Image method for determining value range of microscopic segregation ratio in steel

A technology of value range and segregation, which is applied in analyzing materials, using wave/particle radiation for material analysis, testing metals, etc., can solve the problem that there is no strict regulation on the value range of micro-segregation ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

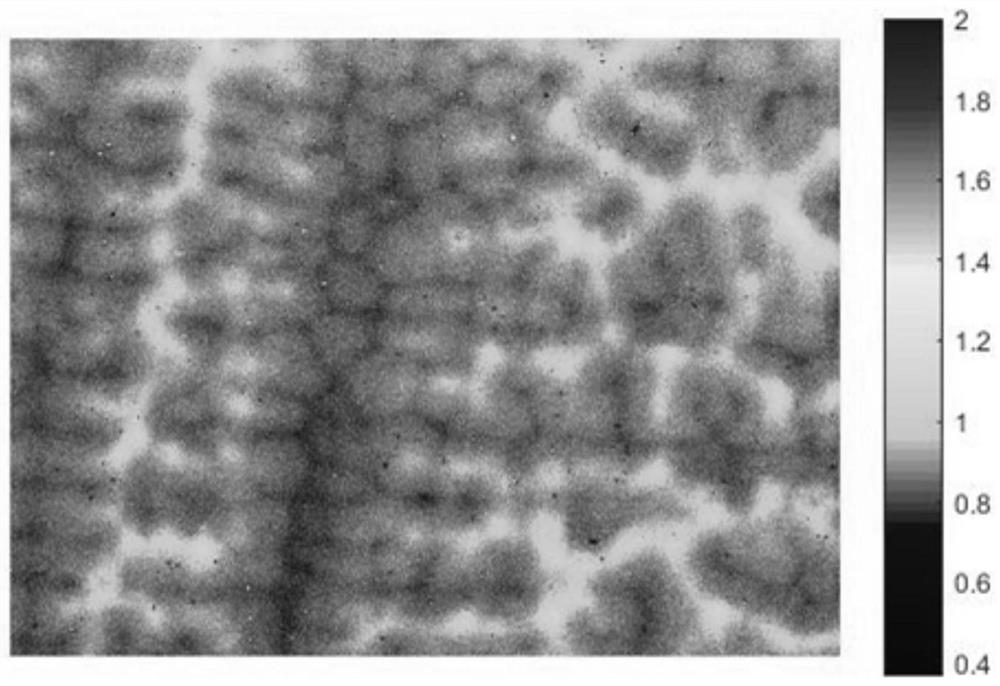

[0036] Dendrite segregation of Mn element in 380 wheel steel slab. Use the electronic probe to scan the surface of the polished surface of the 380 wheel steel billet sample for the Mn element, with a step size of 6 μm, and the scanning results are as follows figure 1 shown. The output is a 404×300 matrix and saved as a table in .csv format. Use Matlab to read the table file to get the matrix A of 404×300. Arrange the elements in the matrix into a 1×121200 sequence in ascending order, with the first place being 0.3668 and the last place being 4.7301. Let X take 5, 10, 15 and 20 respectively, and calculate the interval length L and C L and C (M×N-L) , listed in Table 1.

[0037] Table 1 The length and boundaries of the maximum and minimum intervals of content under different value ranges (Mn, wt%)

[0038] X L C L

C (M×N-L+1)

C min

C max

S R

5 6000 0.7991 0.9927 0.7811 1.0355 1.3256 10 12000 0.8135 0.9564 0.7940 1.0038 1.26...

Embodiment 2

[0044] The 20CrMnTi hot-rolled sample has typical band-like characteristics, and the distribution of Mn and Cr elements is related to the band. Use the electronic probe to scan the surface of the Mn element on the polished surface of the 20CrMnTi sample perpendicular to the rolling direction, with a step size of 1.5 μm. The scanning results are as follows Image 6 As shown, the output is a 400×300 matrix, which is saved as a table in .csv format.

