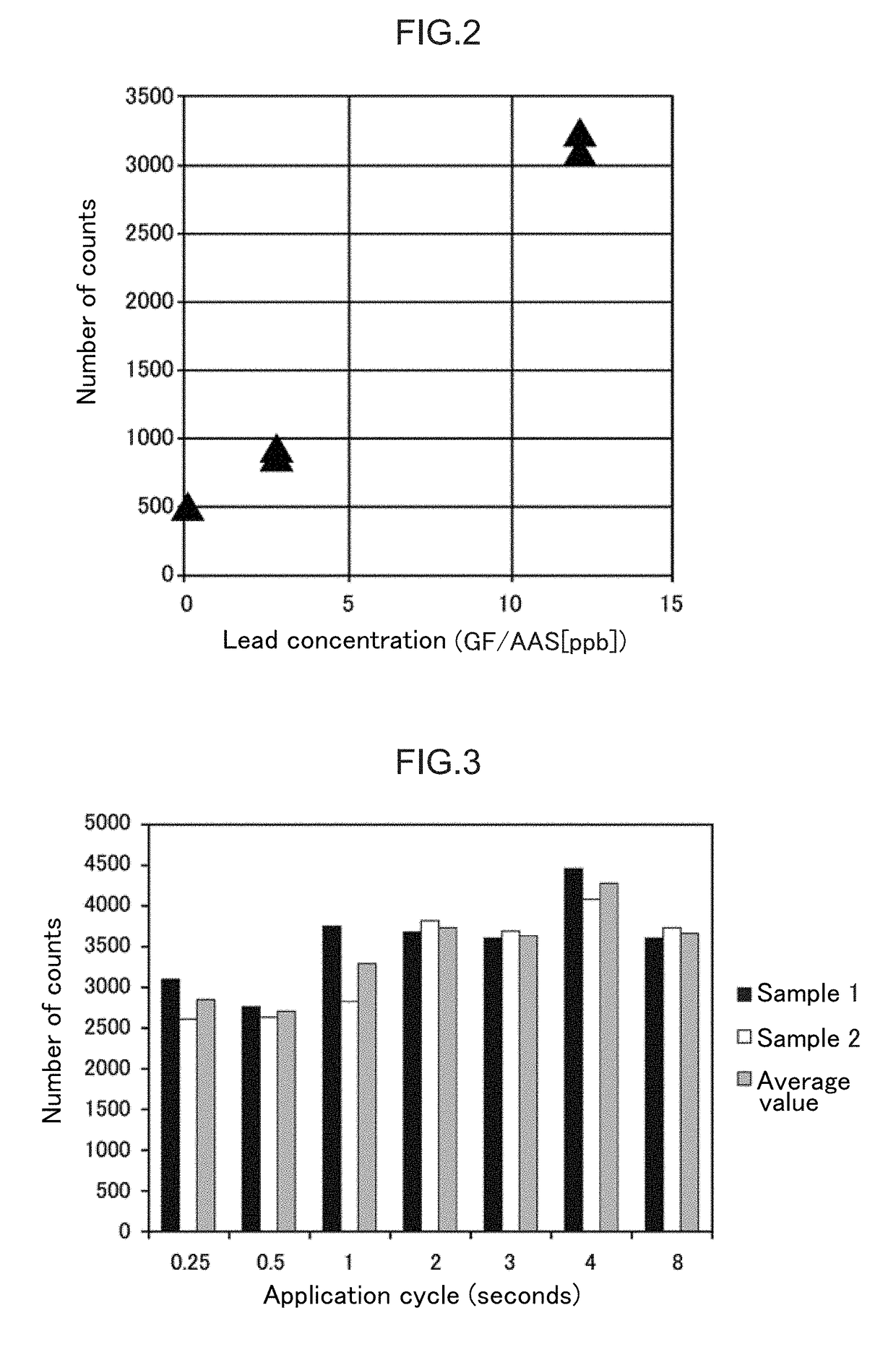

Plasma spectroscopic analysis method and plasma spectroscopic analyzer

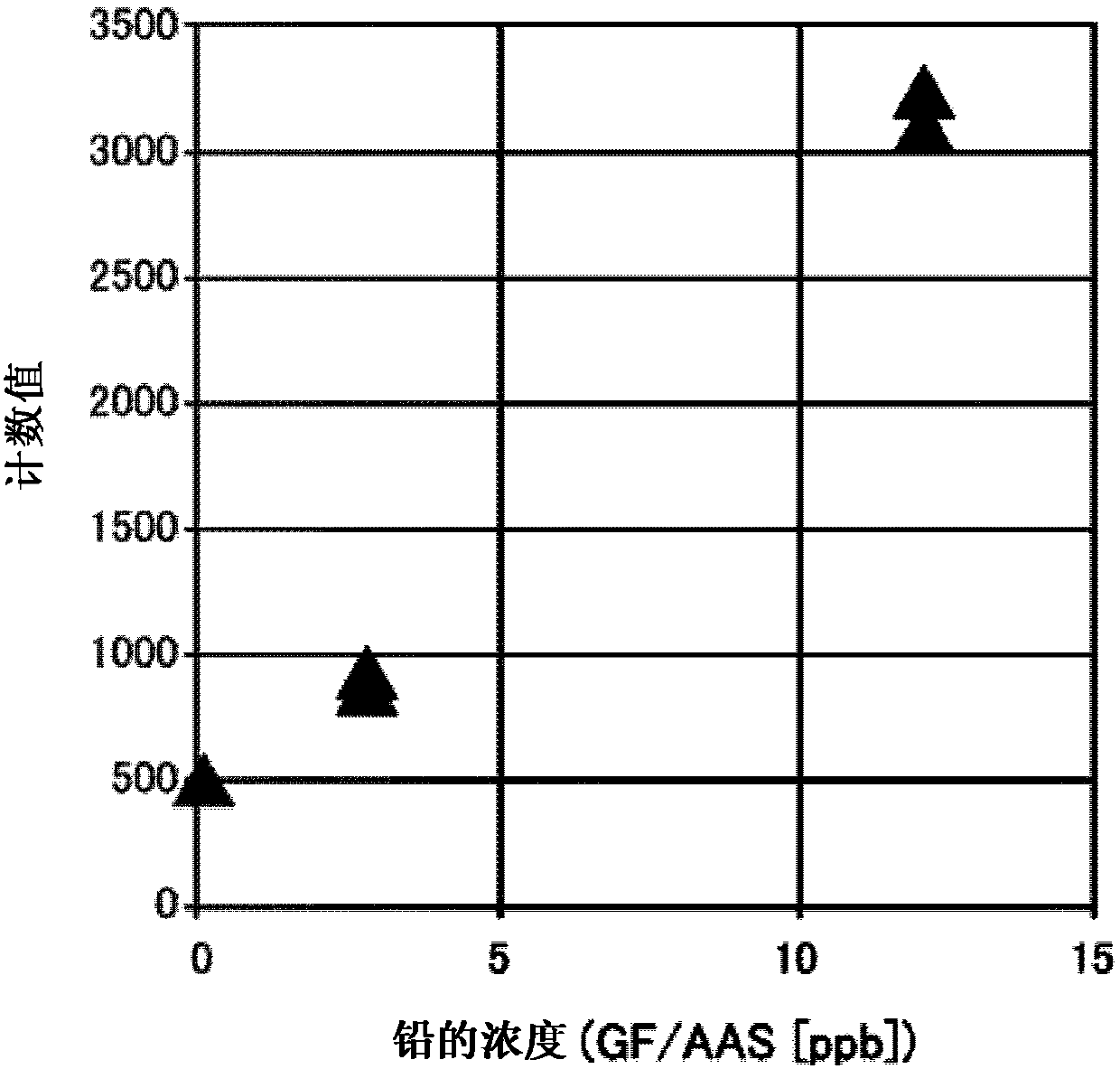

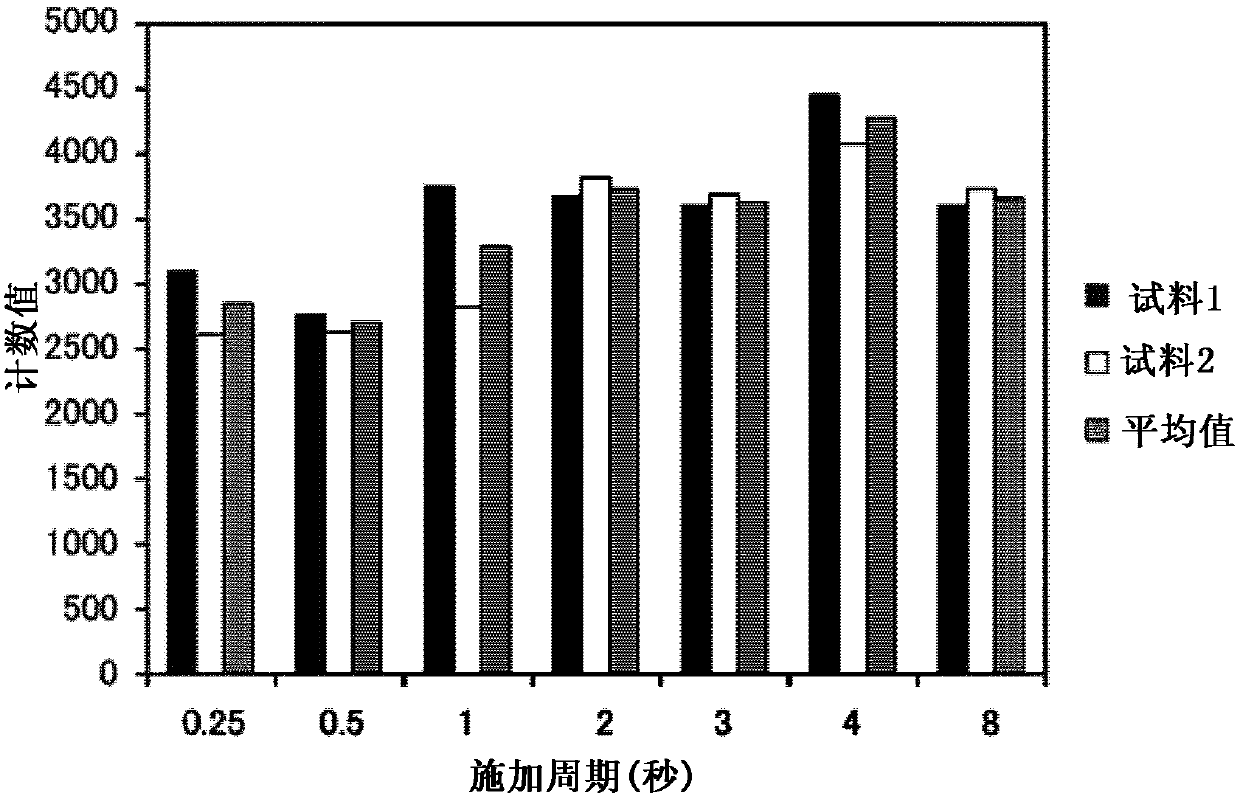

InactiveCN107643279AHigh analytical sensitivitySuppress analysis errorPreparing sample for investigationAnalysis by electrical excitationAnalyteAssay sensitivity

The invention provides a plasma spectroscopic analysis method and a plasma spectroscopic analyzer, the analytical sensitivity is high, and for example, occurrence of analytical errors in sample analysis is suppressed. A plasma spectroscopic analysis method includes a concentration process including a voltage application period in which voltage is applied to a pair of electrodes in the presence ofa sample thereby concentrating an analyte contained in the sample in the vicinity of at least one of the pair of electrodes; and a detection process of generating a plasma by applying voltage to the pair of electrodes and detecting light emitted by the analyte due to the plasma. An electric current between the pair of electrodes is constant while applying voltage for at least a part of the duration of the concentration process.

Owner:ARKRAY INC

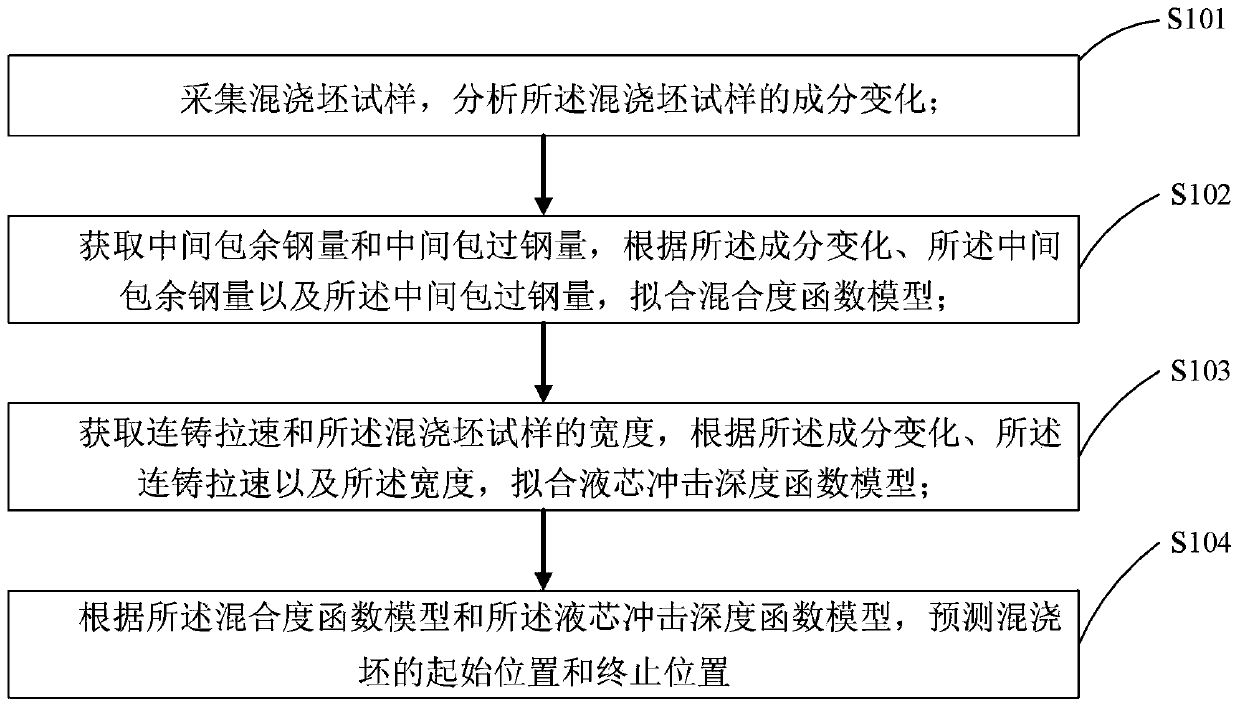

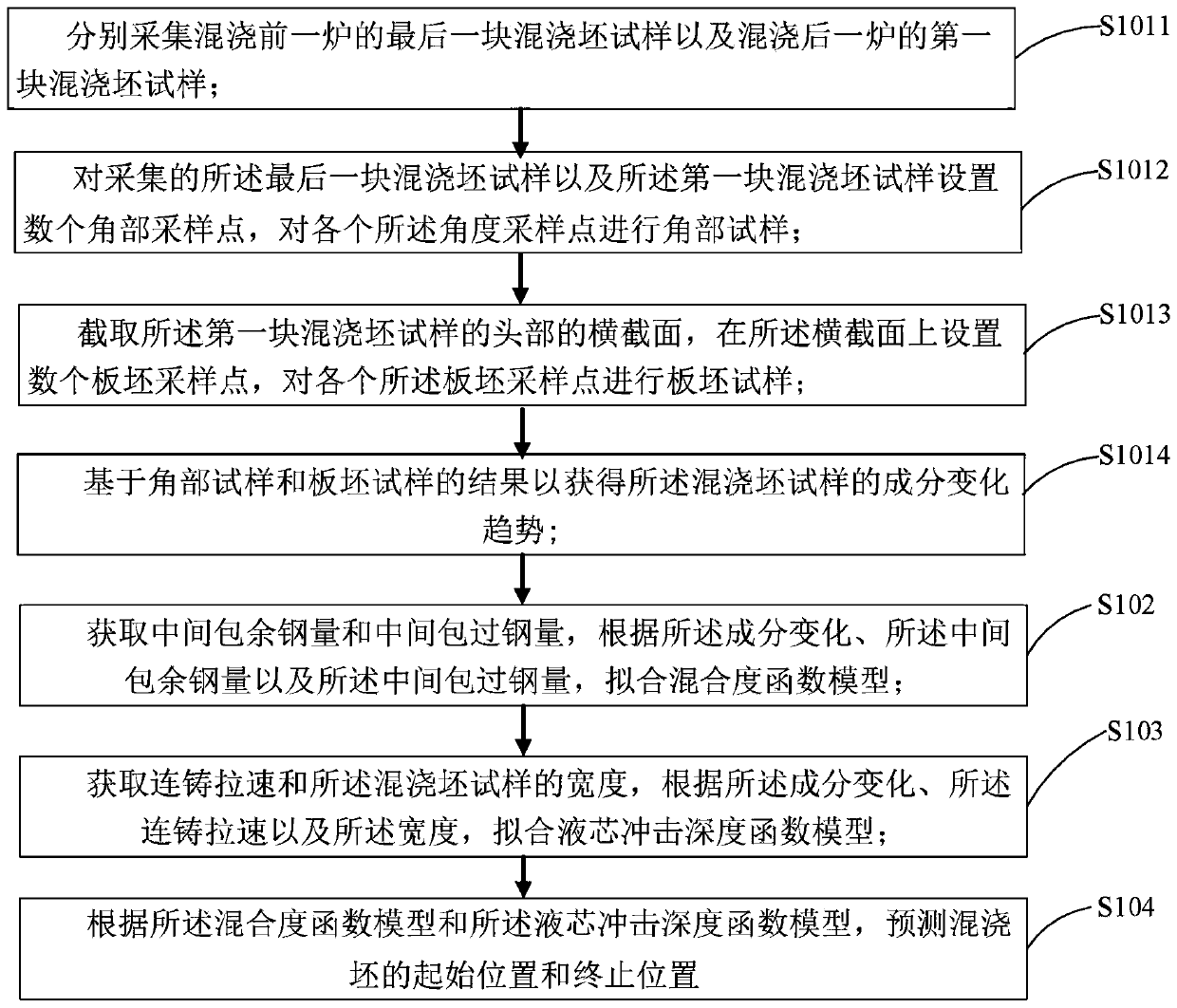

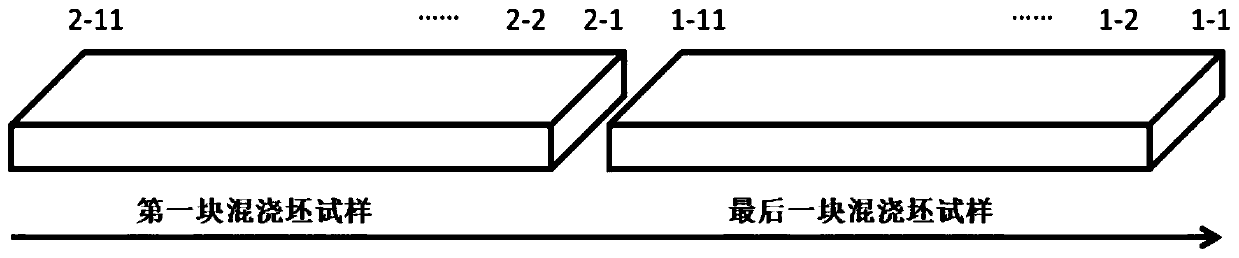

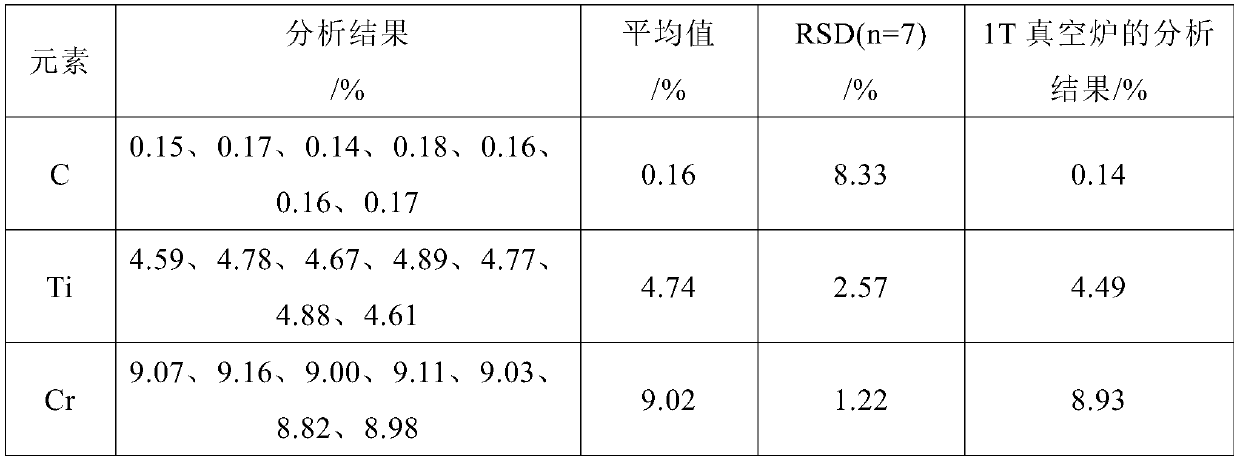

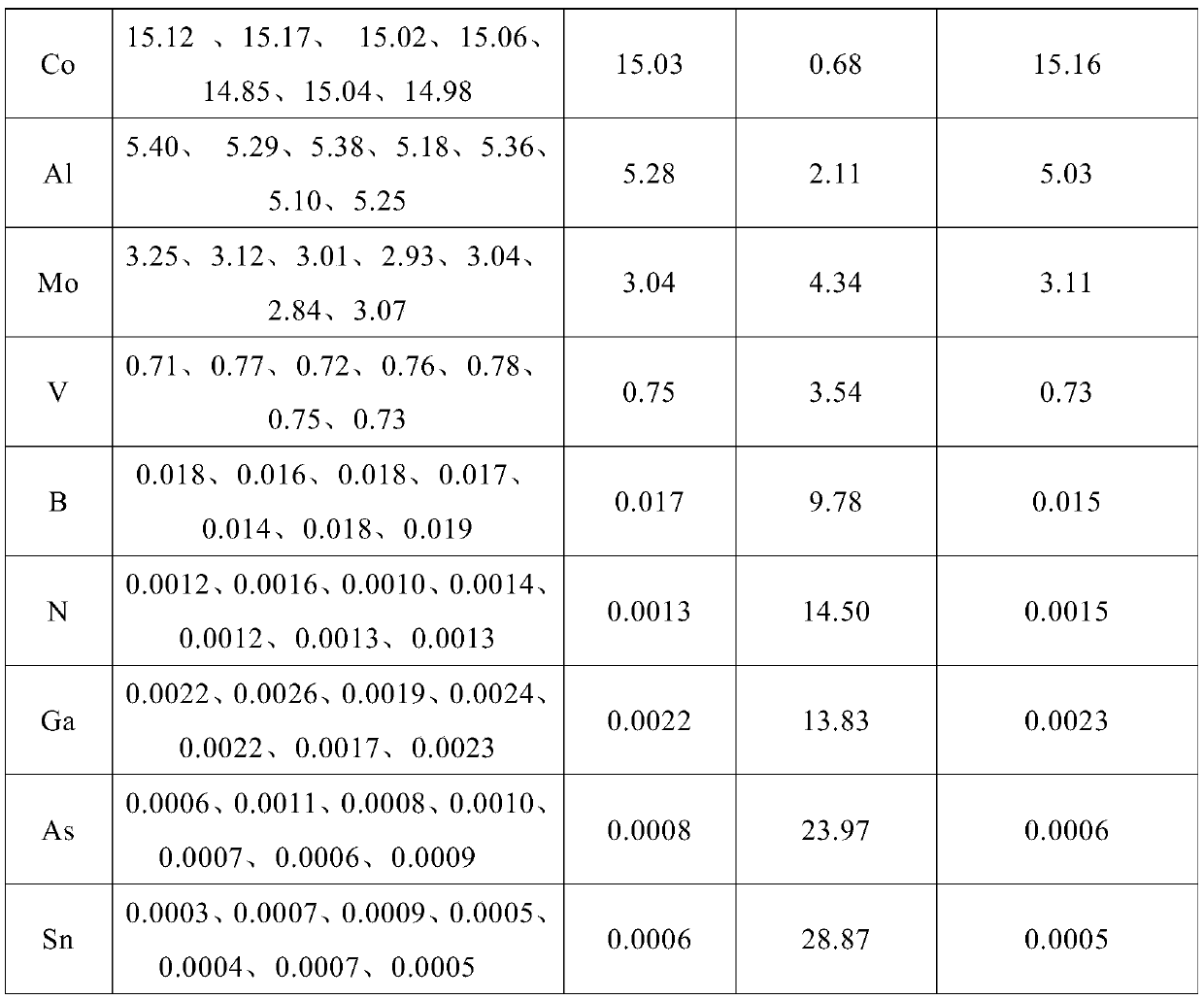

Component change prediction method and system for special steel type mixed casting blank

ActiveCN110261566APredicted starting positionJudging the handover positionAnalysis by thermal excitationComplex mathematical operationsLiquid coreWater model

The invention belongs to the technical field of steel manufacturing, and particularly relates to a component change prediction method and system for a special steel type mixed casting blank, and particularly relates to a component change prediction method for a special steel type mixed casting blank. The method comprises the following steps of: collecting a mixed casting blank sample, and analyzing the component change of the mixed casting blank sample; acquiring the tundish residual steel quantity and the tundish steel production capacity, and fitting a mixing degree function model according to the component change, the tundish residual steel quantity and the tundish steel production capacity; acquiring the continuous casting pulling speed and the width of the mixed casting blank sample, and fitting a liquid core impact depth function model according to the component change, the continuous casting pulling speed and the width; and according to the mixing degree function model and the liquid core impact depth function model, predicting the initial position and the final position of the mixed casting blank, wherein the mixing degree function model and the liquid core impact depth function model are established without depending on laboratory digital analog calculation or water model experiments, so that the prediction accuracy is high.

