Method for evaluating vacuum inclusion removal capacity of RH refining furnace

A technology for inclusions and refining furnaces, applied in the field of RH refining furnace performance evaluation, can solve the problems of lack of systematic quantitative evaluation of process design time and molten steel inclusion level, prominent contradiction between RH process design time and production matching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for evaluating the vacuum removal capability of RH refining furnaces includes the following steps:

[0026] 1. Study the effect and extent of increasing the air flow on the removal of inclusions in the vacuum treatment stage RH

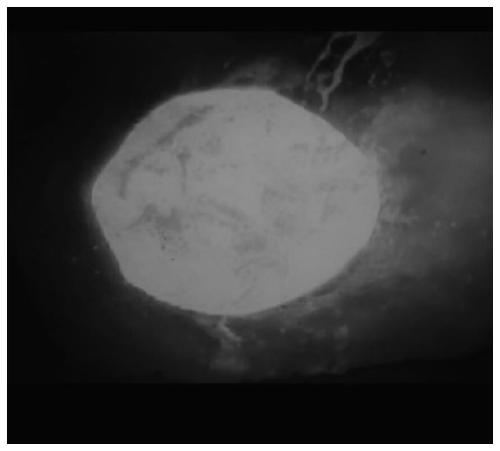

[0027] As shown in Table 1, according to the lifting gas flow rate 100, 120, 140Nm 3 / h for the test, in addition to increasing the gas flow during the test, no other conditions are changed. Such as Figure 1-4 As shown, when the flow rate is 120Nm 3 / h than 100Nm 3 / h, the liquid level fluctuates more obviously, and there is no obvious splashing phenomenon, the shape of the vacuum chamber maintains a better shape, and the flow rate is 140Nm 3 / h, the obvious splashing phenomenon is produced, and the shape of the bottom of the vacuum chamber changes obviously, which has caused nodules such as Figure 4 Shown.

[0028] Table 1 Test plan for increasing gas flow

[0029] Test planFlow rate Nm 3 / h

Insertion depth mm Other process parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com