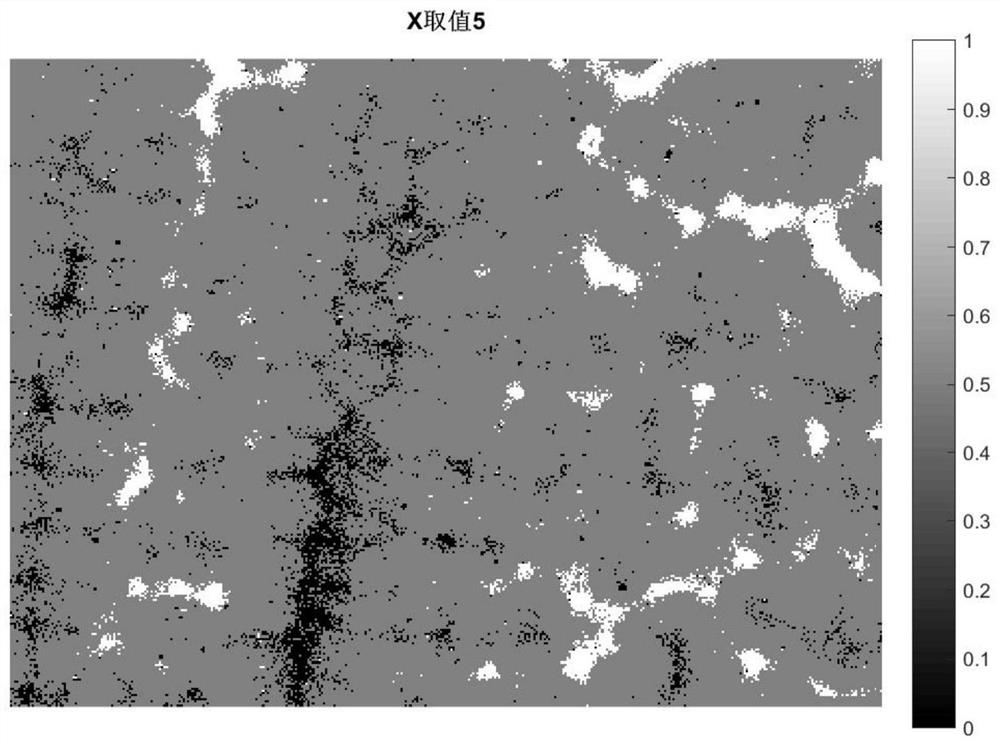

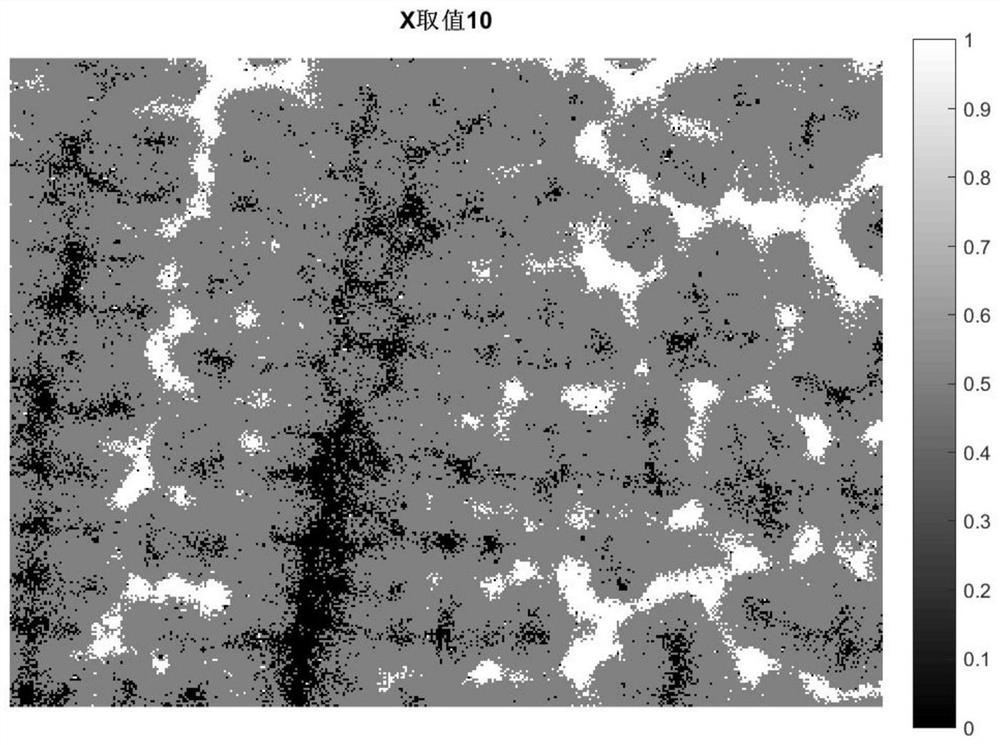

[0045] Using Matlab to read the table file of Mn elements. A matrix A of 400×300 is obtained. Arrange the elements in the matrix into a 1×120000 sequence in ascending order, with the first place being 0.3232 and the last place being 18.2245. Let X take 5, 10, 15 and 20 respectively, and calculate the interval length L and C L and C (M×N-L) , listed in Table 2. By the computer program in embodiment 1, obtain Figure 7 ~ Figure 10 , that is, the distribution of the area with the largest and smallest content when X is 5, 10, 15, ...

Embodiment 3

[0051] Utilize electron probe to do the surface scanning of Cr element to the polished surface of 20CrMnTi sample in embodiment 2, step-length 1.5 μ m, scanning result is as follows Figure 11 As shown, the output is a 400×300 matrix, which is saved as a table in .csv format.

[0052] Using Matlab to read the table file of Cr elements. A matrix A of 400×300 is obtained. Arrange the elements in the matrix into a sequence of 1×120000 in ascending order, the first place is 0.4631, and the last place is 1.8245. Let X take 5, 10, 15 and 20 respectively, and calculate the interval length L and C L and C (M×N-L) , listed in Table 3. By the computer program in embodiment 1, obtain Figure 12 to Figure 15 , that is, the distribution of the area with the largest and smallest content when X is 5, 10, 15, and 20, respectively.

[0053] Table 3 The length and boundaries of the maximum and minimum intervals of content under different value ranges (Cr, wt%)

[0054] X L C L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com