Owner:LIANYUAN IRON & STEEL GROUP CO LTD +1

Rapid analysis method for major elements, minor elements and trace elements in alloy slag charge

InactiveCN110865168AImprove guidanceReduce testing costsPreparing sample for investigationTesting metal constituentsSlagFluorescence

The invention relates to a rapid analysis method for major elements, minor elements and trace elements in alloy slag charge. The rapid analysis method comprises the following steps: performing ultrasonic alkaline liquid cleaning on alloy slag charge, cleaning with pure water, performing ultrasonic cleaning with an organic reagent and blow-drying, preparing a cake-shaped sample by using the alloy slag charge, pressing the cake-shaped sample, grinding, polishing, cleaning with the organic reagent and blow-drying, and analyzing major elements, minor elements and trace elements in the cake-shapedsample by using at least one instrument of a carbon-sulfur analyzer, an oxygen-nitrogen-hydrogen analyzer, a spectrograph, an X ray fluorescent spectrograph and a mass spectrometer. The method provided by the invention can optimize a combination according to detectability and ranges of the instruments and perform analytical determination on the major elements, minor elements and trace elements, and determination cost is reduced; and the method has good guiding effect on high-temperature alloy slag charge remelting and smelting.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

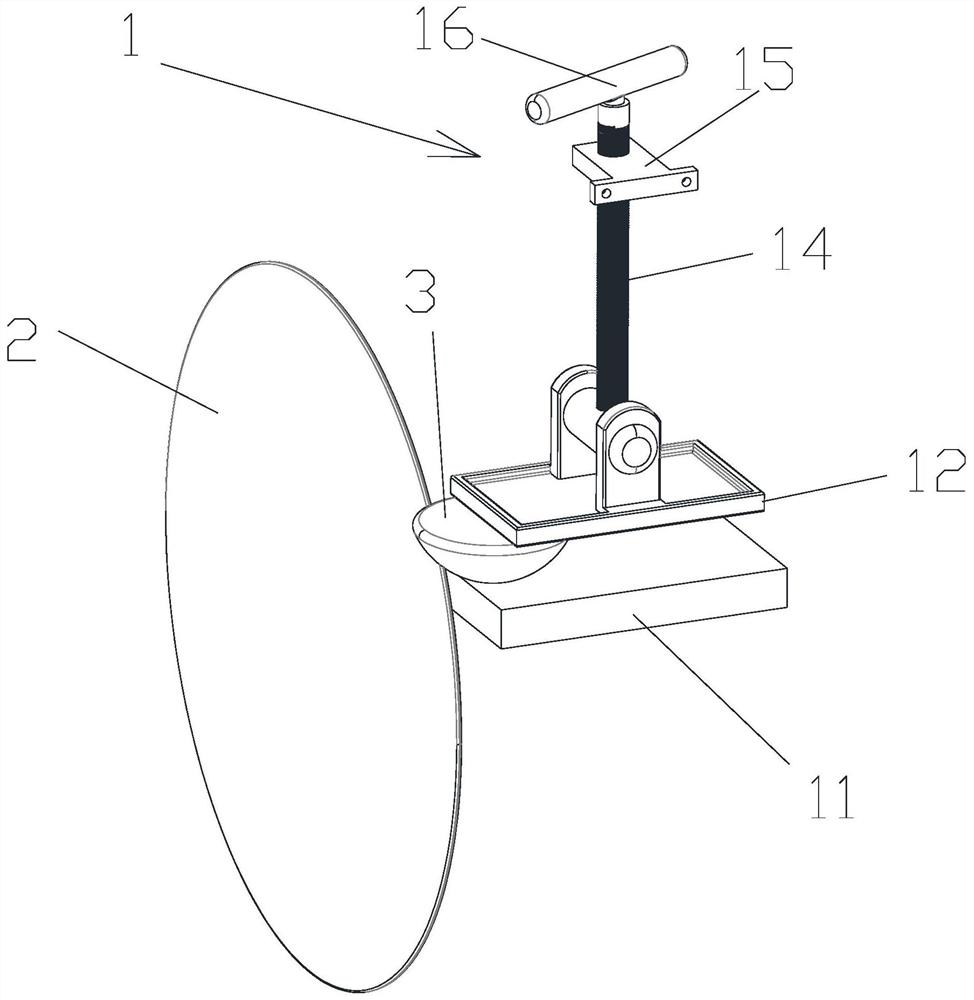

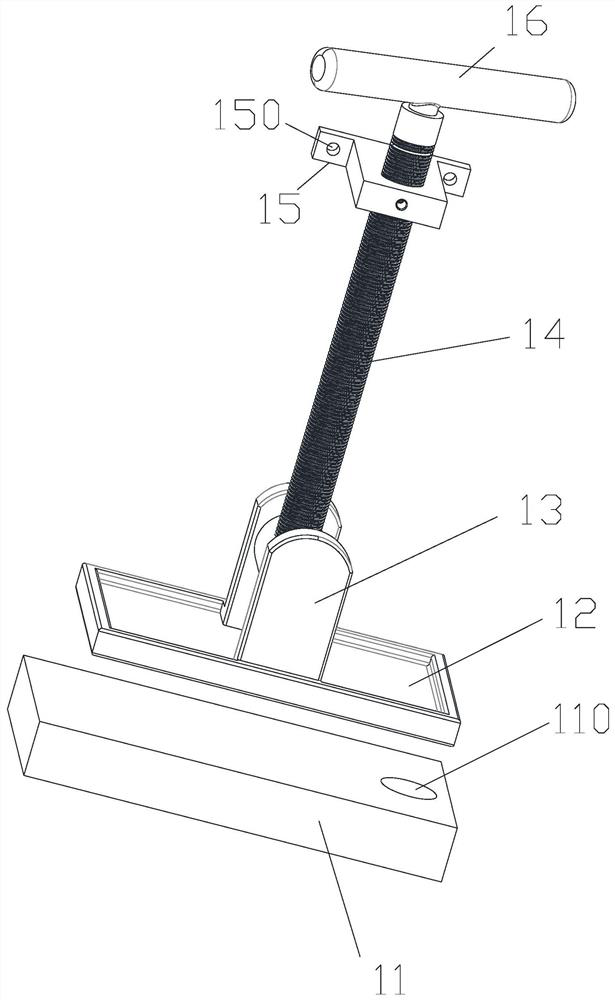

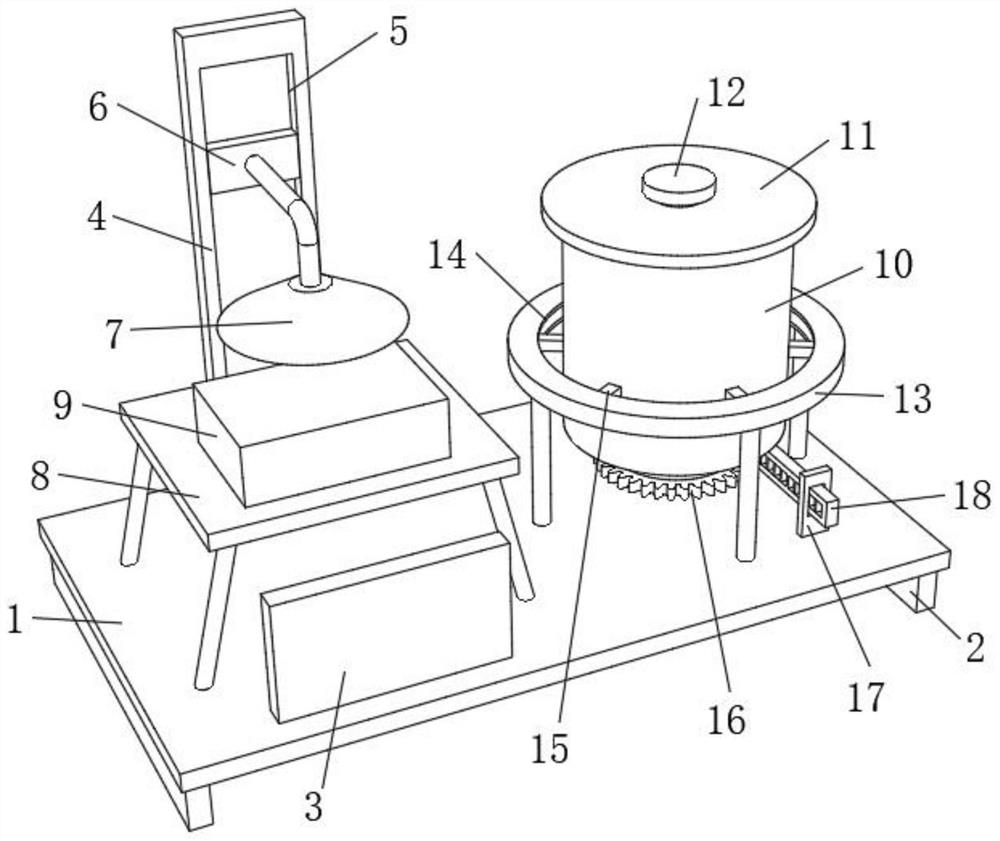

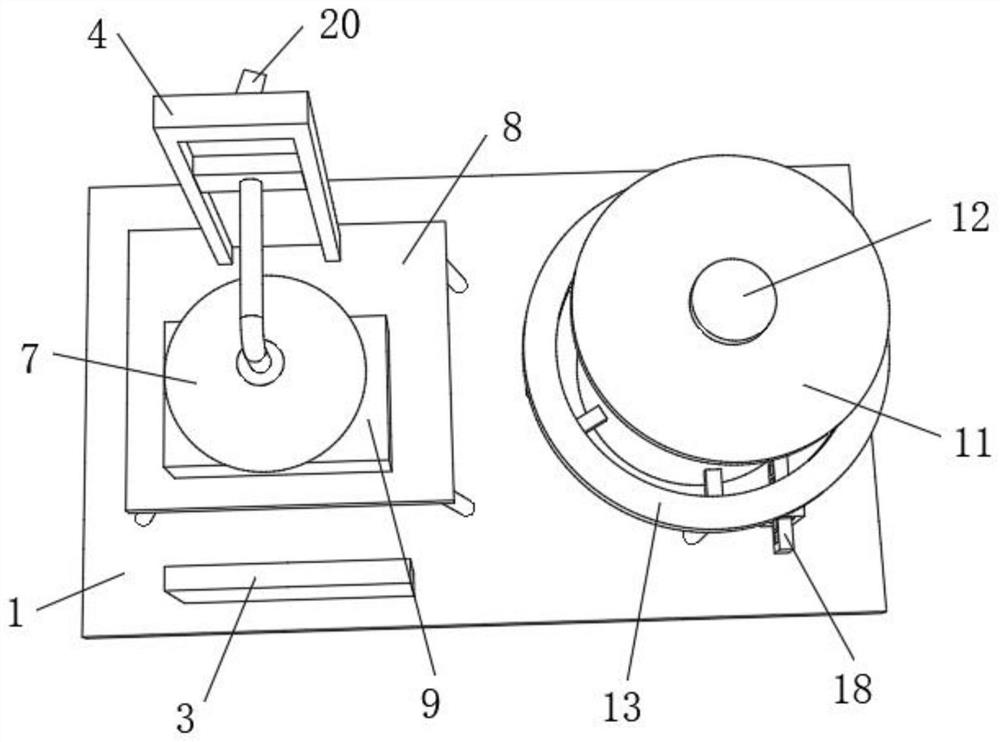

Method for measuring components of scrap steel and processing equipment for detecting scrap steel component sample

The invention provides a method for determining components of scrap steel and processing equipment for detecting scrap steel component sample. The method for determining the components of the scrap steel comprises the steps of A, sampling an iron-containing material containing machining scrap iron and crushed steel slag, and crushing by using a crusher; B, splitting the iron-containing material by using a riffle after crushing; C, under the sample condition, melting the divided iron-containing material obtained in the step B until slag and iron are completely separated, and naturally cooling to room temperature to obtain a slag sample and a steel ingot; and D, analyzing the contents of C, P, S, As, Si, Mn, Cr, Cu and TFe by adopting a spark discharge direct-reading spectrometer. The invention further provides equipment for measuring the components of the scrap steel. The inspection quality can be ensured, and the working efficiency is improved.

Owner:LIUZHOU IRON & STEEL

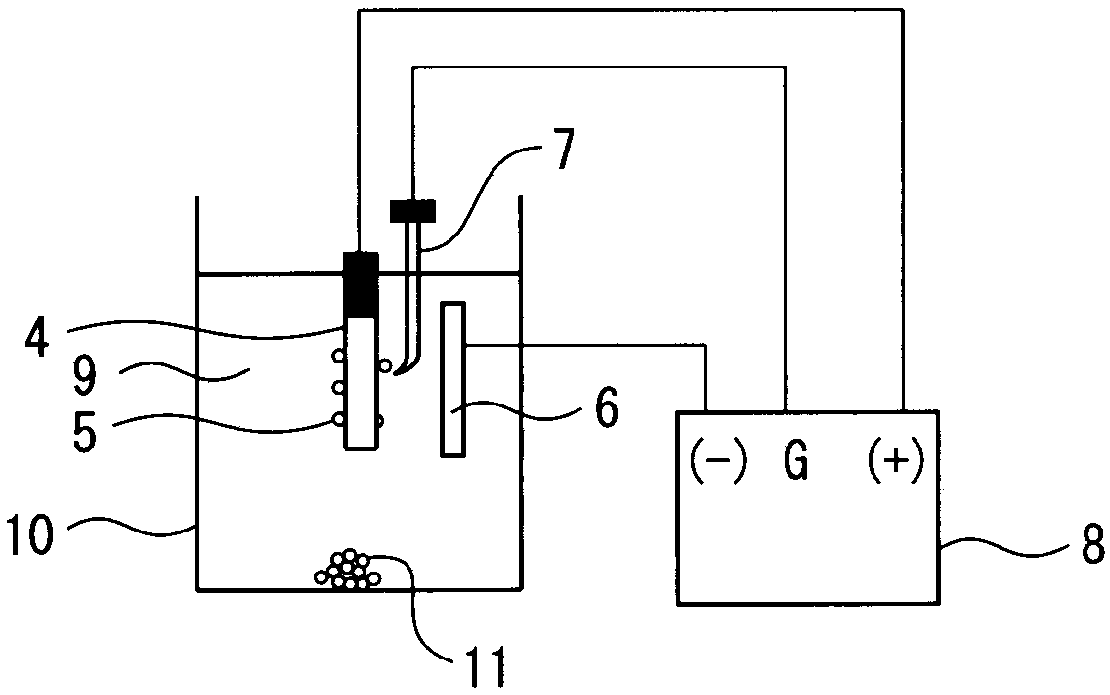

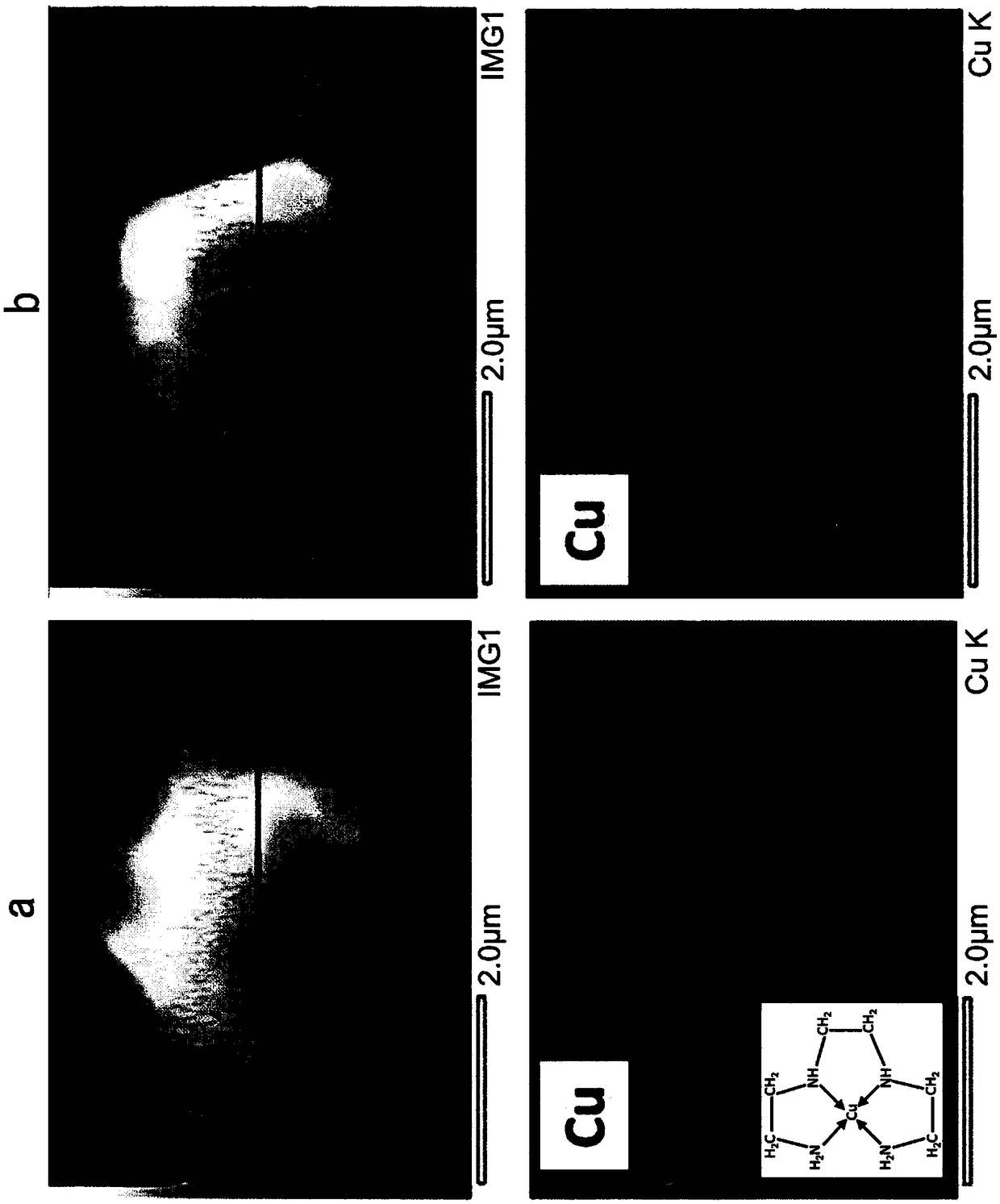

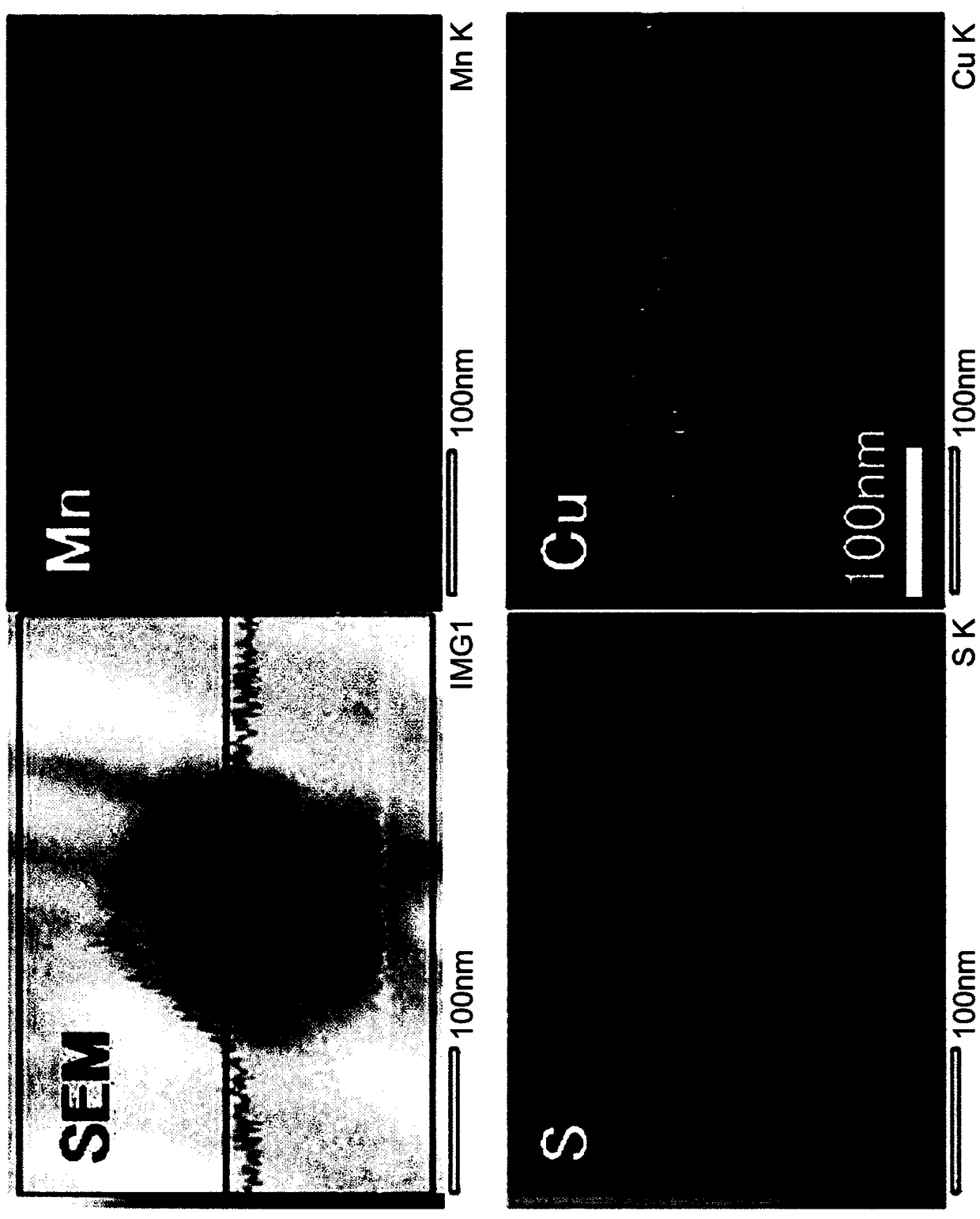

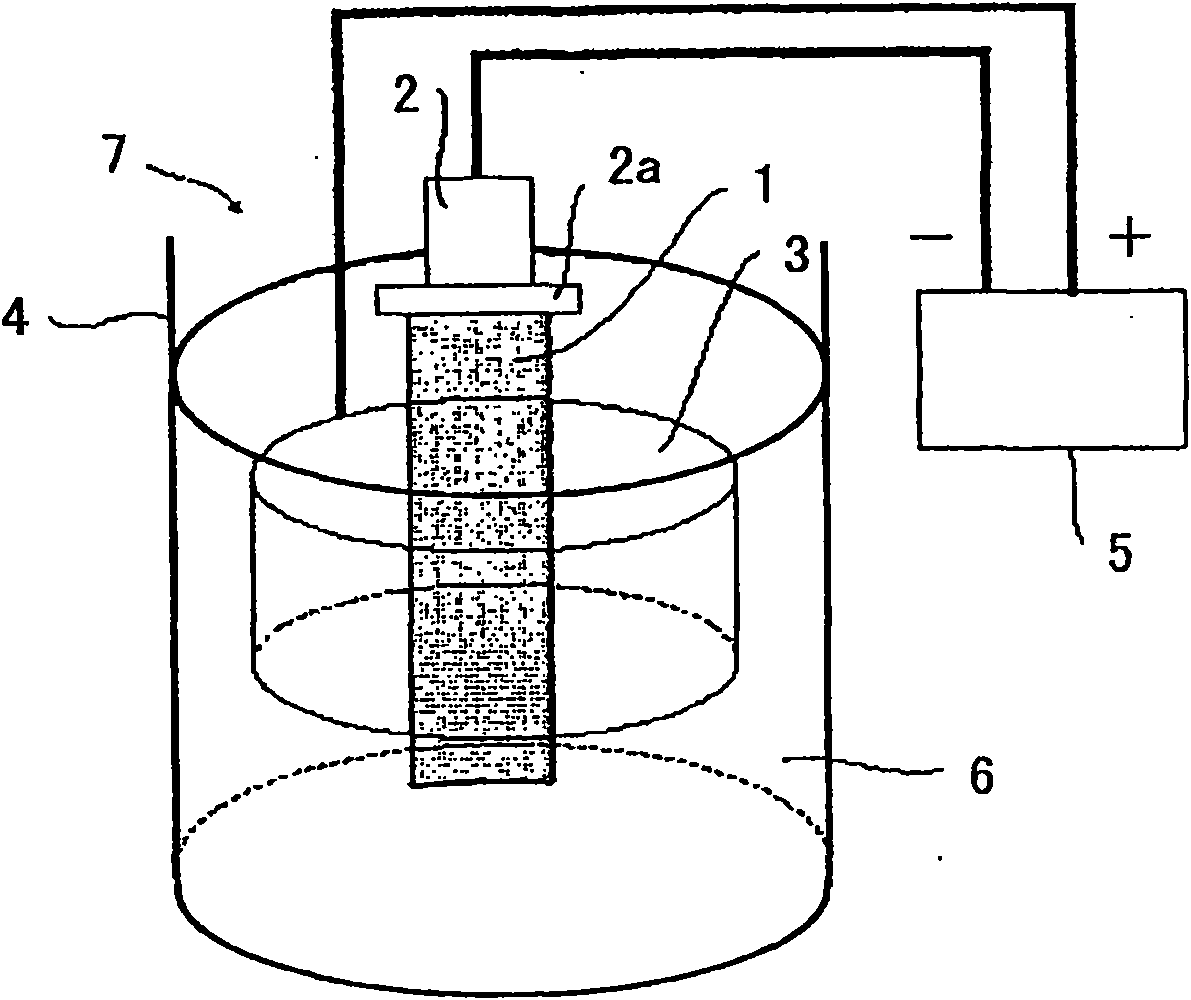

Method for extracting metal compound particles, method for analyzing metal compound particles, and electrolyte solution used in said methods

ActiveCN108139306AUnderstand the real stateAccurately grasp the contentPreparing sample for investigationSurface treatment compositionsElectrolytic agentSolubility

The present invention addresses the problem, in the extraction and analysis of metal fine particles (inclusions, precipitate) in a metal material by means of electrolytic etching using a solvent electrolyte solution, of suppressing surface substitution of the metal fine particles by Cu ions and the like and preventing the generation of artifact CuS and the like without significantly changing conventional extraction / analysis methods. Provided are: a method for extracting metal compound particles in a metal material by etching the metal material in an electrolyte solution, said method using an electrolyte solution that comprises an agent that forms a complex that includes a metal M' wherein if the solubility product of a metal compound M'x'Ay' is defined as Ksp[M'x'Ay'] and the solubility product of a metal compound MxAy to be extracted which is included in the metal material is defined as Ksp[MxAy], delta as defined in the belowmentioned formula is 10 or more; and said electrolyte solution. delta = pKsp[M'x'Ay']-pKsp[MxAy] = (-log10Ksp[M'x'Ay'])-(-log10Ksp[MxAy])

Owner:NIPPON STEEL CORP

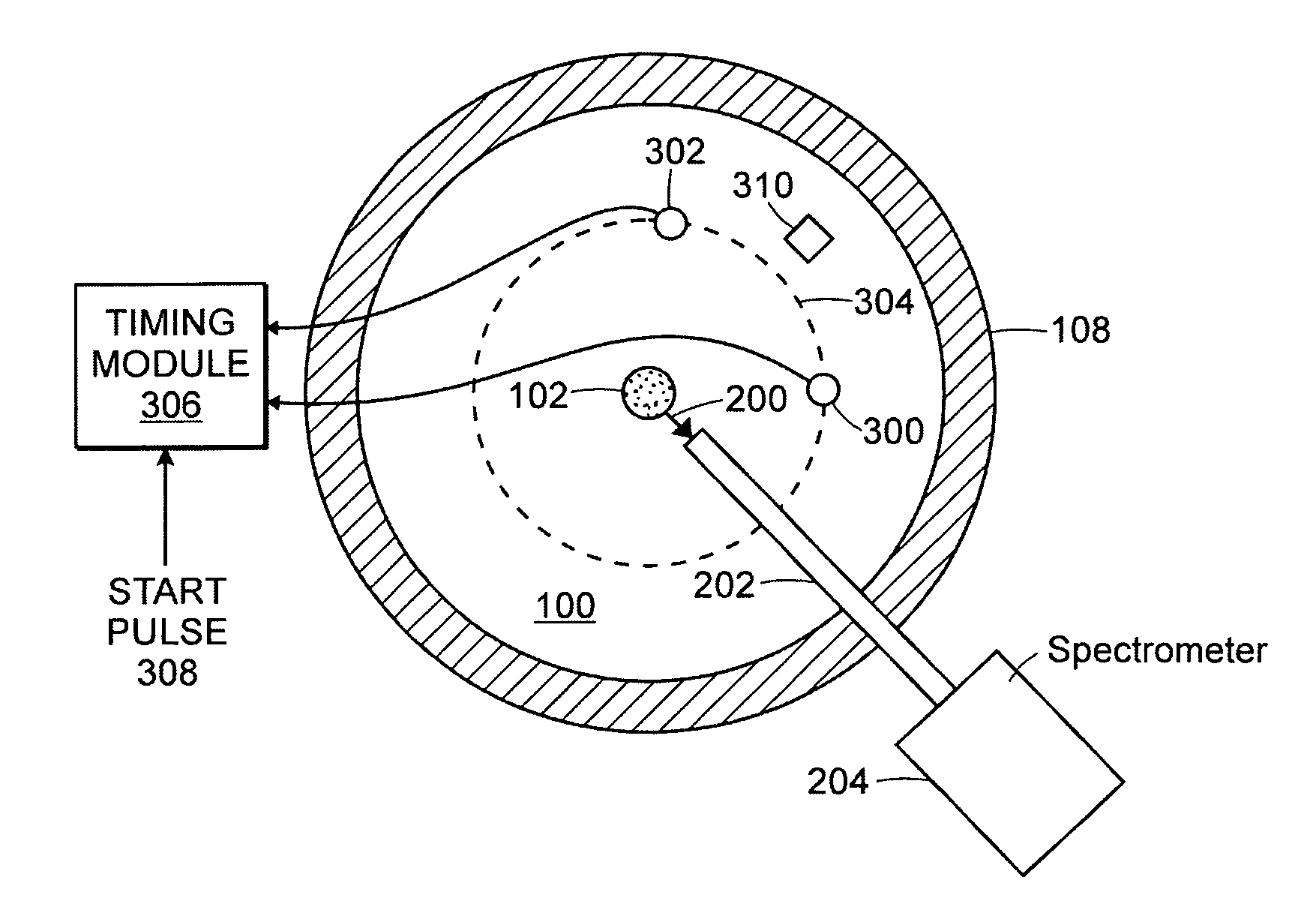

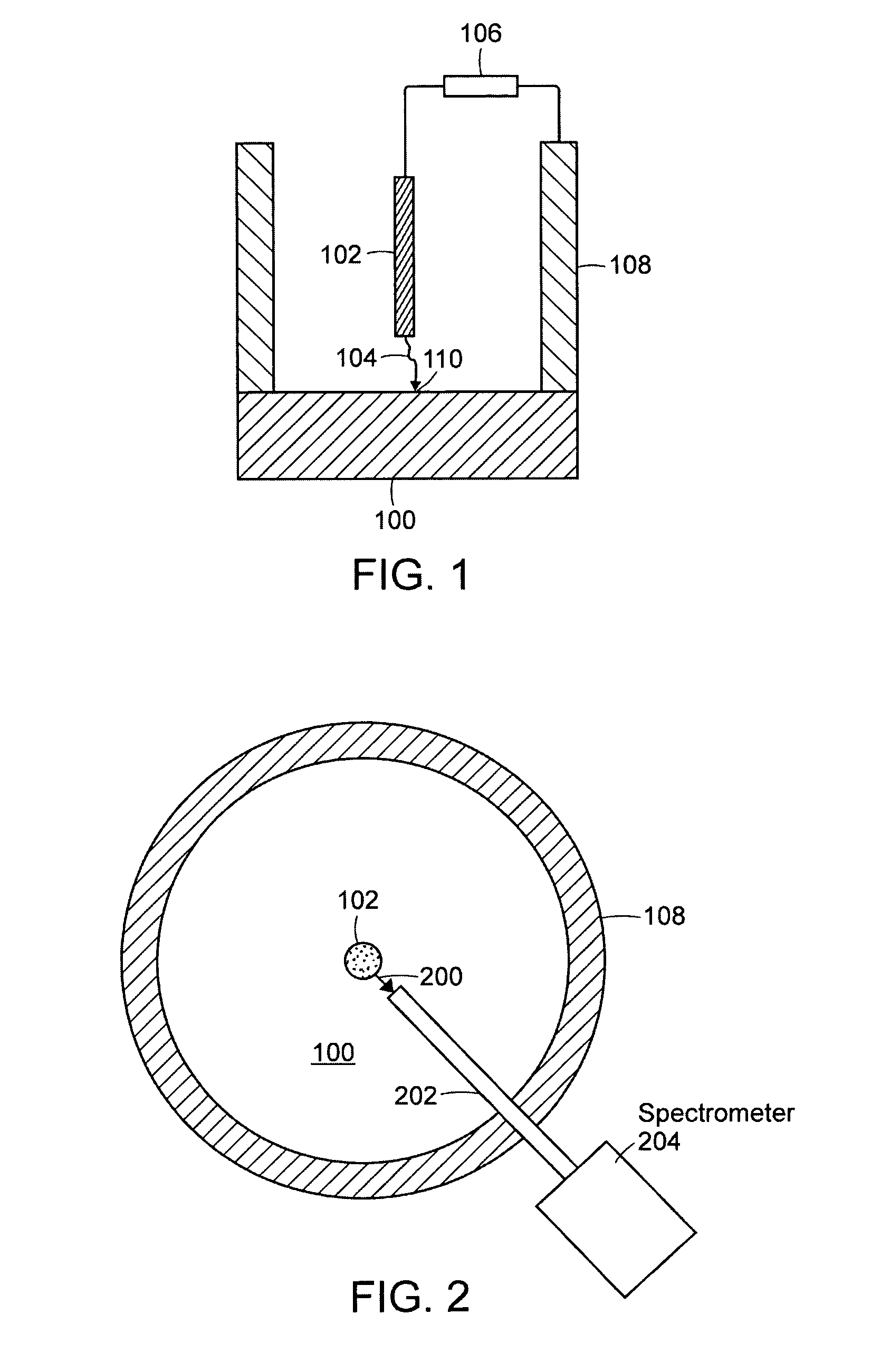

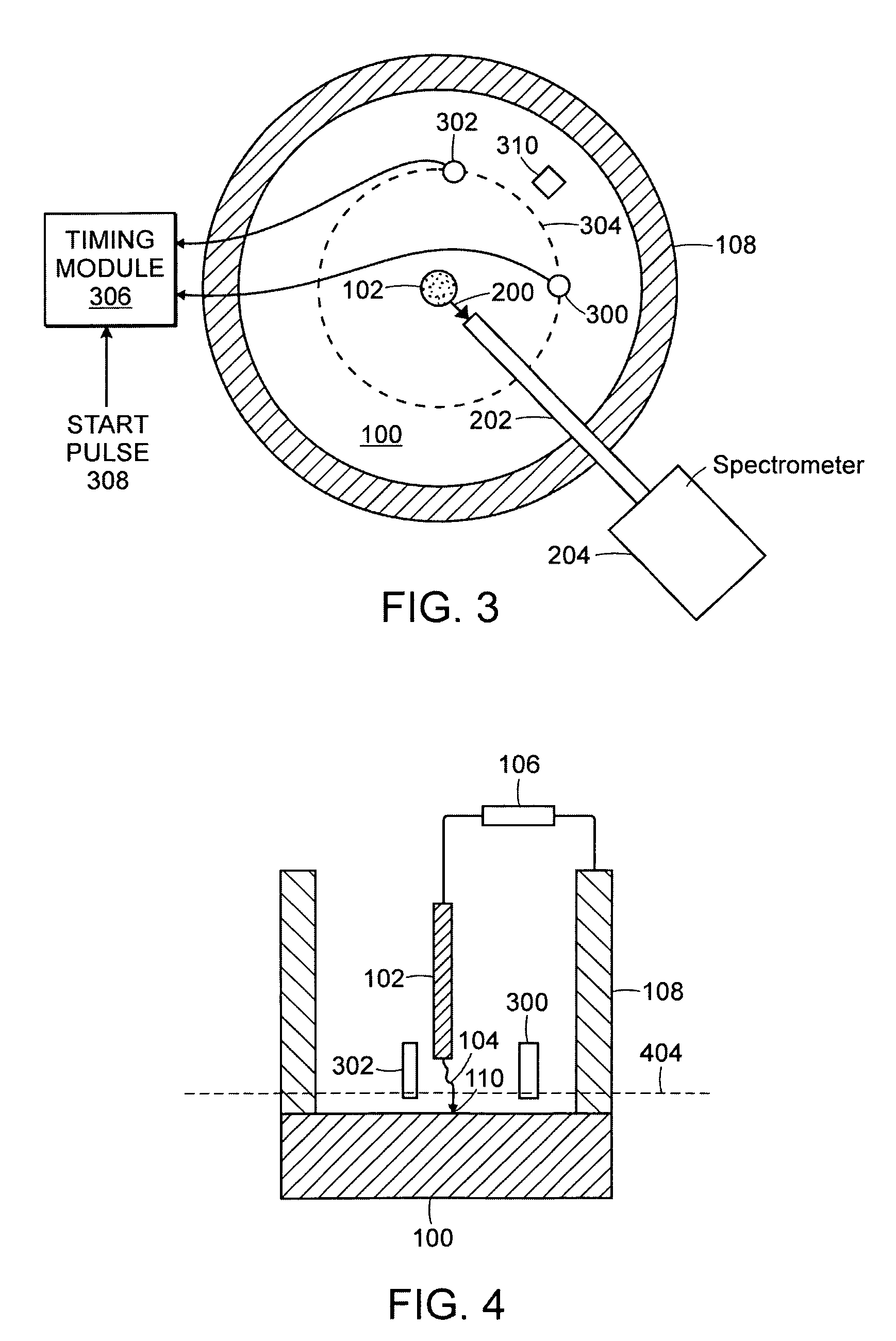

Arc/spark optical emission spectroscopy correlated with spark location

Two or more high-frequency microphones are used to determine where an individual spark or other excitation beam strikes a sample in an optical emission spectroscopy (OES) instrument. The position of the spark can be correlated with the elemental composition of the material in the sample vaporized by the spark. The microphones are placed appropriately in air around a sparker of the instrument, or appropriately on the sample, or on both the sample and in the air. Arrival times of sound from the spark to the microphones, or a difference in the arrival times, yields information, from which the position of the spark relative to the microphones, and hence the absolute position of the spark, is deduced, such as by triangulation. Optionally or in addition, a signal that indicates a time when the spark is produced is correlated with one or more spectra detected by a spectrometer, so a spectrum that results from the vaporized sample can be distinguished from a spectrum that results from heated gas above the sample.

Owner:THERMO NITON ANALYZERS

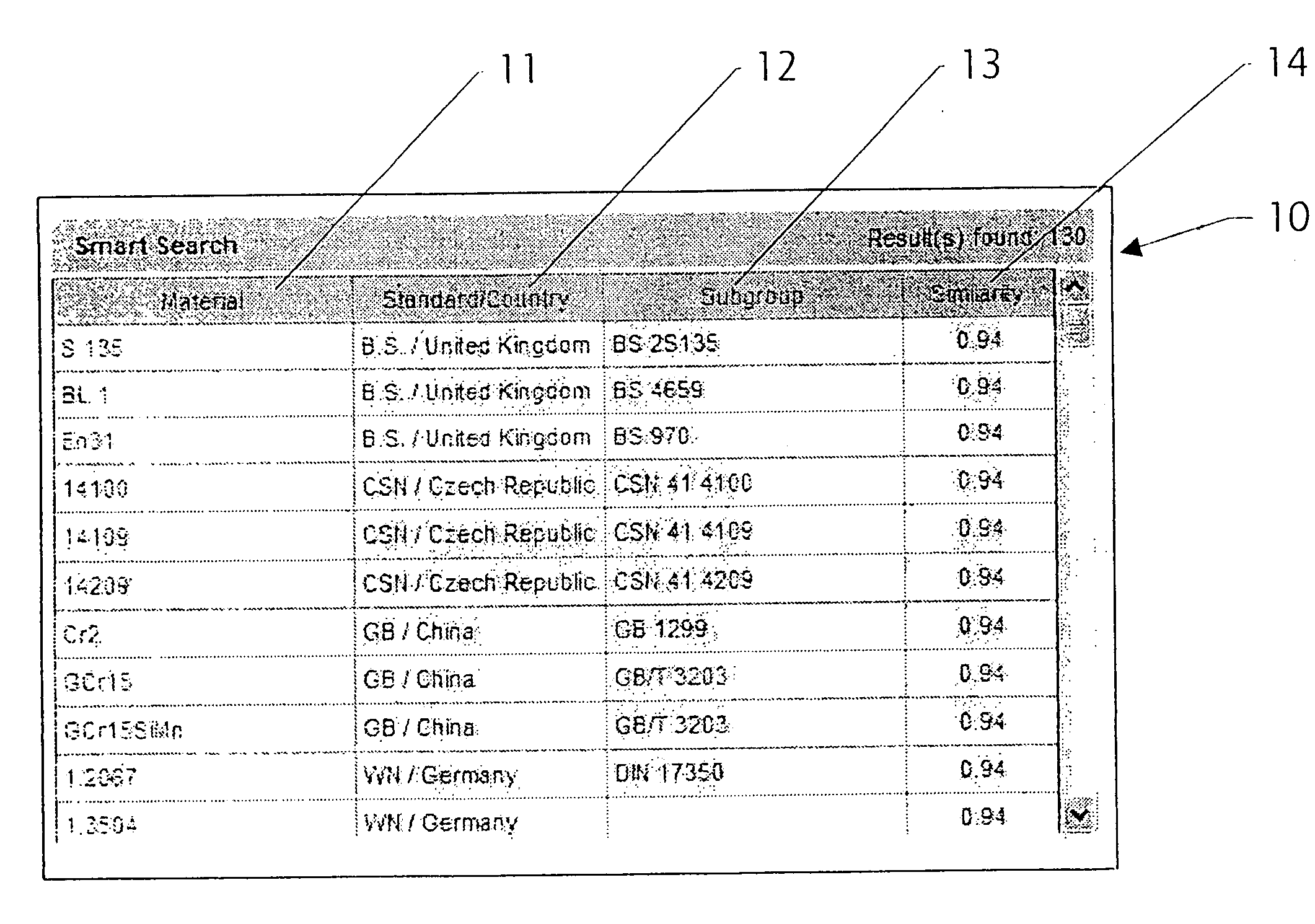

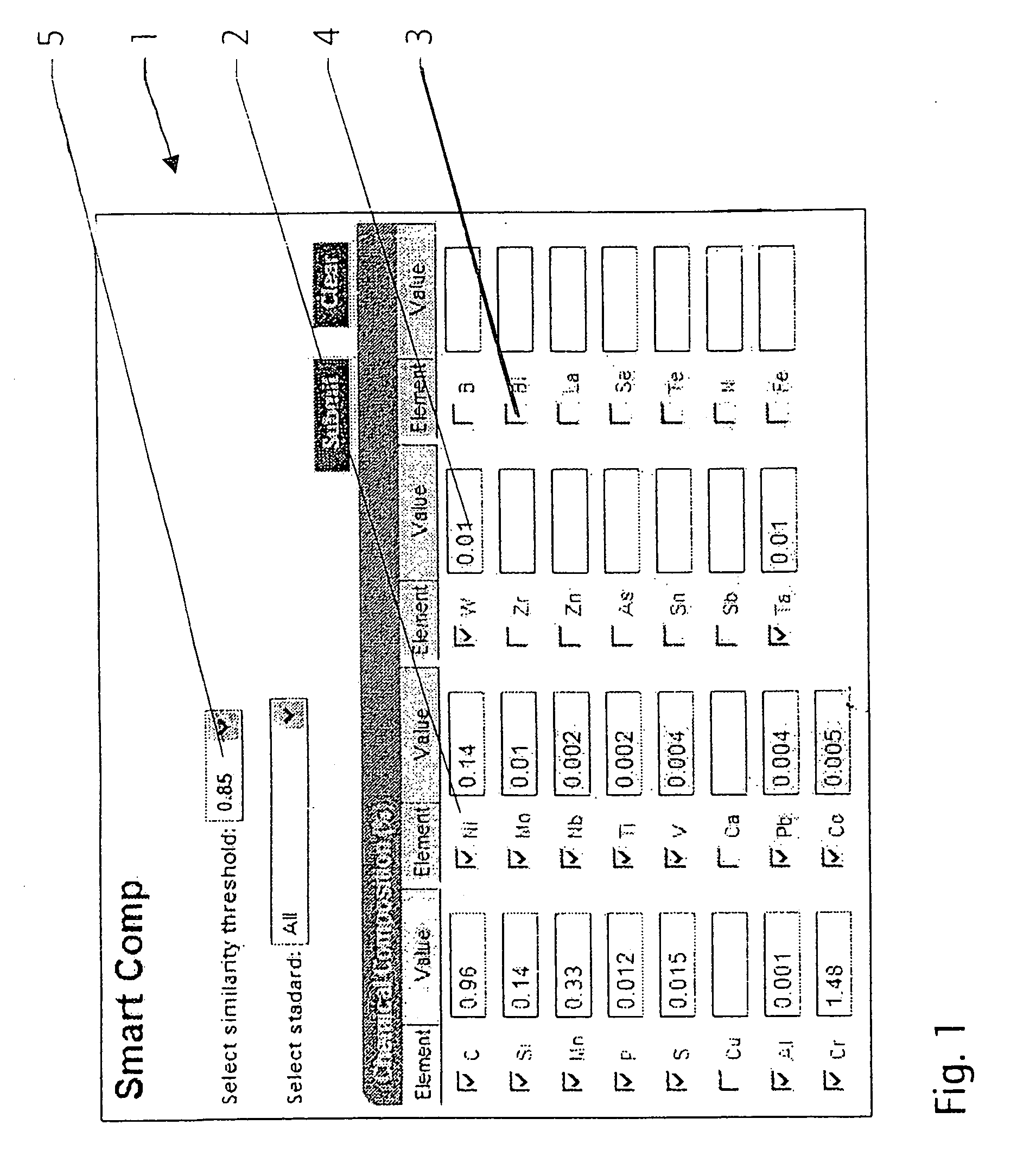

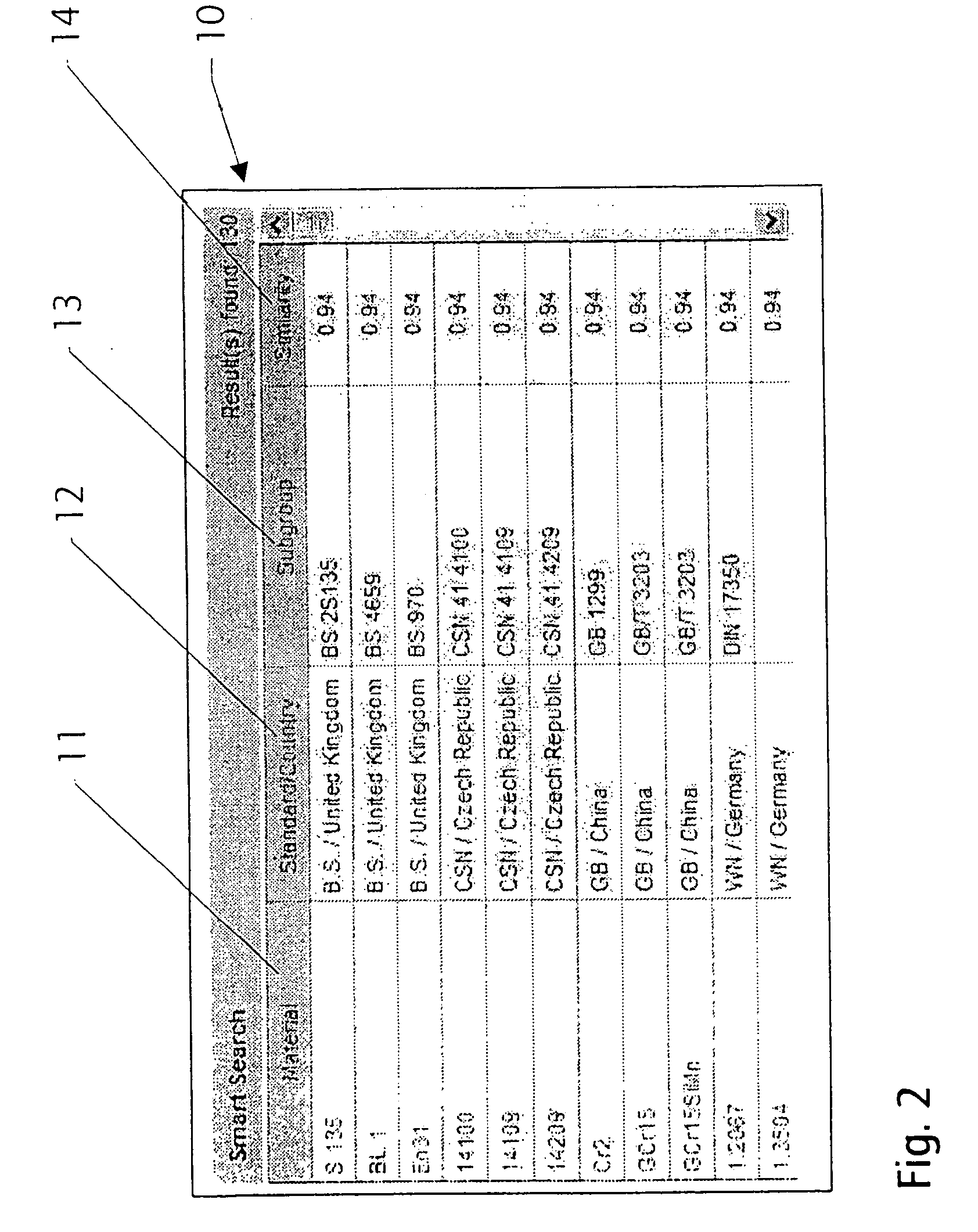

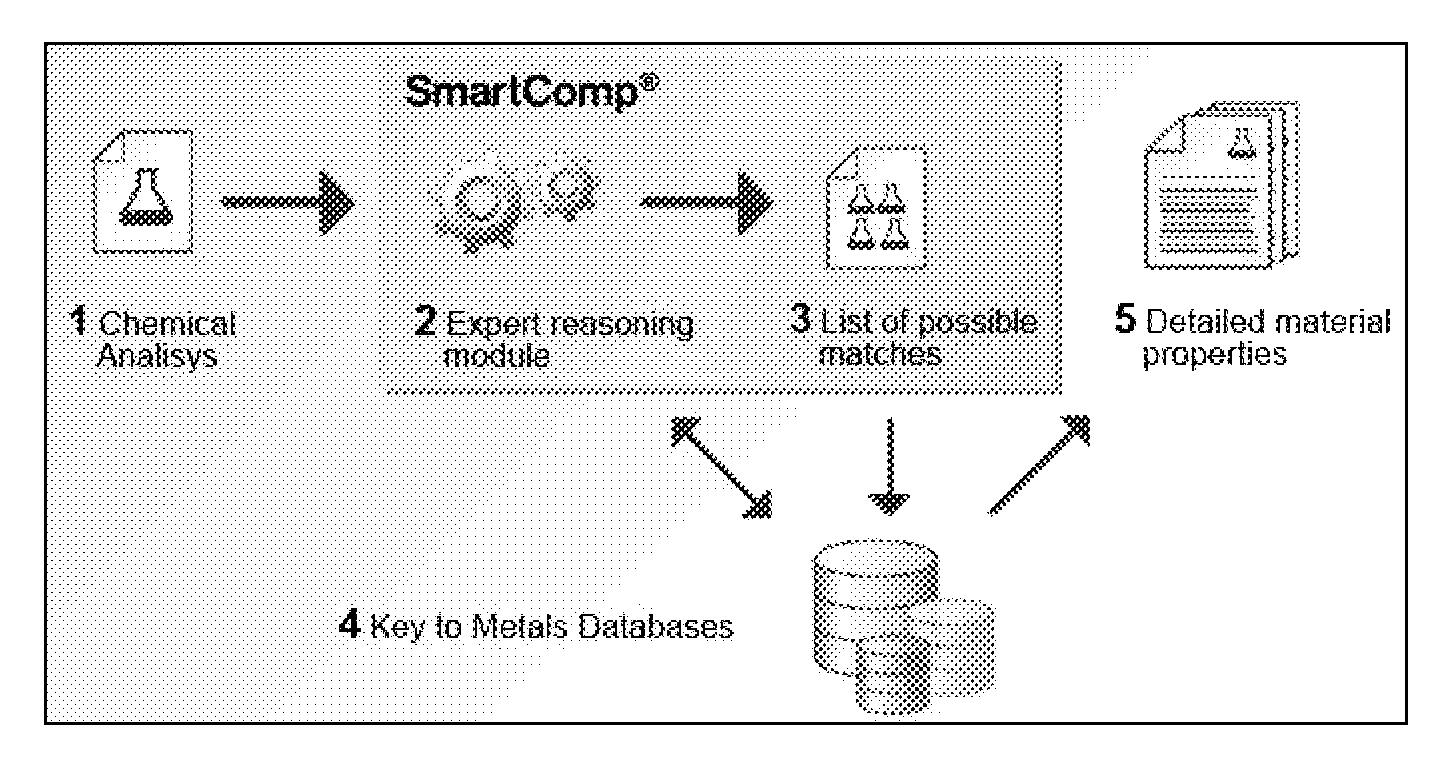

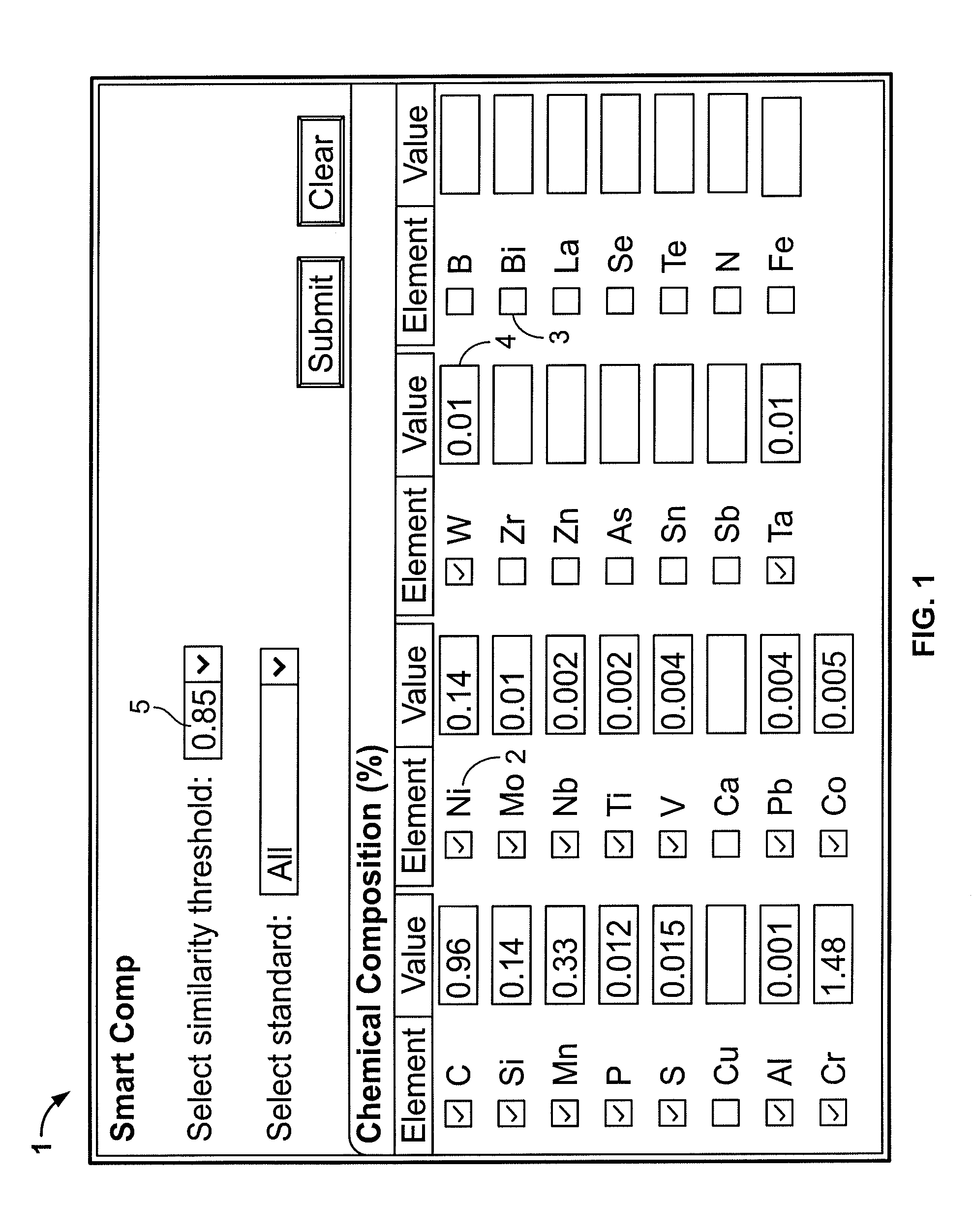

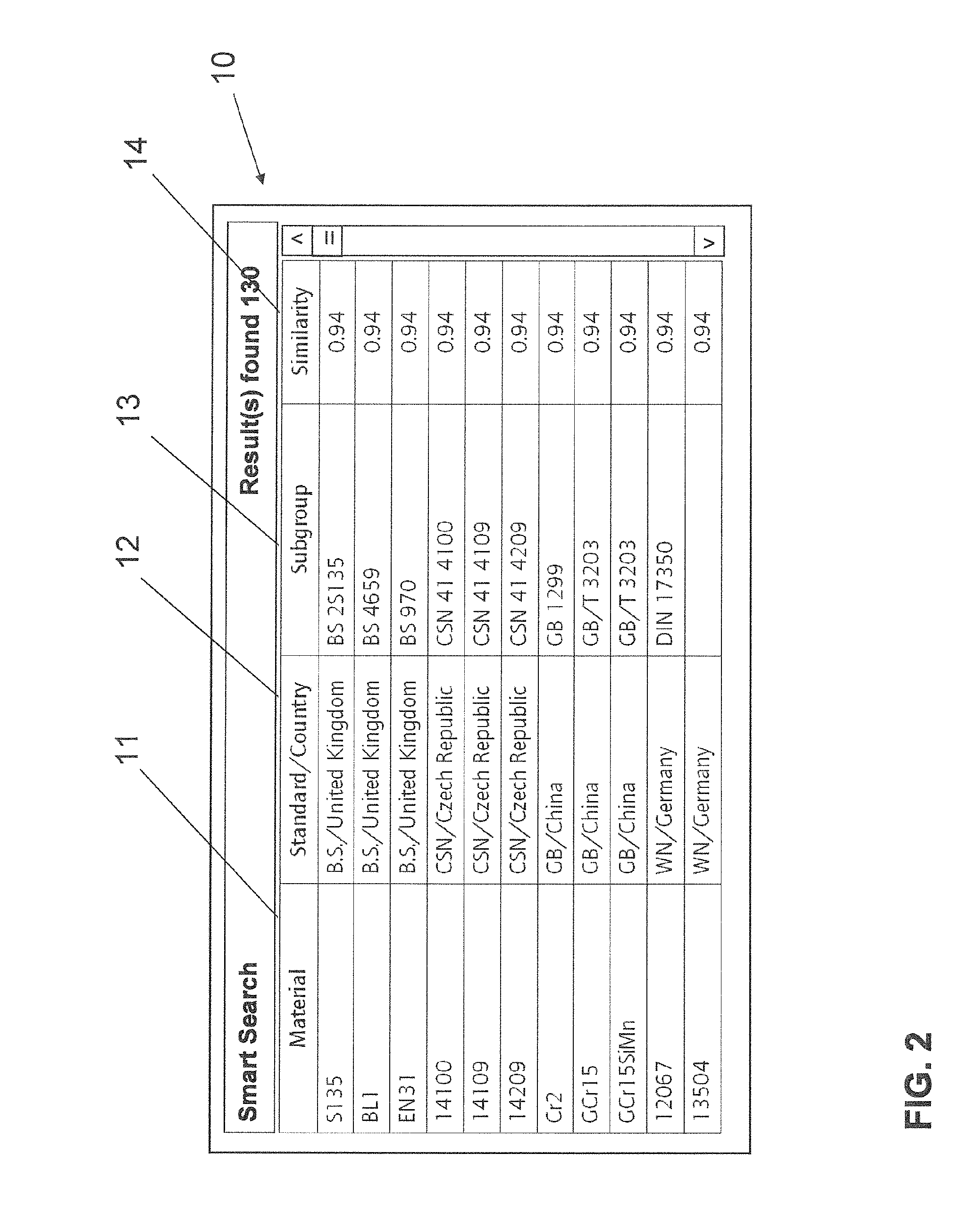

Method and system to identify metal alloys

ActiveUS20090076739A1Accurate identityAccurate identificationSpecial data processing applicationsChemical methods analysisChemical compositionMetal alloy

A method and system to identify an unknown metal alloy based on its chemical composition is provided in the present application. The chemical elements contained in the alloy are separated into key elements and trap elements. Then a correlation factor is applied to each key element and a similarity factor is calculated based on the correlation factors.

Owner:KEY TO METALS

Method and system to identify metal alloys

ActiveUS8918290B2Accurate identificationAccurate identitySpecial data processing applicationsChemical methods analysisCorrelation factorChemical composition

A method and system to identify an unknown metal alloy based on its chemical composition is provided in the present application. The chemical elements contained in the alloy are separated into key elements and trap elements. Then a similarity factor between a relative amount of each key element and a threshold value of said key elements is determined and a correlation factor is formed based on the similarity factors.

Owner:KEY TO METALS

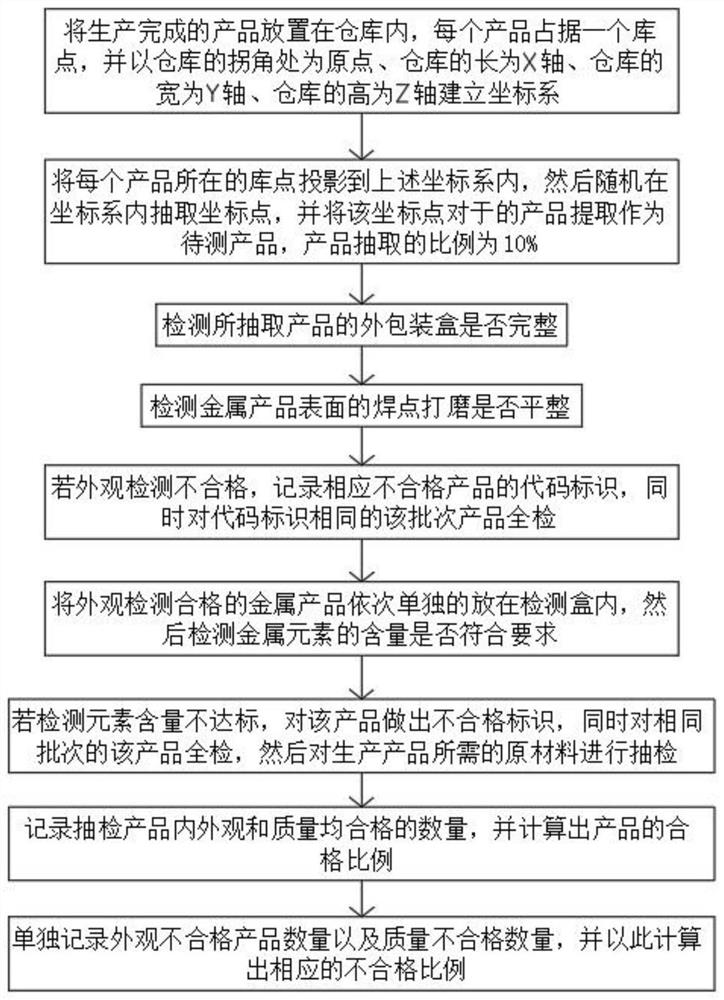

Product quality detection method and detection device

PendingCN114280266AEasy to findStrong randomnessTesting metal constituentsProcess engineeringIndustrial engineering

The invention discloses a product quality detection method and a detection device, and relates to the technical field of solid metal product quality detection. The method comprises the steps of to-be-detected product extraction, product appearance detection, product quality detection and detection report generation, and the to-be-detected product extraction comprises the following steps that 1, produced products are placed in a warehouse, and each product occupies a warehouse point; and establishing a coordinate system by taking the corner of the warehouse as an original point, the length of the warehouse as an X axis, the width of the warehouse as a Y axis and the height of the warehouse as a Z axis. According to the method, the coordinate system is established according to the length, width and height of the warehouse, each product can be projected in the coordinate system, each product has a unique coordinate, points can be selected randomly in the coordinate system when the products are extracted and detected, the randomness is high when the spot check products are selected, the accuracy of product detection can be improved, and the detection efficiency is improved. And the detection result of the product is more credible, and meanwhile, unqualified products can be conveniently found out from a warehouse.

Owner:HENAN PROVINCE PROD QUALITY SUPERVISION & INSPECTION CENT

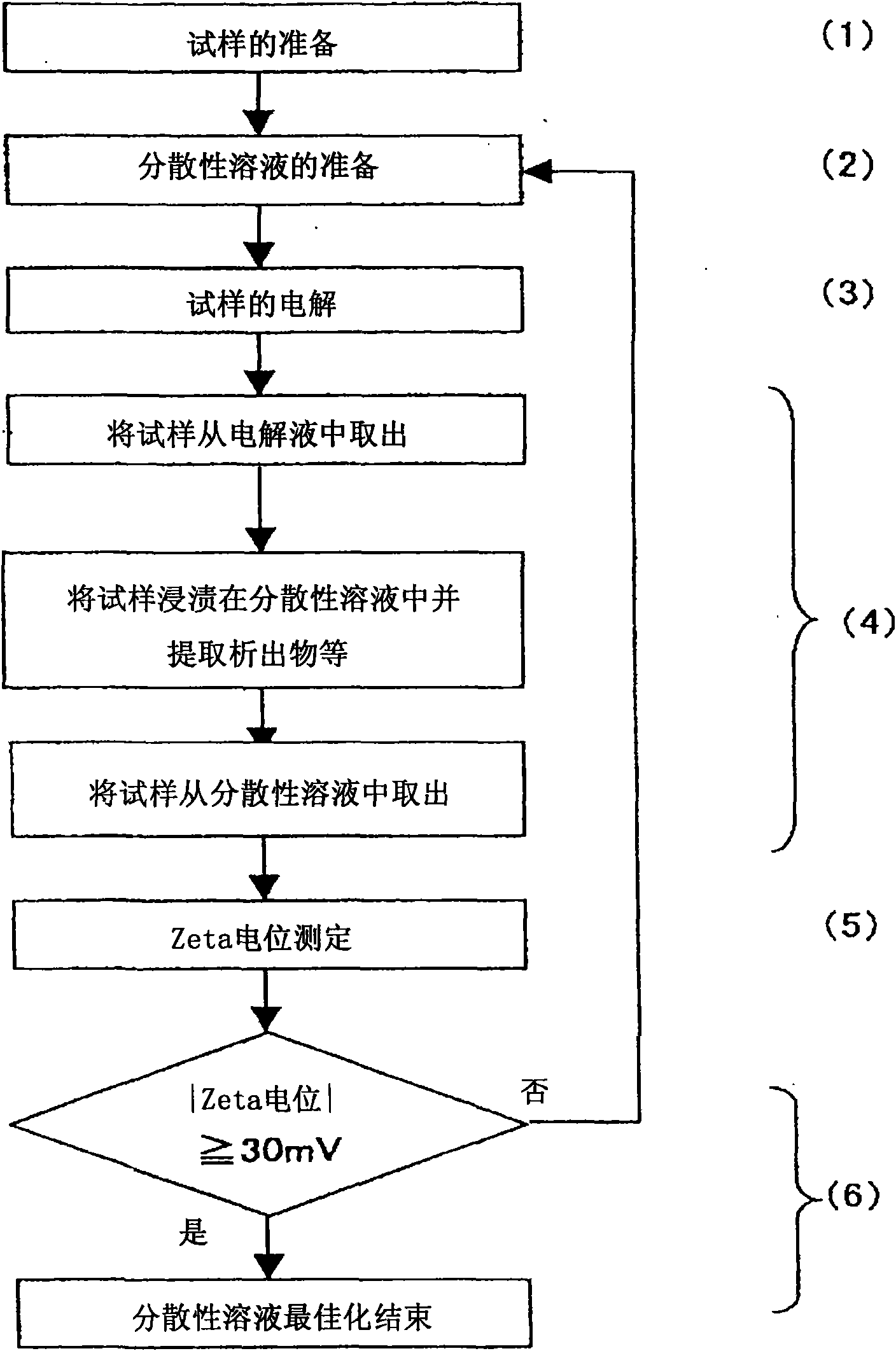

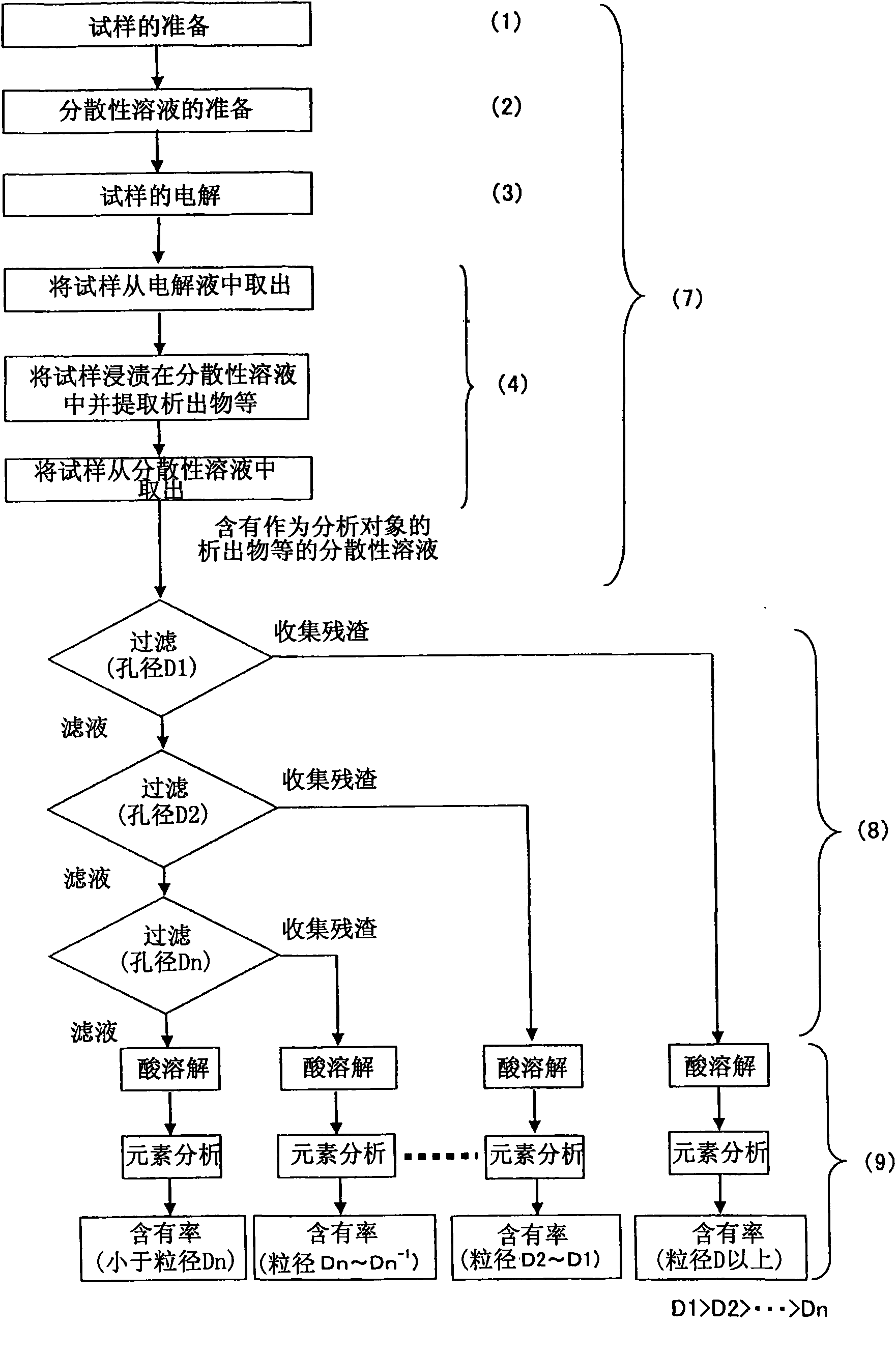

Method for analysis of metallic material

ActiveCN101688822AGood precisionAvoid gatheringPreparing sample for investigationMaterial electrochemical variablesElectrolysisMetallic materials

Disclosed is a method for analyzing a metallic material, which comprises the following steps: an electrolysis step of electrolyzing a metal sample in an electrolysis solution; a step of removing the metal sample from the electrolysis solution after the electrolysis is completed; a separation step of immersing the metal sample removed from the electrolysis solution in a dispersing solution which is different from the electrolyte solution and has dispersibility, thereby isolating at least one member selected from the group consisting of a precipitate and an intervening material adhered to the metal sample; and an analysis step of analyzing at least one member selected from the group consisting of the precipitate and the intervening material extracted in the dispersing solution.

Owner:JFE STEEL CORP

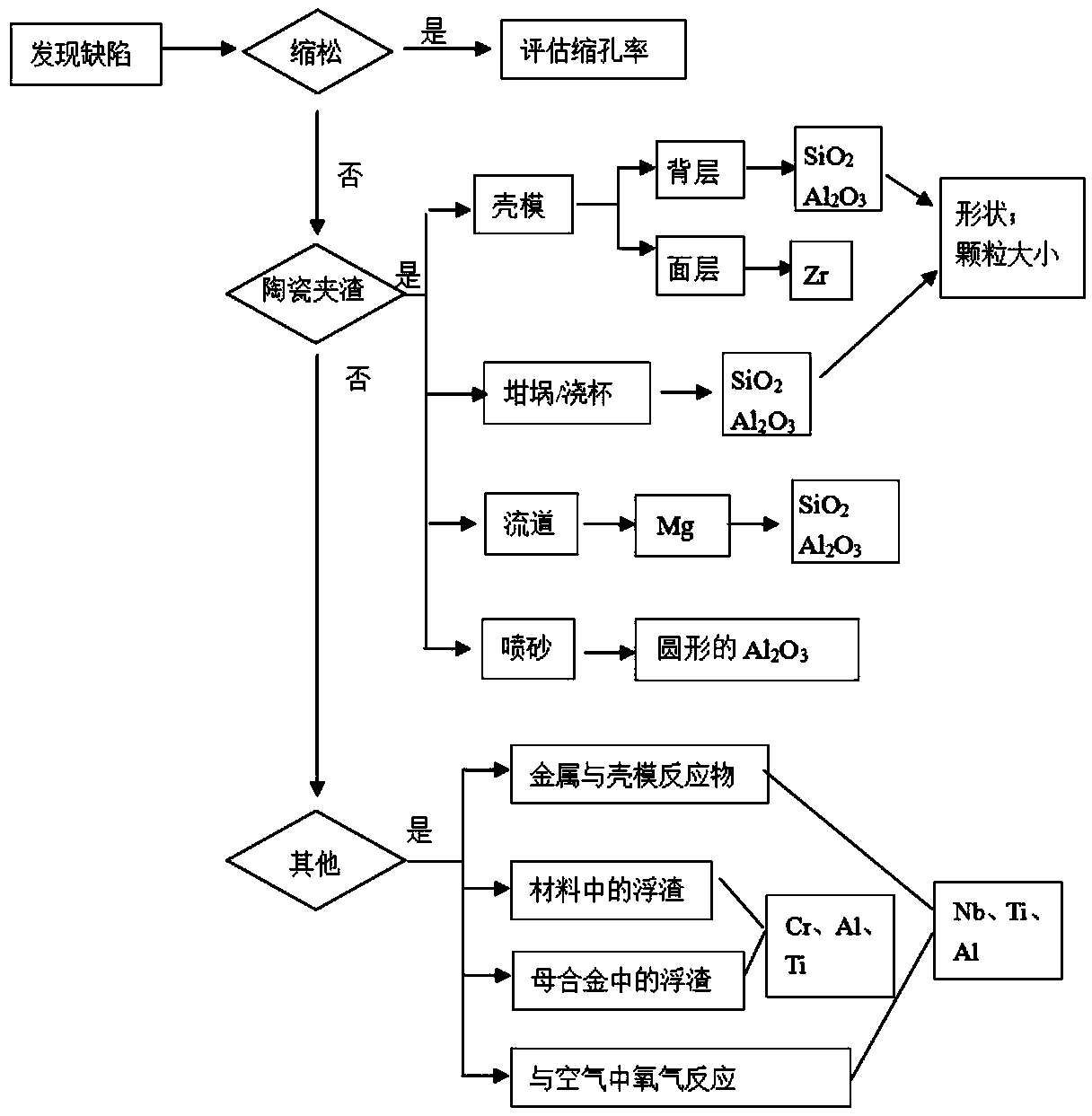

Method for analyzing defect type through scanning electron microscope and microscope

PendingCN110531047AResolve Surface Defect TypesSolve the problem of the cause of the defectMaterial analysis using wave/particle radiationTesting metal constituentsScanning tunneling microscopeScanning electron microscope

The invention discloses a method for analyzing a defect type through a scanning electron microscope and a microscope in the technical field of precision casting. The method comprises the following steps: 1) preliminarily judging the surface defect of a casting to confirm whether the defect is shrinkage porosity or not; 2) performing metallographic confirmation on the defect position by using the electron microscope and the scanning electron microscope; and 3) carrying out comparison according to the morphological characteristics and the element content of the defect to determine the defect type. In the step 1), formation reason and the judgment method of the shrinkage porosity are as follows: formation reason: since a final solidification area of the casting is not fed by liquid metal or alloy, dispersed and fine shrinkage cavities are formed, and the alloy liquid is divided into a plurality of small closed areas; and when the alloy liquid in the closed areas is solidified and shrunk and cannot be supplemented, shrinkage porosity is caused. The problem that the defect type and the defect cause reason cannot be judged can be solved.

Owner:QINGDAO HUAXIANG AVIATION TECH

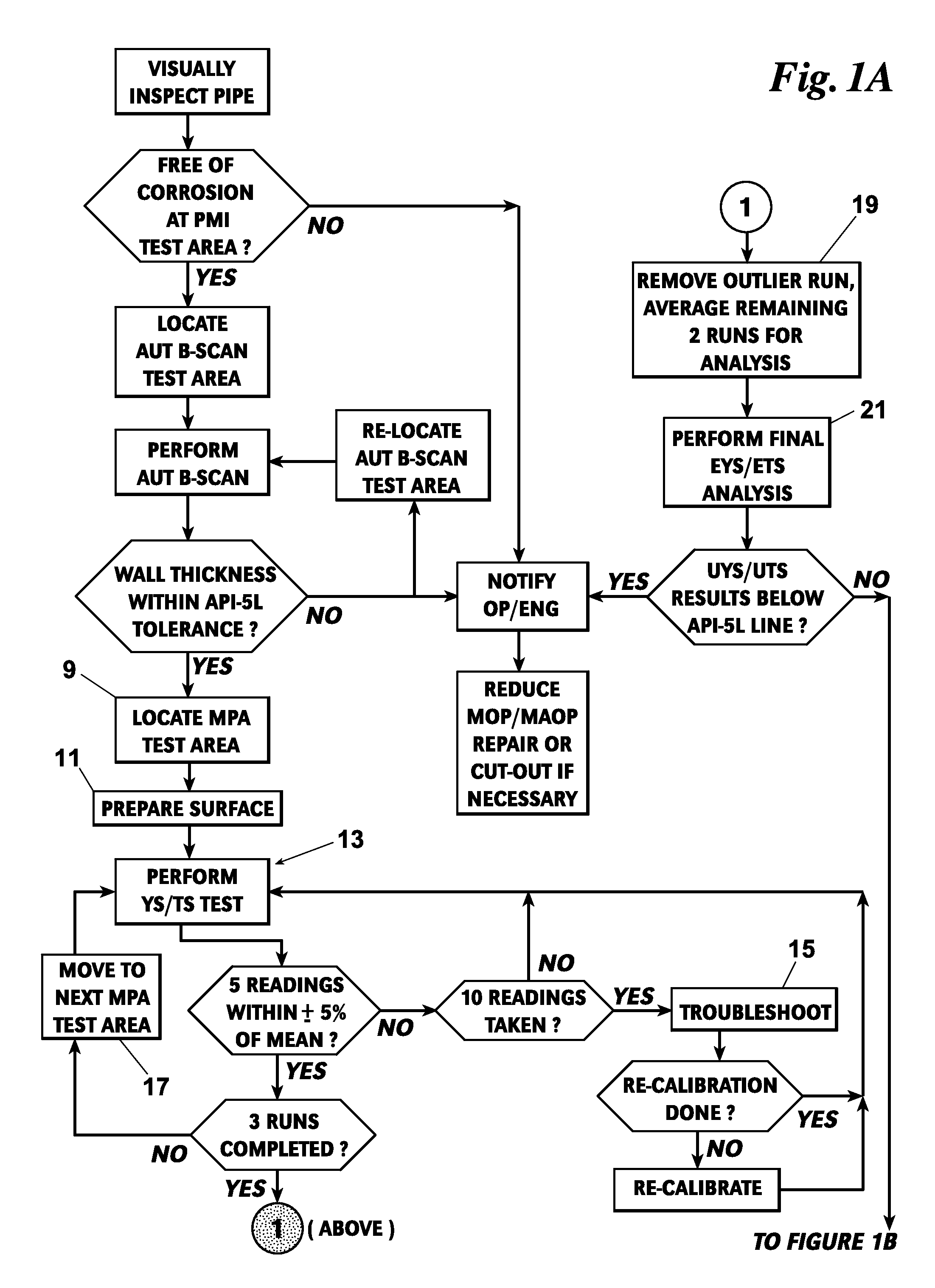

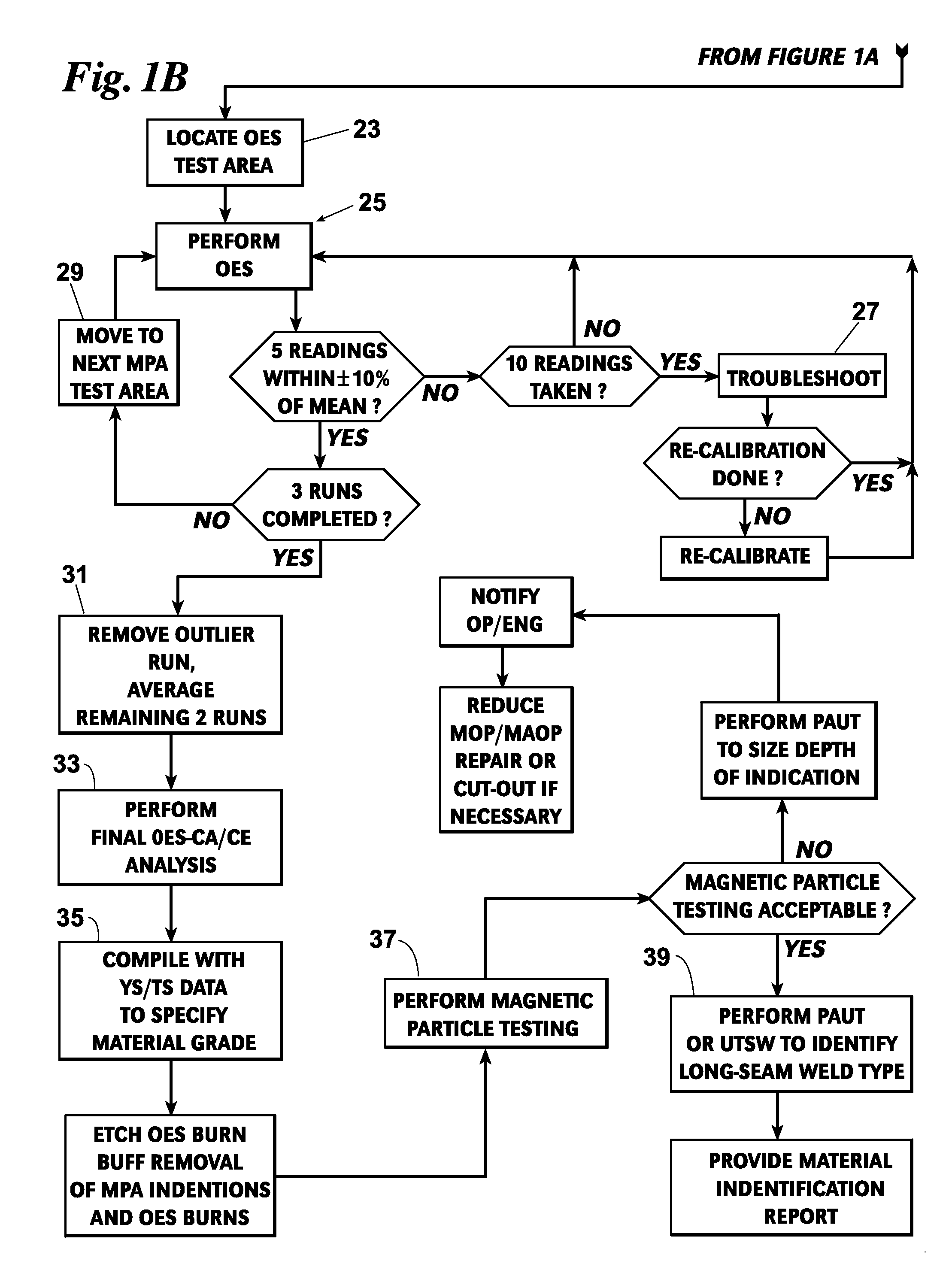

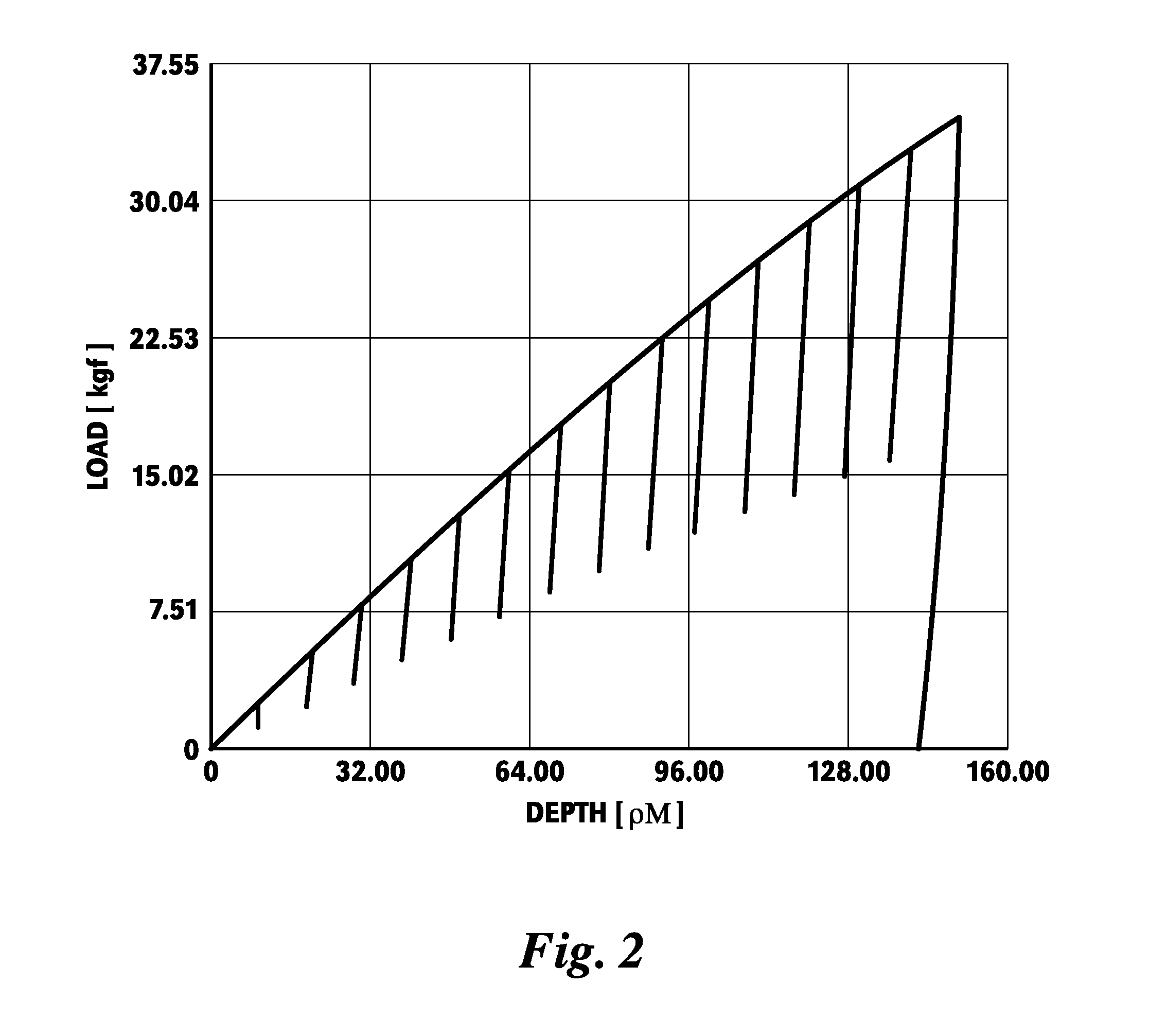

System And Method For Non-Destructive, In Situ, Positive Material Identification Of A Pipe

ActiveUS20150377707A1Positively identifyWithout degrading integrityEmission spectroscopyDetection of fluid at leakage pointNon destructiveMethod selection

A system and method for non-destructive, in situ, positive material identification of a pipe selects three test areas that are separated axially and circumferentially from one another and then polishes a portion of each test area. Within each polished area, a non-destructive test device is used to collect mechanical property data and another non-destructive test device is used to collect chemical property data. An overall mean for the mechanical property data, and for the chemical property data, is calculated using at least two data collection runs. The means are compared to a known material standard to determine, at a high level of confidence, ultimate yield strength and ultimate tensile strength within + / −10%, a carbon percentage within + / −25%, and a manganese percentage within + / −20% of a known material standard.

Owner:TDW DELAWARE INC

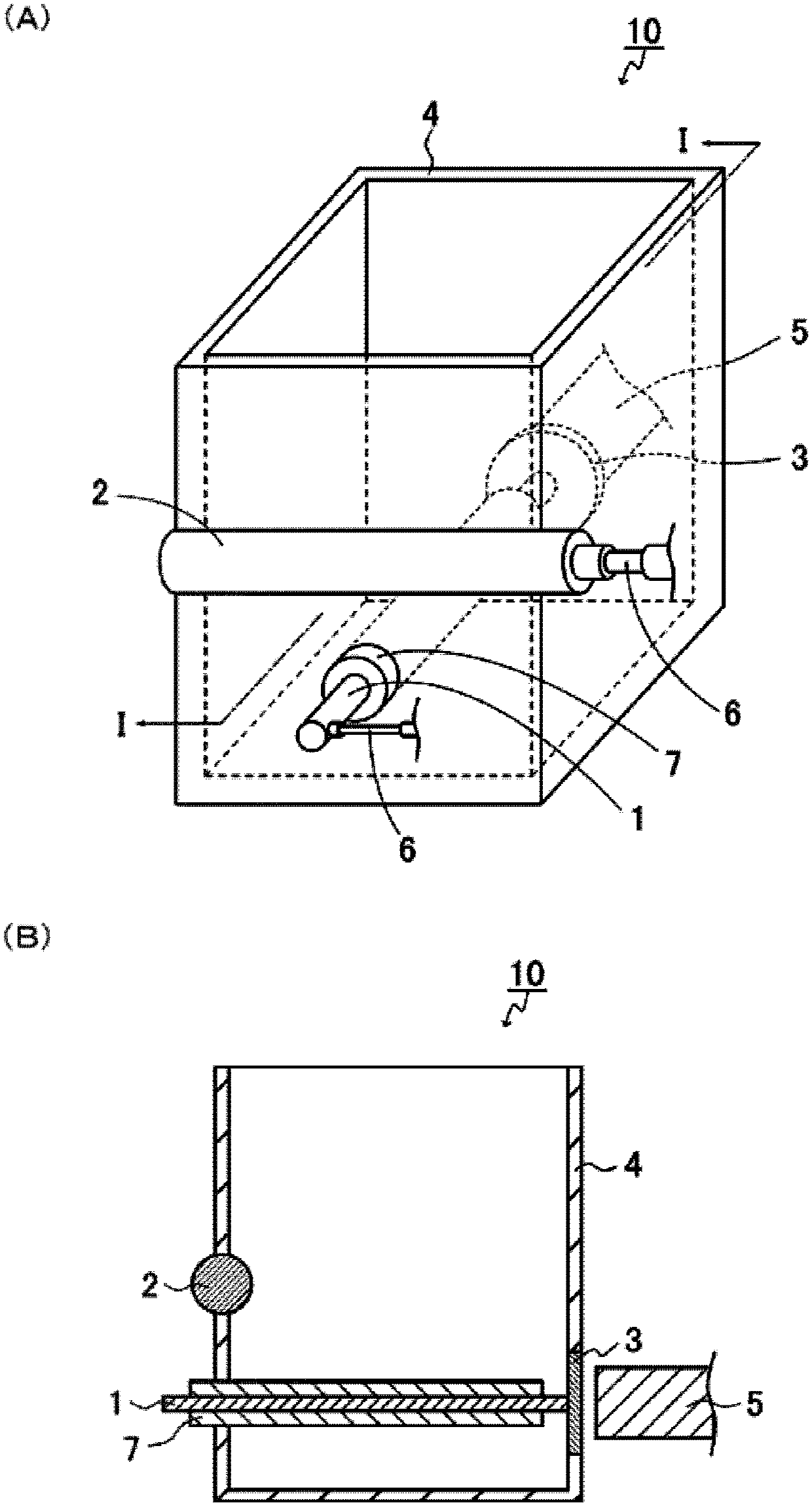

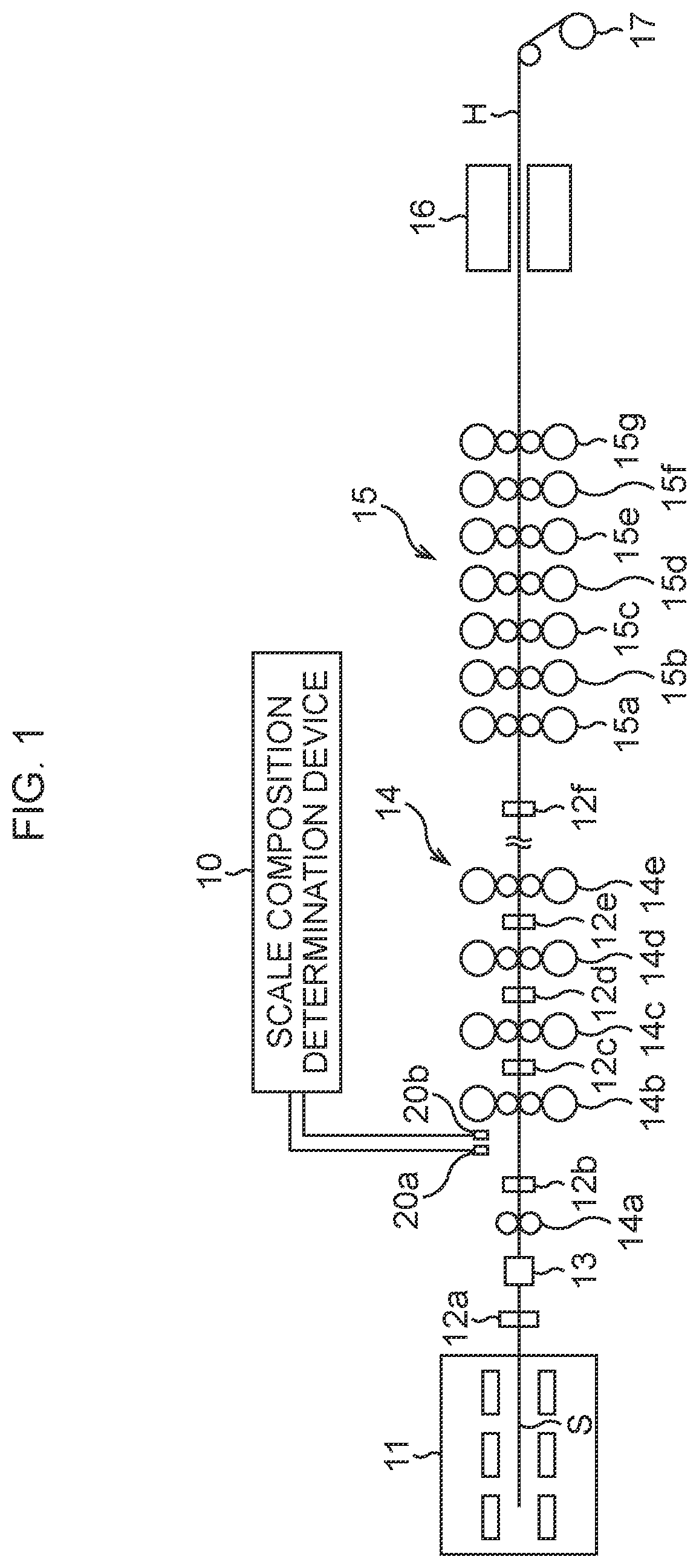

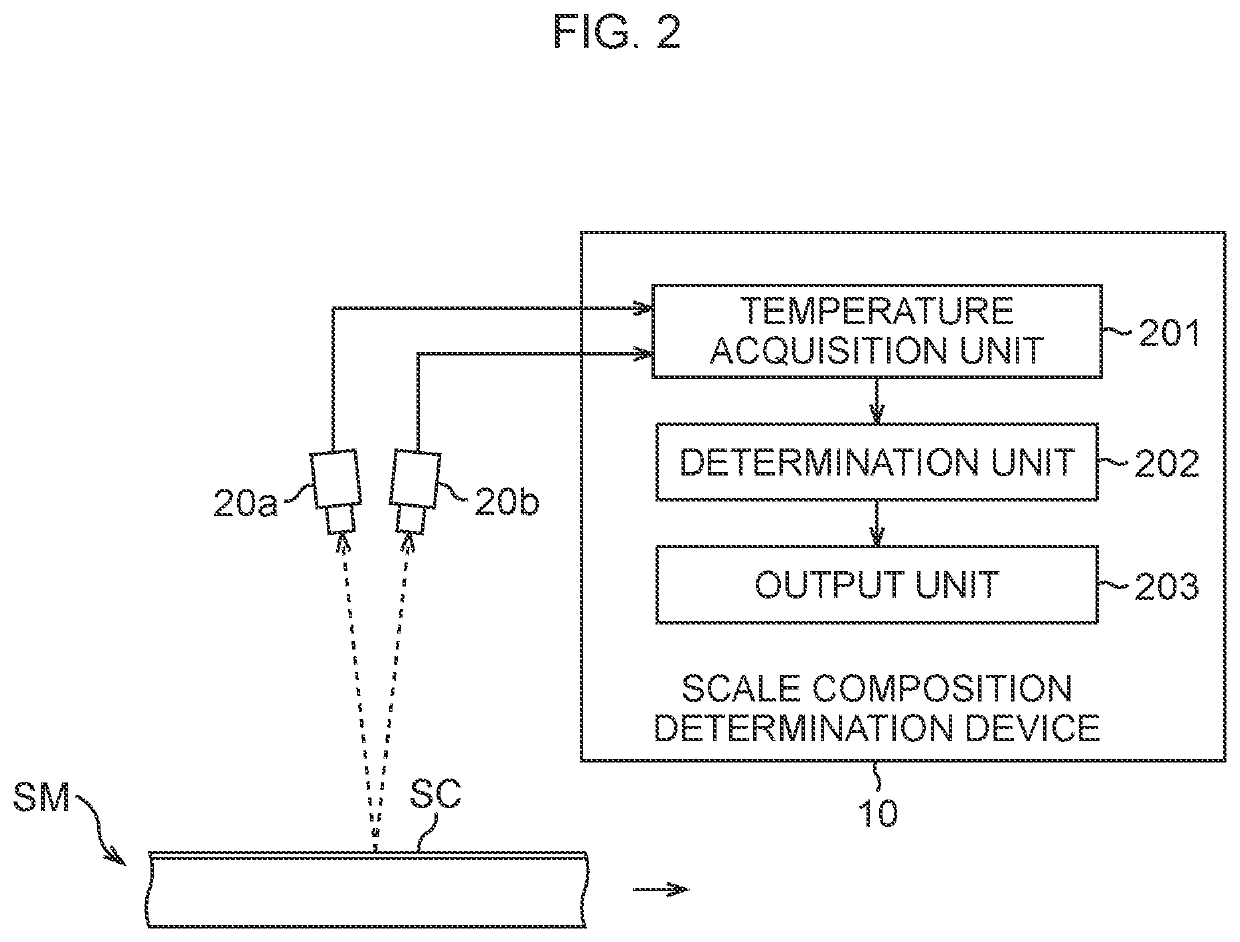

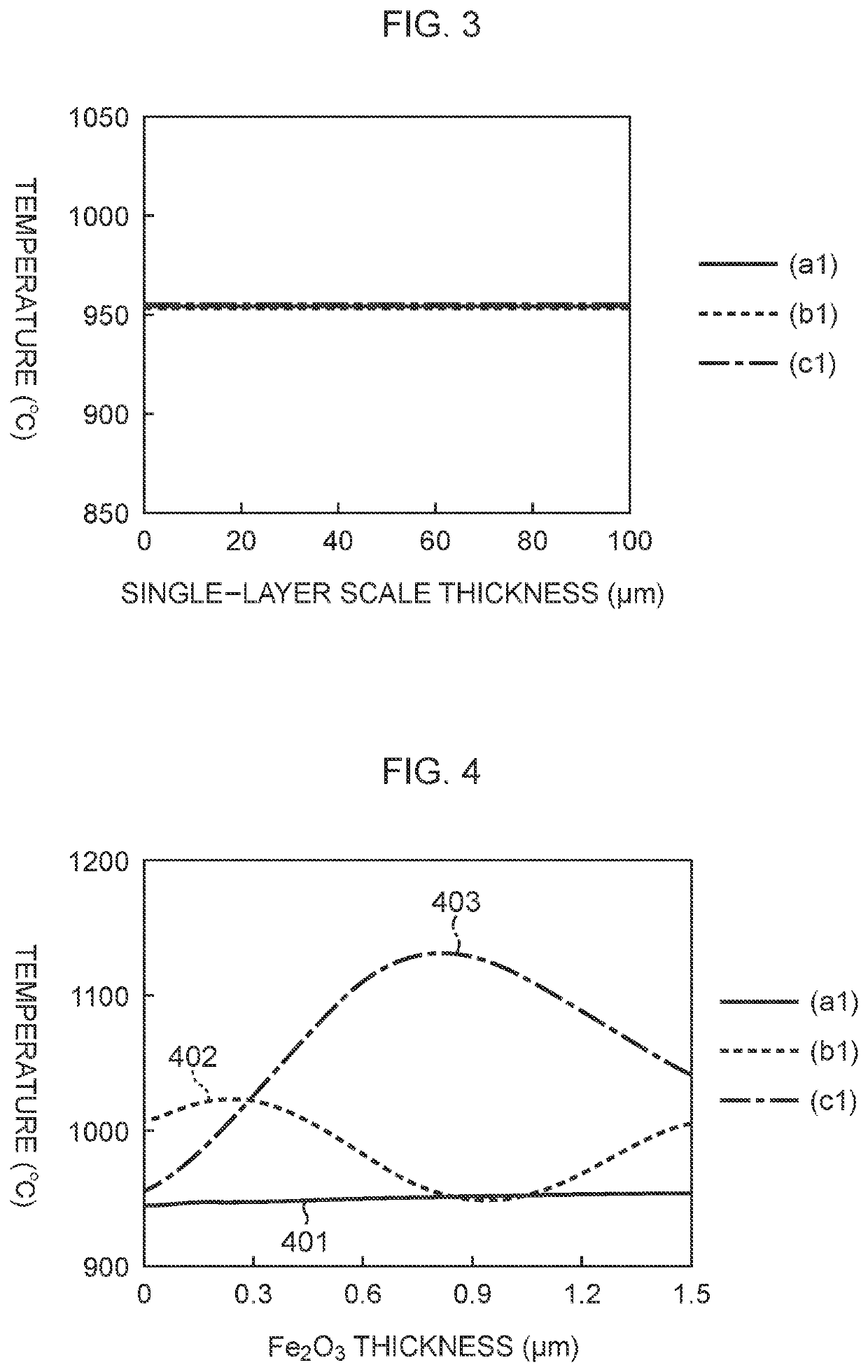

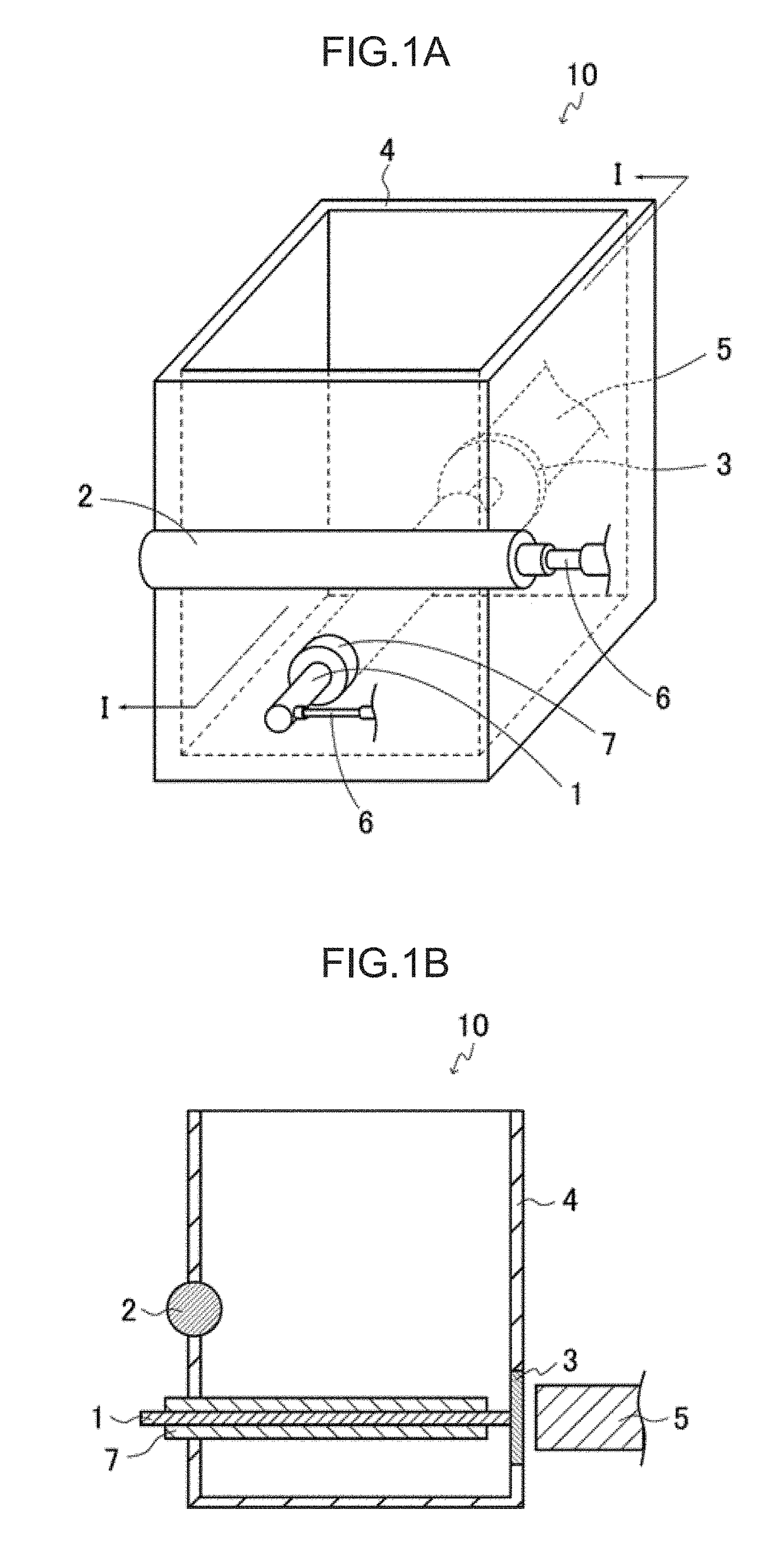

Scale composition determination system, scale composition determination method, and program

ActiveUS20200103285A1Accurately determineWeather/light/corrosion resistanceMeasuring devicesRadiation thermometerEngineering

A scale composition determination device (10) determines that Fe2O3 has been generated in the outermost layer of a scale (SC) in the case where the absolute value of a difference between temperatures of a steel material SM measured by radiation thermometers (20a, 20b) is equal to or more than a predetermined temperature, and determines that Fe2O3 has not been generated in the outermost layer of the scale (SC) in the case where the absolute value of the difference between the temperatures of the steel material SM measured by the radiation thermometers (20a, 20b) is not equal to or more than the predetermined temperature.

Owner:NIPPON STEEL CORP

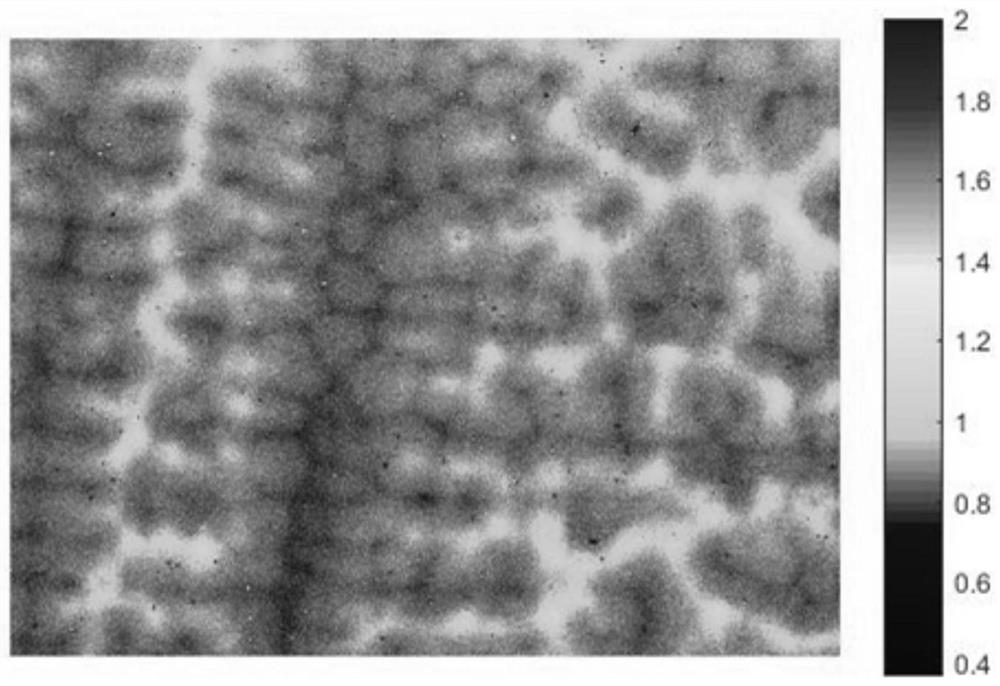

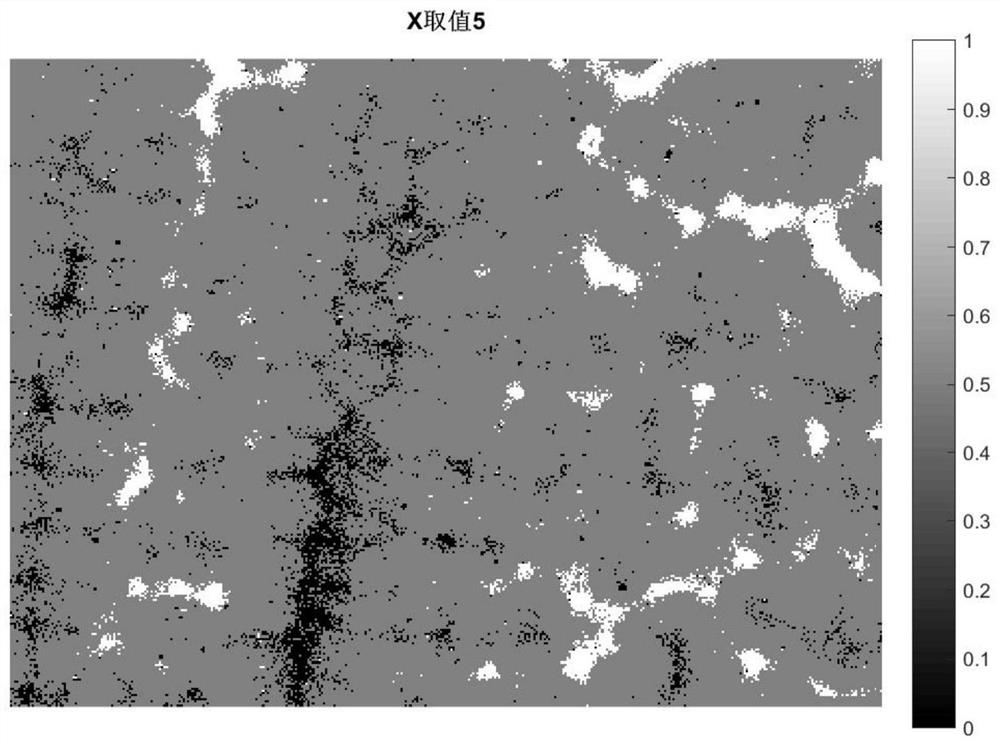

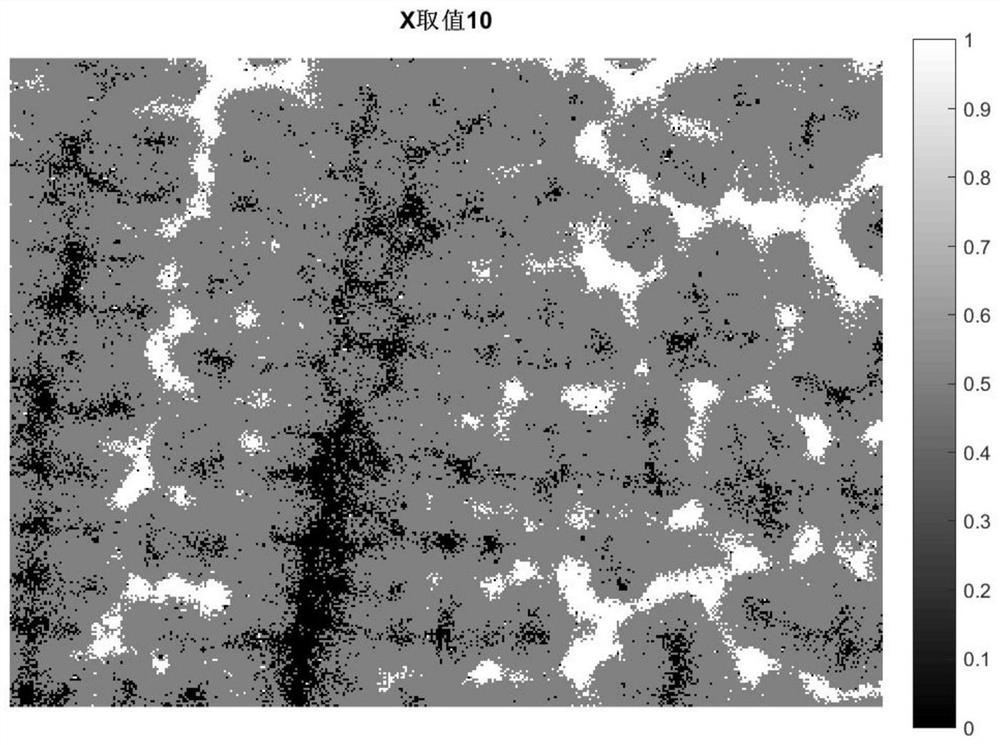

Image method for determining value range of microscopic segregation ratio in steel

ActiveCN111678937AAccurately determine the value range of micro-segregation ratioMaterial analysis using wave/particle radiationTesting metal structuresComputational physicsStatistical physics

The invention discloses an image method for determining a value range of a microscopic segregation ratio in steel, and belongs to the technical field of measurement of microscopic segregation in steel. Surface scanning data of specific alloy element components of a sample are processed through a computer statistical program, and the value of X is determined through an image comparison method, thatis, the value range of the segregation ratio is calculated. And when the value range X changes, the distribution of the data points in the maximum content interval and the minimum content interval isdisplayed on the segregation tissue image in the form of an image. And a proper X value is selected according to the distribution rule of the data points. The method has the advantage that the valuerange of the microscopic segregation ratio in the steel can be accurately determined.

Owner:SHOUGANG CORPORATION

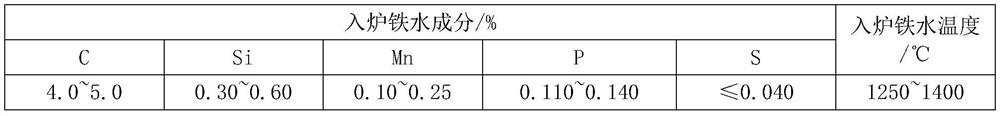

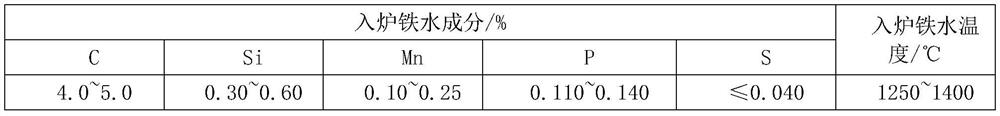

Method for testing zinc content of scrap steel in converter smelting mode

InactiveCN112067778AScientifically optimize the matching ratioReasonably adjust the purchase priceManufacturing convertersTesting metal constituentsSlagDust control

The invention discloses a method for testing zinc content of scrap steel in a converter smelting mode, and the zinc content of the scrap steel is measured through converter material balance. The method for testing the zinc content of the scrap steel comprises the following steps: testing scrap steel hopper matching and performing feeding; adding molten iron into a converter; performing converter smelting; performing tapping; performing deslagging; respectively acquiring weight data of molten iron entering a furnace, molten iron slag entering the furnace, test scrap steel, a converter slag former, a converter coolant, a slag pressing agent, converter terminal molten steel, converter final slag, converter LT-method dedusting coarse ash, converter LT-method dedusting fine ash and converter secondary dedusting ash; respectively sampling molten iron entering the furnace, molten iron slag entering the furnace, the converter slag former, the converter coolant, the slag pressing agent, converter end point molten steel, converter end slag, converter LT method dedusting coarse ash, converter LT method dedusting fine ash and converter secondary dedusting ash, and detecting the zinc content; and solving the zinc content of the tested scrap steel by referring to a zinc content determination formula of the zinc-containing scrap steel.

Owner:LIUZHOU IRON & STEEL

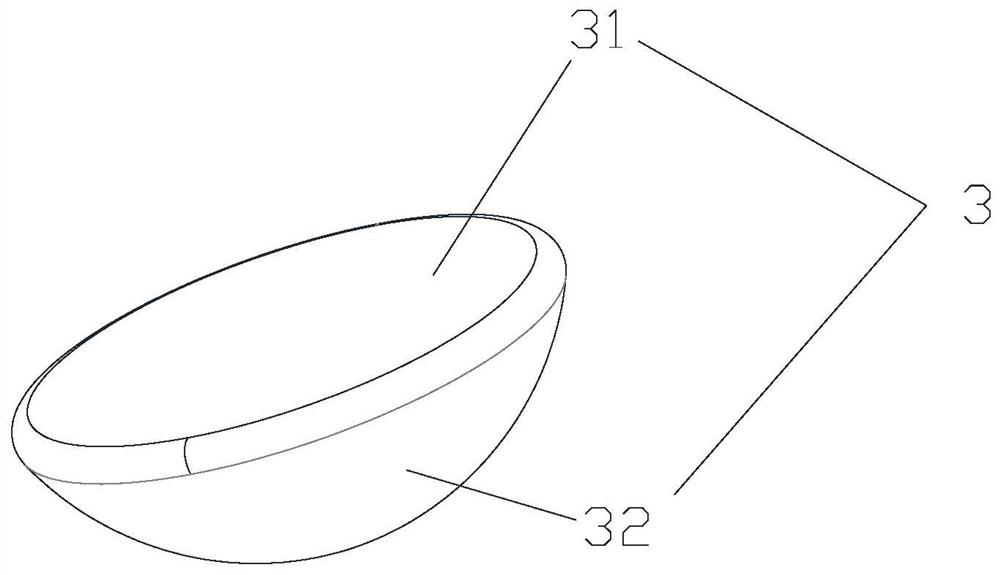

Preparation method for sample used for rapid determination of chemical component in alloy slag charge

InactiveCN110864947AEasy to manufactureEasy to prepare to meet spectralPreparing sample for investigationTesting metal constituentsChemical compositionSlag

The invention relates to a preparation method for a sample used for rapid determination of a chemical component in alloy slag charge. The preparation method comprises the following steps: sorting, performing heated ultrasonic cleaning in an alkaline cleaning liquid, cleaning in pure water, performing ultrasonic cleaning in an organic reagent, melting and performing sample preparation under a negative pressure condition and in an inert gas atmosphere as well as grinding and polishing. The method provided by the invention is simple in steps and easy to operate, and blocky samples meeting spectroscopic analysis or mass spectrometry requirements can be prepared easily; and many samples are molten and can be used for analyzing uniformity of the alloy slag charge.

Owner:JIANGSU LONGDA SUPERALLOY MATERIAL CO LTD

Apparatus and methods for testing impurity content in a precious metal

InactiveUS8211366B2Reduce lossesAvoid lostWeather/light/corrosion resistanceResistance/reactance/impedenceElectrical resistance and conductanceFiber

A precious metal testing apparatus and methods adapted to analyze impurities in a precious metal test sample is described. The testing apparatus contains a test probe that has a replaceable portion and that is connected to a meter to measure resistance. The replaceable portion contains or forms a reservoir that includes at least one electrolyte component, a conductive member, and a fibrous tip. The electrolyte component is fluidly associated with a fiber tip and the conductive member contacts an electrical contact located outside the reservoir. Methods of testing and instructions regarding such methods are also included.

Owner:FMS TECH

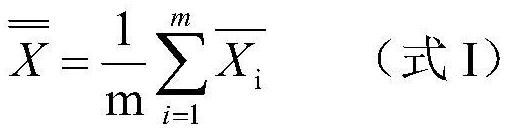

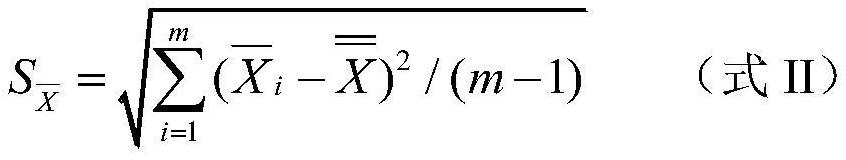

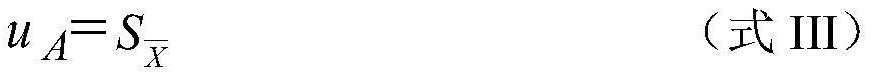

Fisher particle size standard sample and preparation method and application thereof

PendingCN111650096AGood sphericityImprove uniformityMaterial analysis using wave/particle radiationParticle size analysisStatistical analysisPhysical chemistry

The invention discloses a Fisher particle size standard sample and a preparation method and application thereof. The preparation method of the Fisher particle size standard sample comprises the following steps: (1) determining the morphology, rigidity, particle size distribution and specific surface area of a raw material; (2) preparing raw material candidates of which the morphology, rigidity, particle size distribution and specific surface area are within the range determined in the step (1); (3) carrying out uniformity inspection on the candidates; (4) after the uniformity test is qualified, randomly extracting candidates, and delivering the candidates to m test mechanisms for collaborative valuing to obtain valued data, where m is greater than or equal to 6; and (5) carrying out mathematical statistical analysis on the constant value data obtained in the step (4), calculating the characteristic value of the Fisher particle size standard sample, and evaluating the uncertainty of thecharacteristic value. The standard sample prepared by the method can meet the requirement of accurate detection of Fisher particle size.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

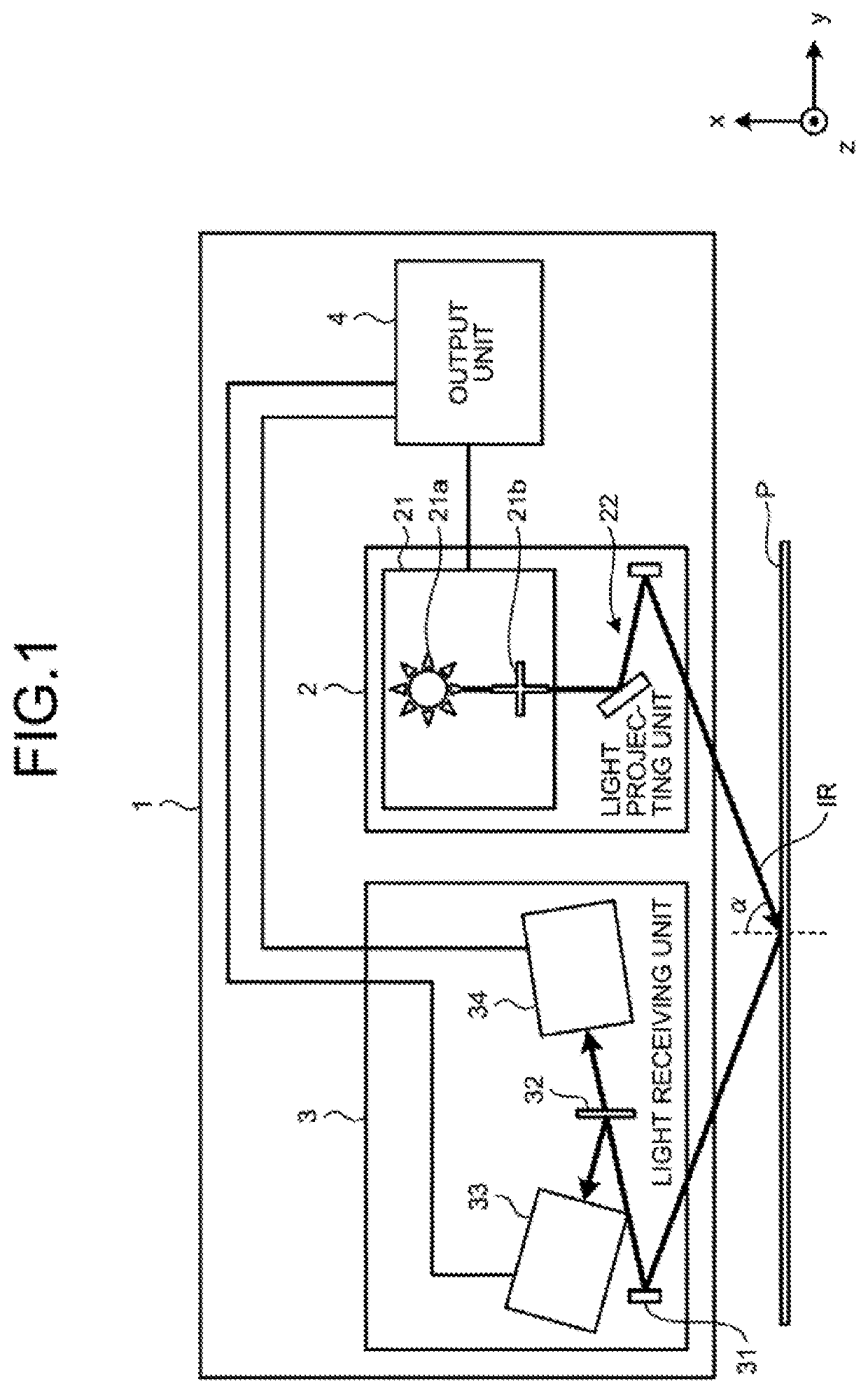

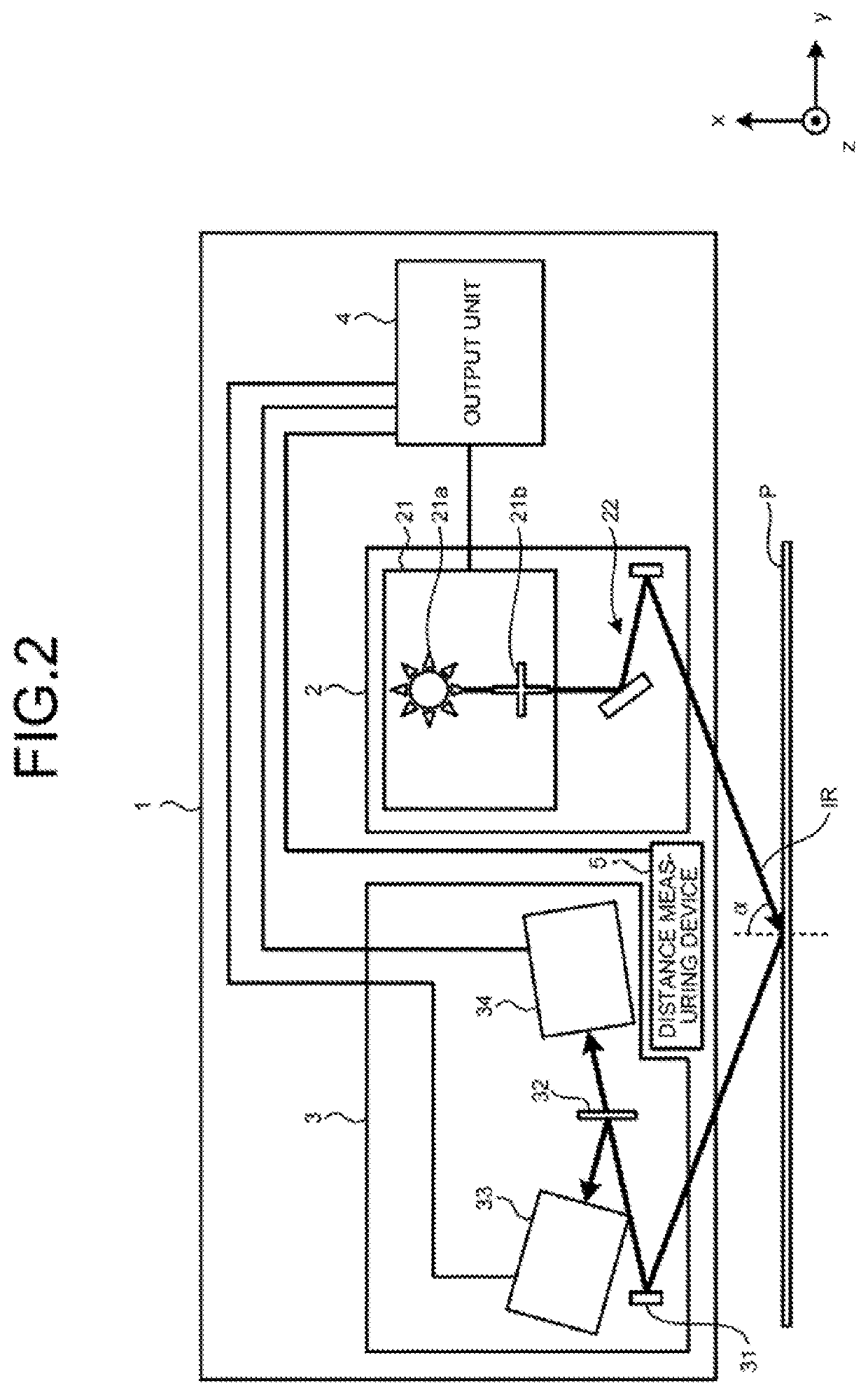

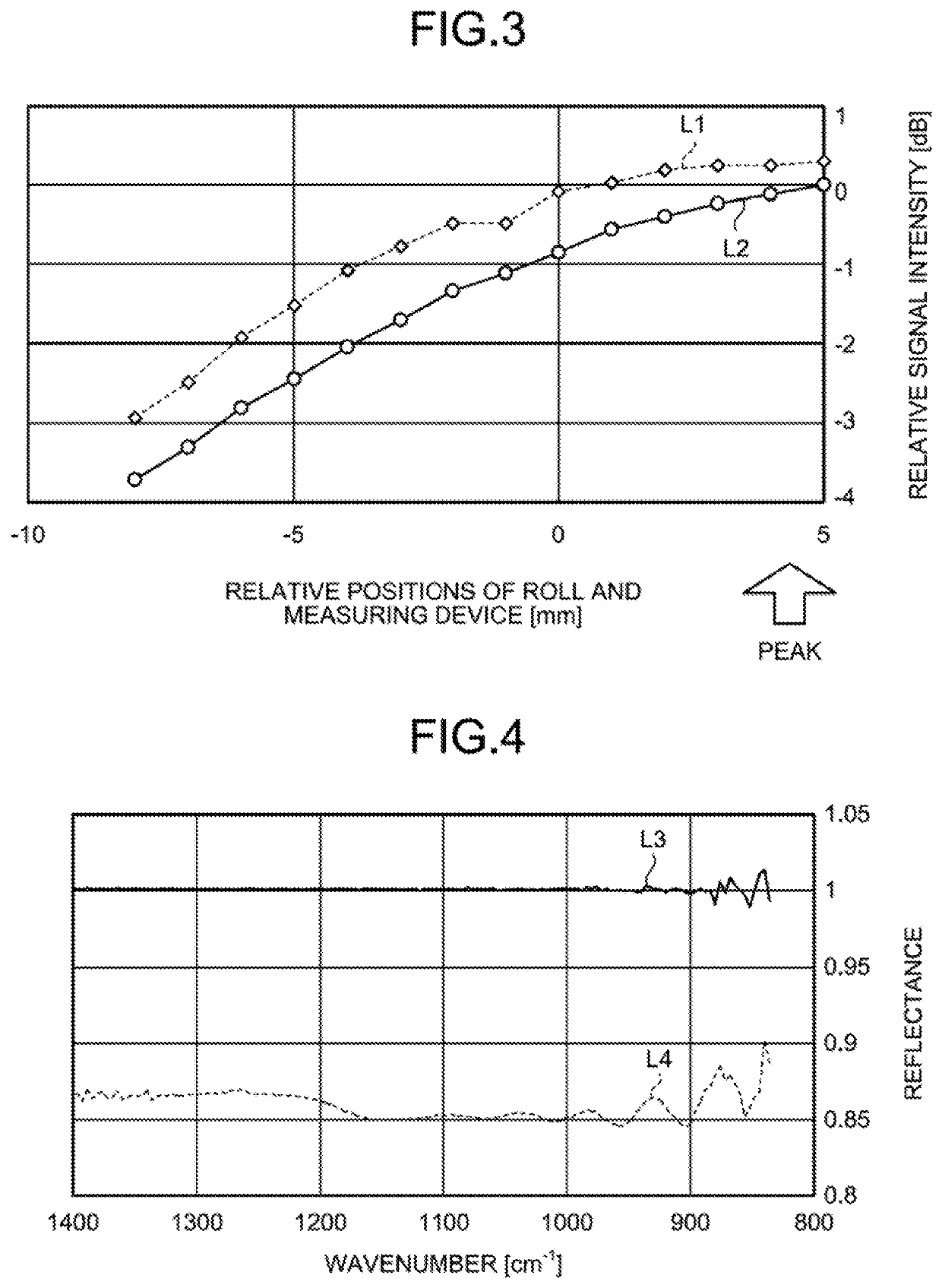

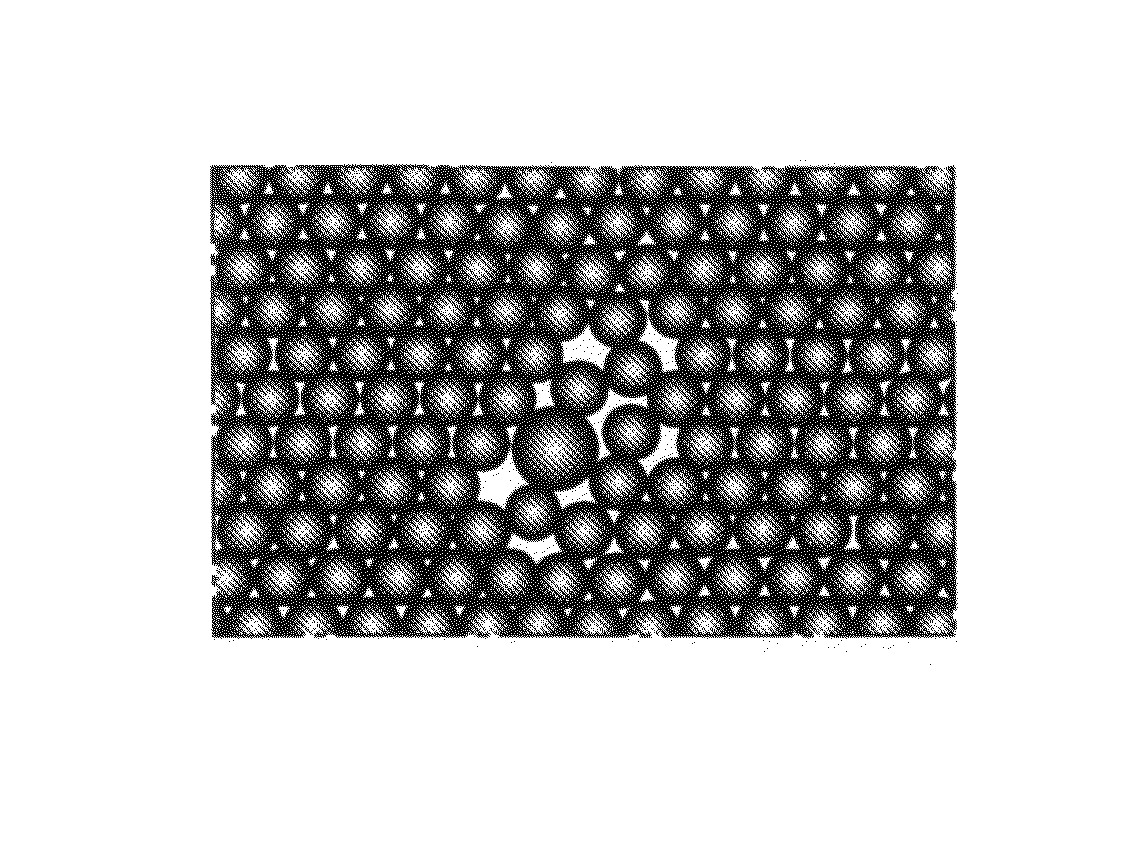

Spectroscopic analysis apparatus, spectroscopic analysis method, steel strip production method, and steel strip quality assurance method

ActiveUS20200393371A1Improve accuracyHigh yieldOptical rangefindersPolarisation-affecting propertiesEngineeringMechanical engineering

A spectroscopic analysis apparatus includes: a light projecting device; a light receiving device; and an output device, wherein the light receiving device includes: a separator configured to separate reflected light into s-polarized light and p-polarized light; a detector for s-polarized light configured to output an electric signal indicating an intensity of the s-polarized light; and a detector for p-polarized light configured to output an electric signal indicating an intensity of the p-polarized light; and the output device is configured to: calculate an absorbance based on a ratio between the intensities of the s-polarized light and the p-polarized light using the electric signals output from the detector for s-polarized light and the detector for p-polarized light; and calculate either or both of the composition and the composition ratio of the surface of the measurement target object using an intensity of the absorbance at any desired wavenumber.

Owner:JFE STEEL CORP

Method and apparatus for estimating a mechanical property

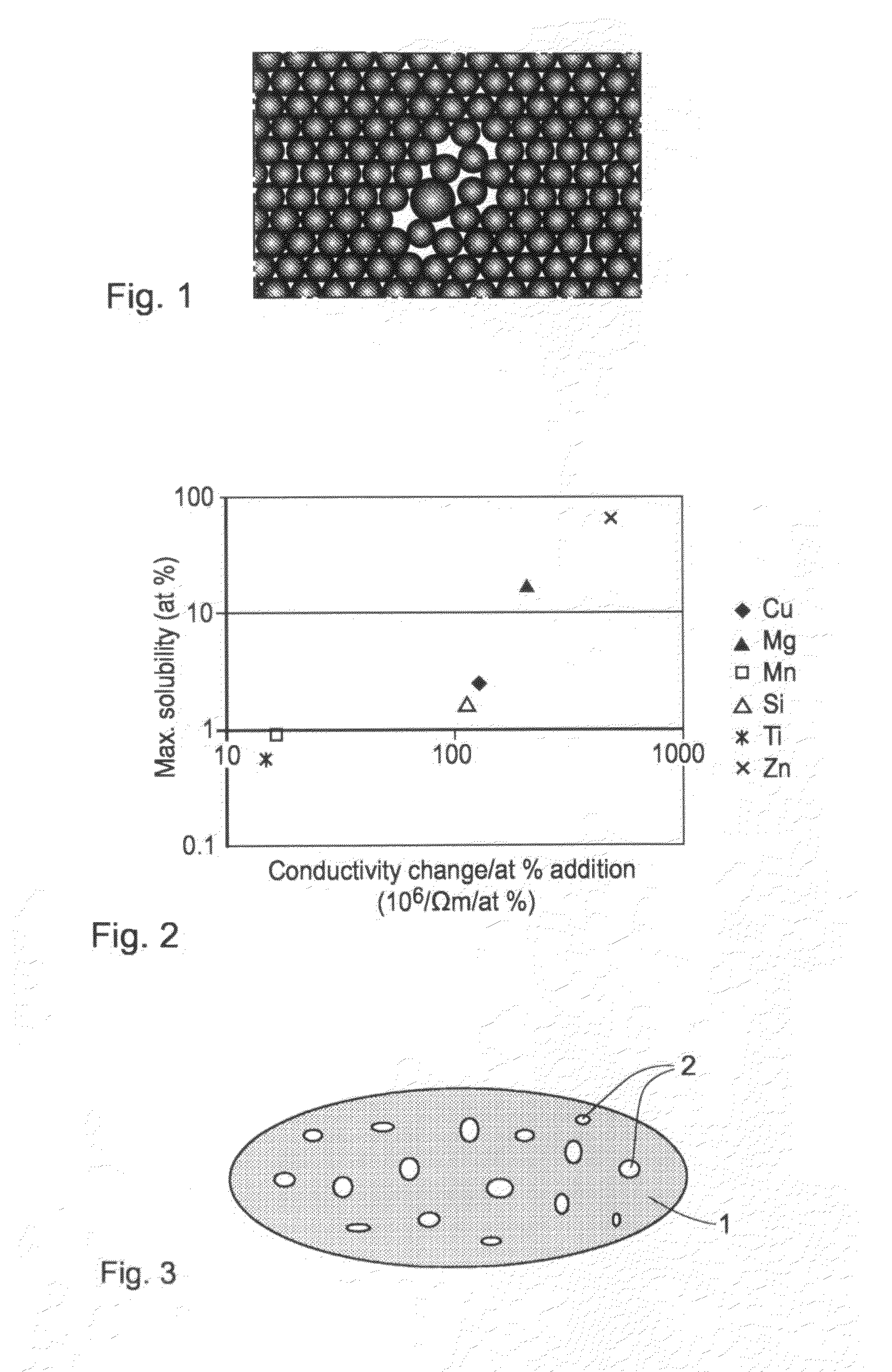

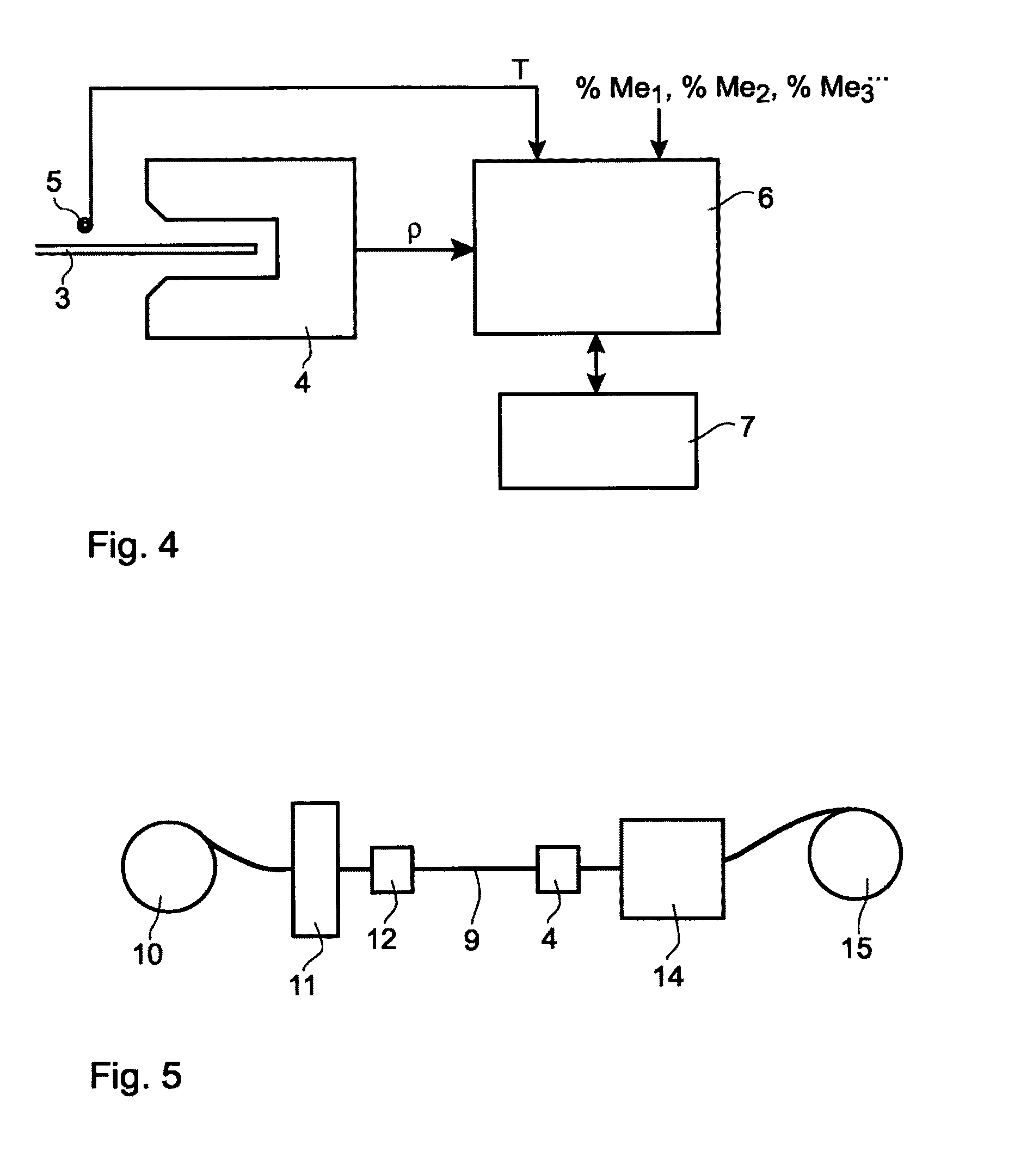

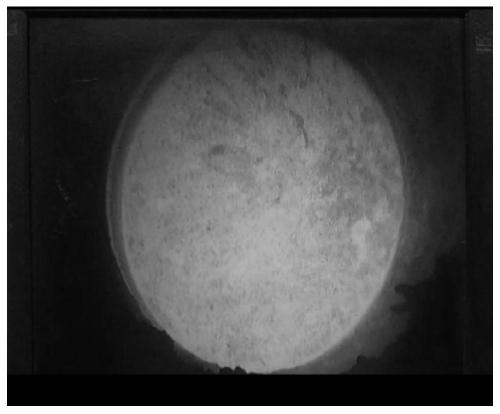

InactiveUS8263409B2Resistance/reactance/impedenceMaterial analysis by electric/magnetic meansChemical compositionObject based

An apparatus for estimating or supervising one or more internal mechanical properties of a metal alloy object with a known chemical composition based on the resistivity of the metal alloy object. The apparatus includes a device for measuring the resistivity of the metal alloy object, and a computation unit adapted to calculate the content of dissolved alloying elements in the metal alloy object based on the measured resistivity and the known chemical composition of the metal alloy, and based thereon to calculate at least one internal mechanical property of the metal alloy object.

Owner:ABB (SCHWEIZ) AG

Method for evaluating vacuum inclusion removal capacity of RH refining furnace

InactiveCN111426811AAchieve high efficiencyMaterial analysis using wave/particle radiationProcess efficiency improvementMetallurgyMolten steel

The invention discloses a method for evaluating the vacuum inclusion removal capacity of an RH refining furnace. Technological factors influencing the inclusion removal effect of the RH refining furnace, such as gas flow increasing and dip pipe insertion depth, are studied; the relation between the inclusion level of the molten steel and the RH process time is quantitatively evaluated, and efficient production of the RH process and clean production of the molten steel are achieved. A good popularization value is achieved for improving the production quality of modern iron and steel enterprises.

Owner:NANJING IRON & STEEL CO LTD

Method and apparatus for the automated assay and valuation of precious metal objects

ActiveUS8532256B1Database may become rather largeFast and accurate resultX-ray spectral distribution measurementMaterial analysis using wave/particle radiationThe InternetTouchpad

A method and apparatus for the metallurgical qualitative analysis (assay) and valuation of precious metals objects such as jewelry or coins. The system integrates a commercially available x-ray florescence (XRF) metals analyzer with associated peripheral devices including a personal computer and keyboard or touchpad computing device, a digitizing scale, a printer, an Internet link for obtaining current precious metals market price quotations, and software for processing the qualitative results with the current market price data and presenting the results to the system operator in real time. The system optionally includes a customer interface including a display screen for presenting the customer with the results of the analysis and valuation, and customer input means for accepting and recording a purchase transaction.

Owner:JETER BOBBY D +1

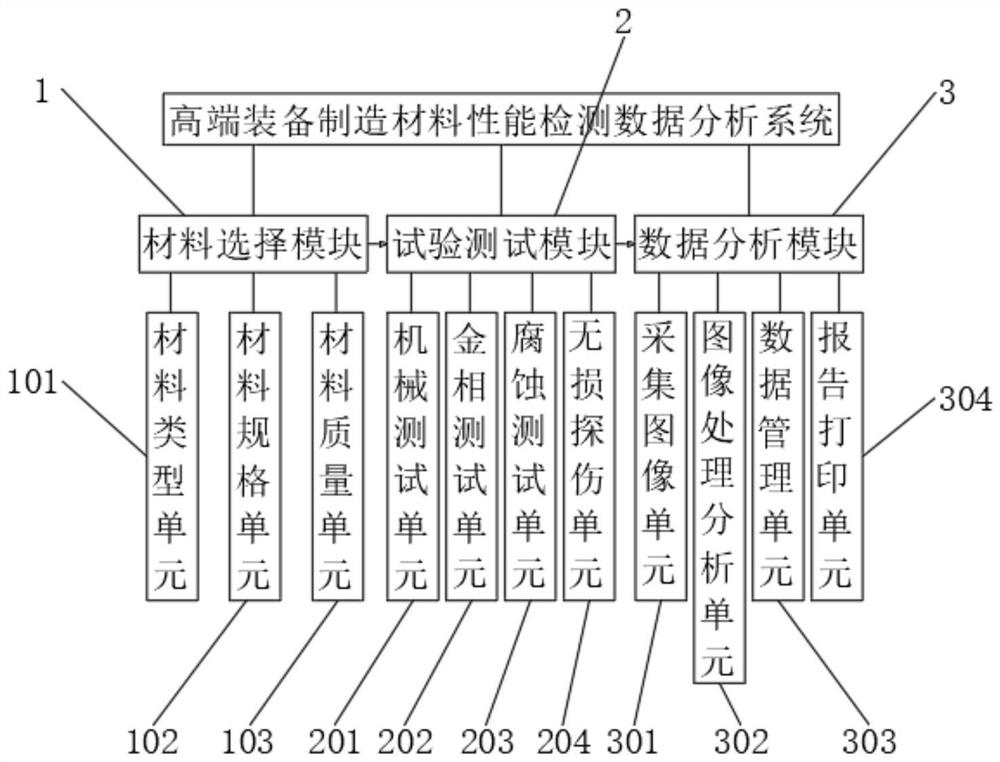

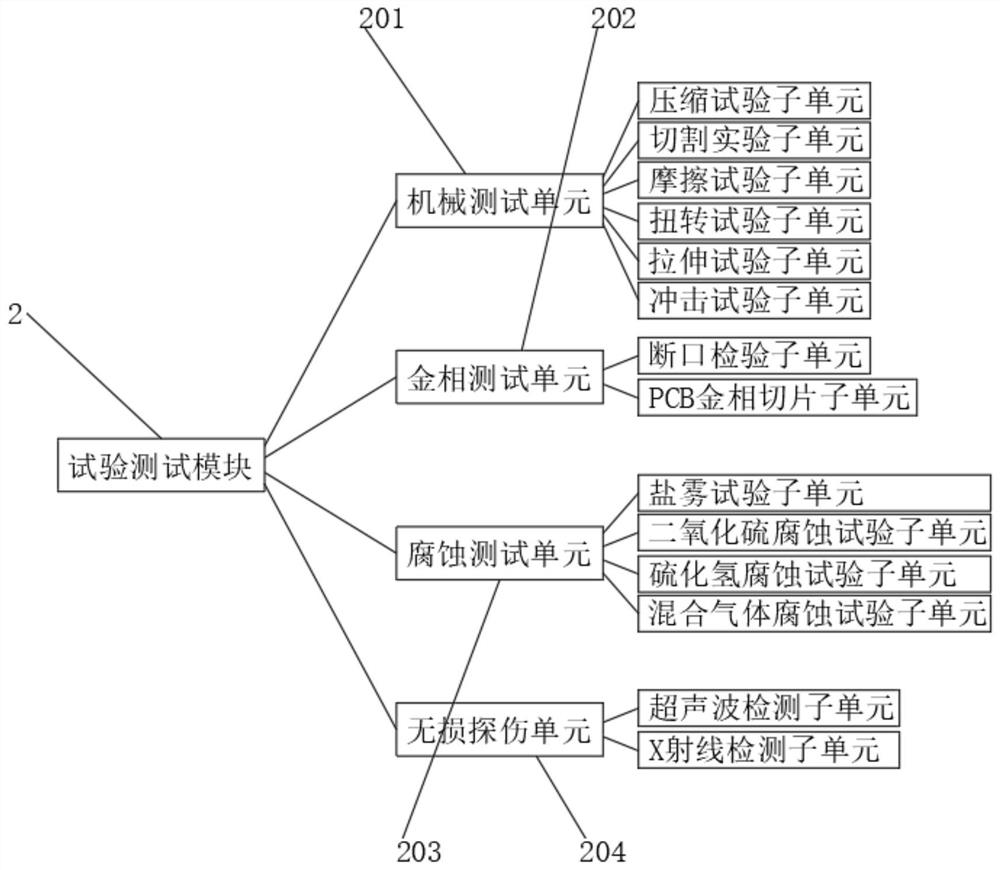

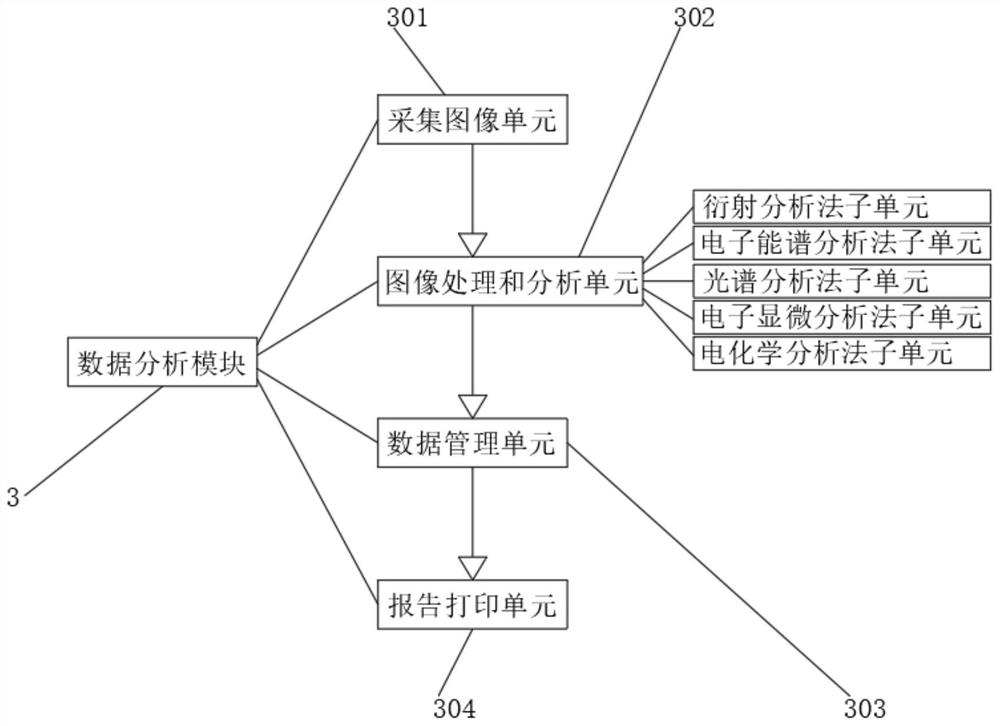

Analysis system for performance detection data of high-end equipment manufacturing material

InactiveCN113376349AJudge qualityJudging whether the quality of the material meets the standard qualityWeather/light/corrosion resistanceTesting metal constituentsMaterial typeProcess engineering

The invention discloses an analysis system for performance detection data of a high-end equipment manufacturing material, and belongs to the technical field of material performance detection. The analysis system for performance detection data of a high-end equipment manufacturing material comprises a material selection module, an experimental test module and a data analysis module, the material selection module is used for inputting basic characteristics of materials; the experimental test module is used for detecting the performance of the material in various aspects; the data analysis module is used for processing, analyzing and managing the performance data of the material; the material selection module comprises a material type unit, a material specification unit and a material quality unit; the material type unit is used for selecting a corresponding material type option according to a detection material; the material specification unit is used for inputting specification information such as length, width, height or radius of the material; performance detection tests are rich and diversified, data arrangement, comparison and analysis are convenient, and material performance data management is convenient.

Owner:ZHENGZHOU UNIV OF IND TECH

Method for quantitatively evaluating influence of vacuum degree and oxidation products on high-temperature alloy performance

ActiveCN111551576AExtremely low solutionSolving Dispersion ProblemsMaterial analysis using wave/particle radiationPreparing sample for investigationSuperalloyMechanical property

The invention discloses a method for quantitatively evaluating the influence of vacuum degree and oxidation products on high-temperature alloy performance, and belongs to the field of high-temperaturealloys. The method comprises the steps of controlling the grading vacuum degree during smelting, solidifying and gathering the oxidation products in sequence, and testing the comprehensive mechanicalproperty of the corresponding state in a matched mode; quantitatively evaluating the vacuum degree, the oxidation product and the influence of the oxidation product on the mechanical property of thenickel-based superalloy. Meanwhile, the type and the content of trace oxidation products in the alloy can be determined, a basis is provided for determination of preparation process parameter tolerance, and technical support and guarantee are provided for preparation of high-purity high-temperature alloy, improvement of the percent of pass of nickel-based high-temperature alloy parts and reductionof cost. The problems that in the prior art, only the vacuum degree, the average gas content (including the oxygen content) of a solidified sample and the alloy mechanical property are considered, and consequently the average gas content and the mechanical property cannot be directly hooked are solved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Plasma spectroscopic analysis method and plasma spectroscopic analyzer

InactiveUS20180024069A1High analytical sensitivitySuppress errorPreparing sample for investigationAnalysis by electrical excitationAnalyteAnalysis method

A plasma spectroscopic analysis method includes a concentration process including a voltage application period in which voltage is applied to a pair of electrodes in the presence of a sample thereby concentrating an analyte contained in the sample in the vicinity of at least one of the pair of electrodes; and a detection process of generating a plasma by applying voltage to the pair of electrodes and detecting light emitted by the analyte due to the plasma. An electric current between the pair of electrodes is constant while applying voltage for at least a part of the duration of the concentration process.

Owner:ARKRAY INC

Popular searches

Electron beam welding apparatus 3D object support structures Additive manufacturing with solids Manufacturing data aquisition/processing Material analysis using radiation diffraction Material analysis by measuring secondary emission Color/spectral properties measurements Volume/mass flow measurement Direction finders using ultrasonic/sonic/infrasonic waves Material analysis using acoustic emission techniques

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com